Pharmaceutical Plant, Singapore

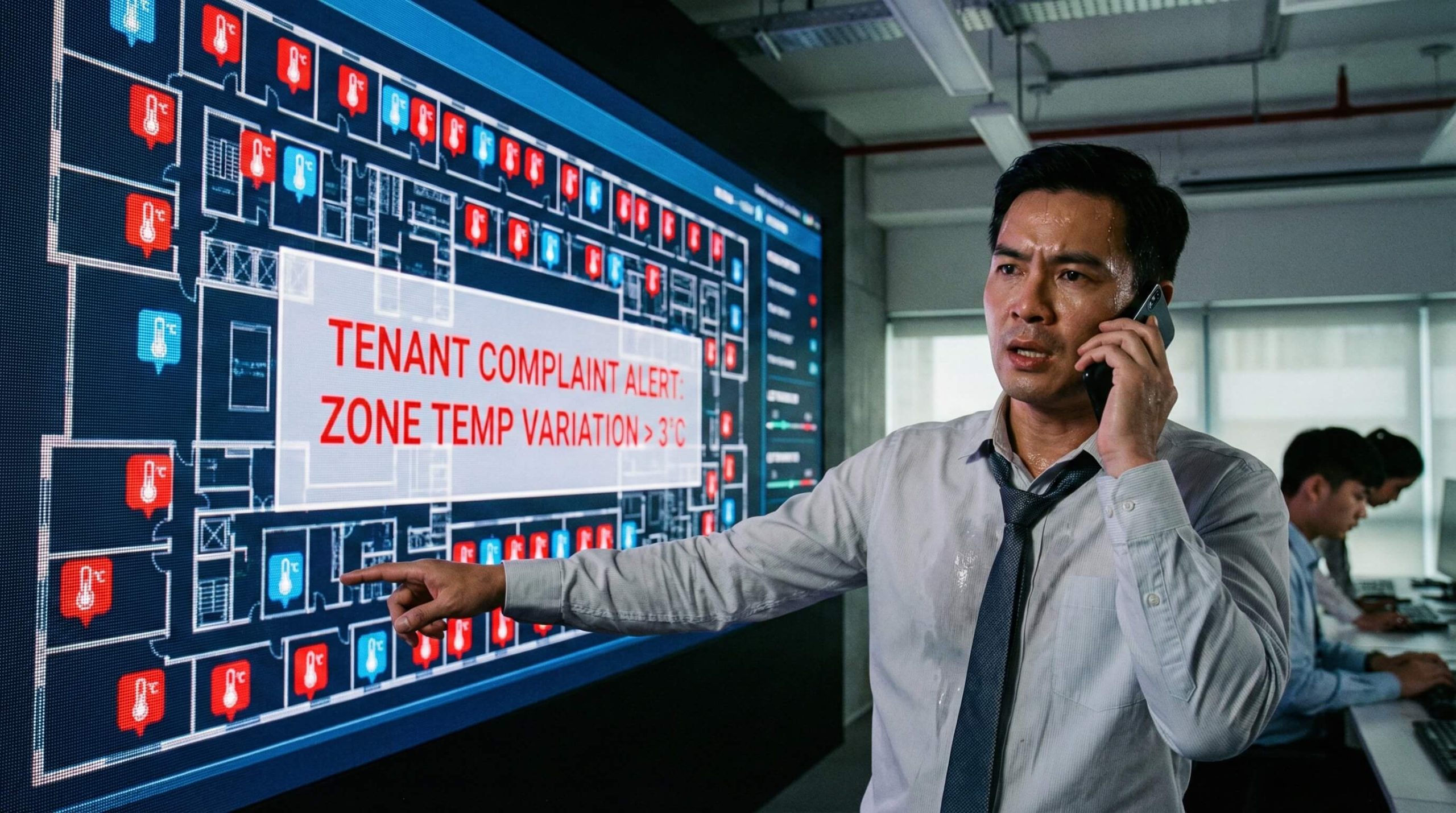

Process cooling system serving temperature-critical production equipment with zero tolerance for thermal excursions that could compromise batch quality or trigger shutdowns.

