Industrial Butterfly Valves for Water, HVAC & Process Systems

DN25–DN3000 | PN10–PN25 | EN / DIN / API

Common Challenges Engineers Face When Sourcing Butterfly Valves

Supply chain inefficiencies and quality inconsistencies can compromise your system integrity. Avoid these costly project risks by partnering with a verified manufacturer.

Incomplete Documentation

Suppliers provide incomplete technical documentation, making it impossible to verify if the valve meets your project specifications.

Unpredictable Lead Times

Unpredictable delivery schedules delay your construction timeline and put critical project milestones at risk.

Inconsistent Quality

Inconsistent manufacturing quality across batches leads to premature valve failure and costly on-site replacements.

Technical Support Gaps

Lack of responsive technical support when you need guidance on material selection or installation requirements.

Certification Compliance

Missing or invalid certifications create compliance headaches and prevent project approval from regulatory authorities.

Customization Limitations

Suppliers refuse or delay custom modifications, forcing you to compromise on system design or source from multiple vendors.

Ready to work with a reliable valve manufacturer?

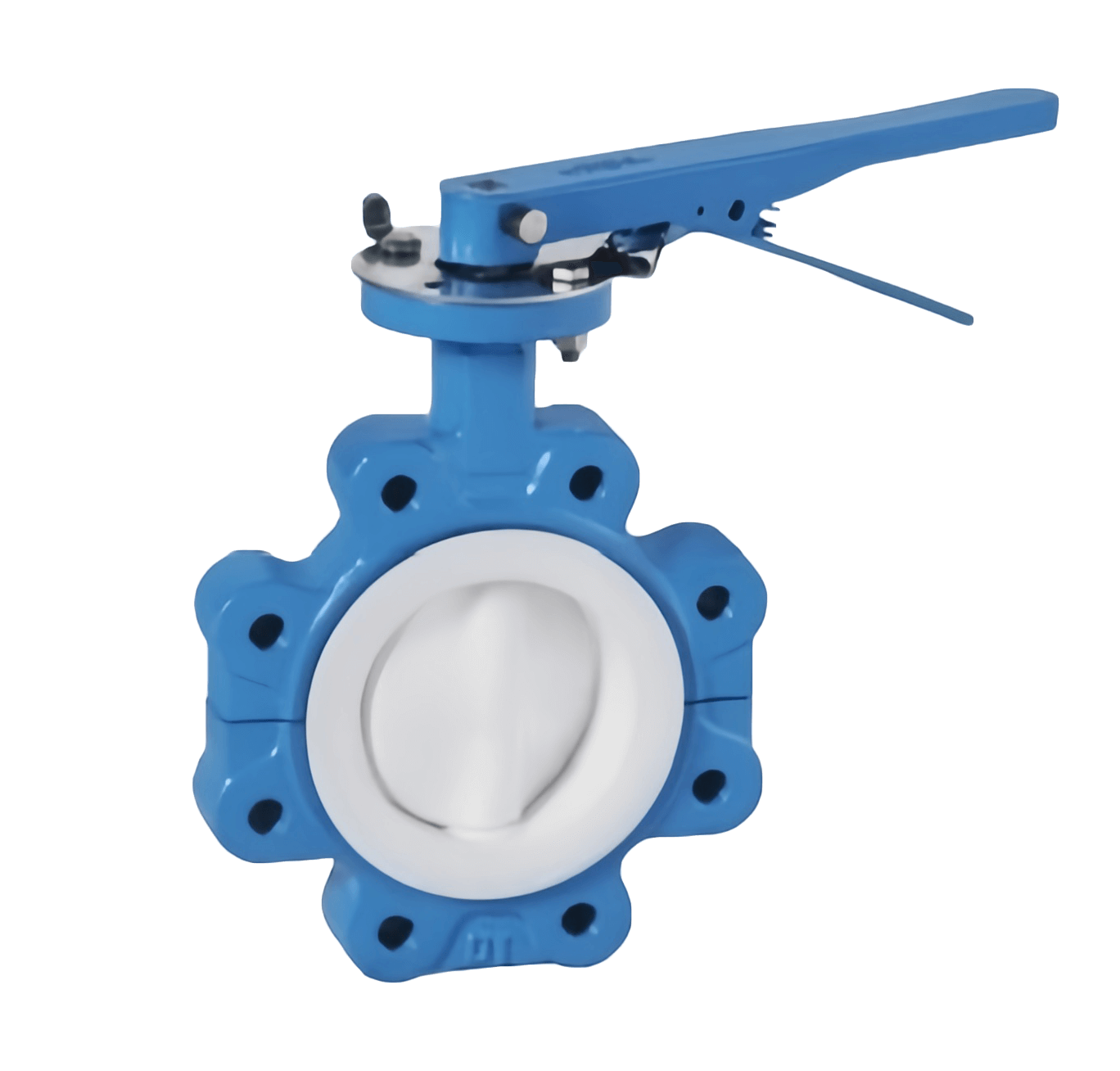

Talk to Our EngineersWhat is a Butterfly Valve?

A compact, cost-effective, and fast-acting flow control solution for modern industrial systems.

A butterfly valve is a quarter-turn rotary valve that uses a circular disc mounted on a shaft to regulate fluid flow. It is designed to start, stop, or throttle flow with maximum efficiency.

Fast Actuation

Moves from fully open to fully closed in a 90-degree turn, allowing for quick operation and emergency shutoff.

Space Efficient

The narrow face-to-face dimension requires significantly less installation space than gate or ball valves.

Versatile Specs

Available from DN25 to DN3000 for pressure ratings PN10–PN25, suitable for water, HVAC, and process lines.

