Industrial Check Valves Engineered for Critical Flow Control

DN15-DN600 | PN10-PN420 | -196°C to +550°C | Multi-Standard Compliance

Four Critical System Failures Caused by Improper Backflow Control

Engineering consequences when check valves are underspecified or incorrectly selected

Backflow Contamination

Reverse flow carries contaminated media back into clean zones, compromising product quality and creating cross-contamination risks in process systems.

Water Hammer Damage

Sudden flow reversal generates shock waves exceeding 10 bar, causing pipe rupture, equipment failure, and catastrophic system damage.

Pump Overload

Backflow forces pumps to work against reverse pressure, leading to motor burnout, bearing failure, and unplanned maintenance shutdowns.

Energy Waste

Unchecked reverse flow wastes pumping energy as fluid flows backward, increasing operational costs and reducing overall system efficiency by 15-30%.

Prevent these failures with properly engineered check valve solutions

What is a Check Valve? Engineering Principle Explained

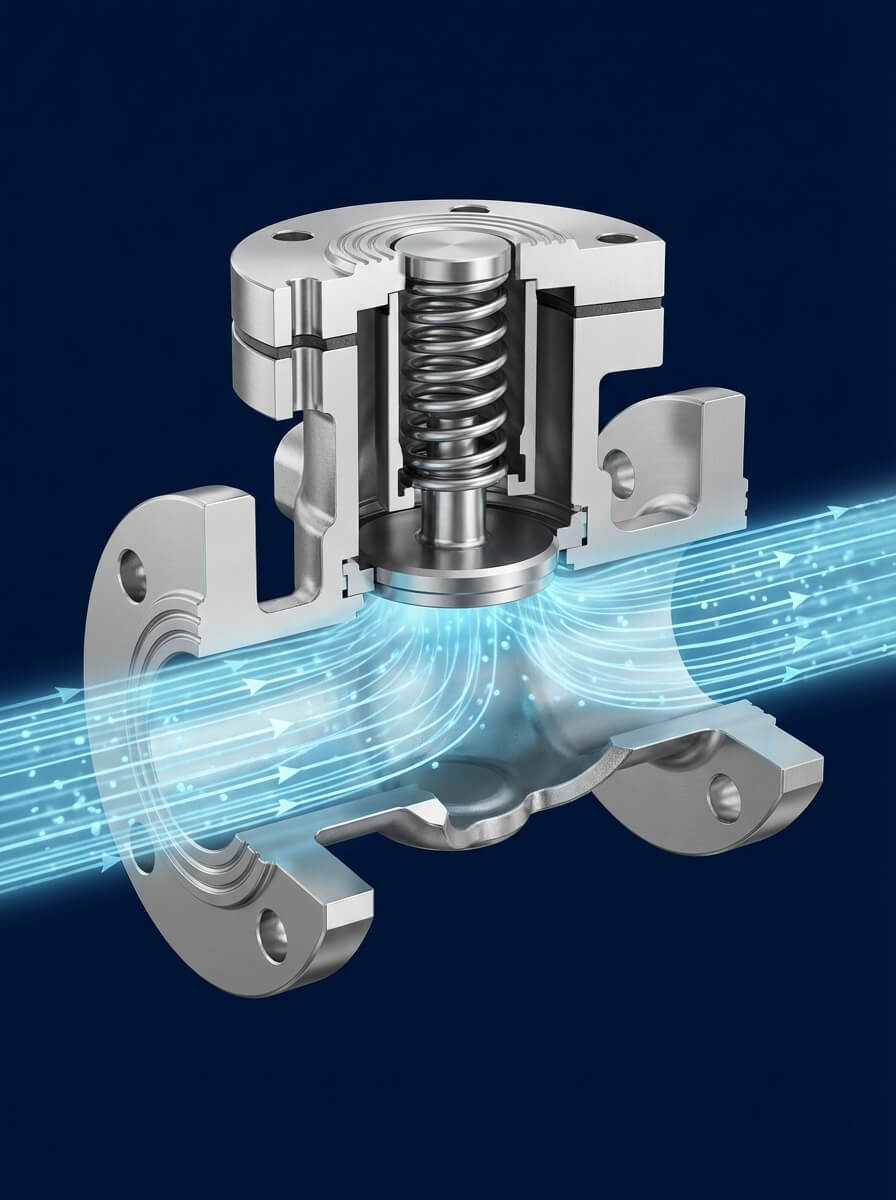

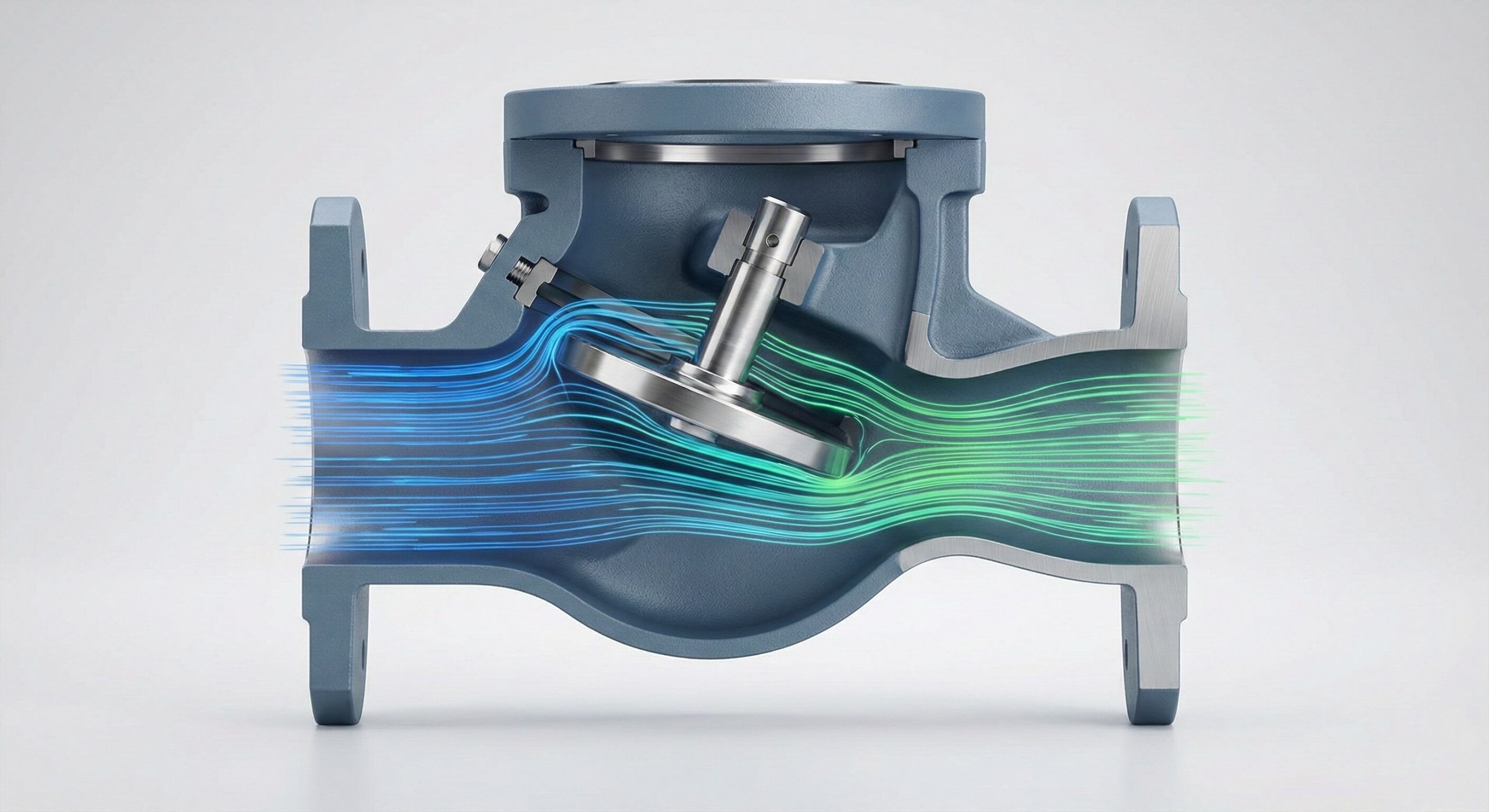

Forward Flow Operation

When system pressure exceeds cracking pressure, the disc lifts automatically, allowing forward flow with minimal pressure drop. The valve body guides media through optimized flow path, maintaining system efficiency.

