Industrial Foot Valve with Integrated Strainer

Designed for municipal water systems, irrigation networks, and industrial pump installations.

Get Technical Datasheet

Why Your Pump System Requires a Foot Valve

Every pump installation depends on reliable priming and backflow prevention to maintain system integrity and operational efficiency

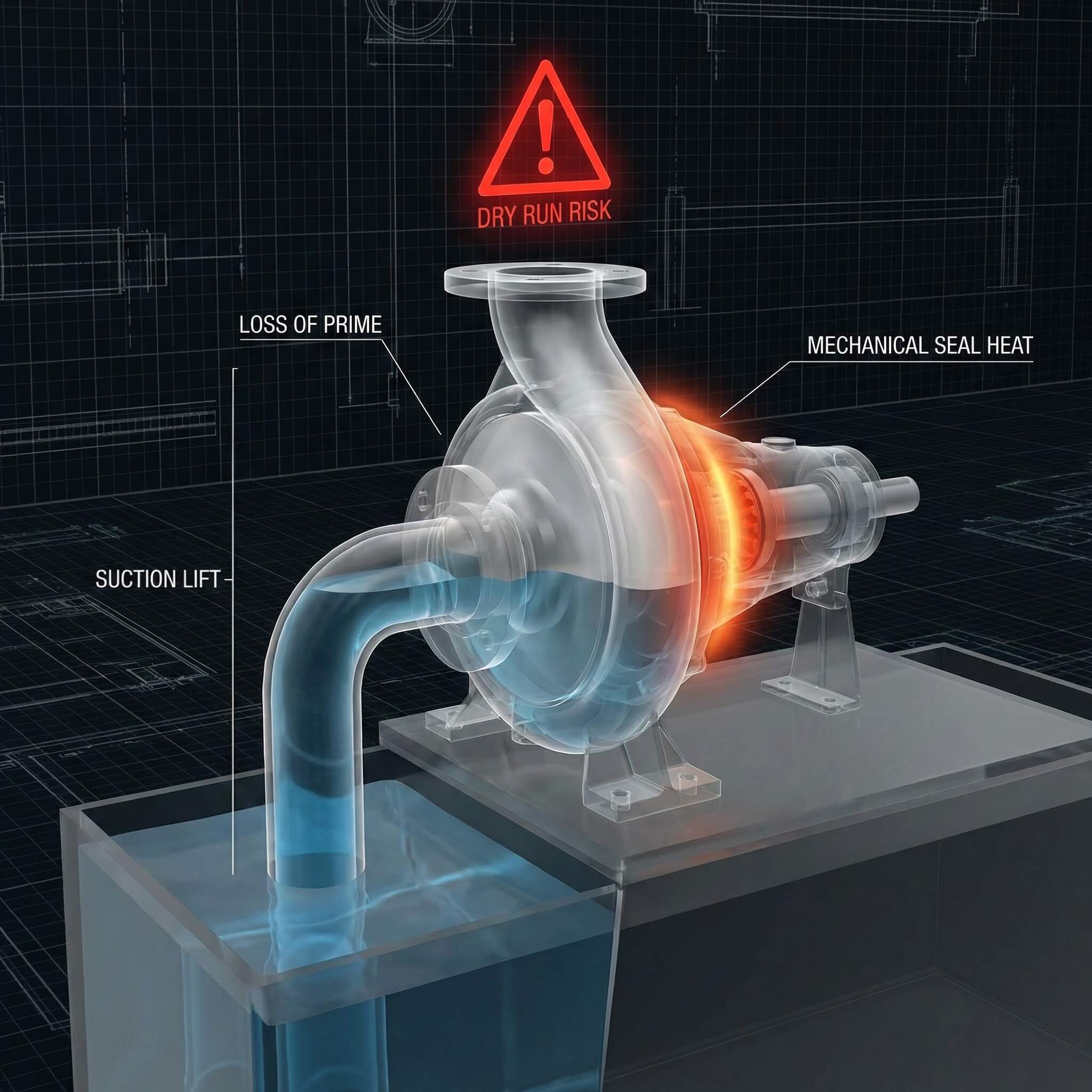

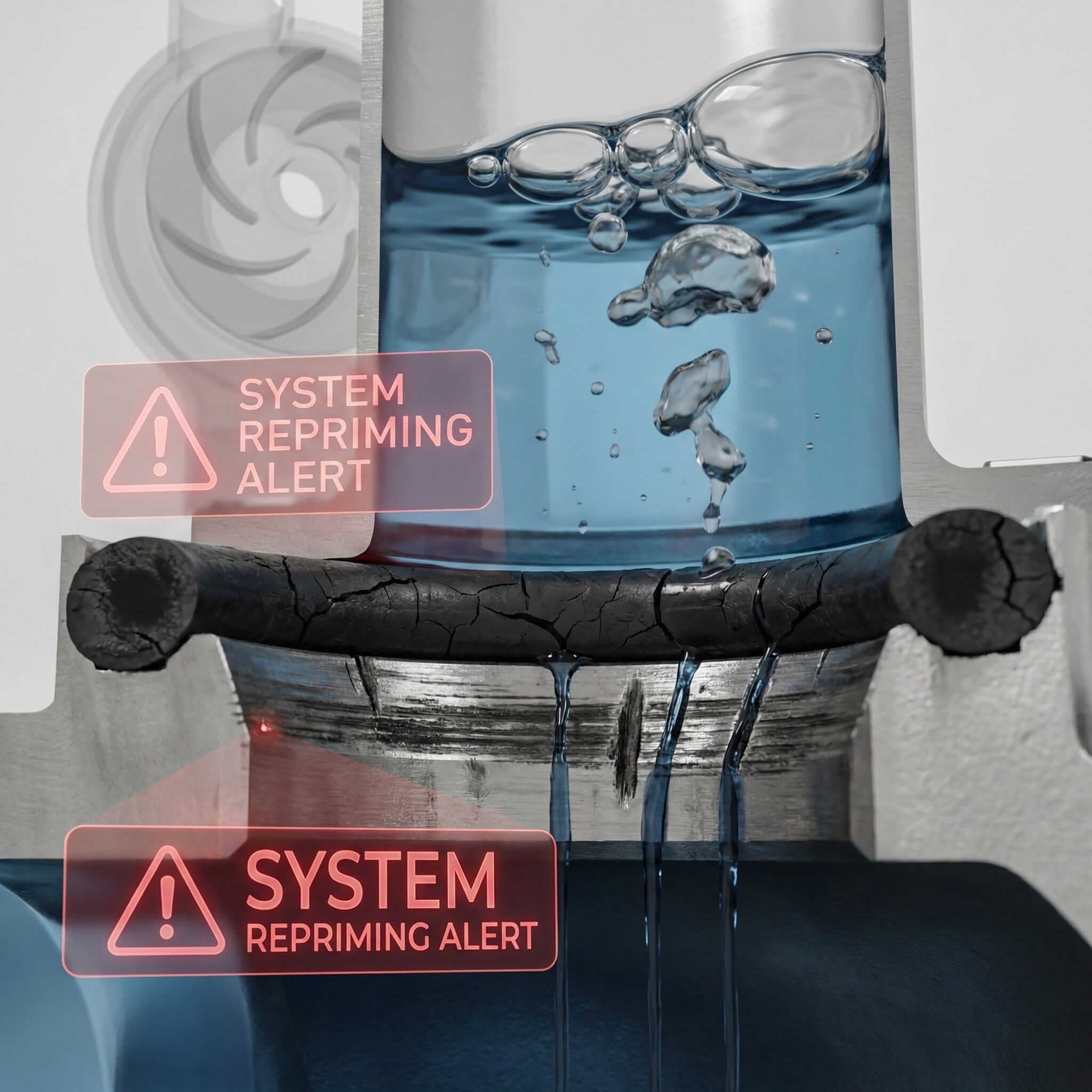

Without Foot Valve

Water drains back through suction line during shutdown. Each startup requires manual repriming, causing extended downtime, increased power consumption, and accelerated seal wear from dry running.