Butterfly Valve vs Gate Valve vs Ball Valve

| Specification | Butterfly Valve | Gate Valve | Ball Valve |

|---|---|---|---|

| Size Range | DN25 - DN3000 | DN50 - DN1200 | DN15 - DN600 |

| Operating Torque | Low (30-70% less) | High | Medium |

| Cost (Same Size) | Lowest | Medium | Highest |

| Maintenance | Low (Quarterly) | Medium (Semi-annual) | Low (Annual) |

| Installation Space | Minimal | Large | Medium |

| Typical Application | HVAC, Water Treatment | On-off, High Pressure | Chemical, Gas |

Need help selecting the right valve type for your application?

Use Our Selection ToolHow to Select the Right Butterfly Valve Configuration

Follow this 4-step technical checklist to ensure your specification meets system requirements and avoids costly mismatches.

Choose Your Connection Type

Lug Type: Dead-end service, frequent maintenance access, DN65-DN1200. Allows single-side removal.

Flanged Type: High pressure, permanent installations, DN100-DN3000. Maximum structural strength.

Specifying wafer type for systems requiring frequent disassembly or high-pressure applications above PN16.

Using wafer valves in high-cycle applications causes bolt fatigue and flange misalignment, leading to leakage.

Select Your Sealing Method

PTFE Seat: Chemical resistance, -30°C to +200°C, aggressive media.

Metal Seat: High temperature (up to 550°C), steam, abrasive media.

Using EPDM seats in applications with temperature fluctuations above 80°C or chemical exposure.

Incorrect seat material causes accelerated degradation and seal failure, resulting in system downtime.

Determine Structure Type

Double Eccentric: Industrial processes, higher pressure, extended service life.

Triple Eccentric: Zero-leakage, high temp, metal-to-metal sealing.

Selecting concentric design for throttling service or applications requiring tight shutoff under pressure differential.

Using concentric valves in high-pressure differential applications causes excessive seat wear.

Choose Actuation Method

Electric: Automated systems, remote control, position feedback.

Pneumatic: Fast response, fail-safe requirement, explosive atmospheres.

Undersizing actuator torque calculation without accounting for differential pressure and safety margin.

Inadequate actuator sizing leads to valve failure to close under working conditions.

Still uncertain about your valve specification?

Speak with a Valve EngineerHow Incorrect Valve Selection Impacts Your Project

Don't let a small specification error compromise your entire system safety and budget. Professional selection prevents these costly failures.

Incorrect Size or Rating

Specifying DN200 PN10 when system operates at PN16 peak pressure, or undersizing valve for flow requirements without proper Cv calculation.

Actuator Overload & Failure

Electric actuator fails to close valve under full differential pressure, causing emergency system shutdown and safety incidents that halt production for 48-72 hours.

Wrong Seat Material

Choosing EPDM seats for systems with chlorinated water above 60°C, or NBR seats in contact with petroleum-based fluids.

Premature Seal Degradation

Seal hardening and cracking occurs within 6 months instead of rated 5-year lifespan, requiring unplanned maintenance and valve replacement during critical operations.

Flange Standard Mismatch

Ordering EN 1092-2 PN16 flanges when existing pipeline uses ANSI B16.5 Class 150, or incorrect bolt hole patterns.

On-Site Installation Delays

Valve cannot be installed without flange adapters, causing 2-3 week project delays while waiting for custom transition pieces and generating additional labor costs.

Ignored Operating Conditions

Failing to consider temperature cycling, flow velocity, suspended solids content, or corrosive media characteristics during valve specification.

Accelerated Component Failure

Disc erosion, shaft bearing wear, and body corrosion develop rapidly, creating safety risks and forcing complete system shutdown for emergency valve replacement.