Instant Closure Mechanism

The moment forward flow stops or reverses, differential pressure immediately forces the disc against the seat. Spring assistance and gravity ensure rapid closure within milliseconds.

Backflow Prevention Function

The sealed disc-seat interface creates a pressure barrier that blocks reverse flow completely. Metal-to-metal or soft-seal contact maintains zero leakage under backpressure.

Need technical specifications for your application?

5 Check Valve Structures: Engineering Comparison Matrix

Compare installation requirements, pressure characteristics, and optimal applications

| Comparison Criteria |

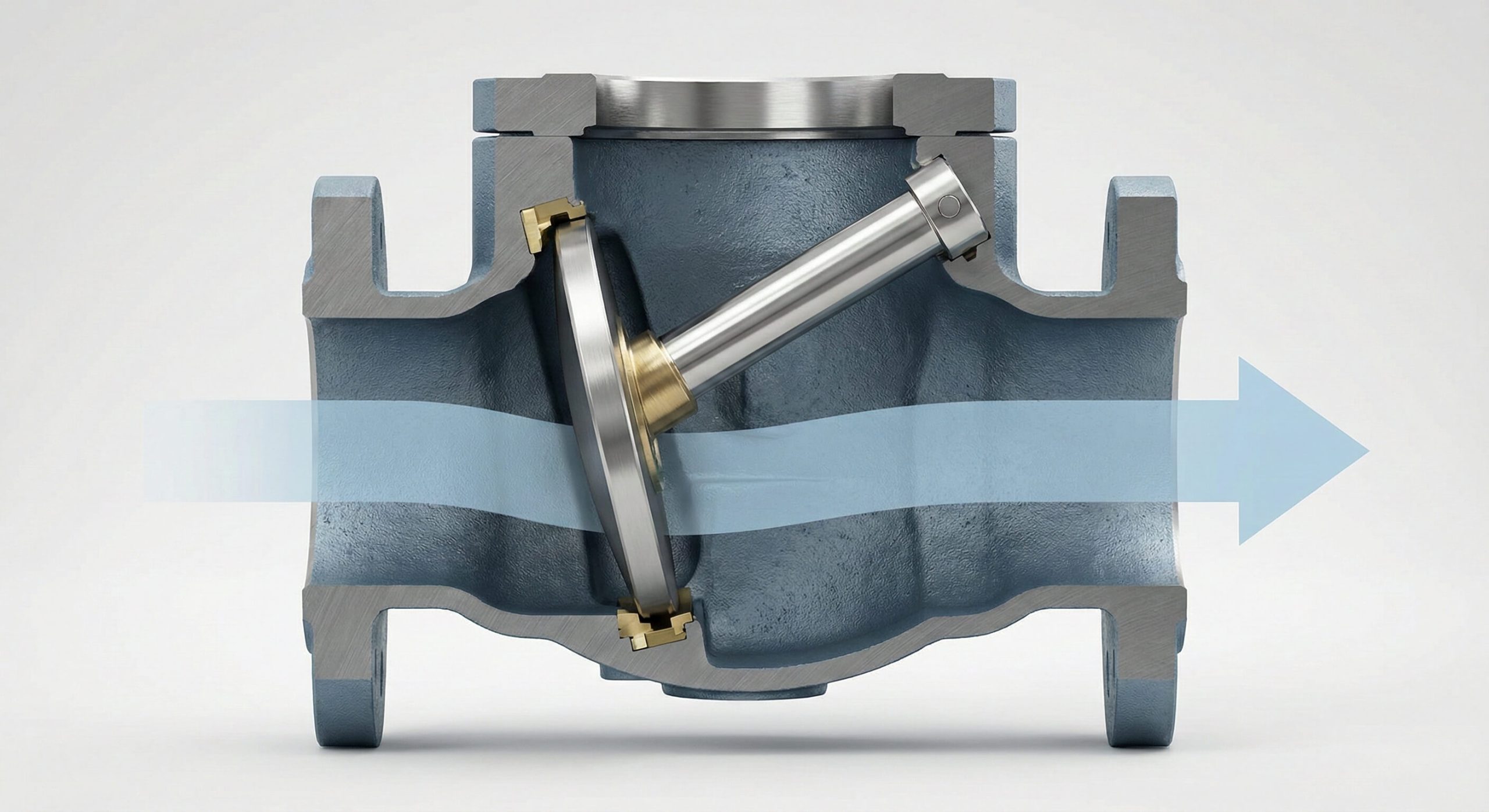

Swing Type

Swing Type

|

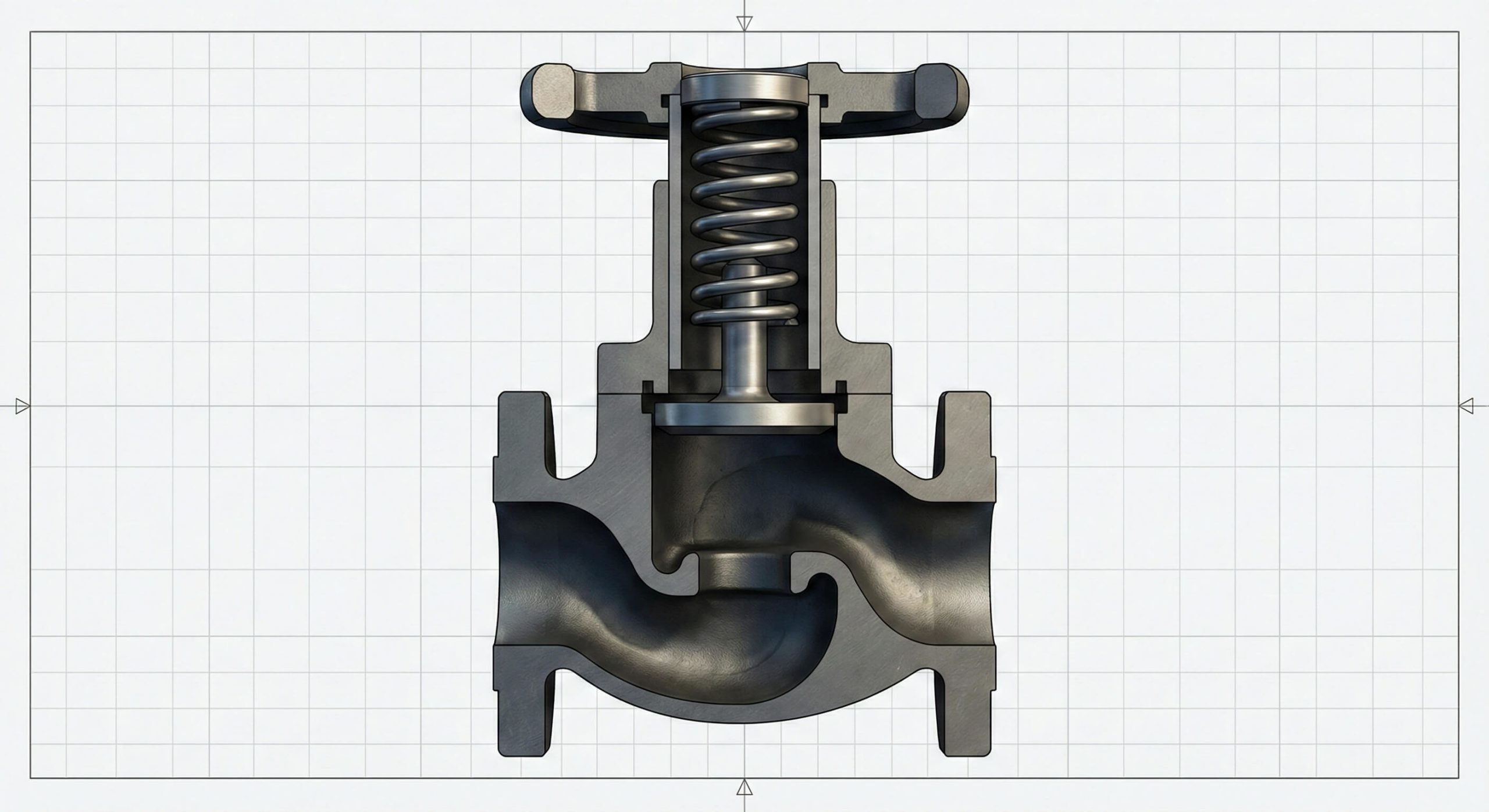

Lift Type

Lift Type

|

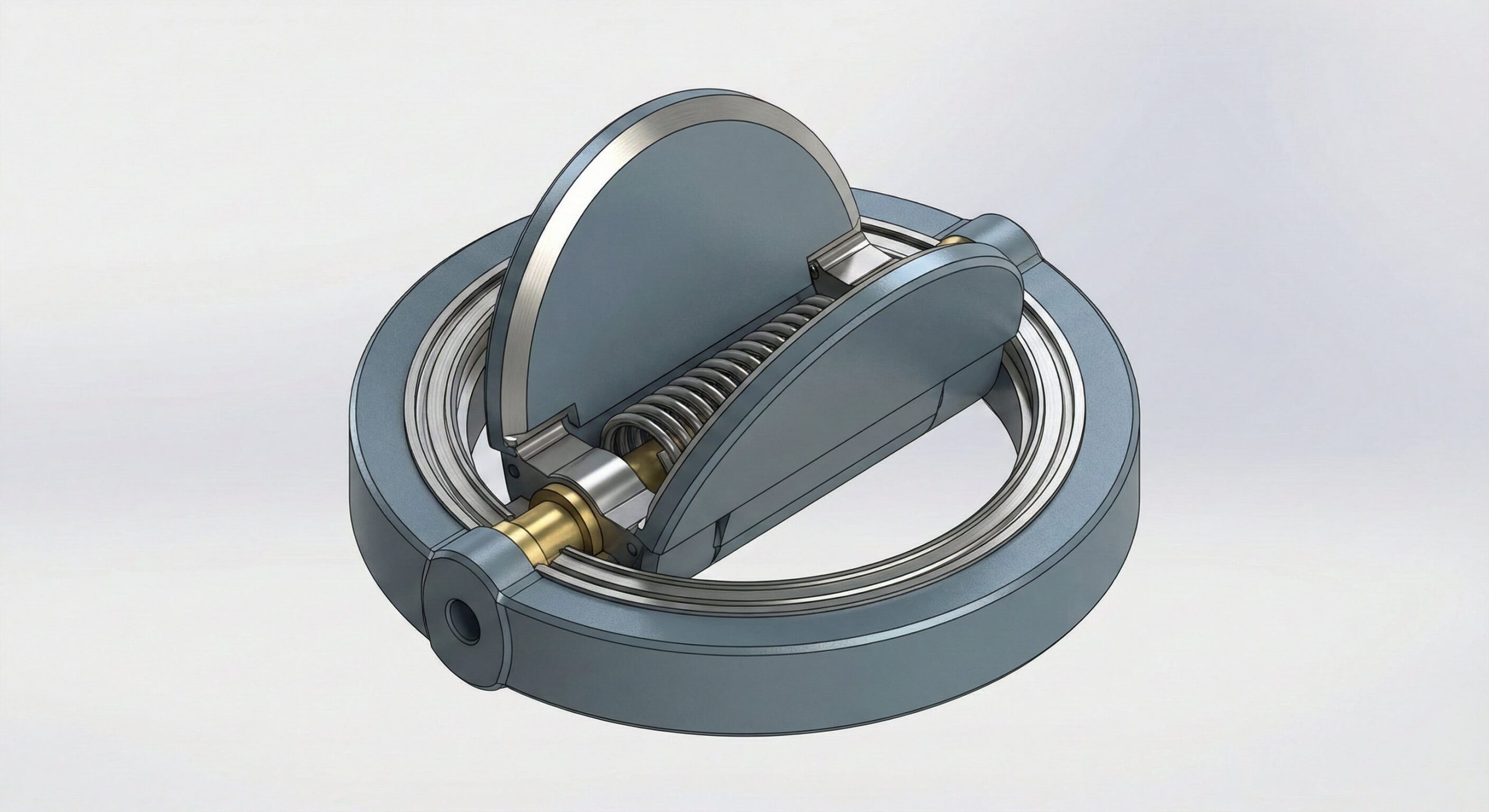

Dual Plate

Dual Plate

|

Ball Type

Ball Type

|

Tilting Disc

Tilting Disc

|

|---|---|---|---|---|---|

| Installation Orientation | |||||