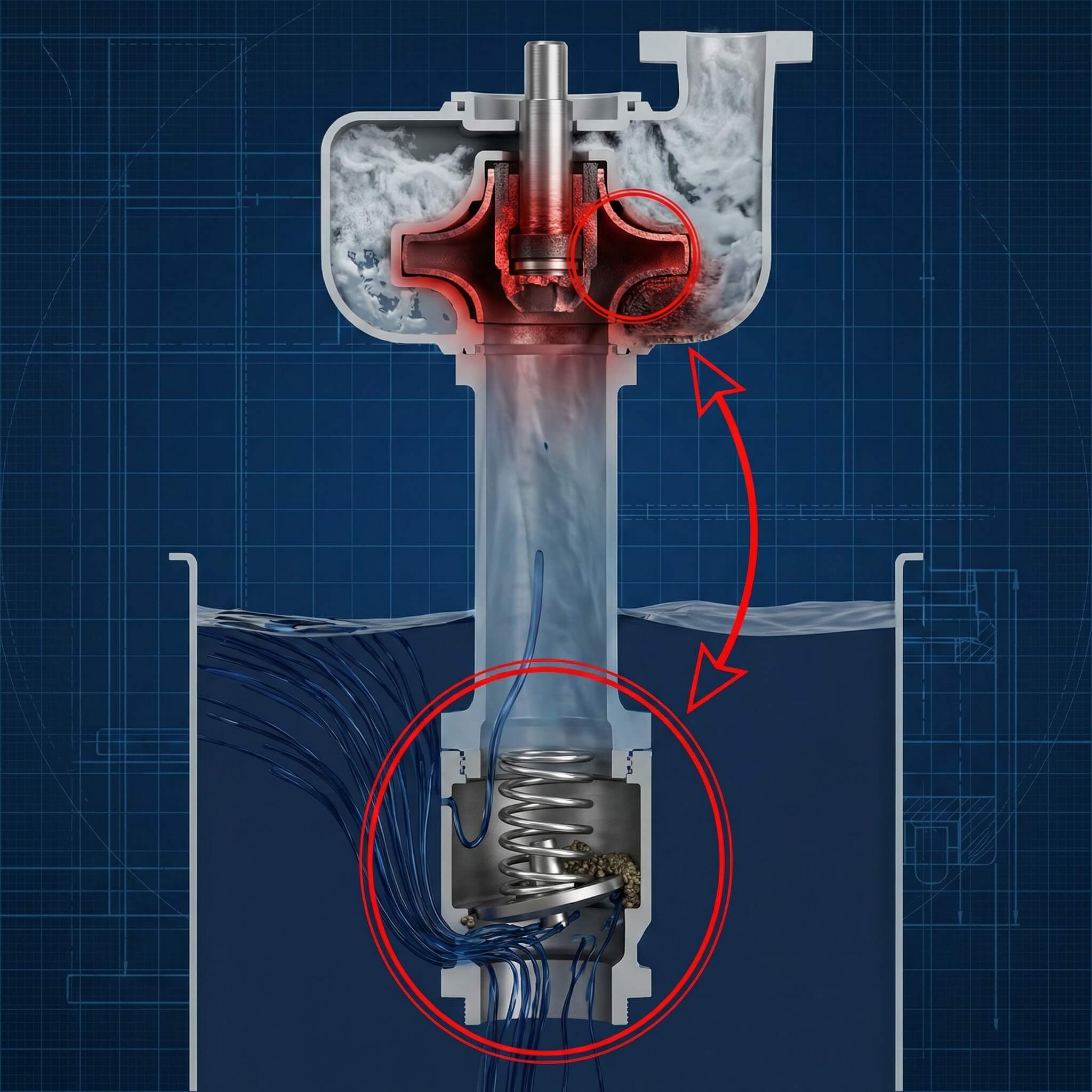

Failed Foot Valve

Disc seizure or spring fatigue allows continuous backflow. System loses prime between cycles, pump operates dry during restart attempts, leading to impeller damage and catastrophic seal failure.

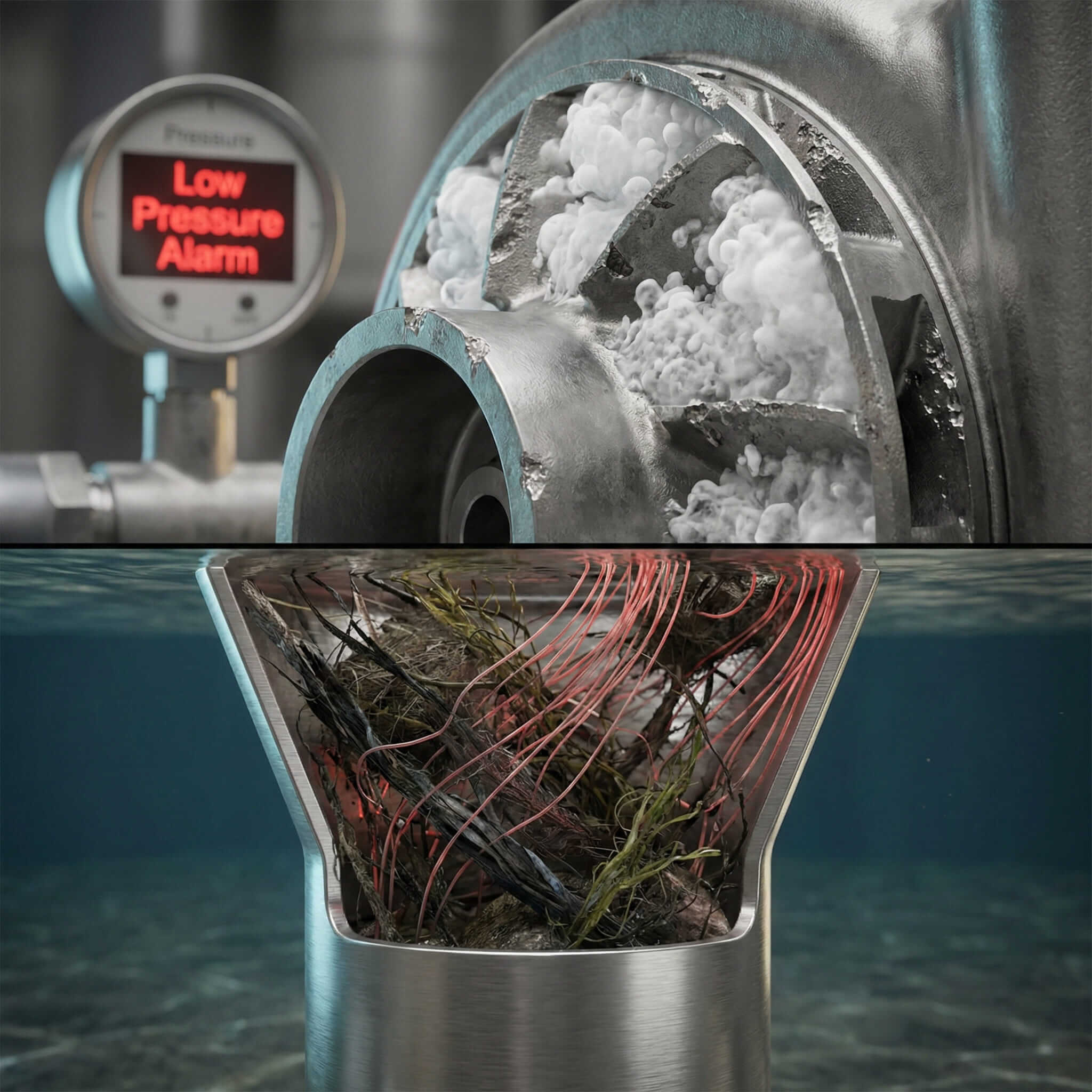

Blocked Strainer

Insufficient strainer area or poor debris clearance creates flow restriction. Reduced suction pressure causes cavitation damage, lower flow rates, and frequent pump trips on low pressure alarms.