Avoid costly mistakes with expert valve specification guidance

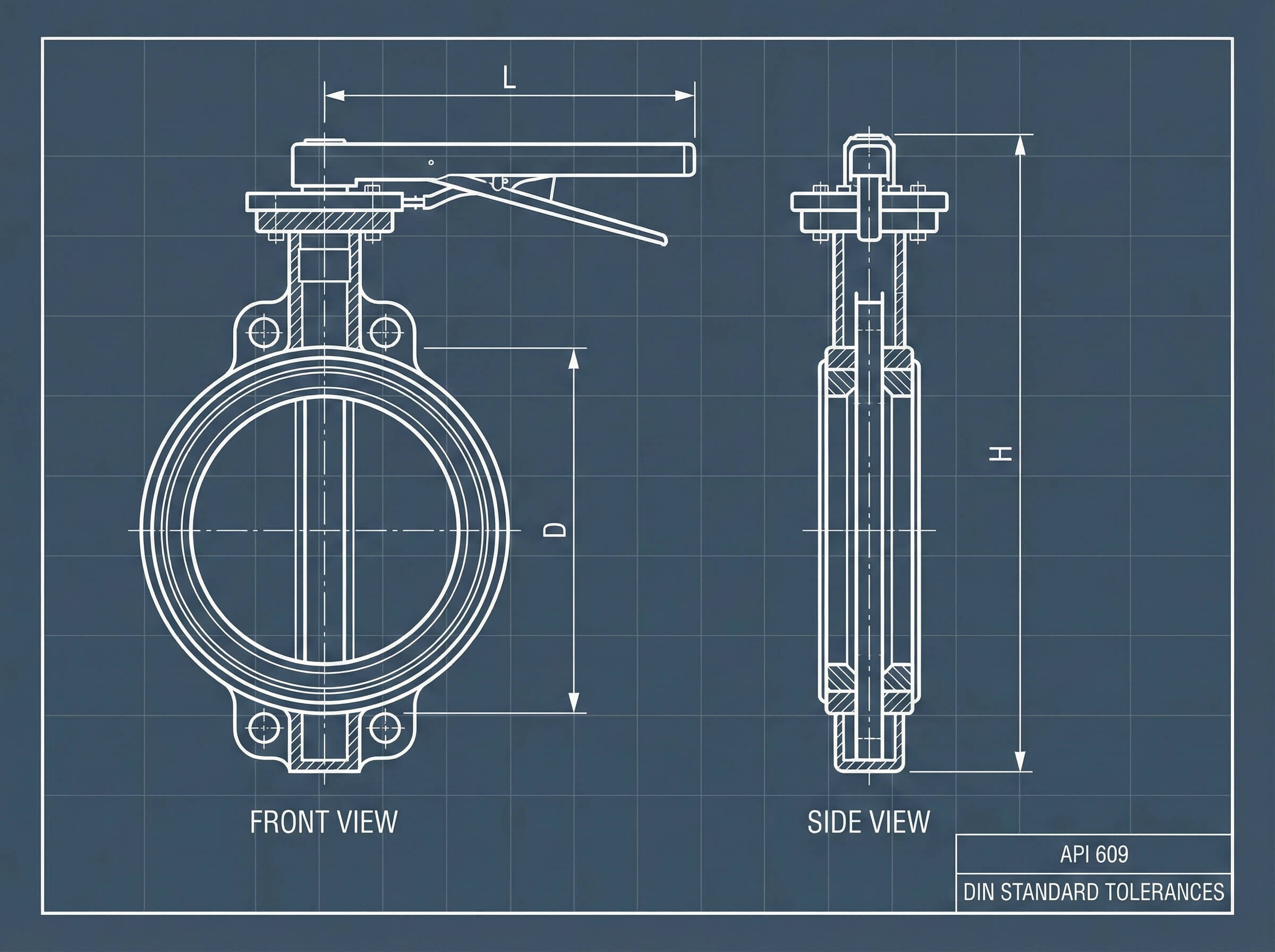

Request Technical ReviewComplete Technical Specifications

Industry-standard parameters covering the full range of butterfly valve configurations for water treatment, HVAC, and industrial process applications.

|

Size Range

|

DN25 – DN3000 |

|

Pressure Rating

|

PN10 (10 bar), PN16 (16 bar), PN25 (25 bar) |

|

Temperature

|

-40°C to +550°C (Material dependent) |

|

Body Material

|

Ductile Iron (GGG40/50), Cast Iron, Carbon Steel (WCB), Stainless Steel (CF8/CF8M), Duplex |

|

Seat Material

|

EPDM, NBR, PTFE, Viton (FKM), Metal-to-Metal |

|

Disc Material

|

DI + Coating, SS304/316, Al-Bronze, Duplex Steel |

|

Design Standard

|

EN 593, API 609, MSS SP-67, AWWA C504, BS 5155 |

|

Test Standard

|

EN 12266-1, API 598, ISO 5208, Fire Safe |

|

Connection

|

Wafer, Lug, Flanged (EN 1092-2, ANSI B16.5) |

Parameters outside these ranges can be engineered to order. Our technical team evaluates non-standard requirements including special materials (Hastelloy, Monel), extended temperature ranges, and higher pressure classes. Engineering drawings and material test reports provided with all custom orders.

Download complete dimensional drawings and performance curves

Get Technical DatasheetMaterial & Sealing Compatibility Matrix

Select the optimal seat material based on your operating conditions. This matrix shows real-world compatibility for common industrial applications.

|

Seat Material

|

Clean Water

|

Seawater

|

Weak Acid/Alkali

|

High Temp

|

High Cycle

|

High Pressure

|

|---|---|---|---|---|---|---|

| EPDM | Excellent | Excellent | Good | Limited | Good | Good |

| NBR | Excellent | Good | Good | Limited | Excellent | Excellent |

| PTFE | Excellent | Excellent | Excellent | Excellent | Excellent | Good |

| Metal Seat | Good | Limited | Good | Excellent | Good | Excellent |

Selection Guideline

EPDM provides best cost-performance for water applications below 80°C. NBR excels in high-pressure and high-cycle service. PTFE handles aggressive chemicals and wide temperature ranges. Metal seats are mandatory for steam and abrasive slurry applications above 200°C.

Custom Engineering

For specialized applications involving extreme pH, cryogenic temperatures, or unique chemical exposure, we engineer custom seat compounds. Provide your complete operating parameters for material recommendations backed by laboratory test data.

Unsure which material fits your application?