| Pressure Drop | |||||

| Response Speed | |||||

| Maintenance Cost | |||||

| Recommended Application | Large diameter pipelines, low-velocity systems | High-pressure steam, gas systems, vertical pump discharge | Space-limited installations, wafer connection, HVAC | Slurry, viscous media, sewage, mining applications | Large flow, low head loss, power generation |

Unsure which structure fits your system parameters?

6 Critical Failures from Incorrect Check Valve Selection

Engineering decision cascade: how one wrong parameter leads to system-wide consequences

Wrong Pressure Rating

Selecting PN16 for PN25 system causes seat failure, external leakage, and potential safety incidents under peak pressure conditions.

Incorrect Material Selection

Using carbon steel in corrosive media accelerates erosion, reducing valve lifespan from 10 years to 6 months and contaminating the process.

Oversized Valve Body

DN100 valve in DN50 low-flow system fails to generate cracking pressure, allowing constant backflow and defeating the valve's purpose entirely.

Wrong Structure Type

Installing swing check valve in vertical pipeline prevents proper disc closure, causing continuous leakage and pump cycling damage.

Temperature Mismatch

Standard EPDM seals in 200°C steam service degrade within hours, causing catastrophic leakage and emergency system shutdown.

Non-Compliant Standards

Using non-certified valves in regulated projects results in inspection failure, project delays, and complete valve replacement at 3x cost.

Eliminate selection risk with our engineering support

Engineering Selection Checklist: 7 Critical Parameters

Systematic approach to valve specification that prevents costly selection errors

Required Information

Fluid composition, viscosity, corrosiveness, particle content, temperature effects on media properties

Required Information

Operating pressure, maximum transient pressure, surge pressure peaks, backpressure conditions

Required Information

Minimum/maximum operating temperature, startup temperature, thermal cycling frequency

Required Information

Pipe orientation (horizontal/vertical/angled), flow direction, available installation space, maintenance access

Required Information

Normal flow rate, maximum flow rate, minimum flow rate, flow velocity, acceptable pressure drop

Required Information

Required design standard (API/ASME/DIN/EN), testing requirements, certification needs, project specifications

Required Information

Industry sector, specific application, criticality level, maintenance access, replacement difficulty

Let our engineers verify your specifications before ordering

Material System Architecture: Body, Seat & Internal Components

Engineered material combinations for optimal performance across operating conditions

Body Material Selection

Seat & Sealing Components

Spring & Internal Parts

Need material compatibility verification for your media?