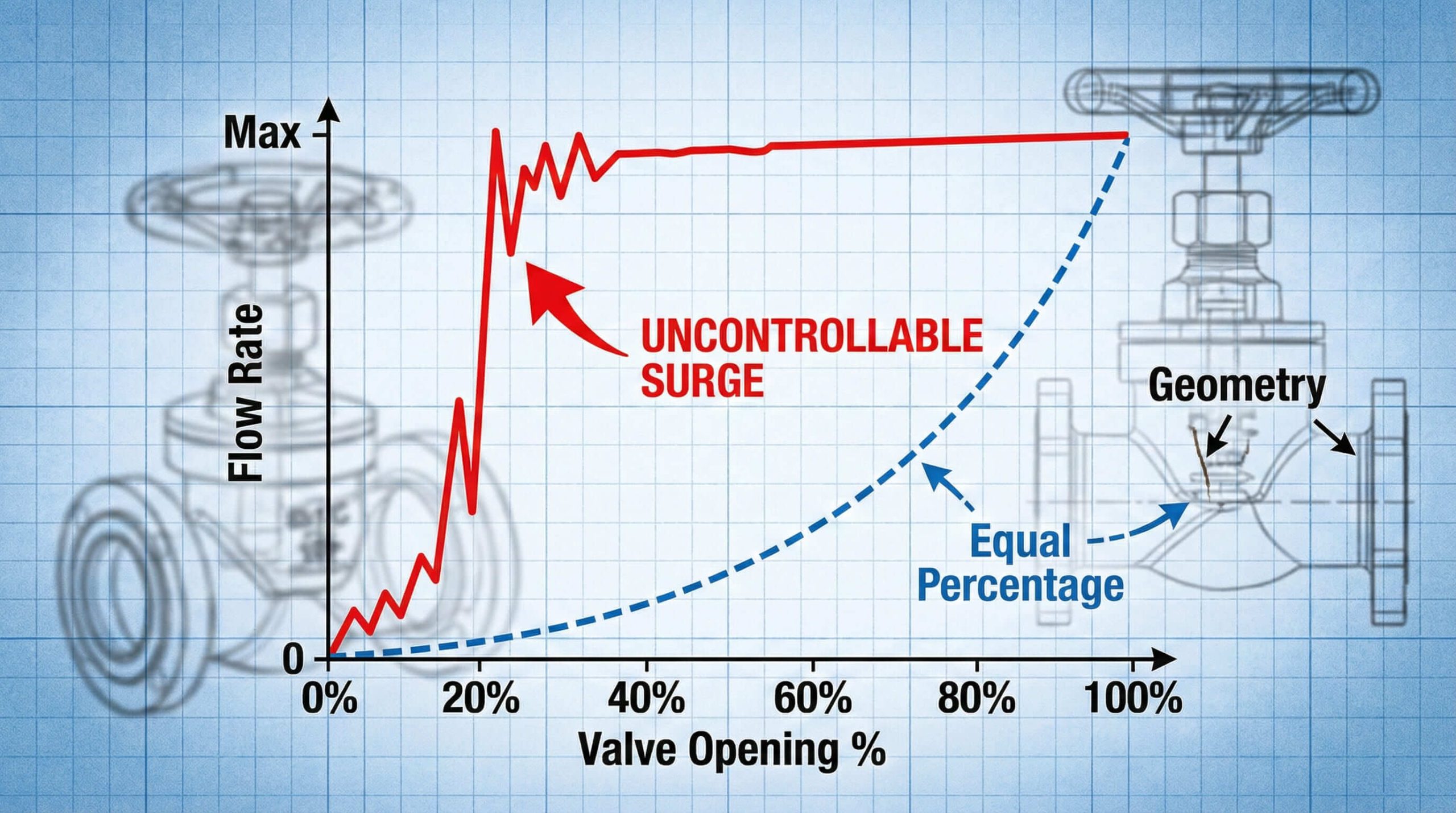

Equipment nearest to cooling plant received excessive flow while distant process lines suffered inadequate cooling. Flow imbalance forced operation at lower setpoints, wasting energy.