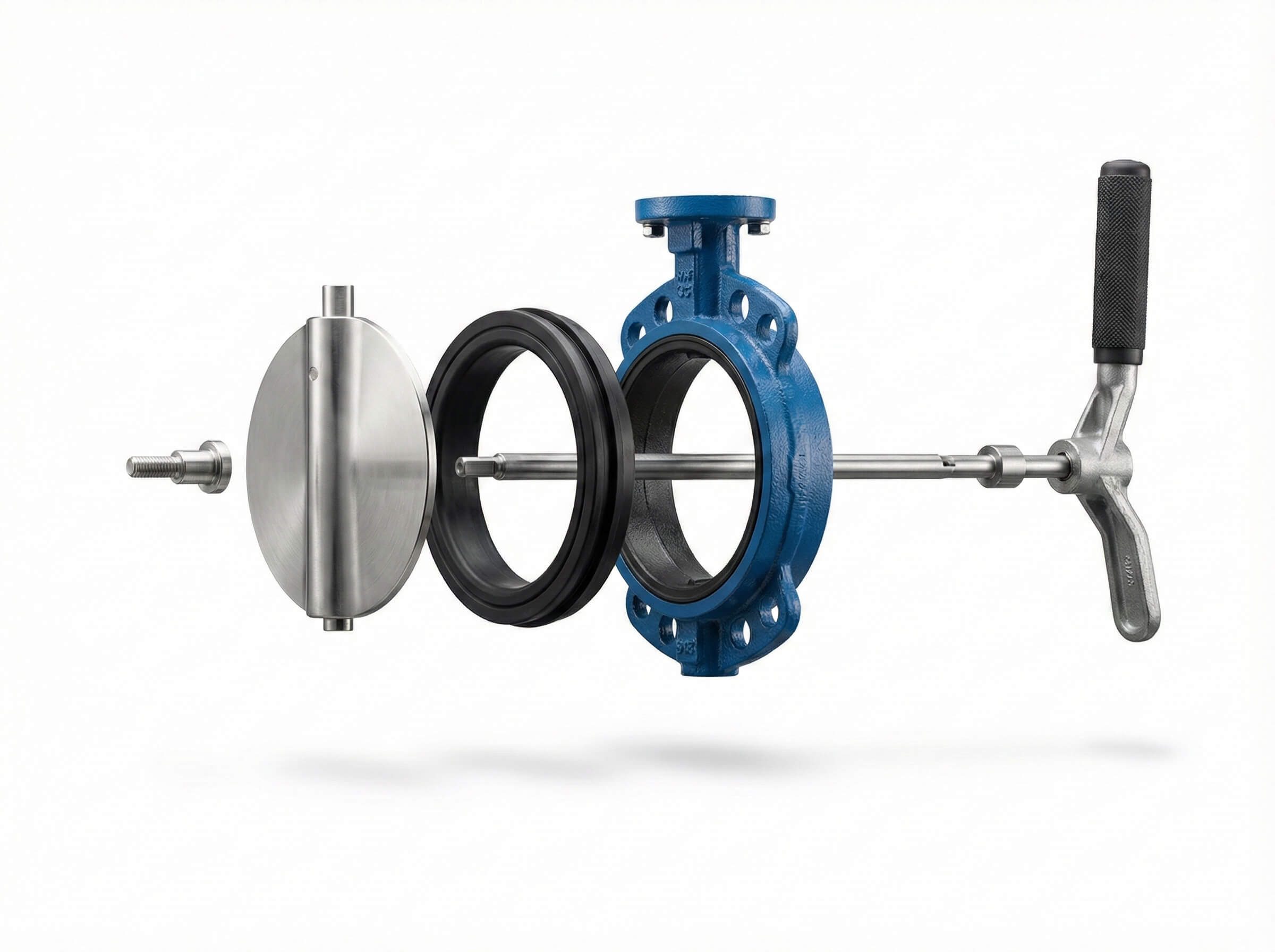

Request Material ConsultationTransparent Manufacturing Process

Every butterfly valve undergoes strict quality control through six critical manufacturing stages, ensuring dimensional accuracy, material integrity, and performance reliability.

Precision Casting

Chemical composition verification per EN 1563, dimensional tolerance ±0.5mm, pressure test casting integrity at 1.5x working pressure

Automated molding line with spectral analysis, heat treatment furnaces per ISO 1083

CNC Machining

Seat sealing surface flatness 0.02mm, bore diameter tolerance ISO 2768-m, shaft concentricity verification

5-axis CNC machining centers, CMM dimensional inspection per ISO 5211

Surface Treatment

Epoxy coating thickness 250-350μm, adhesion test per ISO 2409, salt spray resistance 1000+ hours

Electrostatic powder coating line, coating thickness gauge per ISO 2808

Seat Vulcanization

Vulcanization temperature/time profile control, hardness Shore A 60±5, bonding strength >8 N/mm

Computer-controlled vulcanizing press, hardness tester per ISO 48-4

Precision Assembly

Shaft alignment check, disc-to-seat contact verification, torque test at 25%, 50%, 100% travel

Calibrated torque wrenches, alignment jigs per EN 593 requirements

Final Inspection

Hydrostatic shell test 1.5x PN, seat leakage test per API 598, operation cycle test 200 cycles minimum

