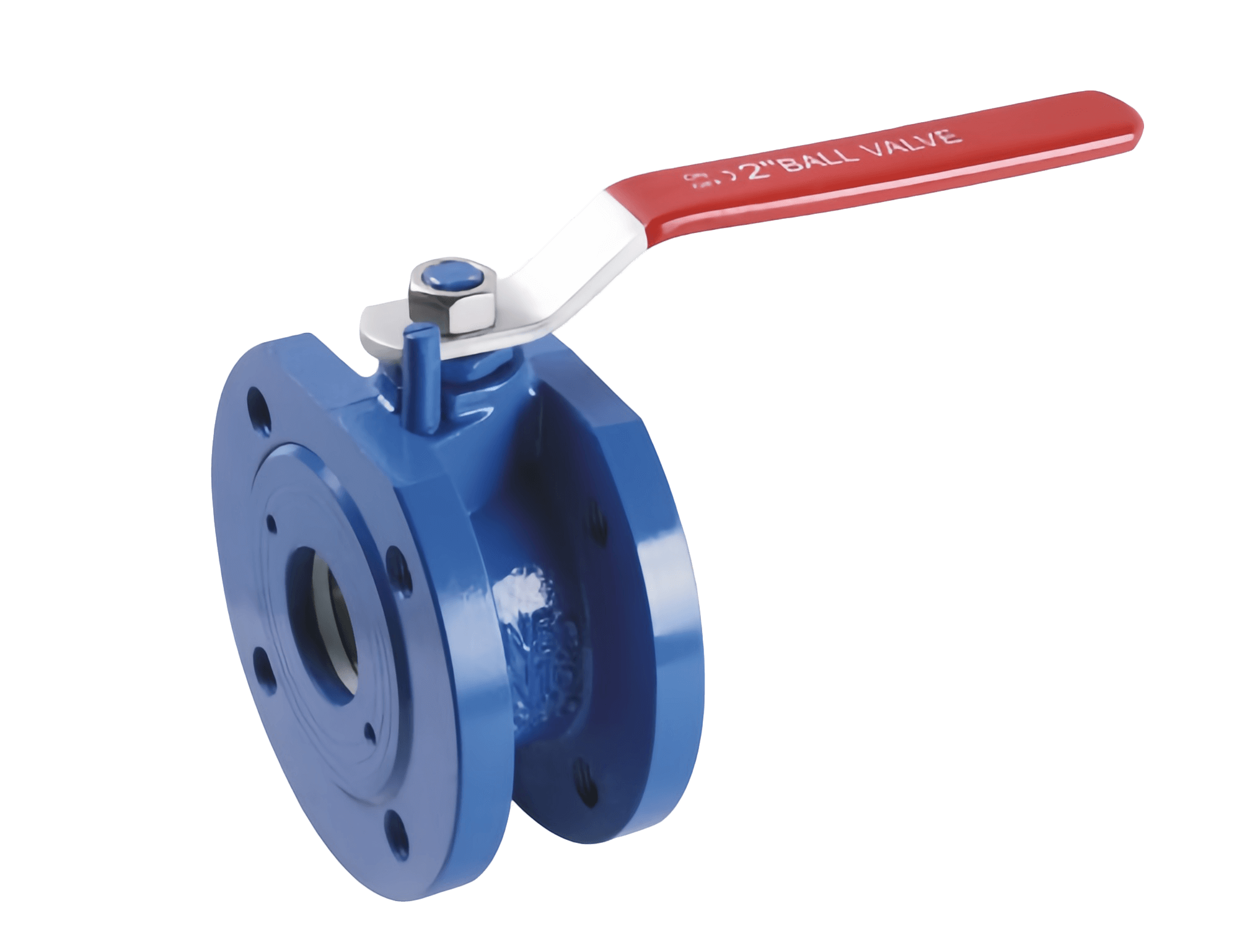

Industrial Ball Valves Engineered for Critical Applications

Precision-manufactured ball valves built to deliver zero-leak performance in demanding environments where failure is not an option

Most ball valve problems start here

Wrong Material Selection

Choosing standard brass or carbon steel for corrosive media leads to rapid degradation, requiring emergency replacement and causing unplanned downtime during critical production phases

Inadequate Seal Design

Soft seats used in high-temperature applications lose integrity within months, causing hazardous leaks that trigger safety shutdowns and regulatory compliance issues

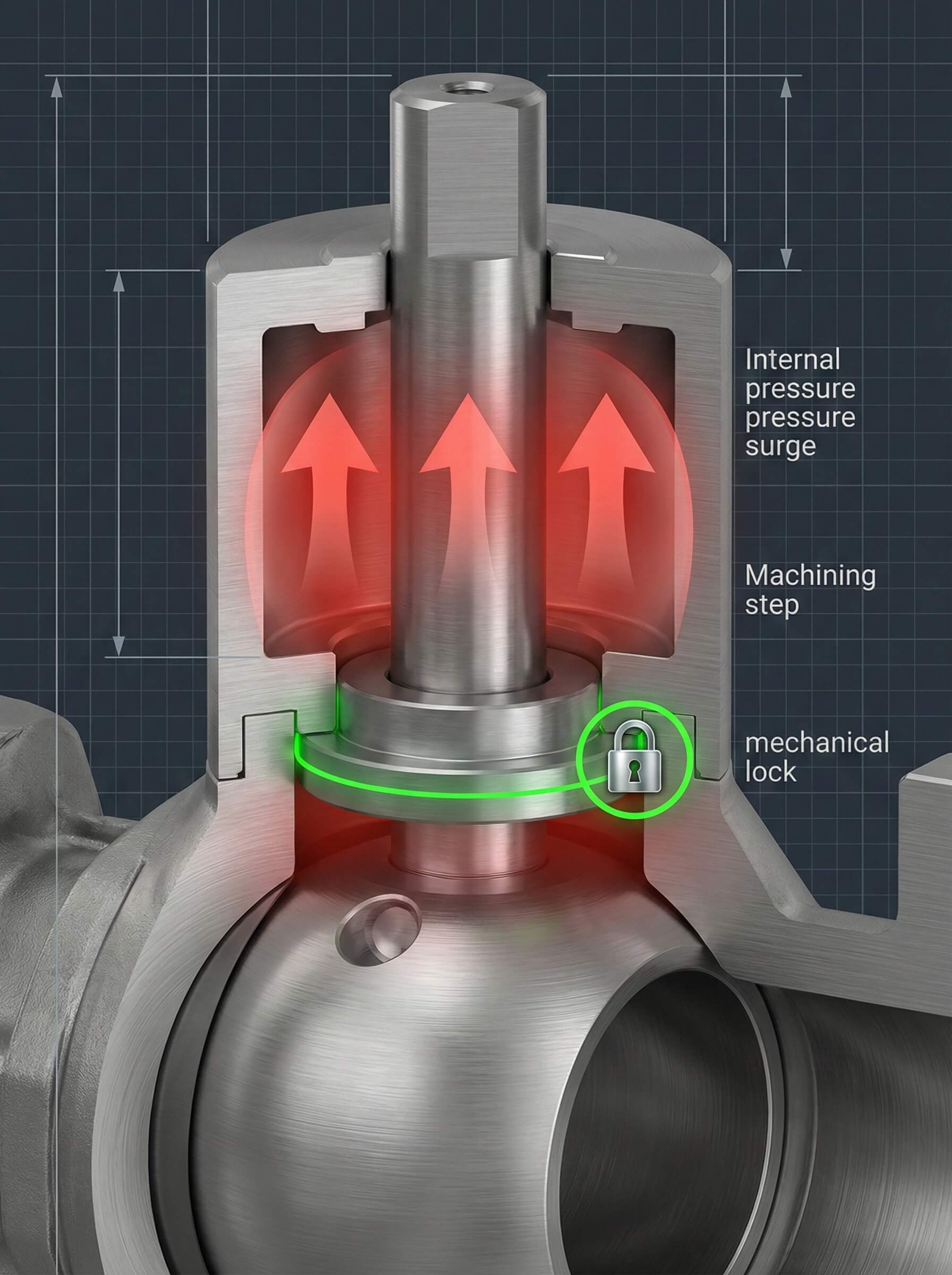

Insufficient Pressure Rating

Underspecified pressure classes result in catastrophic failures during system surges, endangering personnel and forcing expensive emergency repairs that delay project completion

Incorrect Flow Sizing

Reduced bore valves in high-flow systems create excessive pressure drops and cavitation, reducing efficiency and accelerating wear that multiplies energy costs over the system's lifetime

