Built on Engineering Excellence

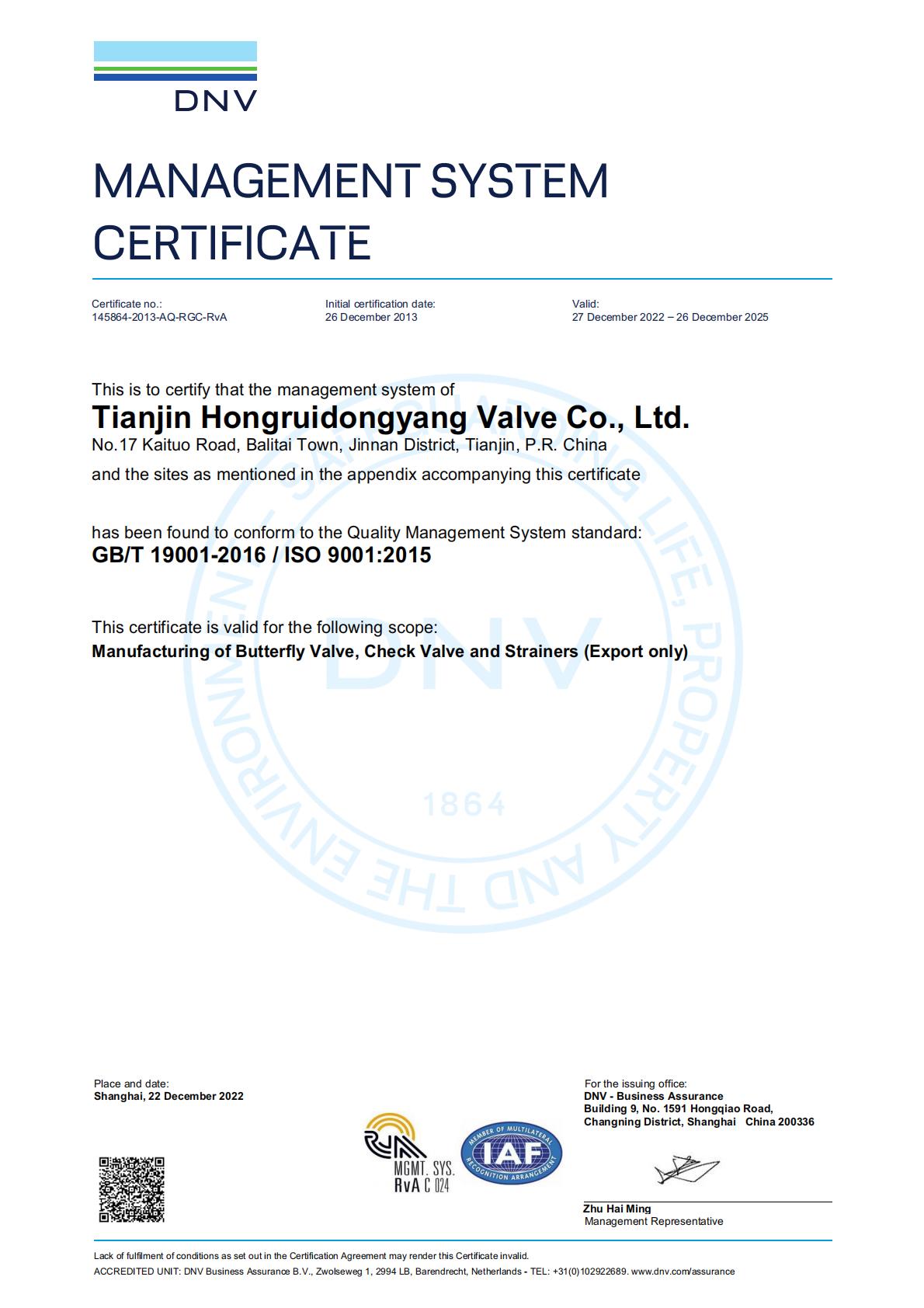

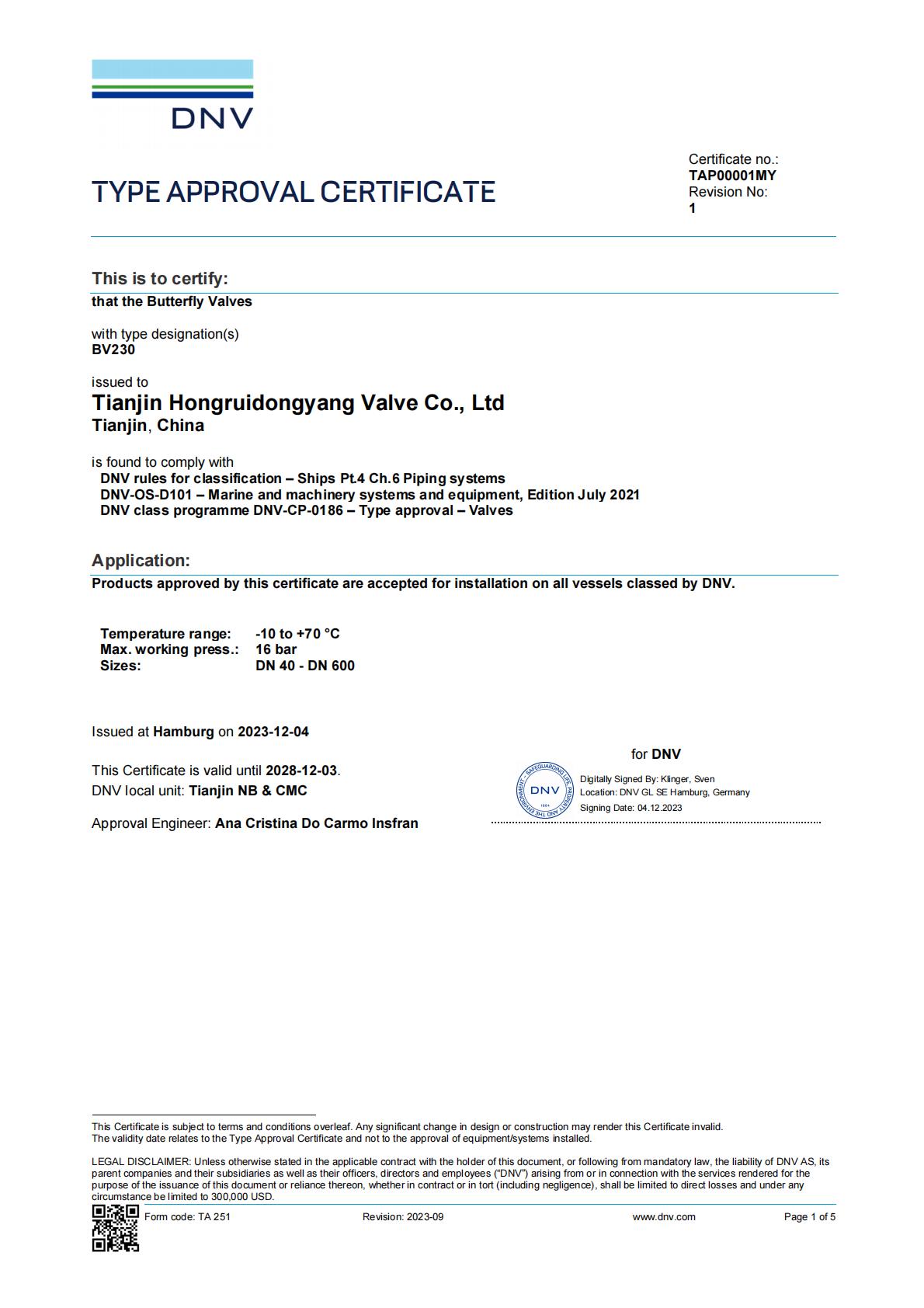

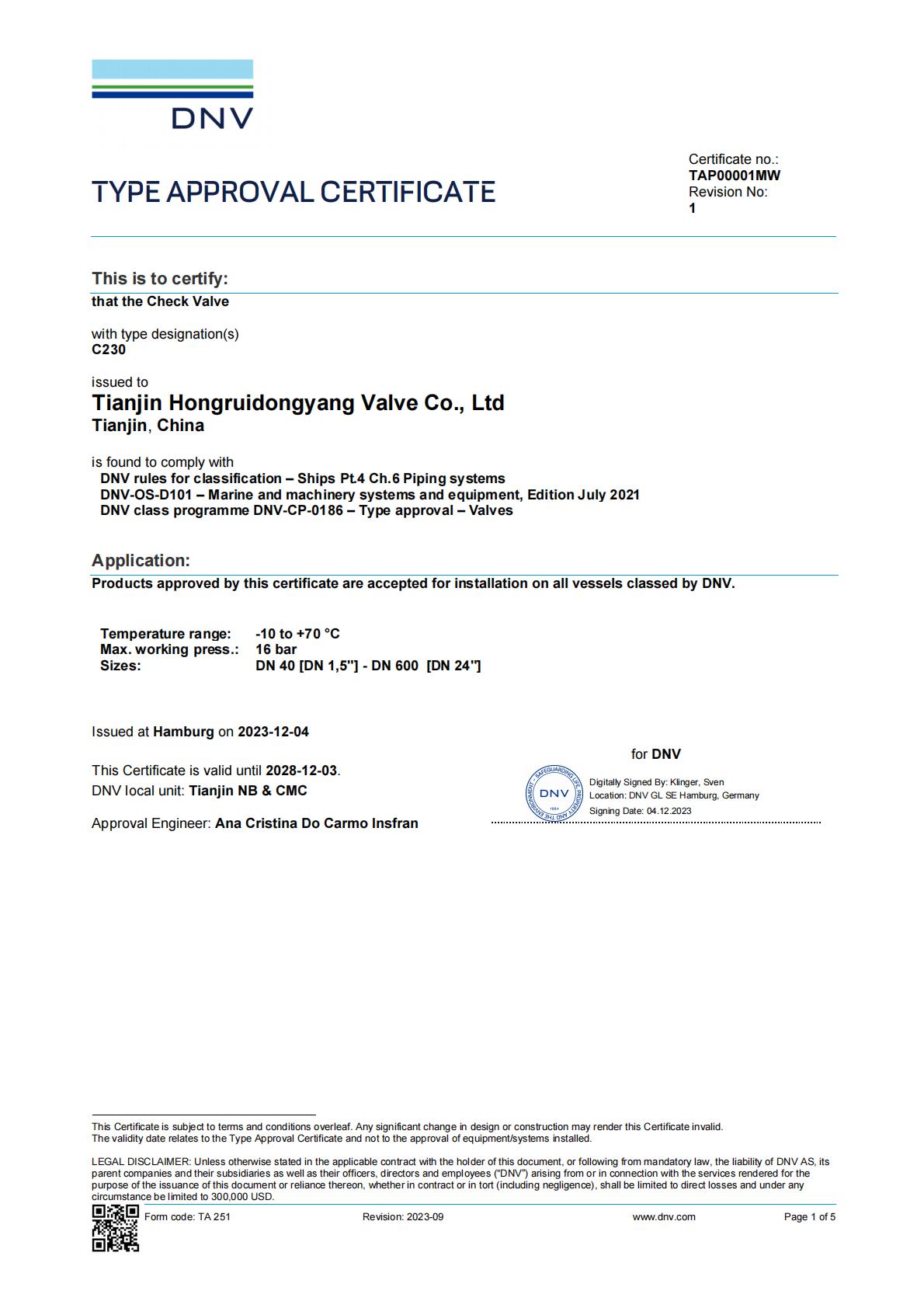