Automated hydro test bench, leakage detection system per EN 12266-1

Request factory inspection documentation or virtual tour

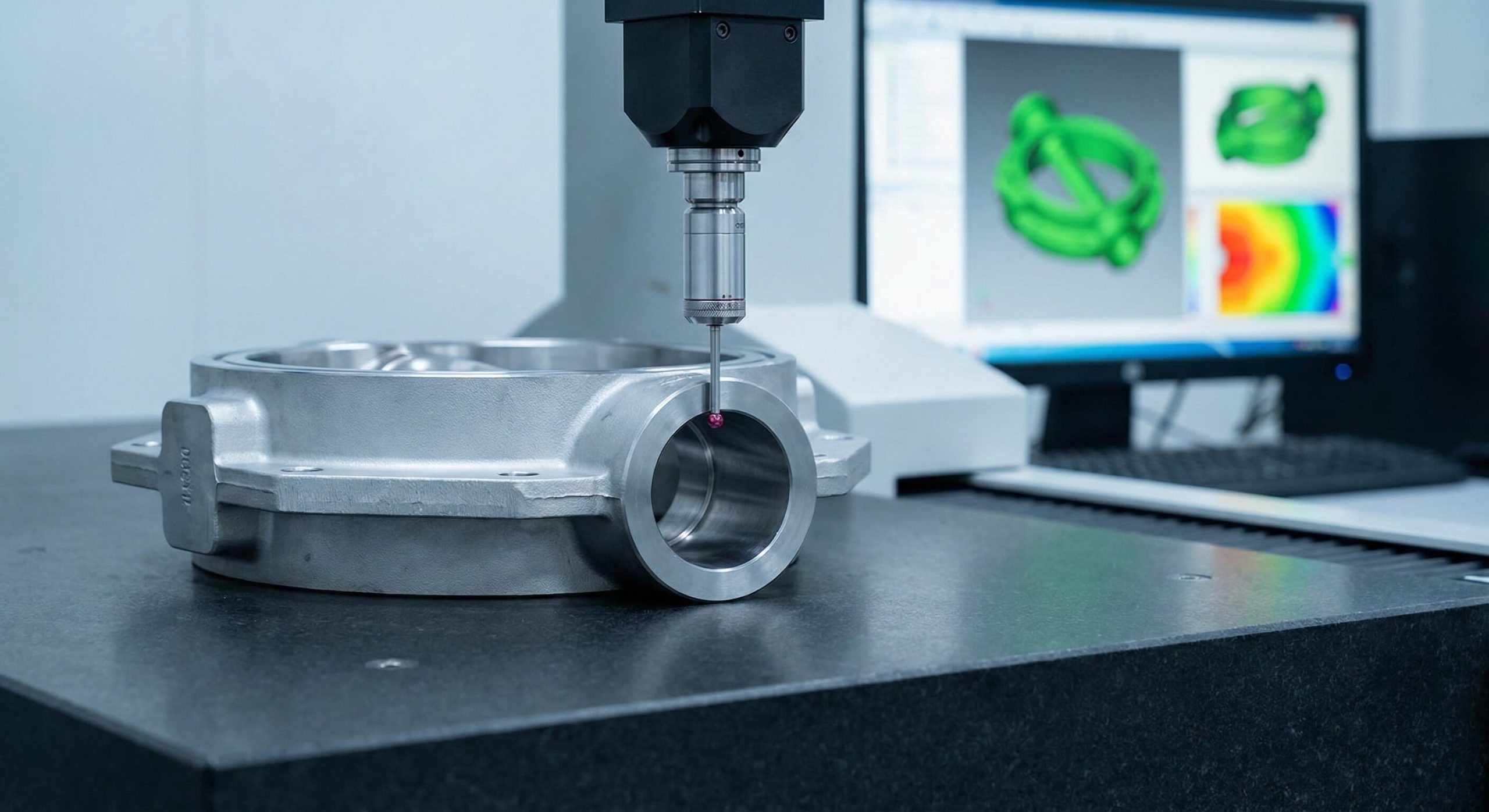

View Manufacturing CapabilitiesComplete Testing & Quality Control System

Every valve passes through six mandatory inspection stages. We don't just check quality; we document it with traceable certification.

Incoming Material Verification

Spectral analysis confirms chemical composition of all cast iron, ductile iron, and stainless steel. Tensile testing validates mechanical properties against design specs.

Precision Dimensional Inspection

CMM verification of critical dimensions including bore diameter, face-to-face length, flange drilling pattern, and shaft concentricity tolerances.

Assembly Quality Audit

Torque testing at 0°, 45°, and 90° validates smooth operation. Fasteners are tightened with calibrated torque wrenches to prevent loosening.

Hydrostatic Shell Test

Body shell pressurized to 1.5x rated pressure (e.g., 24 bar for PN16) for minimum 5 minutes. Automated monitoring ensures zero structural leakage.

Seat Leakage Test

Low-pressure air test at 6 bar to verify bubble-tight shutoff. Ensures zero visible leakage across the seat for soft-seated valves.

Pre-Shipment Inspection

Review of coating thickness, tagging, and packaging. Verification that all previous test data matches the serial number on the nameplate.

Request detailed quality control procedures and sample test reports

Download QC DocumentationDelivery Guarantee System

Structured delivery framework with clearly defined timelines for stock items, rush orders, and custom engineering projects. No ambiguous lead times.