Avoid costly mistakes with proper valve specification from the start

Understanding Ball Valve Technology

Technical fundamentals that impact performance, longevity, and project success

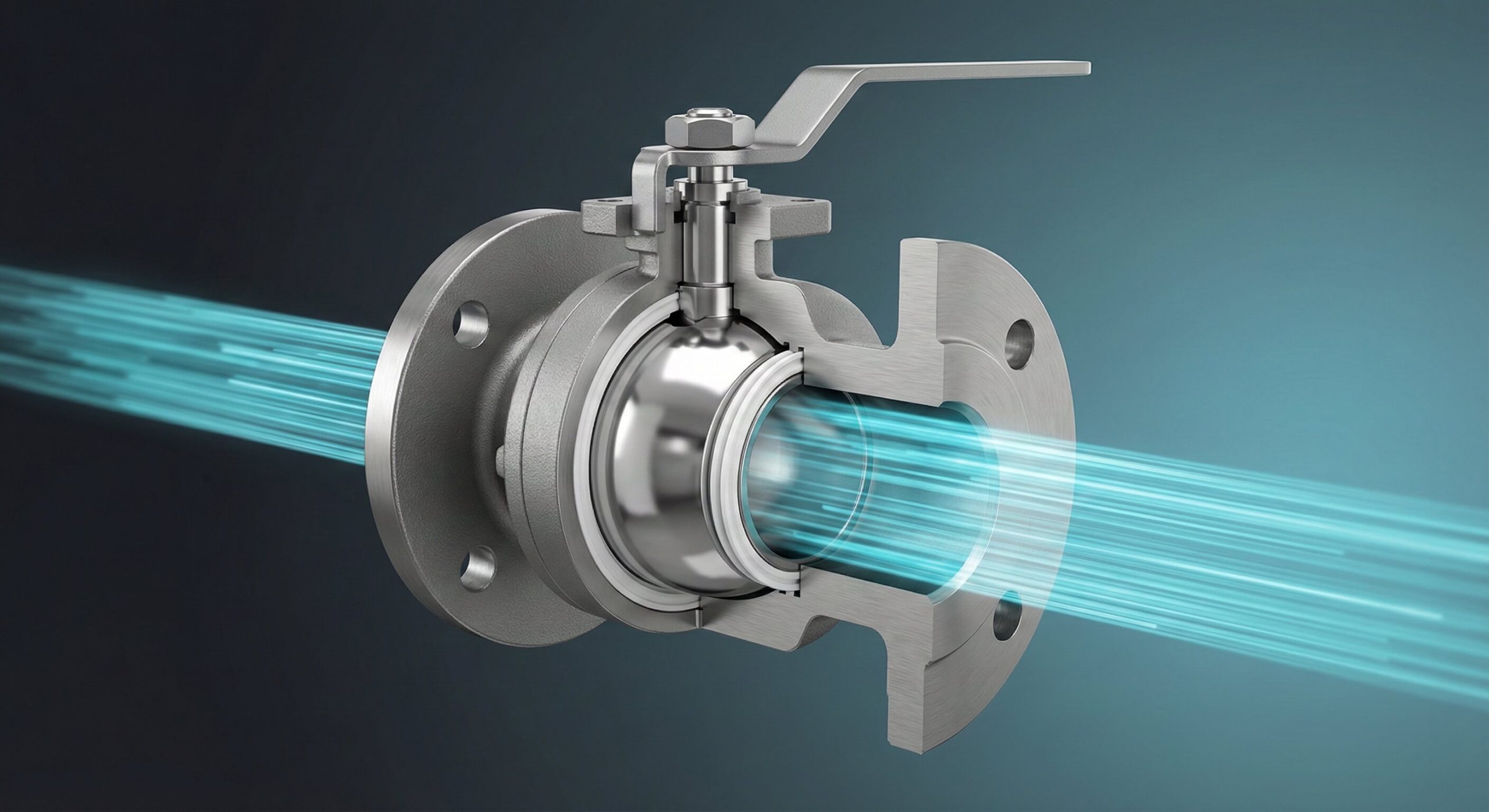

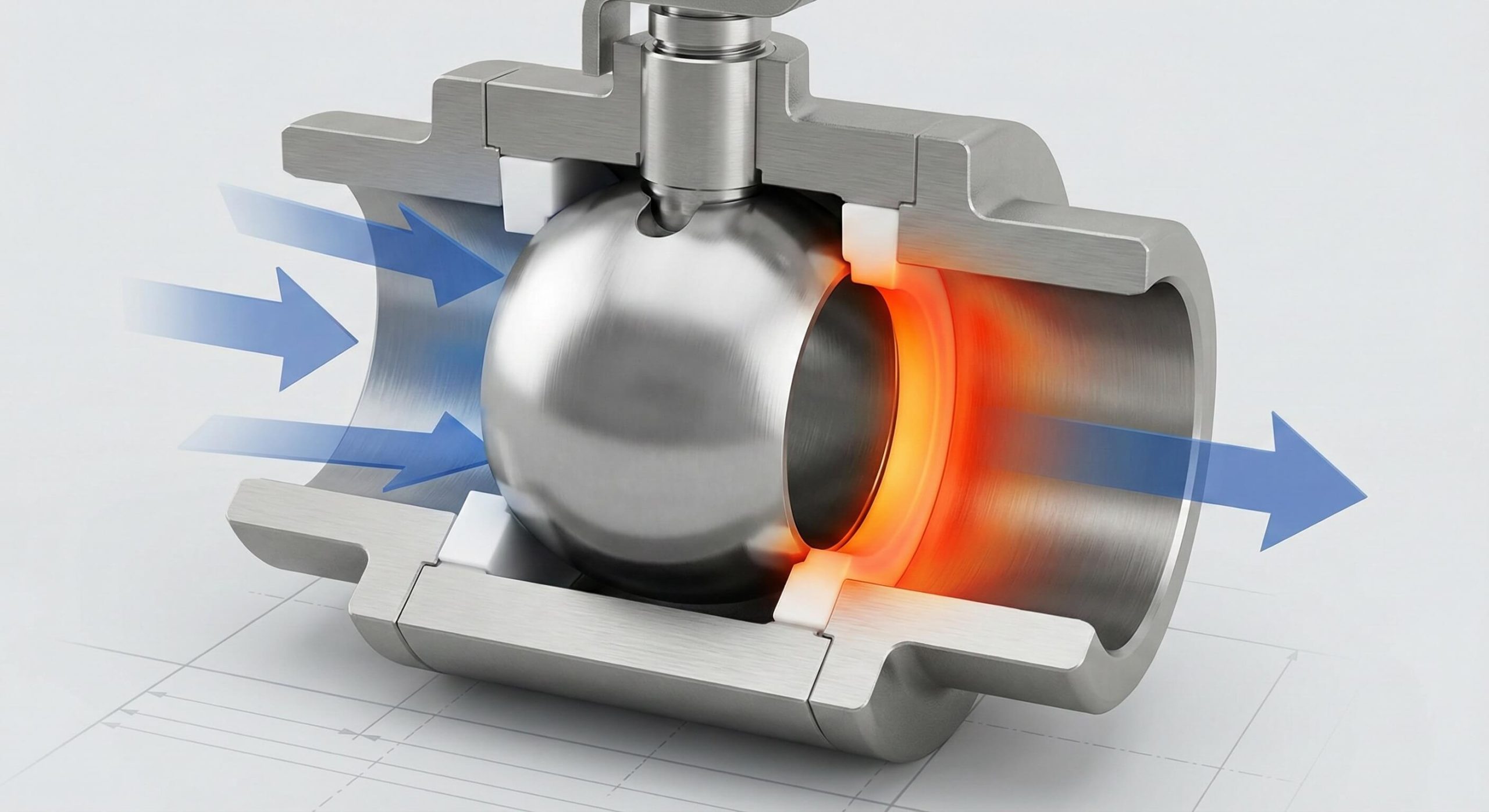

How Ball Valves Control Flow

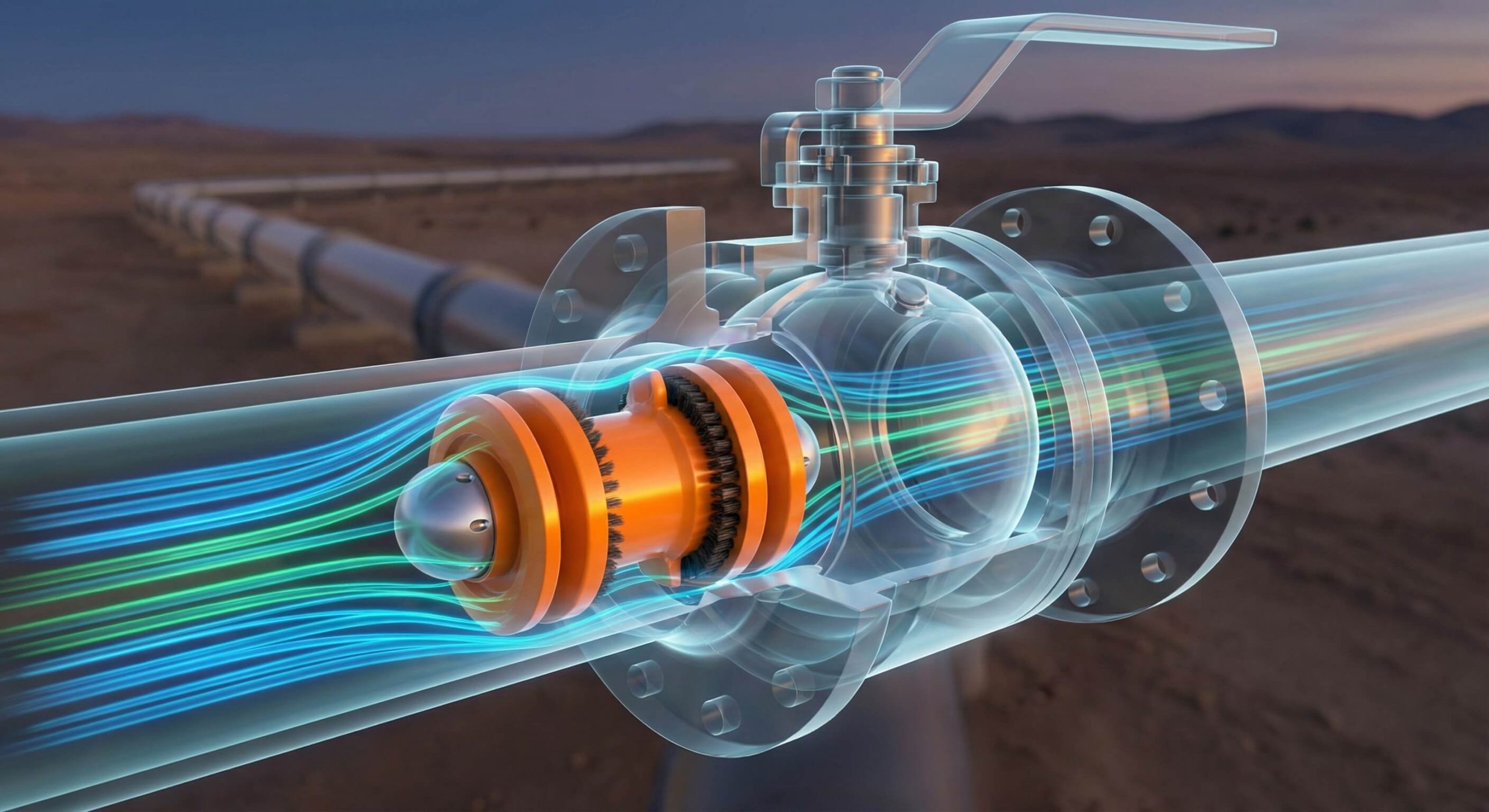

A spherical disc with a through-hole rotates 90 degrees to open or close the flow path. When aligned with the pipeline, flow passes unrestricted. When perpendicular, the solid ball surface blocks flow completely. This quarter-turn operation provides fast shut-off capability essential for emergency isolation, process control, and maintenance operations in industrial systems.

Full Bore vs Reduced Bore Configuration

Full Bore Design

Ball opening matches pipe internal diameter, creating zero flow restriction. Essential for pigging operations, minimizing pressure drop in long pipelines, and applications where unrestricted flow maintains process efficiency. Higher material cost justified by operational benefits in critical systems.