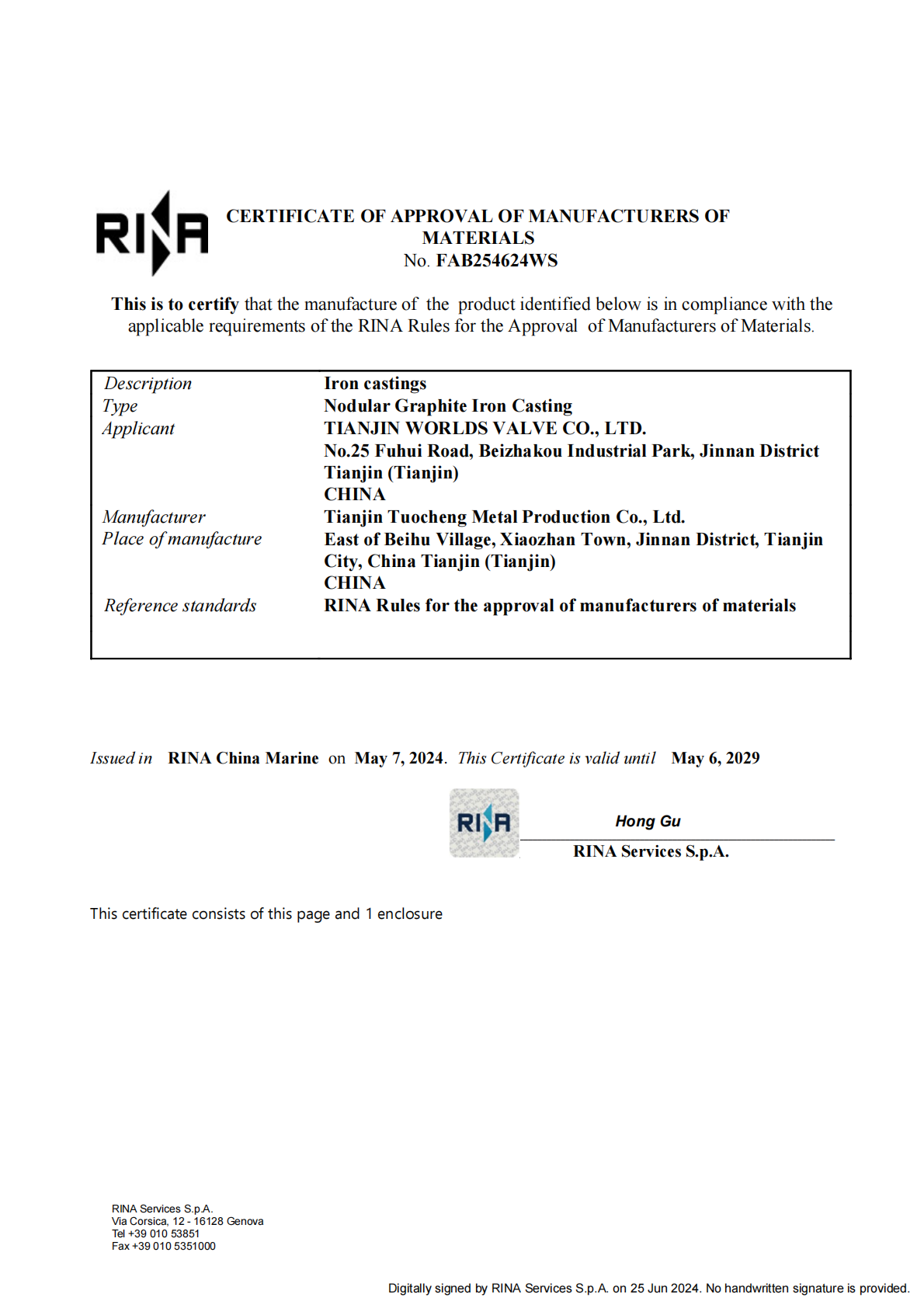

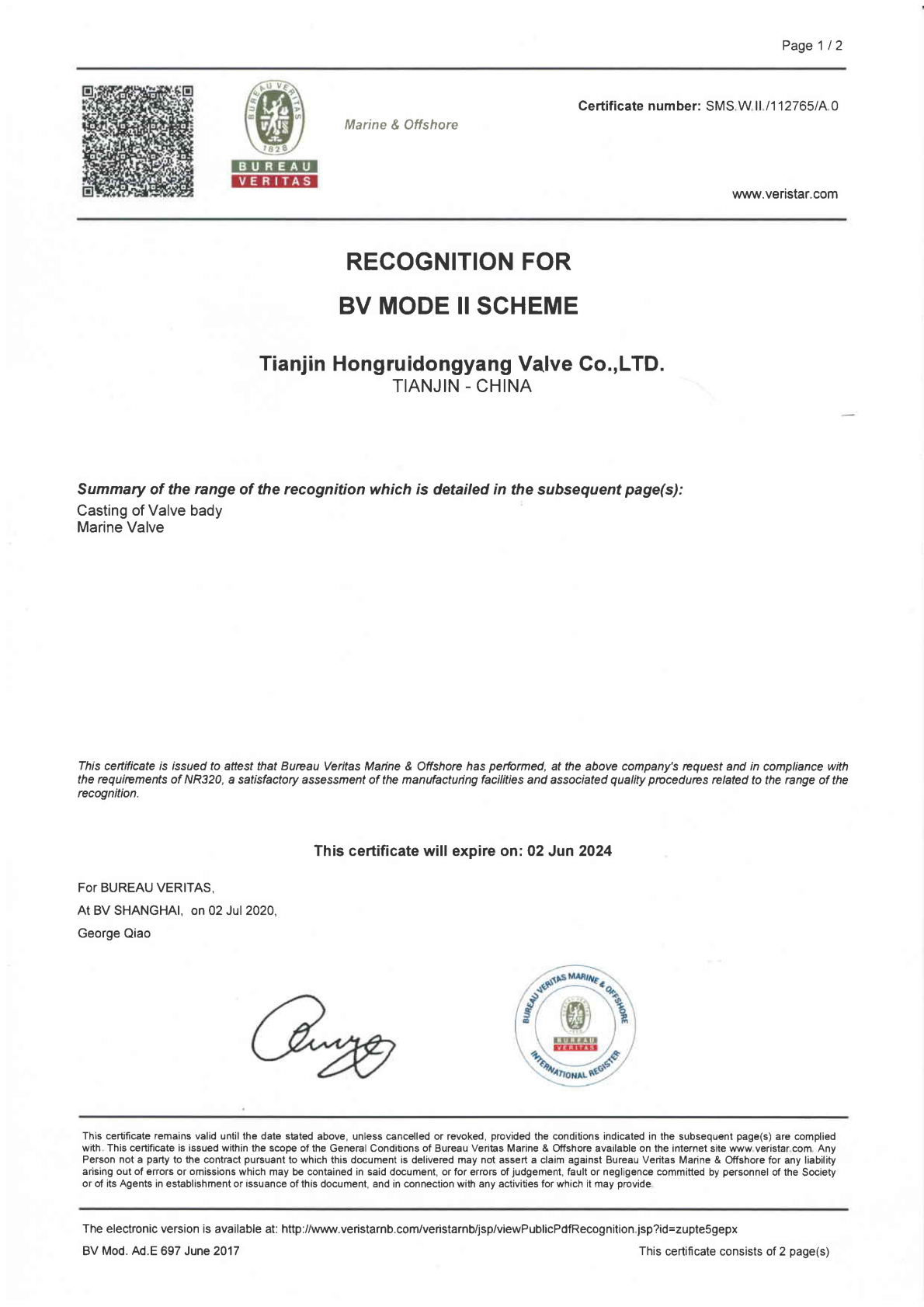

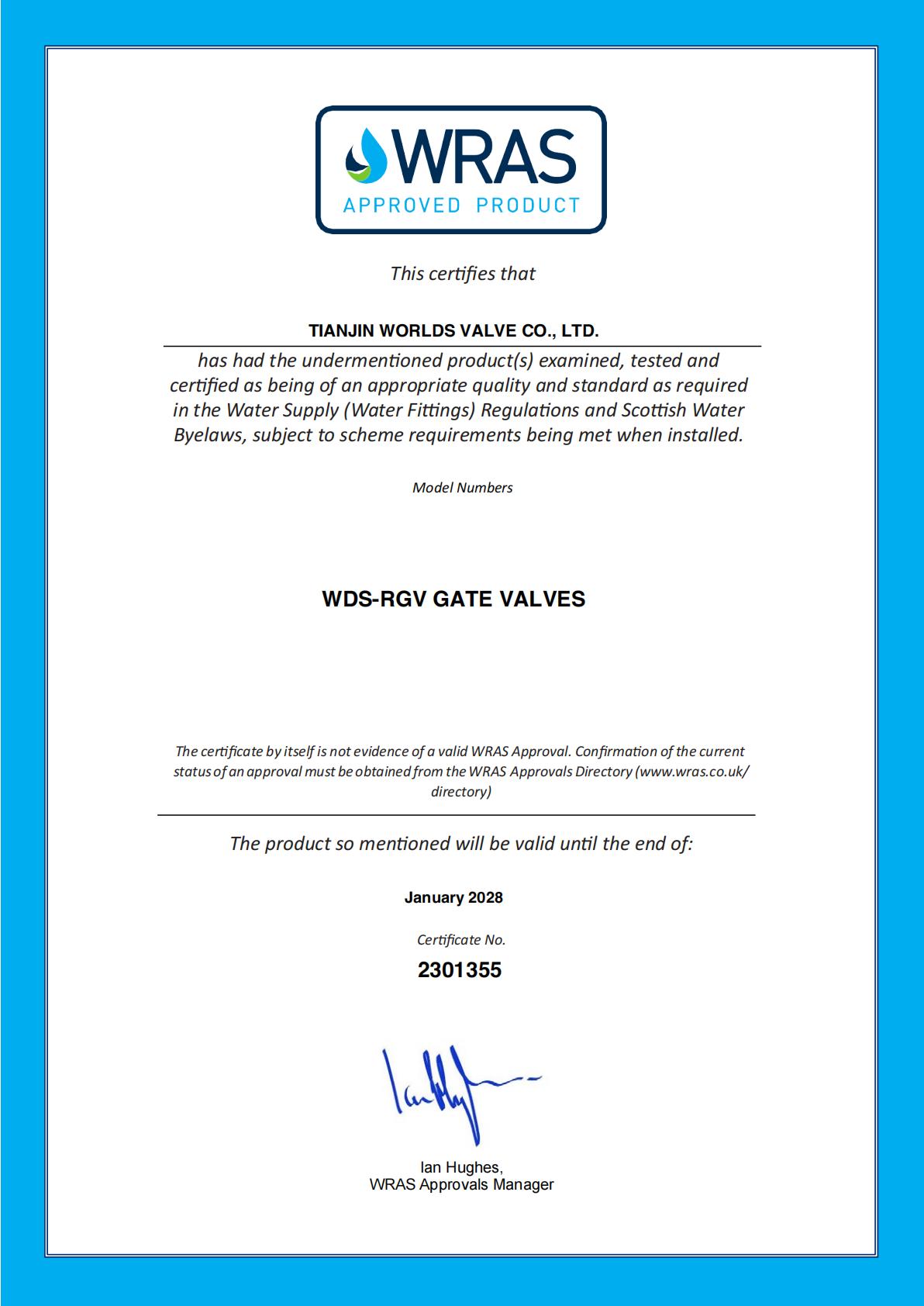

RUITO is a China-based, export-oriented valve manufacturer serving EPC contractors, system integrators, OEMs, and industrial end users. We manufacture to ASME, DIN and EN standards under an ISO 9001 quality management system with stage-gated inspection, full traceability, and documented hydro/seat tests. Each shipment is accompanied by bilingual drawings, material certificates and inspection reports, and we support third-party audits by SGS, TÜV or BV. Our scope covers manufacturing and engineering consultation; we do not undertake on-site installation, system integration or localized after-sales.