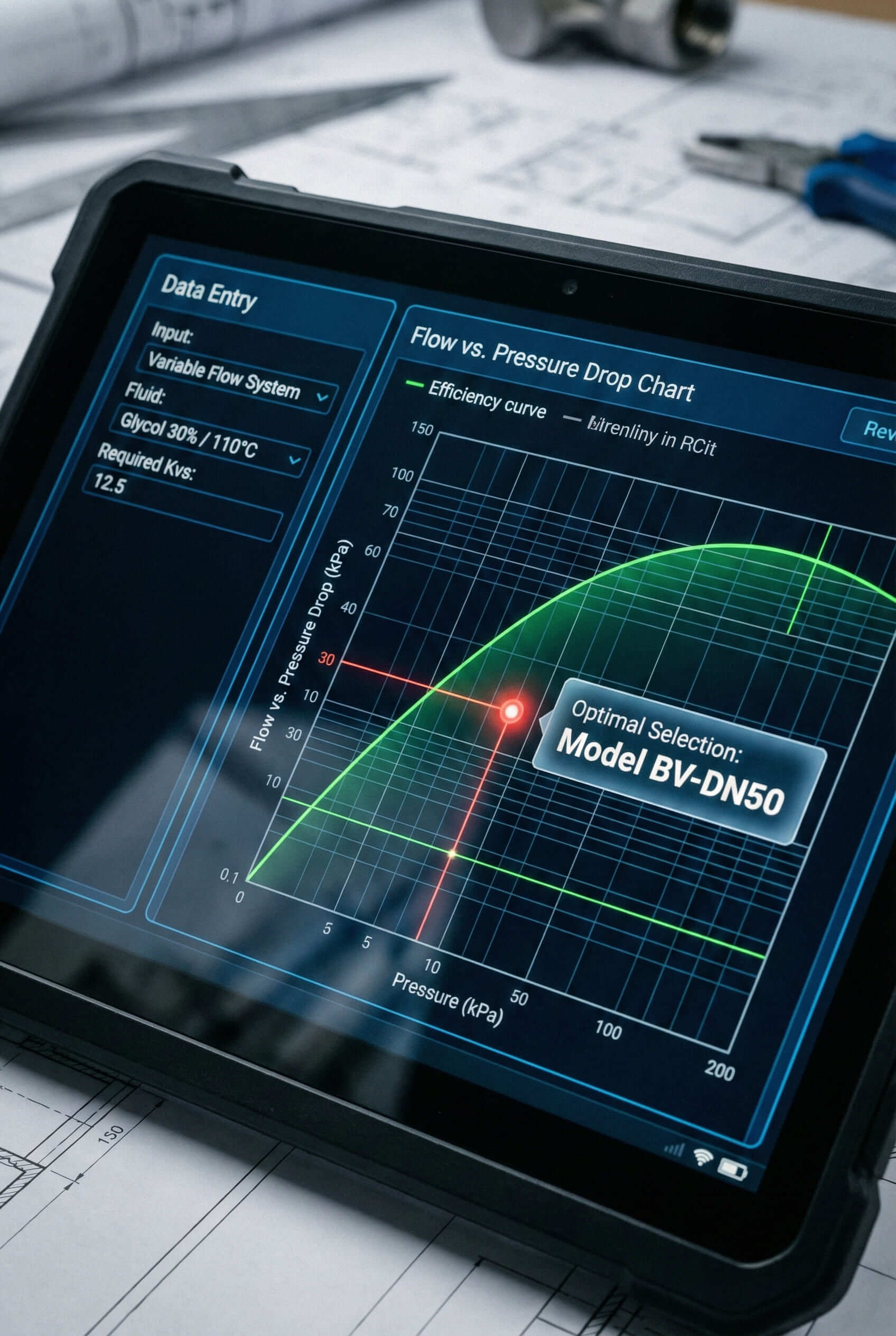

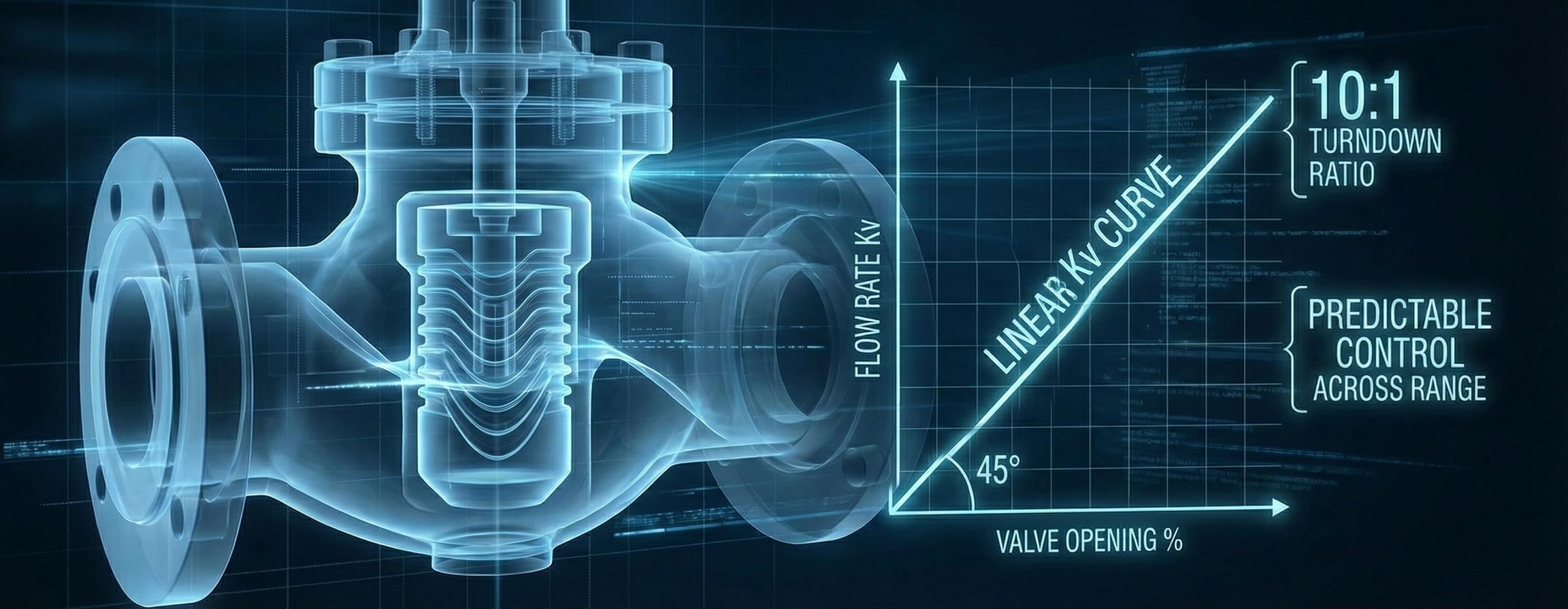

Installed RUITO DN25-DN100 static balancing valves at each equipment cooling supply with Kv selection calculated for 15 kPa target pressure drop. All valves fitted with calibrated measurement ports.

All process equipment achieved design flow within ±3% tolerance. Cooling water supply temperature increased from 6°C to 8°C without compromising process, reducing chiller energy by 18%.