Seal Leakage

Worn or misaligned sealing surfaces permit gradual water loss during standby periods. System requires frequent repriming, increases cycle count, and allows air infiltration that damages pump internals.

Protect your pump investment with engineered backflow prevention

Discuss Your ApplicationCommon Foot Valve Failures That Compromise Reliability

Understanding failure modes helps you specify the right valve for critical applications

Disc Misalignment

Inadequate guide rails or worn pivot points allow disc to tilt during closure, preventing a perfect seal.

System loses prime within 15-30 mins; requires daily manual intervention.

Spring Fatigue

Undersized or low-grade spring material fails under repeated compression cycles, losing closing force.

Intermittent backflow drains system overnight; unpredictable startup failures.

Corrosion Seizure

Incompatible materials or absence of protective coating causes moving parts to freeze in corrosive media.

Complete loss of check function; instant reverse flow destroys system prime.

Seat Erosion

Soft sealing material degraded by suspended particles or chemical attack over time.

Progressive leakage leads to total failure within 3-6 months.

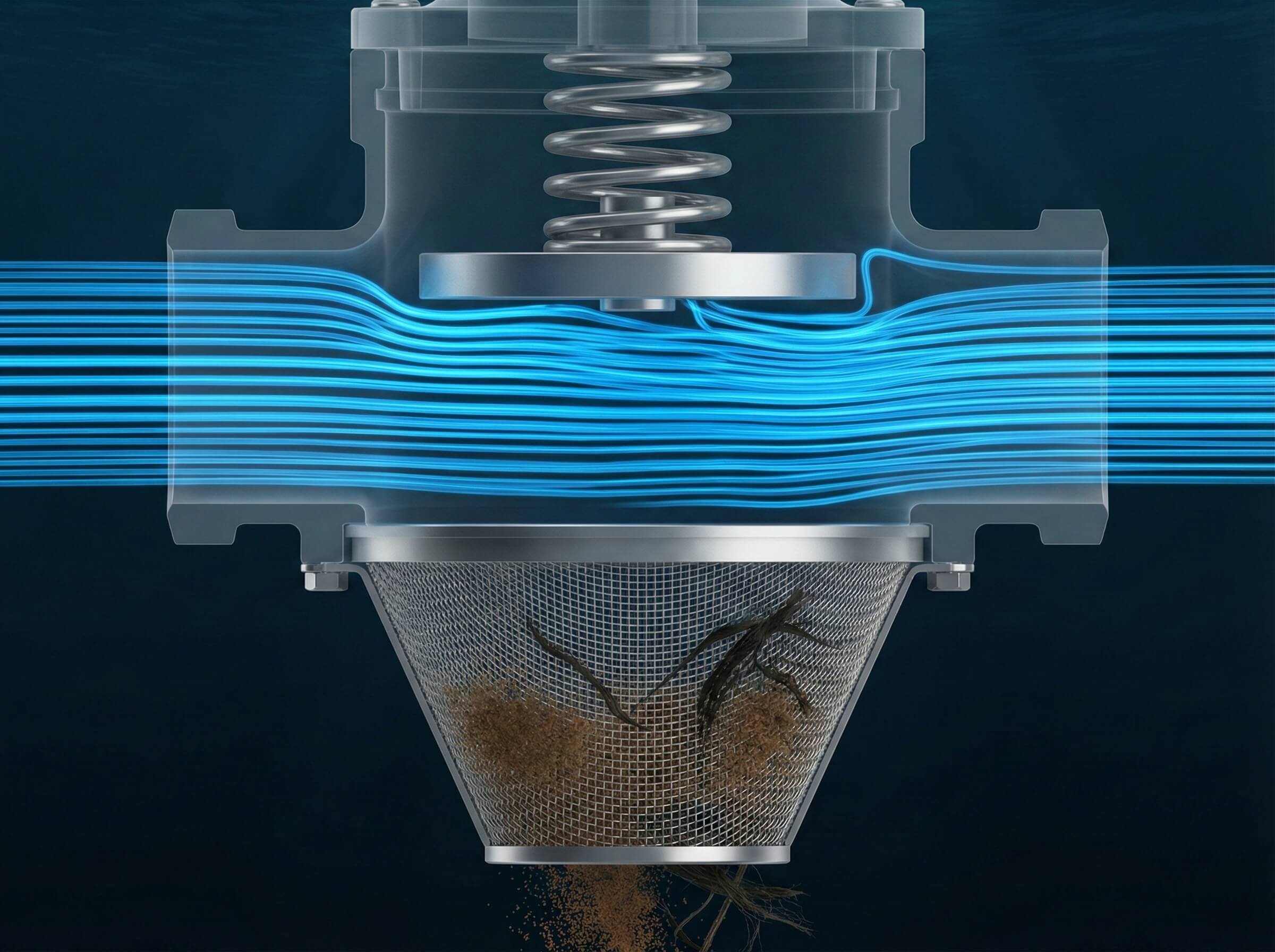

Strainer Blockage

Insufficient open area or mesh spacing inappropriate for debris load creates flow restriction.

