The detail quality control procedure is for raw material, inspection, final testing and dispatch.

PRODUCTION PROCESSProduction Process

Manufacturing and testing process

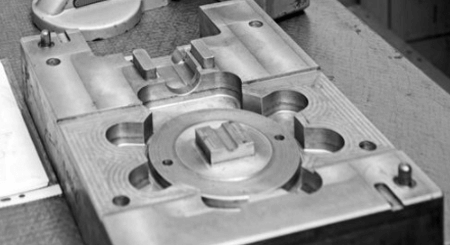

01

Pattern Design

02

Rough Casting

03

Machining

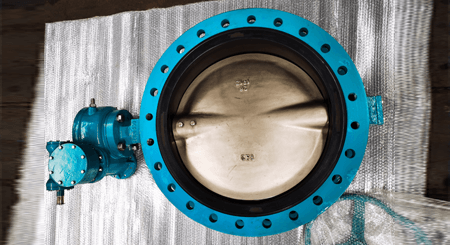

04

Assembly

05

Pressure Test

06

Painting

07

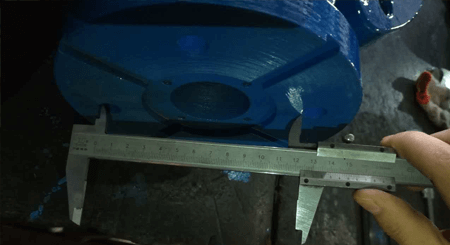

Inspection

08

Packing

The detail quality control procedure

Quality Control Procedures

The detail quality control procedure is attached herewith for raw material, inspection, final testing and dispatch.

We keep all books of standards (latest editions in original) in our library for ready reference.

Following are the few important points covered in our Quality Control Procedure.

Casting

The castings are inspected at the foundries for the following:

Blow holes

Surface finishing

Sand hold-up

Riser cutting

Rib position

Painting line

Heat numbers

Verification of certificates

Castings are again inspected at the shop floor visually. Properties mentioned in certificates are verified with applicable standards. Procurement of casting is done from reliable foundries only.

On all the castings, heat numbers are cast/punched by the foundries. The castings are shot blasted and heat treated as per the required heat treatment procedure. Foundries provide us with the certificates for chemical and physical properties of castings from their own/independent laboratories. The test bars of each heat are available with the foundries for verification of physical and chemical properties.

As a system of quality control procedure and cross verification we check the chemical and physical properties of castings at our end of at least 10% of the quantity received by us. The material for checking chemical and physical properties is sent to a reputable laboratory of the customer’s choice.

The foundries from where we procure castings or forgings are approved by various inspection agencies such as Lloyds,Bureau Veritas,DNV,etc

Since we accept only sound casting, we do not adopt any welding process on pressure withstanding areas. The castings are sent back to the foundries for any welding, if required, and the same is duly stress relieved after welding.

Quality Control Plan

Quality Control plan for checking of raw material/finished items/individual components

All the coupon plates of CAST products such as body, bonnet, cover, yoke, hinge, bracket, wedge, disc, yoke sleeve and seat rings are subjected to these metallurgical tests as per the requirement of the client/third party inspection agency. The results are compared with the foundry test certificates. Various castings are checked for dye-penetrate test, ultrasonic testing and magnetic particle check test.

All stainless steel products are 100% checked for chemical/corrosion and microstructure qualities before machining. The items made from these stainless steel products include spindle, bonnet bush, gland bush, ball, washers, etc.

All fasteners, stud bolts, nuts made of carbon steel (A193 Gr. B7, ANSI B 1.1 Class 2A and ASTM A194 Gr. 2H, heavy series) and stainless steel are initially visually checked. Later about 10% are checked for their metallurgical properties and 100% testing is carried on. The fasteners are also bought from approved vendors along with the manufacturers test and guarantee certificates. Other hardware items such as eyebolts, cross bolts, nuts are also checked at 10%, randomly.