Reduced Bore Design

Ball opening typically one size smaller than pipe diameter, creating manageable restriction. Suitable for general service where slight pressure drop is acceptable. Reduces valve weight and cost while maintaining adequate flow capacity for most HVAC, water distribution, and low-velocity applications.

Floating vs Trunnion Mounting Systems

Floating Ball Construction

Ball moves slightly under pressure, pressing against downstream seat to create seal. Simple, economical design suitable for sizes up to DN150 and moderate pressures. Ideal for building services, HVAC, and general industrial applications where operating torque and seat wear are not limiting factors.

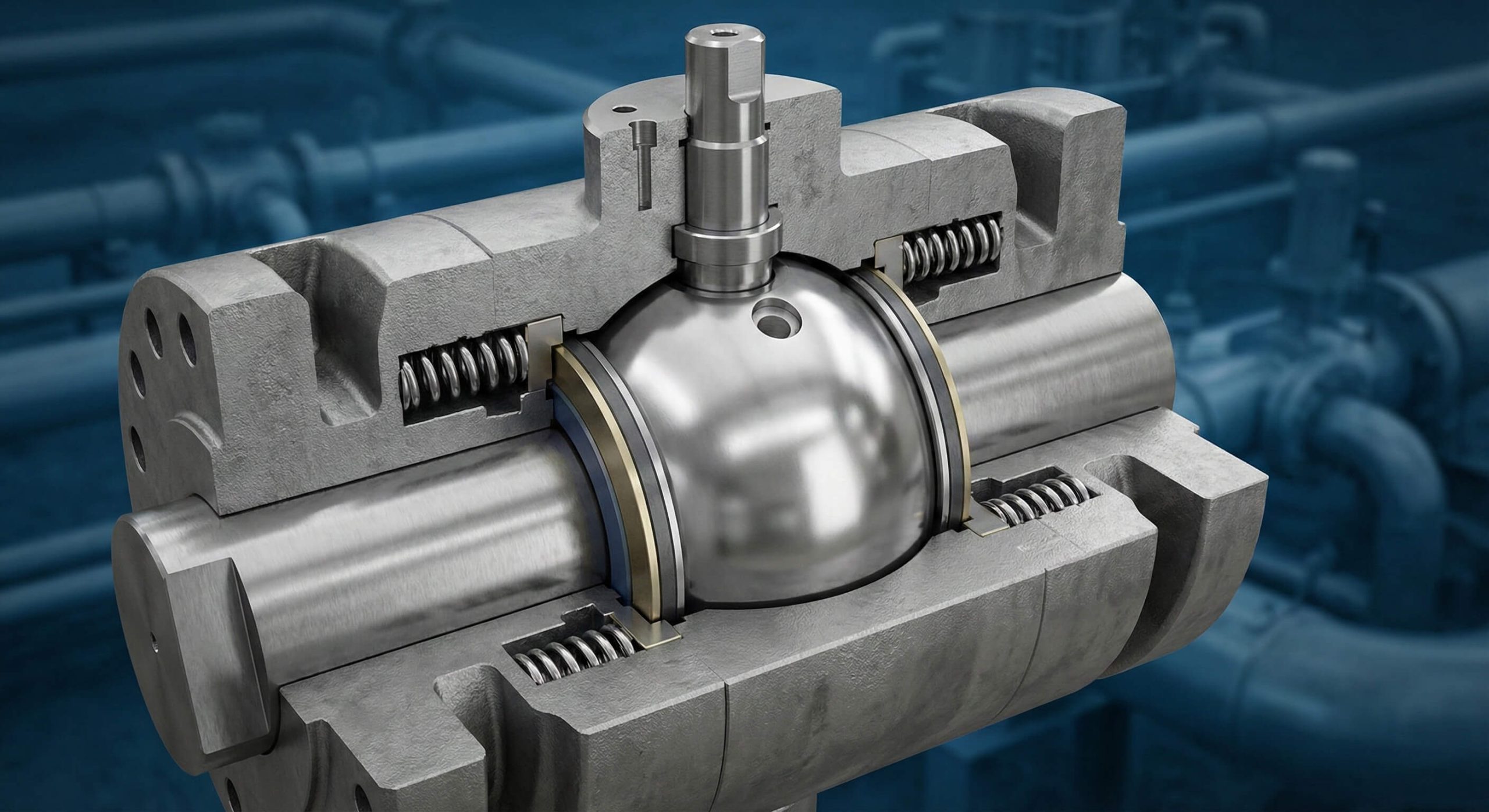

Trunnion Mounted Ball

Ball is mechanically anchored to prevent movement, with spring-loaded seats maintaining seal. Required for large diameters, high pressures, and applications demanding low operating torque. Prevents seat damage from excessive loading, extending service life in demanding oil, gas, and chemical processing environments.