Suction-side cavitation drops efficiency by 50% and damages bearings.

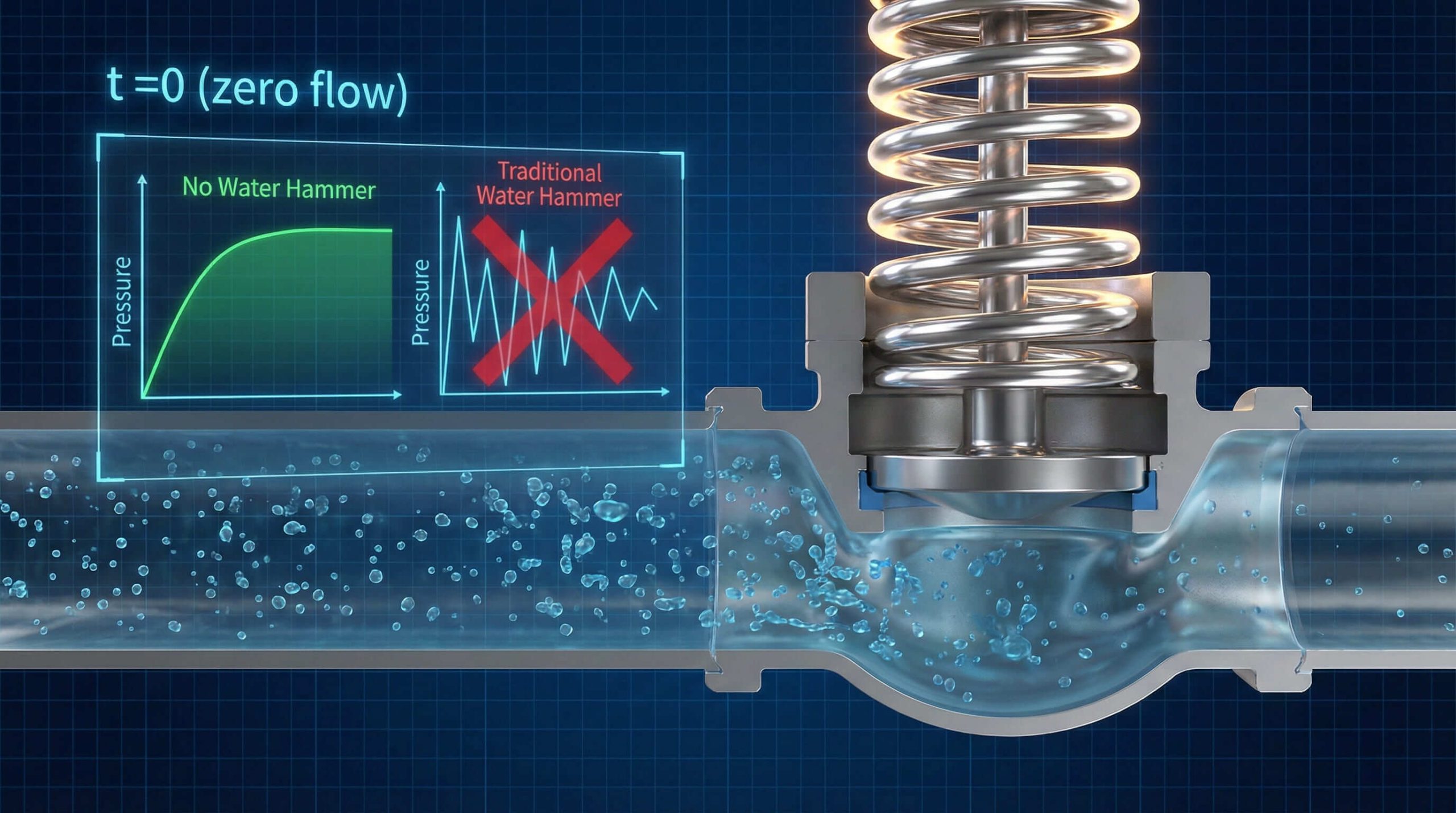

Water Hammer

Slow closure allows reverse flow momentum to build up before slamming shut, creating destructive pressure surges.

Ruptured pipelines, fractured pump casings, and catastrophic noise/vibration.

Eliminate these failure modes with proven engineering solutions

See How RUITO Solves ThisEngineering Solutions to Critical Failure Points

Each design challenge addressed with verified materials, precision manufacturing, and systematic quality control