All gaskets are checked for dimensions and manufacturers test certificate is acceptable. The various gaskets used are compressed asbestos fiber, stainless steel 304/316 spiral wound gasket, etc., procured from a reputed manufacturer. 10% of packing material is checked for wire insert.

Radiography

The castings manufactured by us are of radiographic quality and the foundries supply the radiographic films as and when informed in advance. Moreover, as per our standard quality control procedure we take radiographic test of 10% of our castings on critical areas as per ANSI B 16.34. We have a tie up with a leading metallurgical services provider for carrying out the radiography.

All the round bars, plates, etc., which are used for trim are thoroughly inspected and tests are conducted for surface defects, cracks, laminations, etc., by doing ultrasonic inspection done in a reputable laboratory. The material is also checked for the chemical and physical properties, which is all done in a laboratory.

Castings as well as other materials are inspected thoroughly at various stages of machining.

The valve shell, seat (both sides) and back seat are hydrostatically/pneumatically tested as per the approved standards.

We provide back seat arrangement for all gate/globe valves and therefore, repacking of gland packing under full working pressure is possible, i.e., without disturbing the working conditions.

Swing check and lift check valves are subjected to hydrostatic test.

Drilling operations are done with the help of hardened and ground drilling jigs and templates; hence, there is no problem during installation. All the spindles are hardened and ground.

Spindle diameters, threading tolerances, etc., are all according to relevant standards. Go and No Go gauges are employed for checking the threading diameter. Spindles are constantly checked on line during machining.

Wall thickness of the valve body, flange diameter, flange thickness, spindle diameter are maintained as per standard specifications and all such dimensions are checked stage wise during machining.

Quality Control plan for final inspection

During the course of final inspection, the third party inspector checks the raw material records and the machining records that will be crossed checked again. Before painting, third party inspection is shown unpainted valves for final dimension check and hydro/pneumatic testing. After being approved and stamped by the third party inspection authority, they are taken up for final cleaning, greasing, painting, labeling of nameplates and packing for dispatch. All gland packing are removed and fresh gland packing are inserted. The end flanges of the painted valves are fitted with wooden flanges bolted to the valve flanges and then packed in wooden boxes. For smaller size valves, plastic/rubber end caps are used to protect the valve. Each valve is tagged by an aluminum tag fastened to the hand wheel with an aluminum wire, referring to the size, class, material and client reference number. Every client for every purchase order will be given an easy valve handling and maintenance instruction manual.

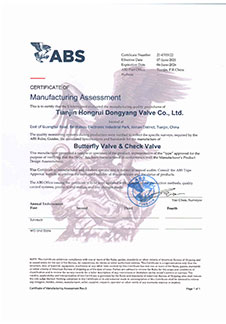

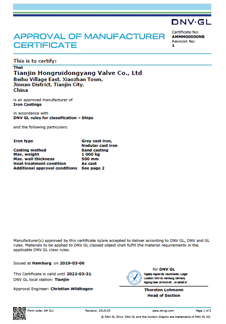

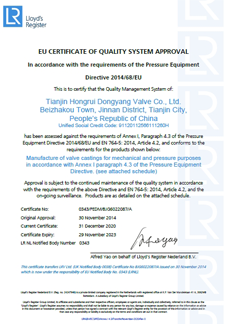

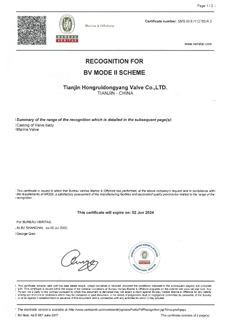

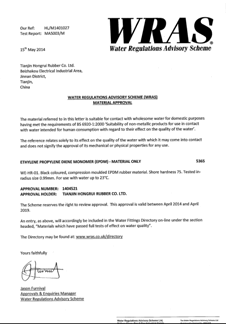

CERTIFICATIONS

DNV · GL

Lloyd's Register

Bureau Veritas

WRAS