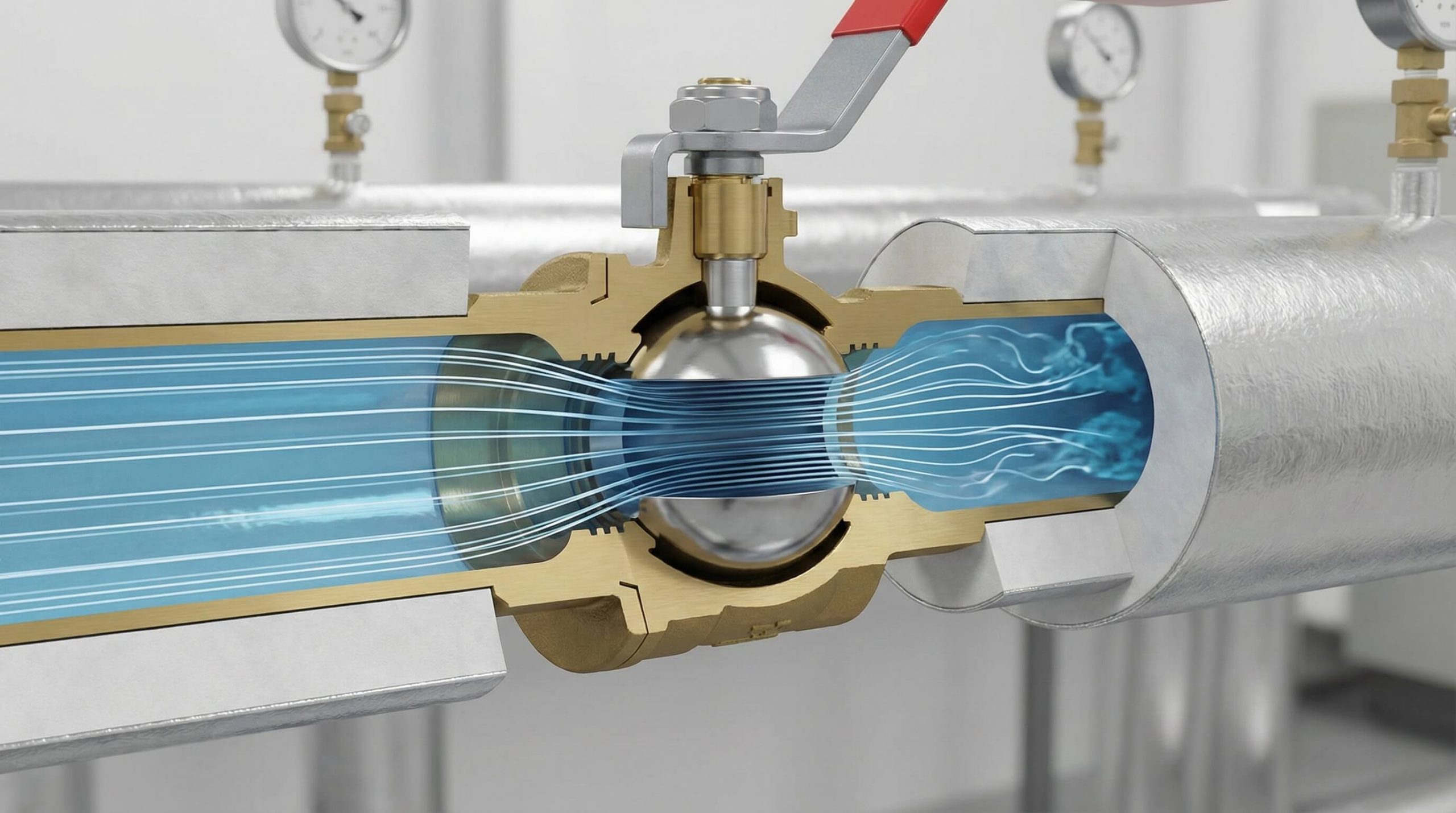

Soft Seat vs Metal Seat Sealing

Soft Seat Technology

PTFE, reinforced PTFE, or elastomer seats provide bubble-tight shut-off at temperatures from -50°C to +230°C depending on material. Excellent for clean fluids, water, gases, and non-abrasive chemicals. Lower cost and superior sealing but limited by temperature and abrasion resistance. Widely used in general industrial service.

Metal Seat Design

Hardened metal-to-metal sealing withstands extreme temperatures up to 540°C, high erosion, and abrasive particles that destroy soft seats. Essential for steam, high-temperature oils, slurries, and applications with solid contaminants. Higher initial cost offset by extended service life in harsh environments where soft seats fail rapidly.

Apply this knowledge to select the optimal valve configuration for your specific application

6 Critical Selection Mistakes That Compromise Projects

Understanding the cascading consequences of improper valve specification

Standard PTFE Seats for Steam

Specifying soft seats rated for 180°C in applications where steam temperature reaches 210°C.

Rapid Seat Degradation

Thermal breakdown causes seat material to lose elasticity and crack within 3-6 months.

Emergency Replacement Cycle

Unplanned maintenance shutdowns, significant production losses, and expedited costs.

Carbon Steel for Chlorinated Water

Choosing economical carbon steel without considering chlorine's corrosive attack.

Accelerated Internal Corrosion

Chlorine causes pitting and wall thinning that progresses faster in stagnant areas.

Premature System Failure

Contamination of water supply and complete re-piping required within 2-3 years.

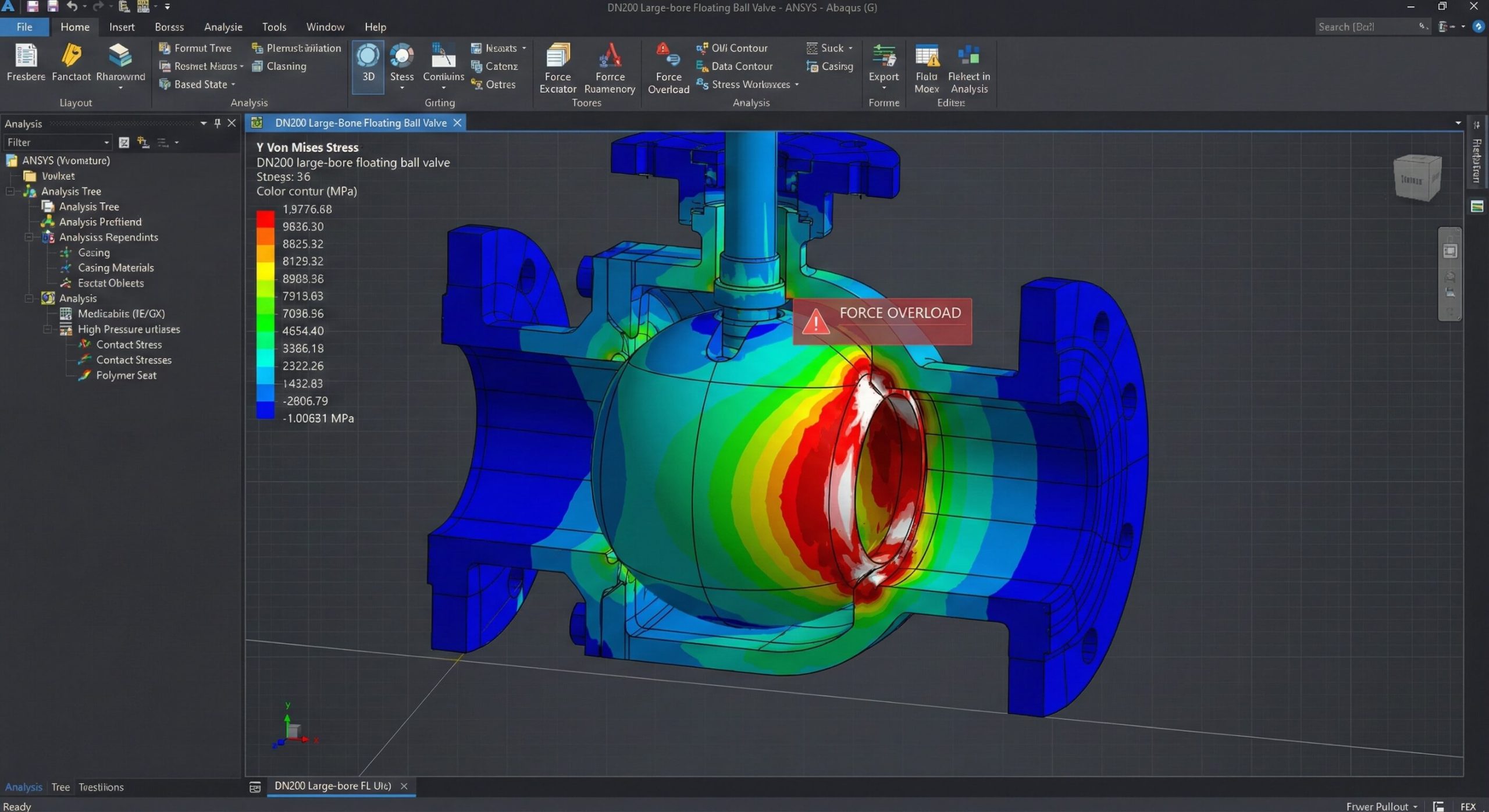

Floating Ball for PN40 Gas Line

Using floating ball design in DN200 high-pressure gas application.