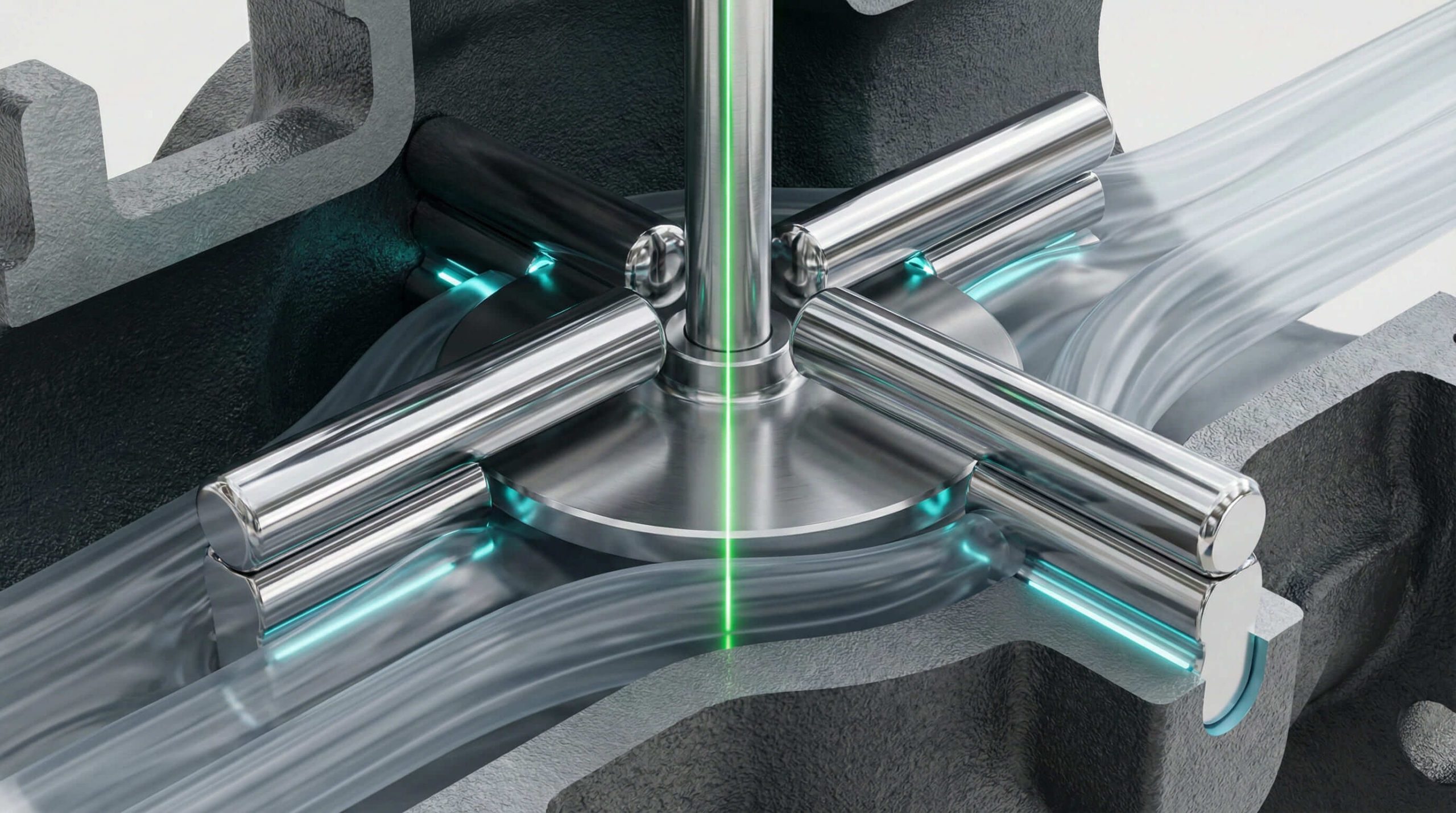

Precision Guide System

Four-point guide rail maintains disc alignment. Hardened stainless pins resist wear over 100,000 cycles, eliminating tilting under all flow conditions.