Stock Inventory

Expedited Production

Custom Engineering

Check current stock availability or discuss your delivery requirements

Request Delivery ScheduleEngineering Case Studies

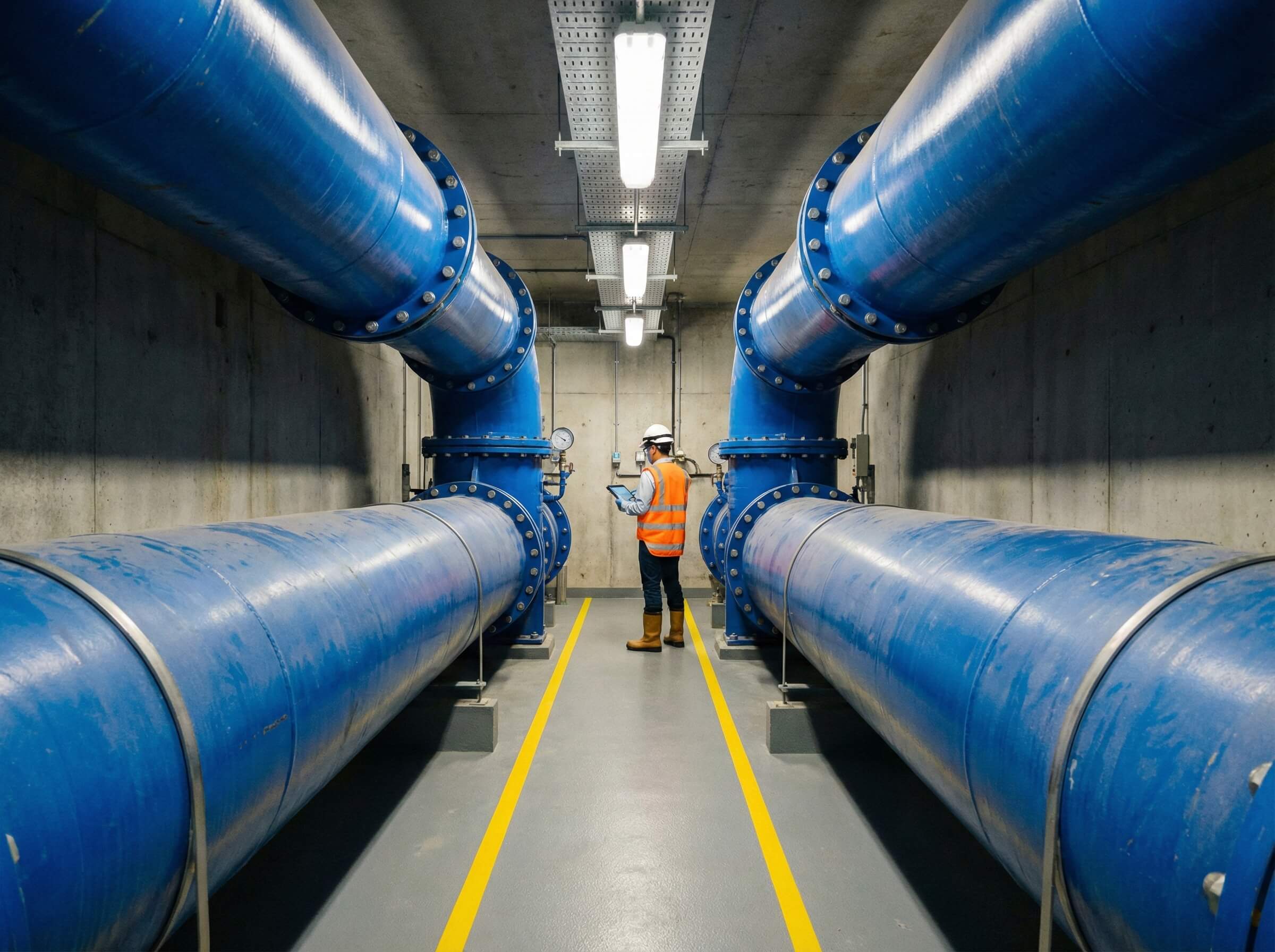

Real-world applications demonstrating how RUITO butterfly valves solve critical system challenges across water treatment, HVAC, and industrial process installations.

Municipal Water Plant Upgrade

Existing gate valves required excessive torque; limited installation space prevented direct replacement.

Supplied 12 DN600 double-eccentric valves with electric actuators. Wafer design matched bolt spacing.

Operating torque reduced by 65%. Installation completed in 3 days without system shutdown.

High-Rise Commercial Building

High-cycle operation (15,000+ cycles/year) causing seat wear; Glycol/water mixture compatibility.

Engineered 24 units with low-friction PTFE seats and pneumatic actuators for precise control.

Zero maintenance in 18 months. Energy consumption reduced by 12% due to improved flow control.

Corrosive Media Handling

Dilute sulfuric acid at 60°C degrading standard materials; required strict safety compliance.

Custom triple-eccentric CF8M stainless steel valves with metal-to-metal sealing.

Passed 100% leak test. Material traceability expedited regulatory approval. Delivered in 35 days.

Discuss how we can solve your specific application challenges

Request Project ConsultationCertifications & Compliance Documentation

Complete certification portfolio ensuring regulatory compliance across global markets. All certificates available for verification.

ISO 9001:2015

Quality Management

CE / PED 2014/68/EU

EU Pressure Safety

UKCA / PER

UK Conformity Assessed

WRAS Approval

Water Regulations

ACS Certificate

Sanitary Conformity

DNV Marine

Maritime Classification

ABS Marine

American Bureau

RINA / Casting

Material & FoundryNeed specific certification documents for your project approval?