Excessive Seat Loading

Pressure forces ball against seats with extreme force, causing rapid seal failure.

Safety Hazard and Downtime

Leakage triggers emergency shutdowns and mandated valve replacement delays.

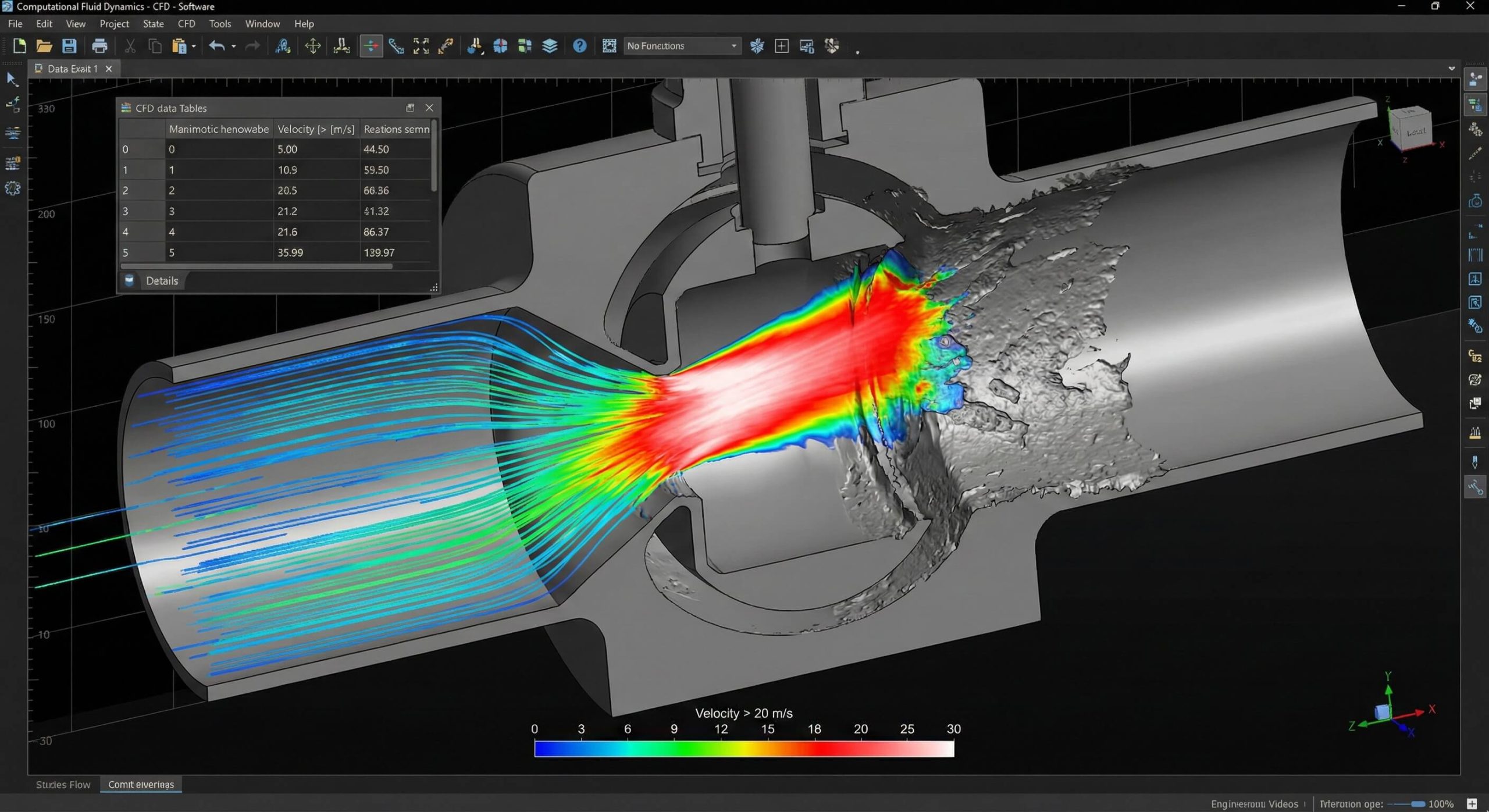

Reduced Bore in Slurry System

Installing reduced bore valves to save costs in abrasive slurry lines.

Velocity Increase and Erosion

Flow restriction accelerates velocity, multiplying erosive wear on valve surfaces.

Frequent Replacement Costs

Service life reduced to 6-9 months; maintenance costs exceed initial savings by 400%.

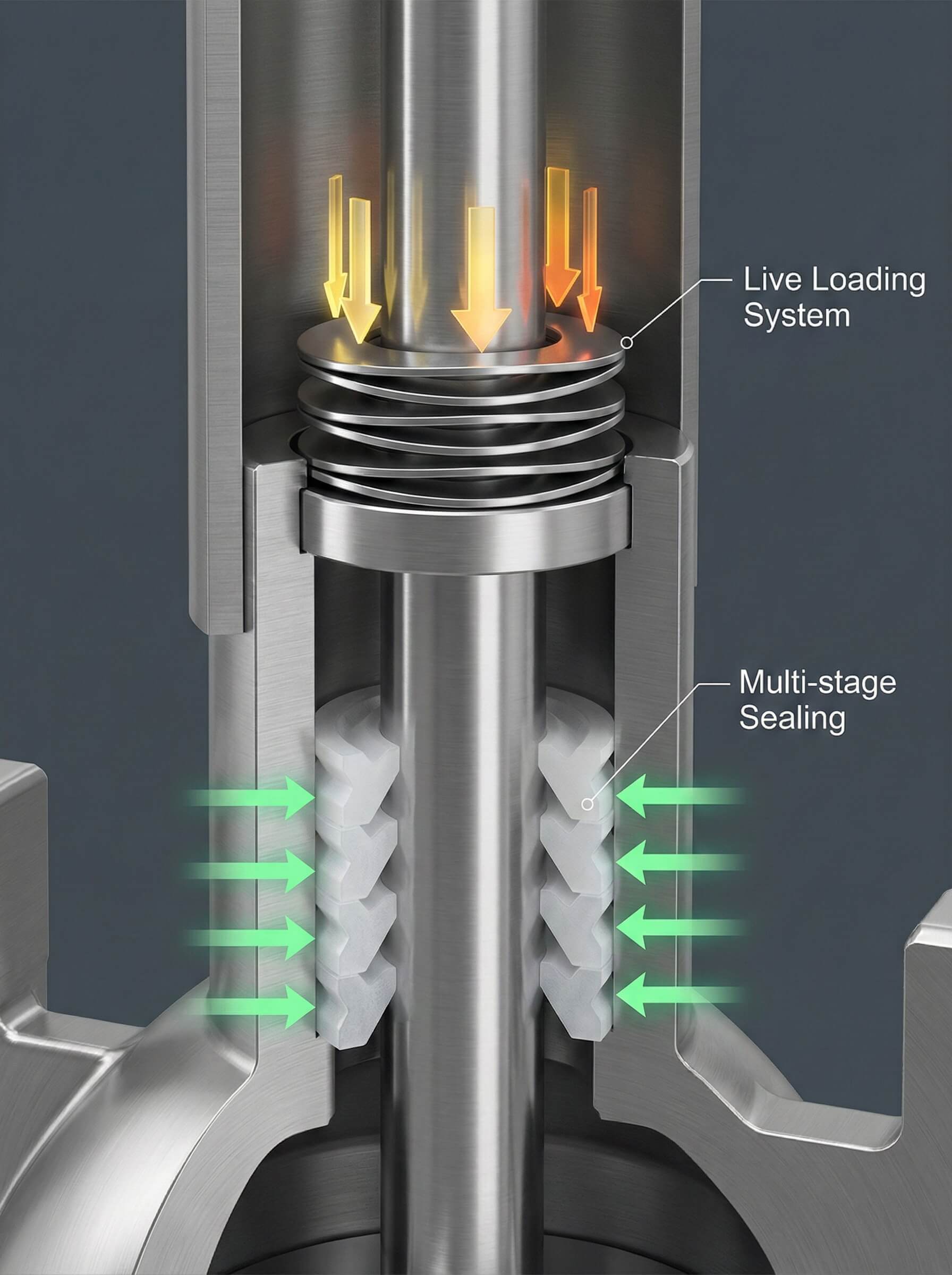

Standard Packing for LNG

Specifying conventional stem sealing for liquid natural gas at -162°C.

Thermal Contraction & Leakage

Cold causes packing to shrink and harden, allowing fugitive emissions.

Compliance Failure

Emissions trigger regulatory fines and mandatory retrofits with cryogenic-rated valves.