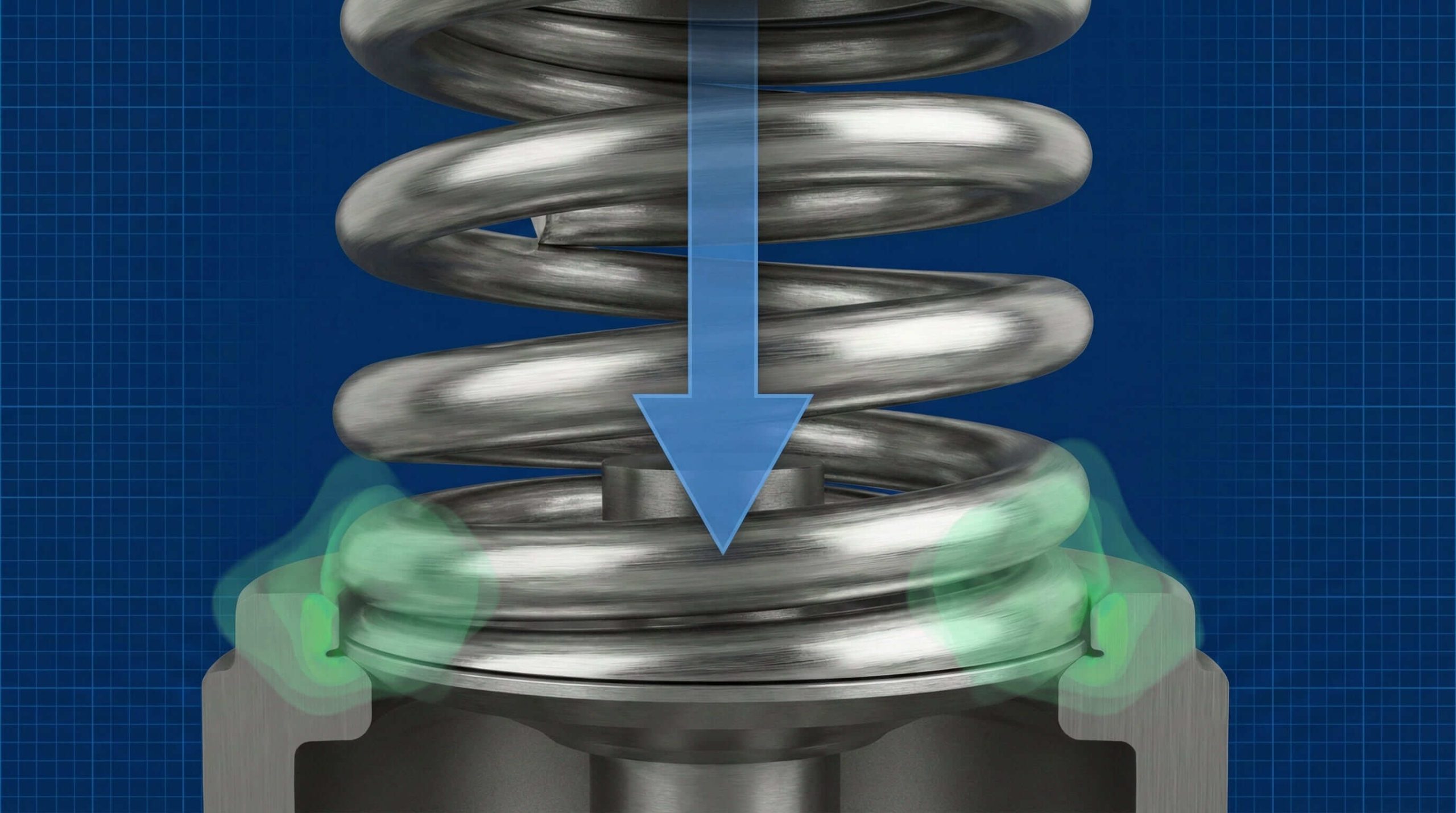

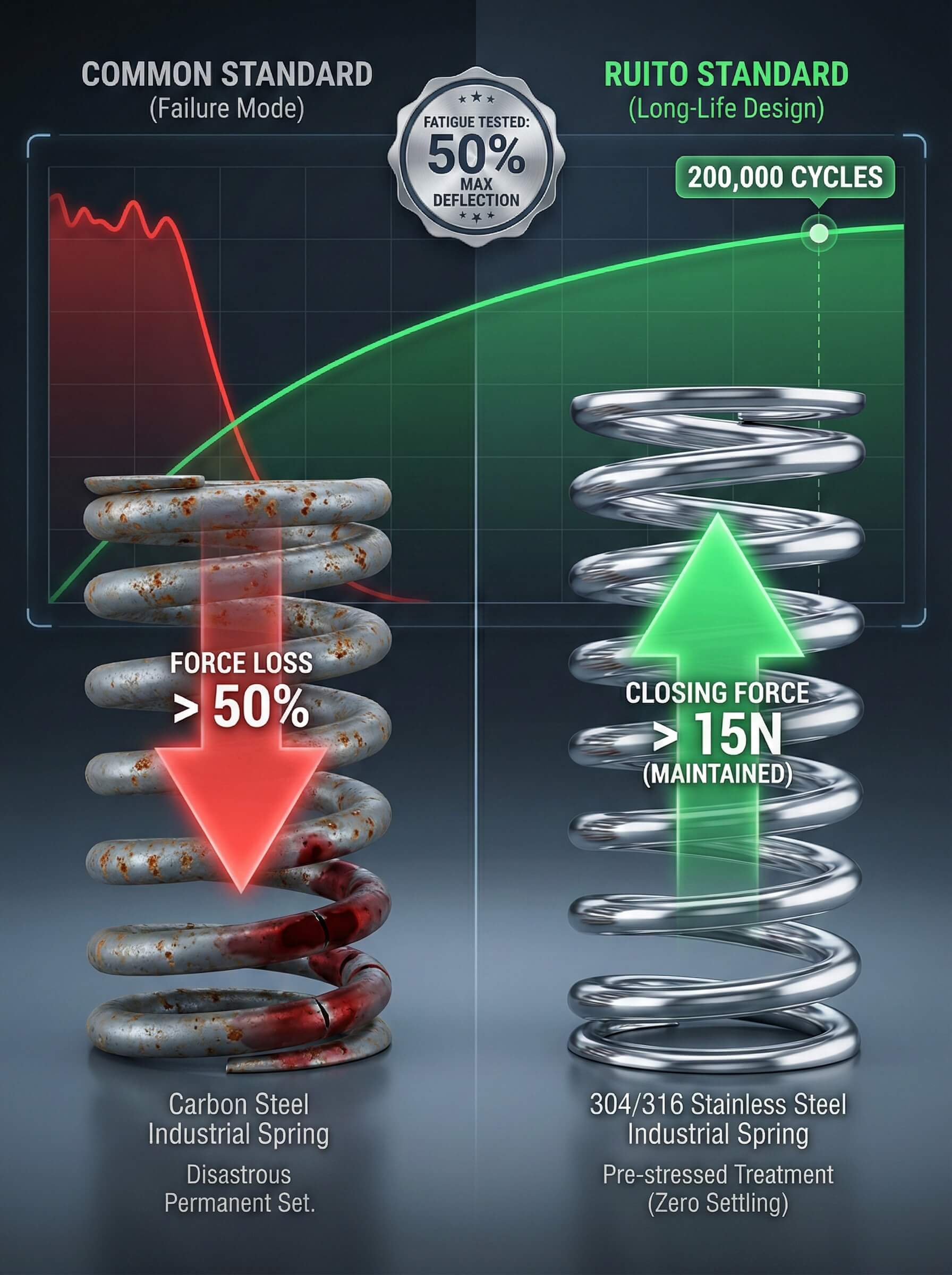

High-Cycle Spring Design

Grade 304/316 stainless spring sized for 50% max deflection. Maintains closing force >15N. Pre-stressed to eliminate settling.

Material Compatibility Matrix