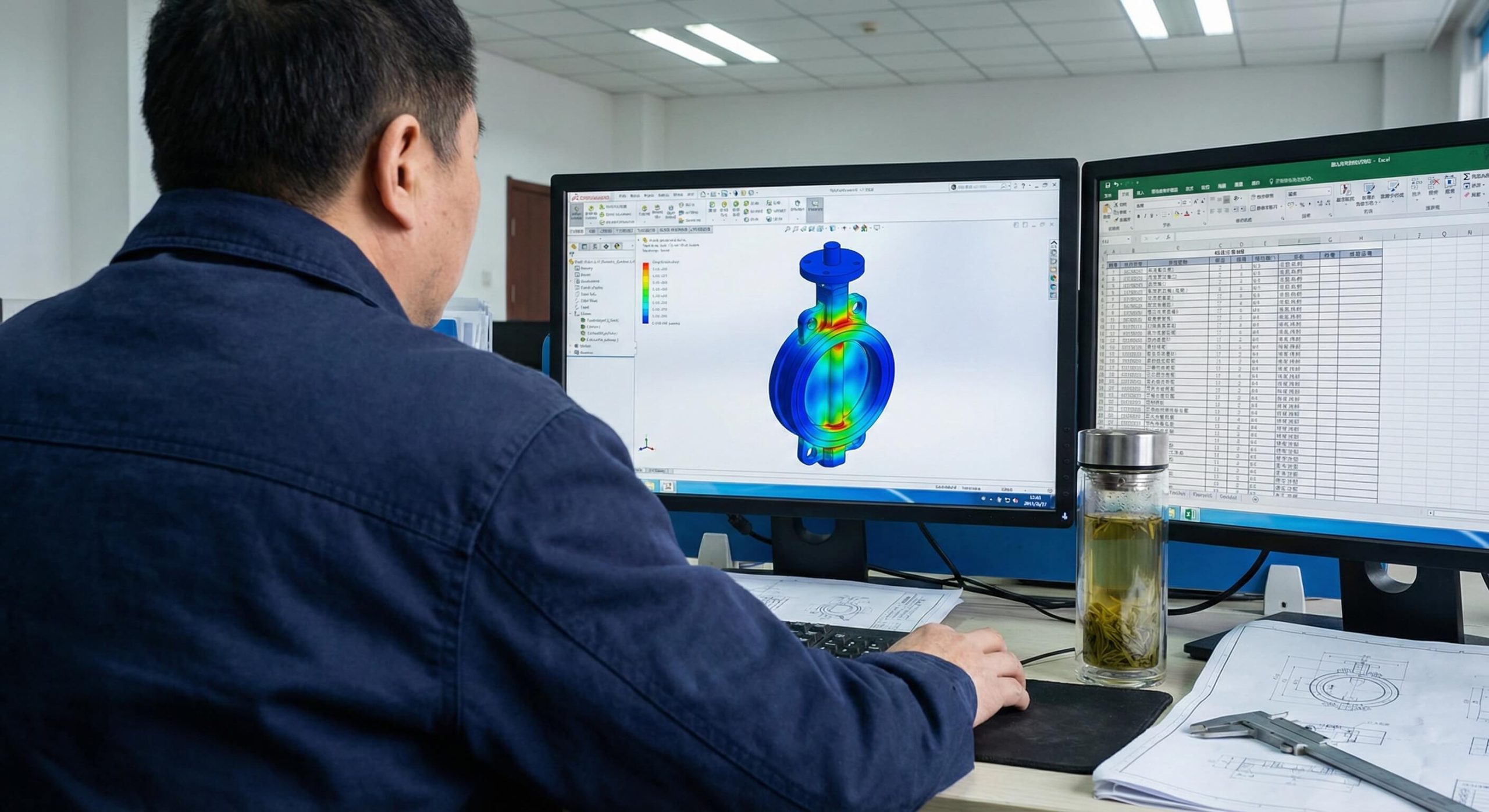

Request Certification PackageOEM / ODM Custom Engineering Process

From concept to mass production, our engineering team transforms your specifications into fully certified butterfly valves with complete design ownership.

Technical Requirements Input

Submit your drawings, specifications, or performance requirements. We accept customer prints, competitor samples, or verbal descriptions with operating parameters.