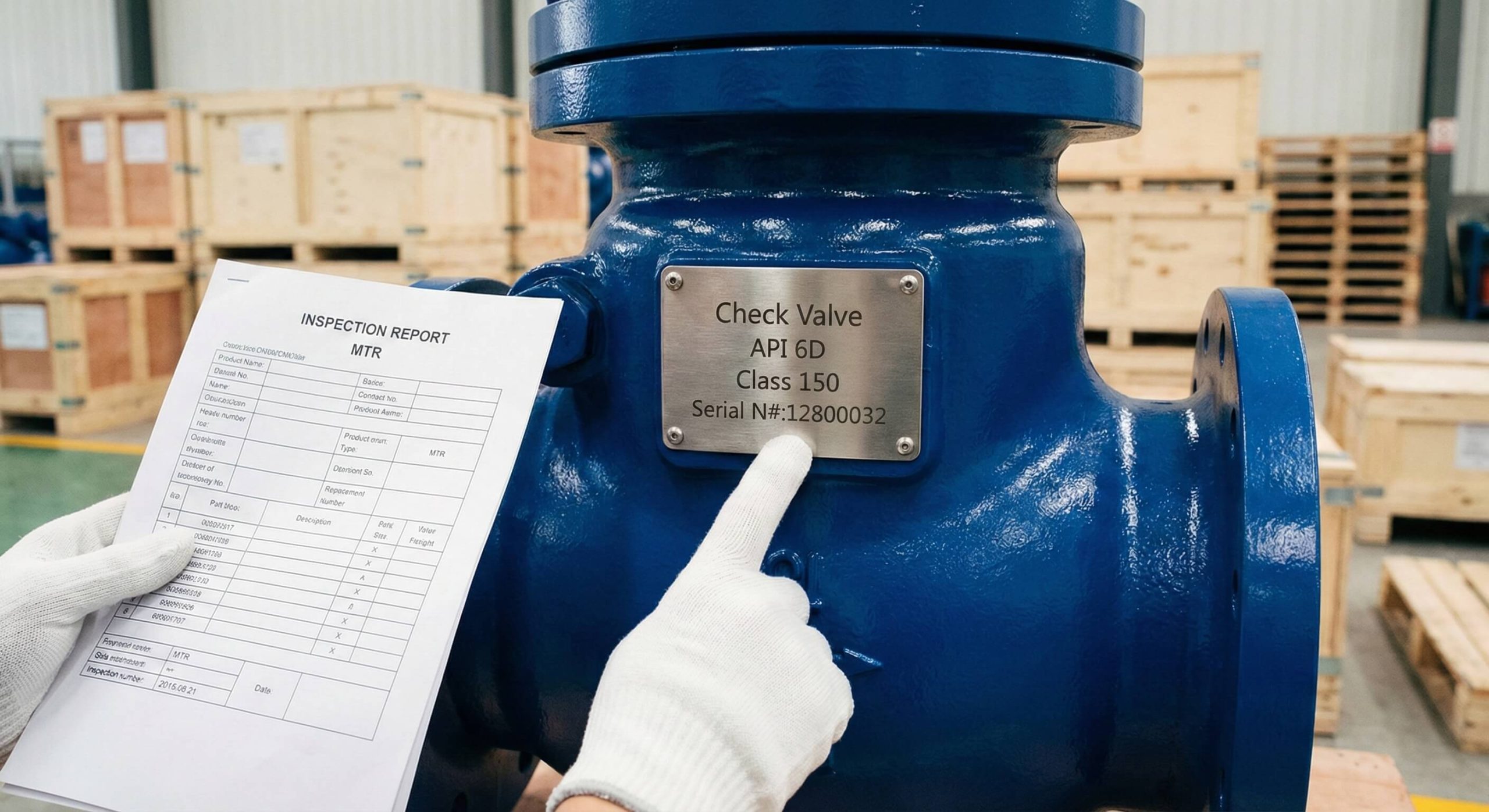

Project Compliance Checklist: Standards & Documentation

Comprehensive certification coverage for global engineering projects and regulatory requirements

API 6D, ASME B16.34, EN 12516-1, DIN 3202, BS 1868, ISO 14313, MSS SP-61, AWWA C508

ASTM A216, ASTM A351, ASTM A995, EN 10213, EN 10283, GB/T 12229, Material test reports with full traceability

ASME B16.5 (Class 150-2500), ASME B16.47 (Series A/B), EN 1092-1 (PN10-PN420), DIN 2501, JIS B2220

API 598 (shell & seat testing), EN 12266-1, ISO 5208, MSS SP-61, Hydrostatic test at 1.5x rated pressure

ISO 9001:2015, CE/PED 2014/68/EU (Module H), ABS, DNV, Lloyd's Register, ATEX (on request)

Need specific certification documentation for your project?

