Ruito is a professional manufacturer and trading company.

ABOUT RUITO-TIANJIN HONGRUI DONGYANG VALVERUITO manufactures a wide range of general valves including butterfly valves, check valves, strainers, pump diffusers, and valve accessories in various materials on demand.

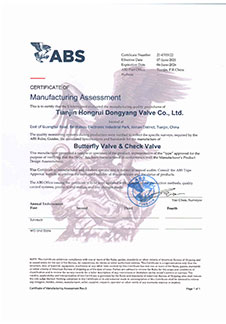

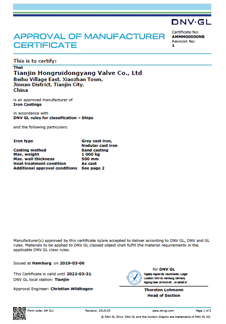

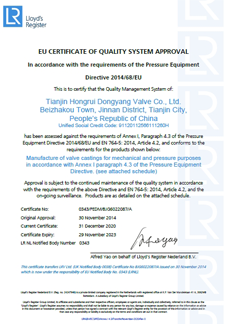

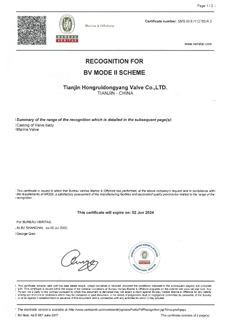

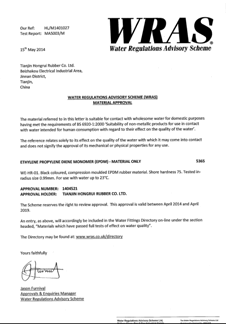

Global mainstream institutions also approve our products like DNV, Lloyd, Bureau Veritas, ABS, and WRAS, widely used in water treatment, marine, and other fields.

Our primary customers are from Europe, North America, and Asia. After long years of cooperation, business partnerships are formed on the competitively priced products, on-time delivery, service, and our tradition of product reliability.

RUITO’s mission is to offer cost-effective shipbuilding and industrial pipeline solutions, by combining product and quality with value-added customer services.

We warmly welcome your business connections and visit.

RUITO is a company that specialized in the design and manufacture of industrial valves, with the ultimate goal of offering excellent quality in its products and flawless service to the customer.

The enterprise is orientated toward clients’ satisfaction; in this way, it adapts its valves to your requirements and delivers them within deadlines rigorously established. The technical and human staff, highly qualified, works every day in order to offer you the most innovative solutions and to strengthen the commitment with the customers.

Also, RUITO pursues socially responsible behavior. The essence of our philosophy as an organization is to strive for a pleasant working environment, strengthen human relationships, and minimize impacts on the environment.

For all these reasons, to have Ruito as a specific partner in valves is a wise choice.

OUR MISSION

EXCELLENCE AND RELIABILITY

The members of the staff of Ruito are very rigorous with the reliability and the quality of the products. For this reason, as a manufacturer of valves, our missions are:

To subject our products to quality assurance controls

To comply with the established delivery dates and the expected quality in each supply

To offer a customized and value added service to our customers

To make further progress in the design and manufacture of our products

QUALITY ASSURANCE

Quality control is a top priority at Ruito.During the production process,we emply several stages of quality control.

Quality control of incoming materials and components

Incoming materials undergo several types of analysis – for example material analysis, hardness analysis or porosity analysis. Further analysis is carried out in cooperation with external laboratories and certification authorities.

During the production stage, all machined components are being checked for accuracy. For this measurement, CNC controlled 3D machines are used (Contura G2 RDS 1000) with error of measurement at 1000 mm = 3,5 µm. Designated specialists are able to measure very effectively complex machined parts in a quick and reliable way via self-generating measure programs. Before serial production is started, the first piece of each series is checked on the CNC controlled 3D machines. In case of positive result, serial production gets started. Random checks are performed on the running production. Results from all relevant measurements get recorded by quality inspection workers. After evaluation of all results recorded, long term actions are suggested by our professionals. This approach enables us to achieve continuous improvement in our production process.

In-production quality control

Assembly inspection

RUITO quality standards require that every single piece of valve passes a tightness test performed by assembly line operators and randomly checked by independent quality workers. Tightness tests at ABO are performed under standard conditions acc. PED 97/23/ES. ABO testing procedures also comply with API 598, EN 12266 and GOST R. Tightness tests according to other standards can be provided upon customer request.

At RUITO, final quality inspection is performed after complete valves are handed over from the assembly line but before they are made available for expedition by the packaging and storage department. During the final inspection process, finished valves are inspected for conformity with customer requirements. This check is performed by auditors who are independent the production department, and only after conformity is confirmed, valves are released for expedition.

Adhering to these strict quality assurance and control standards has helped us to keep non-conformities to an absolute minimum.

Final inspection

CERTIFICATIONS

DNV · GL

Lloyd's Register

Bureau Veritas

WRAS