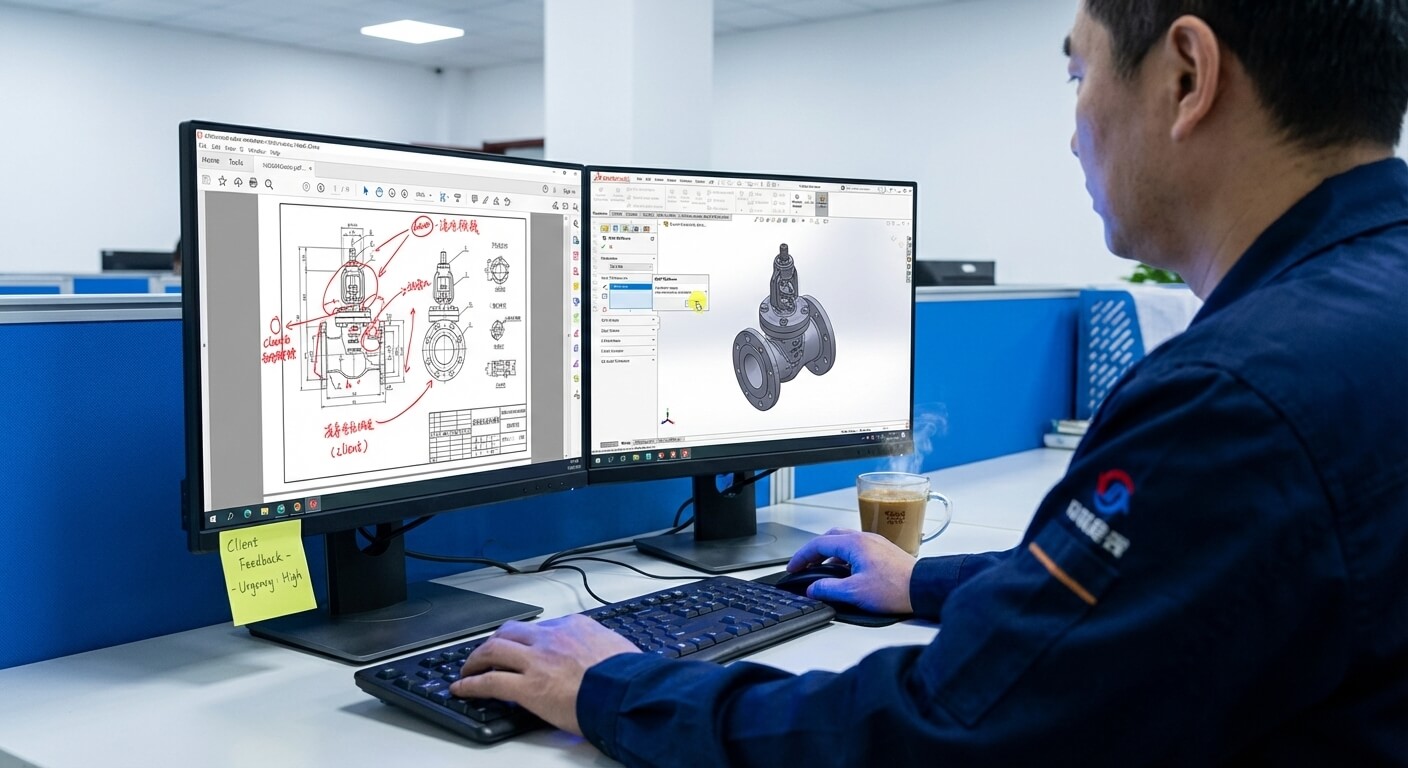

Engineering Analysis & Design

Detailed analysis including stress calculations, flow dynamics, and material selection. 3D models and technical drawings prepared for your review.

Rapid Iteration & Feedback

First design iteration delivered within 48 hours. Subsequent revisions completed within 24 hours. Design freeze occurs only after your written approval.

Prototype & Validation

First article produced using production tooling. Complete dimensional inspection and performance testing conducted. Sample shipped for your verification.

Mass Production & QA

Dedicated production run ensures batch consistency. In-process quality checks at critical stages with photo documentation available.

Ongoing Support & Versioning

All tooling and drawings archived. Design revisions tracked with version control. Repeat orders expedited using established production parameters.

Ready to start your custom valve development project?

Submit Technical InquiryWhy Choose RUITO Over Generic Suppliers

Engineering-driven approach with factory-direct pricing and complete accountability. Compare what sets RUITO apart from typical valve distributors.

Experience the difference of working directly with the manufacturer

Start Your PartnershipTransparent Cooperation Process

Clear expectations at every stage from initial inquiry to final delivery. Know exactly what happens next and what we need from you to keep your project moving forward.

Submit Technical Parameters

Send valve specifications including size, pressure rating, connection type, material requirements, and application details.

Engineering Assessment

Our technical team reviews your requirements, confirms feasibility, identifies potential issues, and requests clarification if needed (within 24 hours).

Confirm Final Requirements

Approve technical specifications, quantity, delivery timeline, and any special testing or documentation requirements.

Detailed Quotation

Complete quotation with unit pricing, lead time, payment terms. Technical data sheets and dimensional drawings provided for verification.

Review Commercial Terms

Evaluate pricing, payment schedule, delivery terms (FOB/CIF), and contract conditions. Request modifications if needed.

Sales Contract

Formal contract issued with all agreed terms. Production slot reserved upon contract signature and deposit receipt.

Optional: Sample Request

For first-time orders or critical applications, request pre-production sample for physical inspection and testing.

Sample Production

First article manufactured using production processes. Complete testing per agreed standards. Sample shipped with inspection documentation.

Issue Purchase Order

Submit official PO with confirmed specifications, quantities, and delivery requirements. Release production authorization.

Manufacturing & QC

Production initiated per delivery schedule. Weekly progress updates with photos. All valves undergo 100% hydro test and inspection.

Shipment & Payment

Confirm shipping details (forwarder, port, delivery address). Release balance payment per agreed terms upon shipment notification.

Final Shipment

Valves packaged per export standards. Complete documentation: invoice, packing list, test certificates, manuals. Tracking provided.

Ready to begin? Start with a simple technical inquiry

Initiate Your OrderEngineering & Technical FAQ

Technical answers to common questions about butterfly valve selection, installation, operation, and maintenance. Reliable expertise you can trust.

Valve Selection

Valve sizing depends on required flow rate (Cv), pressure drop, and pipe diameter. For most water apps, matching pipe size is fine.

- Concentric: Rubber lined, low pressure, lower cost.

- Double-Eccentric: High performance, reduced wear.

- Triple-Eccentric: Metal seat, high temp, zero leakage.

Yes, especially Double/Triple eccentric designs. Best control range is between 20% and 80% open.

Material & Sealing

EPDM is optimal. It resists hot water up to 120°C and carries WRAS/NSF approvals. NBR is not recommended above 80°C.

1. Temperature spikes. 2. Chemical incompatibility. 3. Abrasive media (sand/solids). Always verify actual service conditions.

Mandatory for temps >200°C, fire-safe requirements, or abrasive slurries where soft seats would be destroyed.

Operation

Likely causes: Operating against full line pressure, thermal expansion, or debris buildup. Do not force the valve.

It can occur at 5-15° open positions due to turbulence. Avoid prolonged operation in this range to prevent damage.

Installation

Horizontal shaft is best to reduce sediment buildup. Vertical is okay if supported. Ensure actuator is accessible.

Recommended for critical systems where maintenance cannot wait for a full system shutdown.

Still have technical questions?

Can't find the answer you need? Our engineering team is ready to help. No chatbots, just real experts solving your fluid control challenges.

Ask a Technical Question

Take the Next Step

Choose the action that best fits where you are in your decision process. No high-pressure sales tactics — just clear information and professional support.

Get Technical Data

Download complete datasheets, dimensional drawings, and material specifications.

Engineers in early design phase needing specs for comparison.

Instant PDF download. No registration required.

Talk to Engineering

Discuss your specific application parameters with our senior valve engineers.

Technical decision-makers with custom or non-standard requirements.

Engineer contacts you within 24 hours. Technical consultation only.

Request Quotation

Receive formal pricing with lead times, payment terms, and shipping options.

Procurement teams with finalized specs ready to evaluate commercial terms.

Detailed quotation sent within 24 hours via email.