Ignoring Safety Factor in Sizing

Selecting actuators based on nominal torque without accounting for 'stiction' after inactivity.

Actuator Stall Failure

Valve fails to open/close on demand because the actuator cannot overcome static friction.

Process Lockout & Manual Override

Critical process interruption requiring manual intervention and actuator upgrade.

Prevent these costly errors with proper engineering consultation during specification phase

RUITO Engineering Selection Framework

Systematic approach ensuring optimal valve specification for long-term reliability

Media Compatibility Analysis

Identify chemical composition, contaminants, and phase to select materials that resist corrosion, erosion, and chemical attack throughout the design service life.

Operating Envelope Definition

Establish maximum pressure, temperature extremes, and flow conditions including transient surges to specify appropriate pressure class and construction.

Flow Characteristic Matching

Calculate required Cv, evaluate pressure drop tolerance, and determine if full bore or reduced bore optimizes system performance and energy efficiency.

Sealing System Selection

Choose between soft seats for tight shut-off in clean service or metal seats for high temperature, abrasive, or erosive applications based on operating envelope.

Mounting Configuration Decision

Select floating or trunnion design based on valve size, pressure rating, and required operating torque to ensure reliable operation and manageable actuation.

Standards Compliance Verification

Confirm valve meets applicable industry codes, certifications, and project specifications for pressure testing, materials, and documentation requirements.

Work with our engineering team to apply this proven methodology to your specific requirements

Ball Valve Solutions by Application

Engineered configurations optimized for specific industry demands and operating conditions

Water Systems & HVAC

Typical applications include municipal water distribution networks, chilled water circuits in commercial buildings, heating systems requiring low-torque operation, and potable water installations where drinking water compliance certification is mandatory.

Chemical Processing

Suitable for sulfuric acid transfer lines, chlorine handling systems, pharmaceutical production facilities requiring sterile design, and petrochemical plants processing corrosive hydrocarbons where material compatibility prevents costly failures.

Oil & Gas Applications

Critical for natural gas transmission pipelines requiring fire-safe certification, crude oil processing units operating at elevated pressures, offshore platform installations exposed to saltwater corrosion, and wellhead control systems.

High Temp & Special Media

Designed for steam systems operating above 200°C, thermal oil circuits in industrial heating, cryogenic LNG terminals requiring extended stem bonnets, and vacuum service applications where conventional seals lose effectiveness.

Find the optimal valve configuration for your specific application requirements

Critical Design Features That Ensure Reliability

Engineering details that differentiate performance-grade valves from commodity products

Ball Valve Internal Construction - Key Component Locations

Anti-Blowout Stem Design

Multi-Layer Stem Sealing System

Precision-Machined Seat Pockets

Full Penetration Body Welds

Specify valves with proven design features that prevent field failures

Why Supply Chain Decisions Impact Project Outcomes

Understanding the hidden costs of inadequate supplier capabilities

Inconsistent Material Quality

Using uncertified raw materials or substituting grades results in failure to meet compatibility requirements and liability issues.

Certified Material Traceability

Every component includes mill certificates with heat numbers traceable to the foundry, satisfying inspector requirements.

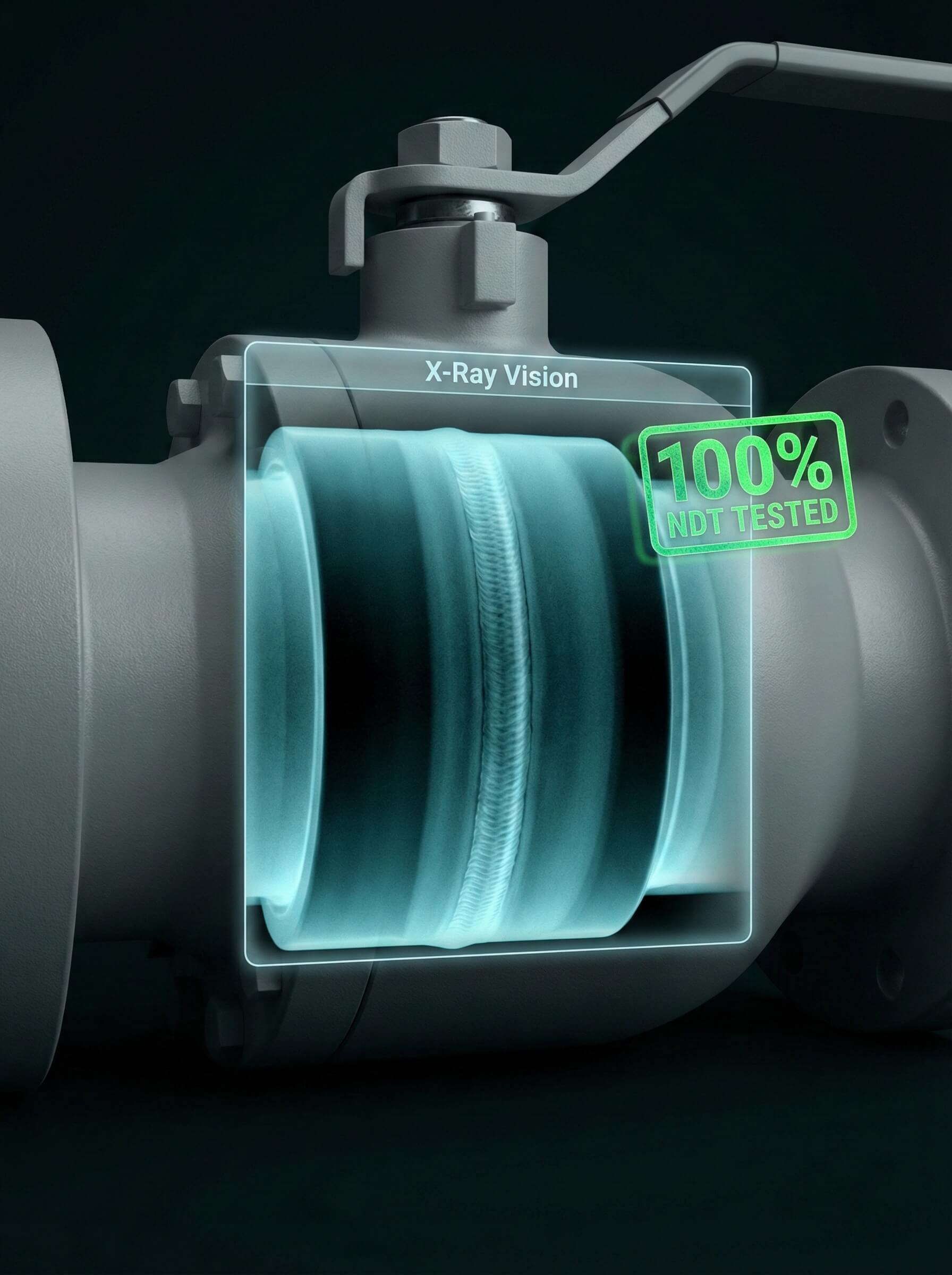

Inadequate Pressure Testing

Skipping hydrostatic testing allows defective valves to pass inspection, leading to expensive field failures during commissioning.