Application-Specific Check Valve Solutions

Engineered valve configurations optimized for industry-specific requirements and operating conditions

Water Treatment

Oil & Gas

Power Generation

Chemical Processing

Marine & Offshore

HVAC Systems

Can't find your specific application? We engineer custom solutions

Master Specification Table: Complete Technical Range

Comprehensive parameter overview for rapid technical qualification and specification verification

Download complete technical specifications with dimensional drawings

Engineering Customization Workflow: From Concept to Delivery

Structured project management process ensures specifications are met precisely at every stage

Parameter Confirmation

Complete technical datasheet with operating conditions, material requirements, and compliance standards verified by engineers

Drawing Design

CAD drawings with full dimensions, material specifications, and assembly details provided for client approval before manufacturing

Engineering Review

Multi-department review confirms manufacturability, performance calculations, and compliance with project specifications and standards

Sample Production

First article manufactured under controlled conditions with dimensional inspection and material traceability documentation

Testing Validation

Pressure testing, seat leakage verification, and performance validation per API 598 with certified test reports issued

Batch Manufacturing

Full production run with continuous quality monitoring, final inspection, and complete documentation package for shipment

Ready to start a custom valve project with full engineering support?

Manufacturing Process Flow: Quality Control at Every Stage

Systematic quality checkpoints from raw material to final shipment ensure consistent performance and reliability

Casting & Material Inspection

CNC Machining

Assembly Process

Surface Treatment

Pressure Testing

Packaging & Documentation

Want to verify our manufacturing capabilities and quality systems?

International Project References: Proven Performance

Real engineering projects demonstrating successful valve deployment across critical industrial applications

Operating continuously for 3+ years with zero failures. Low head loss design maintains system efficiency while preventing backflow.

Dual plate design passed extreme corrosion testing. Compact wafer installation saved critical space on platform with DNV approval.

Lift type valves with PTFE seats achieved Class VI leakage tightness. Material compatibility verified, no corrosion after 2 years.

Handles high flow with minimal pressure drop. Fast closure prevents water hammer. CE/PED certified with full traceability.

Need detailed case studies or reference contacts for your industry?

Supplier Assessment Scorecard: Engineering Decision Criteria

Evaluation framework aligned with procurement requirements for industrial valve suppliers

Standard lead time 4-6 weeks for stock sizes, 6-8 weeks for custom orders. Production schedule tracking system provides real-time updates. On-time delivery rate exceeds 96% measured over past 24 months.

ISO 9001:2015 certified quality management system with documented procedures for every process stage. First article inspection and ongoing process control ensure batch-to-batch consistency. Defect rate maintained below 0.3%.

Dedicated engineering team responds to technical inquiries within 24 hours. Pre-sales valve selection assistance, CAD drawing support, and material compatibility analysis provided at no charge. Post-delivery technical support continues throughout product lifecycle.

Complete documentation package includes material test reports with heat number traceability, hydrostatic test certificates, dimensional inspection reports, and compliance certificates (CE, PED, ABS, DNV as applicable).

Manufacturing facility open for customer audits and third-party inspections. Video documentation of production process available for remote verification. Quality hold points can be witnessed by customer representatives.

Evaluate our capabilities against your supplier assessment criteria

Engineering Client Feedback: What Project Managers Say

Direct feedback from procurement and engineering professionals on supplier performance

The technical support team provided detailed valve selection calculations that matched our system requirements perfectly. Documentation was complete and delivery met our tight project schedule.

Material certificates showed full traceability back to mill test reports. The duplex stainless valves have performed flawlessly in our corrosive offshore environment for over two years now.

Factory inspection confirmed their quality control procedures match ISO 9001 standards. The batch we received passed all our incoming inspection criteria without any rejections.

They customized the valve dimensions to fit our space-limited installation. Engineering drawings were accurate and the final product matched specifications exactly.

Fast response to our urgent order requirement. They expedited production and coordinated with our freight forwarder to meet our installation deadline.

The pressure test reports showed results well within API 598 requirements. Seat leakage testing confirmed Class VI tightness as specified in our purchase order.

Join engineering teams who trust RUITO for critical valve applications

Procurement Process FAQ: Questions by Project Stage

Common technical and procurement questions organized by purchasing workflow timeline

Pre-Order Stage: Selection & Specification

Production Stage: Manufacturing & Quality

Post-Delivery: Warranty & Technical Support

Have specific questions not covered here? Our engineering team is ready to help

Ready to Specify the Right Check Valve for Your Project?

Submit your project parameters and our engineering team will provide technical recommendations within 24 hours

Project Information Request

Complete the simplified form below to receive support