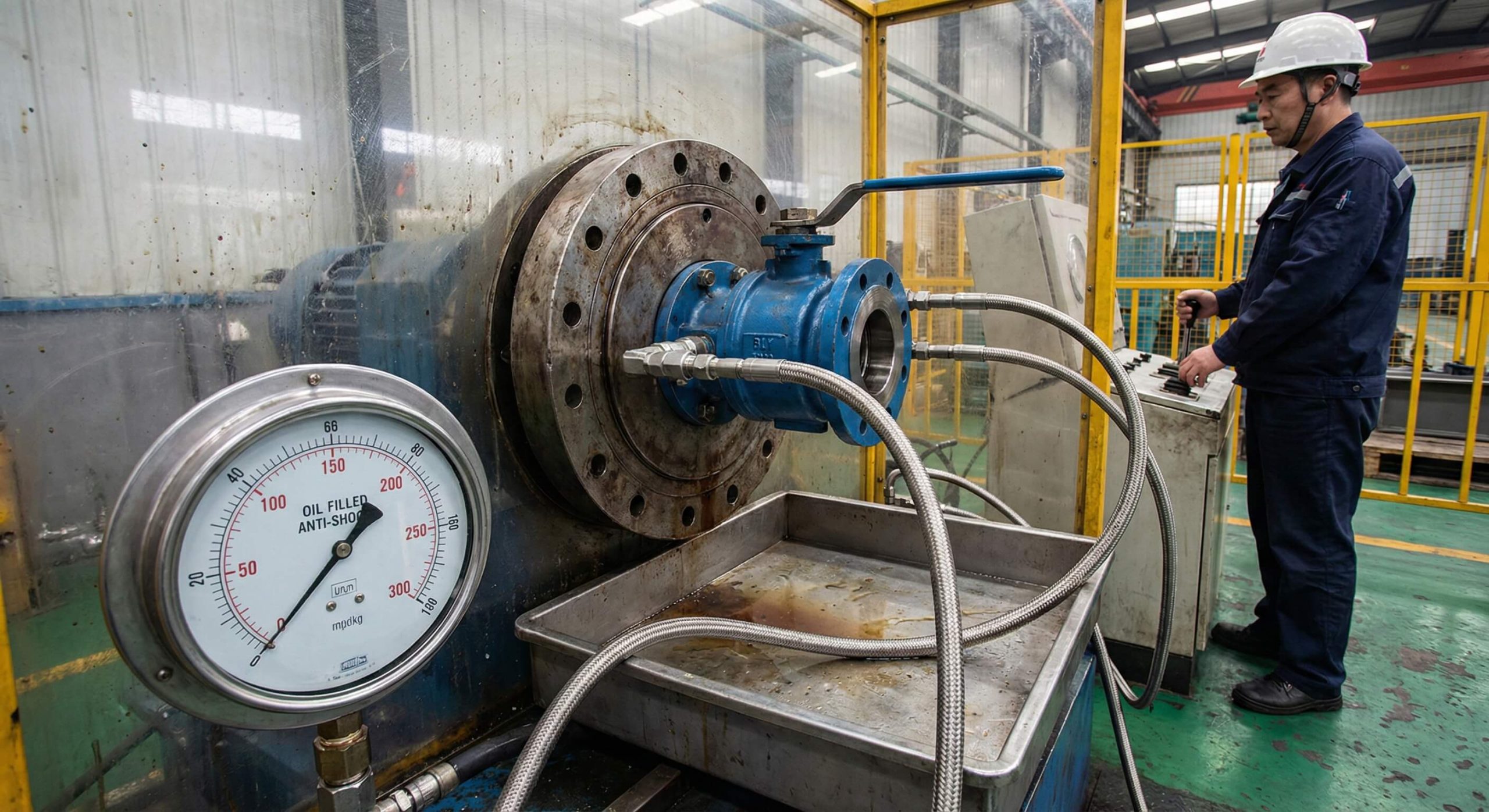

Rigorous Testing Protocols

100% hydrostatic and pneumatic testing at 1.5x rated pressure with documented results confirms performance before shipment.

Missing Documentation

Inability to provide compliance docs prevents customs clearance, delays acceptance, and creates audit failures.

Complete Documentation Package

Orders include material certificates, test reports, and compliance declarations for smooth customs and regulatory approval.

Poor Delivery Reliability

Unpredictable lead times disrupt schedules, force costly expediting, idle crews, and cause penalty fees.

Predictable Delivery Schedule

Confirmed lead times with progress updates allow accurate planning; standard orders complete in 3-4 weeks.

No Technical Support

Lack of engineering assistance leads to specification errors, improper sizing, and avoidable installation problems.

Engineering Consultation Available

Technical team reviews specifications, calculates flow coefficients, and provides sizing recommendations before ordering.

Limited Customization

Rigid product lines force compromise solutions that don't fully meet requirements, reducing system performance.

Custom Configuration Capability

In-house manufacturing allows special trims, exotic materials, and modified designs to match exact requirements.

Partner with a manufacturer that supports your project from specification to commissioning

Certifications & Standards Compliance

Third-party verification ensuring quality, safety, and regulatory acceptance

How These Certifications Protect Your Project

Full pressure equipment compliance for both European Union (CE) and United Kingdom (UKCA) markets.

Confirms materials are safe for potable water, preventing contamination of drinking systems.

Certified by TÜV Rheinland for use in safety-instrumented systems (SIS) to ensure reliable shutdown.

Ensures compatibility with critical oil & gas infrastructure operating at high pressures.

Bureau Veritas (BV) certified fire safety and SGS verified low fugitive emissions for hazardous environments.

Qualifies valves for offshore and marine vessels requiring saltwater corrosion resistance.

Request certification documentation for your specific project requirements

Manufacturing Process: From Raw Material to Tested Product

Integrated production capabilities ensuring consistent quality at every stage

Casting & Raw Materials

Investment casting and forging processes create valve bodies and components from certified raw materials with verified chemical composition.

Prevents porosity defects and ensures uniform wall thickness through heat number documentation.

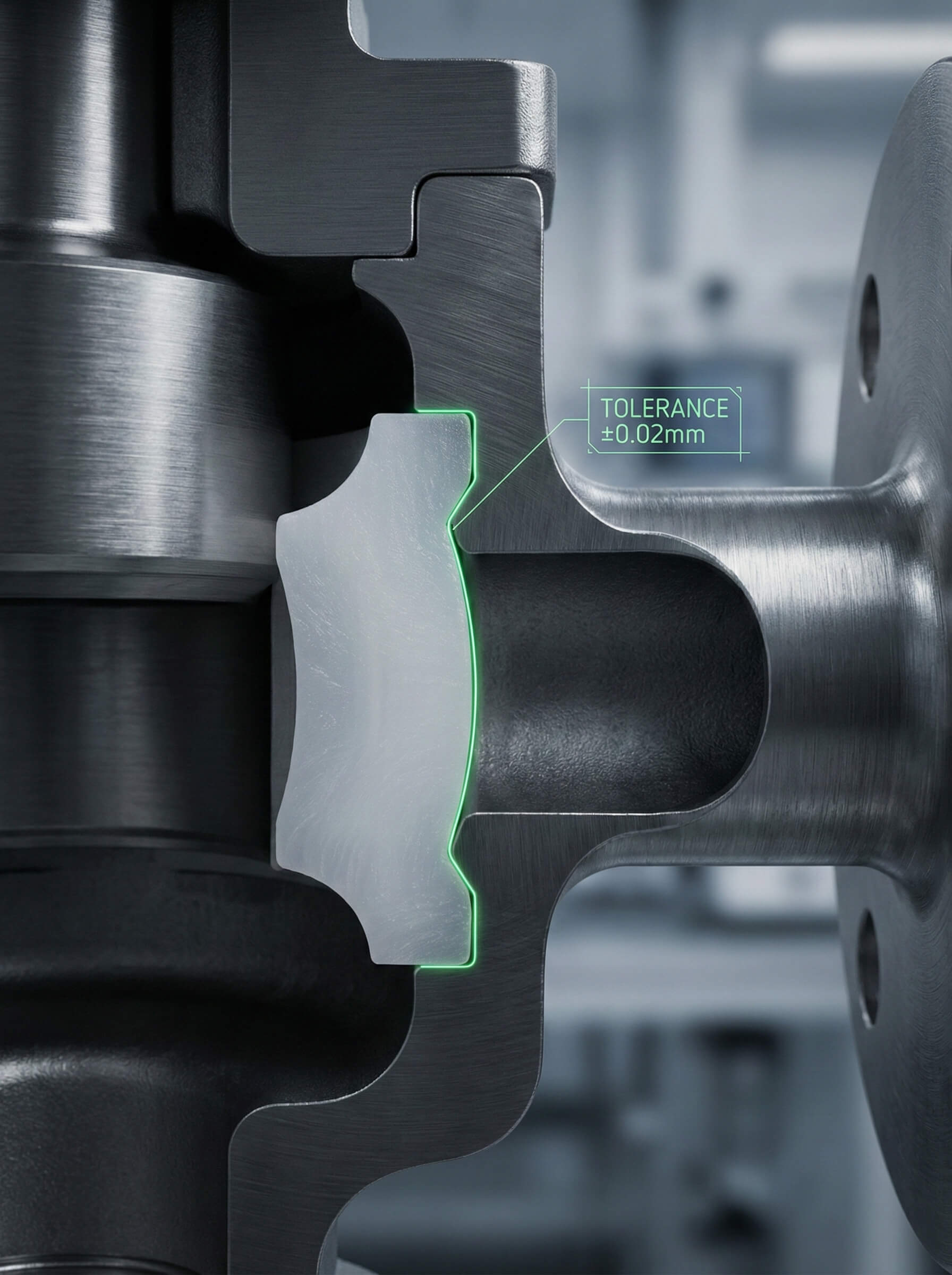

CNC Machining

Computer-controlled machining centers precisely bore seats, drill ports, and finish sealing surfaces to tight dimensional tolerances.

Eliminates dimensional variations that cause seat leakage and improper component fit.

Surface Treatment

Epoxy coatings, electroplating, or passivation processes protect external surfaces from corrosion during storage and installation.

Prevents surface corrosion during long-term storage and extends service life in corrosive atmospheres.

Assembly & Integration

Trained technicians install seats, seals, balls, and stems following documented procedures with controlled torque specifications.

Prevents over-torquing and maintains consistent assembly quality across production batches.

Pressure Testing

Every valve undergoes hydrostatic shell testing and seat leakage testing at pressures exceeding rated values with documented results.

Identifies defective welds and seat leaks before shipment, eliminating field failures.

Packaging & Shipment

Protective caps seal port openings, desiccants prevent moisture intrusion, and plywood cases protect valves during transport.

Prevents shipping damage and contamination of internal components.

Experience the quality difference of vertically integrated manufacturing

5-Stage Quality Verification Process

Systematic inspection ensuring every valve meets specification before shipment

Incoming Material Inspection

All raw materials undergo chemical composition analysis using spectroscopy, mechanical property testing for tensile strength, and dimensional checks against purchase specifications.

Eliminates use of substandard materials with incorrect chemistry that would cause premature corrosion.

In-Process Manufacturing Control

Critical dimensions are measured during machining using calibrated micrometers. Surface finish is verified with roughness testers, and first-article inspection validates programs.

Catches machining errors and dimensional drift before batch completion, ensuring proper assembly fit.

Hydrostatic Pressure Testing

Shell testing at 1.5x rated pressure verifies body integrity, followed by seat leakage testing to confirm bubble-tight shut-off performance according to API 598 standards.

Identifies porous castings and seal failures before installation, eliminating costly field leaks.

Final Product Inspection

Inspectors verify dimensions against drawings, confirm marking matches purchase orders, check operation torque, and ensure protective coatings have proper thickness.

Catches assembly errors, damaged threads, and missing parts that would cause installation delays.

Documentation Package Assembly

Quality department compiles material certificates, pressure test reports, and compliance declarations. Documents are verified against valve serial numbers before shipment.

Ensures complete documentation for customs clearance and regulatory acceptance.

Request detailed quality documentation for your project requirements

Flexible Delivery Options Matching Project Schedules

Predictable lead times and inventory strategies supporting various procurement scenarios

Stock Items

Common sizes in brass, carbon steel, and SS316 with PTFE seats.

Maintenance spare parts, small project quantities, and urgent replacements.

Urgent Production

Priority manufacturing for standard specifications with expedited line.

Project delays, unexpected equipment failures, or schedule recovery.

Standard Production

Full range of materials and pressures manufactured to spec.

New construction projects, planned shutdowns, and bulk orders.

Special Customization

Non-standard materials, special trims, or engineered solutions.

Unique process conditions, exotic media, or extreme temps.

Flexible Delivery Coordination

We support split shipments aligned with your construction milestones, enabling partial deliveries as project phases progress. Valves can be staged to match installation sequences, reducing on-site storage requirements.

Discuss your project timeline and receive confirmed delivery commitments

Proven Performance in Demanding Applications

Real installations demonstrating reliability across industries and operating conditions

Sulfuric Acid Transfer System

New chemical production facility requiring corrosion-resistant valves for concentrated sulfuric acid transfer at 98% concentration and ambient temperature.

Extreme Corrosion Resistance

Standard stainless steel unsuitable due to rapid corrosion. Required duplex stainless steel 2205 bodies with RPTFE seats rated for acid service.

Custom Material Configuration

Supplied DN50-DN150 ball valves in duplex 2205 with reinforced PTFE seats, FKM seals, and extended stem bonnets with full material traceability.

4 Years Zero Maintenance

All valves operating without leakage or maintenance interventions. No corrosion detected during annual inspections. Client reordered for facility expansion.

Drinking Water Distribution

Upgrade of aging water distribution network serving 50,000 residents requiring WRAS-approved valves for potable water service.

Regulatory Compliance

All components contacting water must hold WRAS approval confirming safety. Delivery needed to match phased construction schedule.

Certified Brass Valves

Delivered DN80-DN200 WRAS-certified brass ball valves with EPDM seals in three shipment phases aligned with contractor pipeline installation progress.

On-Time Phased Delivery

All shipments arrived per schedule enabling continuous installation. Network operational with no valve-related issues reported after 6 years service.

High-Rise Office Complex

45-story commercial tower requiring isolation valves for chilled water distribution serving tenant floors and common areas.

Large Quantity Fast Delivery

MEP contractor faced schedule pressure requiring 300+ valves delivered within compressed timeframe to avoid liquidated damages.

Expedited Batch Production

Allocated dedicated production line for DN25-DN150 stainless steel ball valves, completing manufacture and testing in 18 days with air freight.

Schedule Recovery Achieved

Delivery enabled contractor to recover 2-week schedule slip. HVAC system commissioned on revised timeline. No valve failures during 3-year operation.

Explore how our solutions can address your specific application challenges

How Engineering Clients Work With Us

Streamlined 6-step process from initial inquiry to ongoing support

Send Parameters

Submit your technical requirements including size, pressure, material, and connection type.

You: Provide specs/drawings

We: Review in 4 hours

Technical Confirmation

Engineers verify application details and recommend optimal configurations if needed.

You: Confirm conditions

We: Submit approval drawings

Quotation & Lead Time

Receive detailed pricing and confirmed delivery schedule within 24 hours of finalization.

You: Receive offer

We: Guarantee lead time

Sample or Production

Testing samples can be provided for critical applications before full production runs.

You: Validate sample

We: Report progress

Shipment & Documents

Valves ship with full documentation including certificates, test reports, and compliance docs.

You: Track shipment

We: Provide all certs

After-Sales Support

Ongoing technical assistance for installation, troubleshooting, and spare parts supply.

You: Get support

We: Maintain records

Start the process with a no-obligation technical consultation

Engineering Client Feedback

Documented results from industrial installations across multiple sectors

"Valves performing to specification in sulfuric acid service. No leakage incidents recorded. Material certificates matched delivered products perfectly. Documentation supported our CE compliance audit without any issues."

"Delivered on committed schedule enabling phased construction. WRAS certificates were accepted by the water authority immediately. No operational problems after 6 years of continuous service."

"Expedited production met our critical deadline, avoiding liquidated damages. Valves arrived with complete documentation. Installation proceeded without compatibility issues. System commissioned successfully."

"Consistent quality across multiple shipments over our 5-year contract. Technical support is responsive when application questions arise. Defect rate is significantly lower than alternative suppliers."

Join engineering firms who rely on our proven track record

Common Engineering Questions Answered

Technical and commercial information for informed procurement decisions

Our ball valves are designed, manufactured, and tested in accordance with multiple international standards to ensure global project compatibility and regulatory acceptance.

- Design: API 6D, ASME B16.34, EN 12516

- Testing: API 598, EN 12266-1, ISO 5208

- Fire Safety: API 607, BS 6755

Yes, we hold both WRAS approval for potable water applications in the UK and CE marking under the Pressure Equipment Directive for European market compliance.

- WRAS certificates for brass/SS valves

- CE Declaration of Conformity (PED)

- EN 10204 3.1 Material Certificates

MOQs vary based on valve size and complexity. Standard configurations have low MOQs suitable for small projects, while extensive customization requires higher quantities.

- Stock sizes (DN15-100): 10 pieces

- Standard production: 20-50 pieces

- Fully custom designs: 50-100 pieces

We maintain inventory for immediate shipment and offer expedited production for urgent requirements. Confirmed lead times are provided with every quotation.

- Stock items: 3-5 working days

- Urgent production: 10-15 working days

- Standard production: 25-35 working days

Yes, we manufacture to customer-provided drawings and support OEM partnerships requiring specific designs, private labeling, or proprietary configurations.

- Manufacturing to supplied drawings

- Private label branding & packaging

- Design optimization support

Every shipment includes comprehensive quality documentation to support customs clearance and project acceptance.

- Material Test Reports (Heat Numbers)

- Pressure Test Reports

- Dimensional Inspection Reports

We provide an 18-month warranty from shipment date covering manufacturing defects. Claims are processed promptly with technical investigation.

- Technical installation guidance (Remote)

- Operational troubleshooting

- Spare parts availability (Seals/Seats)

Absolutely. We welcome inspections from authorized third-party agencies (such as SGS, BV, TUV, or DNV) at our facility to witness testing and verify quality prior to dispatch. This ensures the products meet your exact specifications before they leave our factory.

- Visual & Dimensional verification

- Witnessed Hydrostatic Pressure Testing

- Review of Material Certificates & Docs

- Packaging & Marking inspection

Have additional questions not covered here? Our technical team is ready to assist

Choose Your Next Step

Select the option that matches your current project stage

Download Technical Catalog

Access comprehensive product specifications, pressure-temperature charts, and material options to evaluate if our valves match your requirements.

Schedule Technical Consultation

Discuss your application with our engineering team to verify valve selection, confirm material compatibility, and review operating conditions.

Request Detailed Quotation

Submit your specifications to receive pricing, confirmed delivery schedule, payment terms, and complete commercial proposal.