Bronze body, 316 SS internals. Fusion-bonded epoxy coating available. Materials matched to media to prevent galvanic coupling.

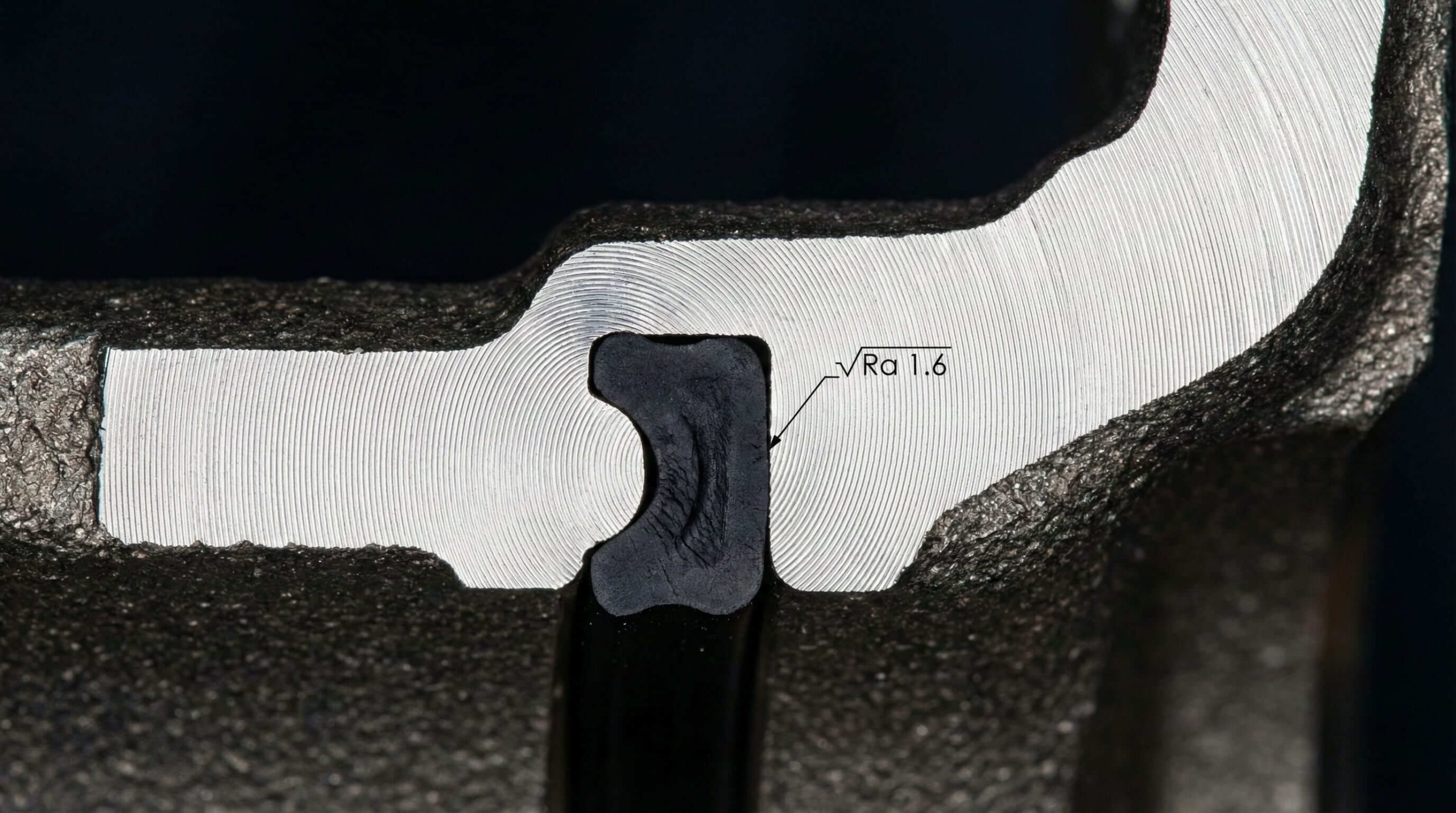

Engineered Sealing Materials

NBR/EPDM seats (Shore A 70) for water systems. Seat pocket machined to 1.6μm Ra finish ensures optimal contact and leak-free seal.

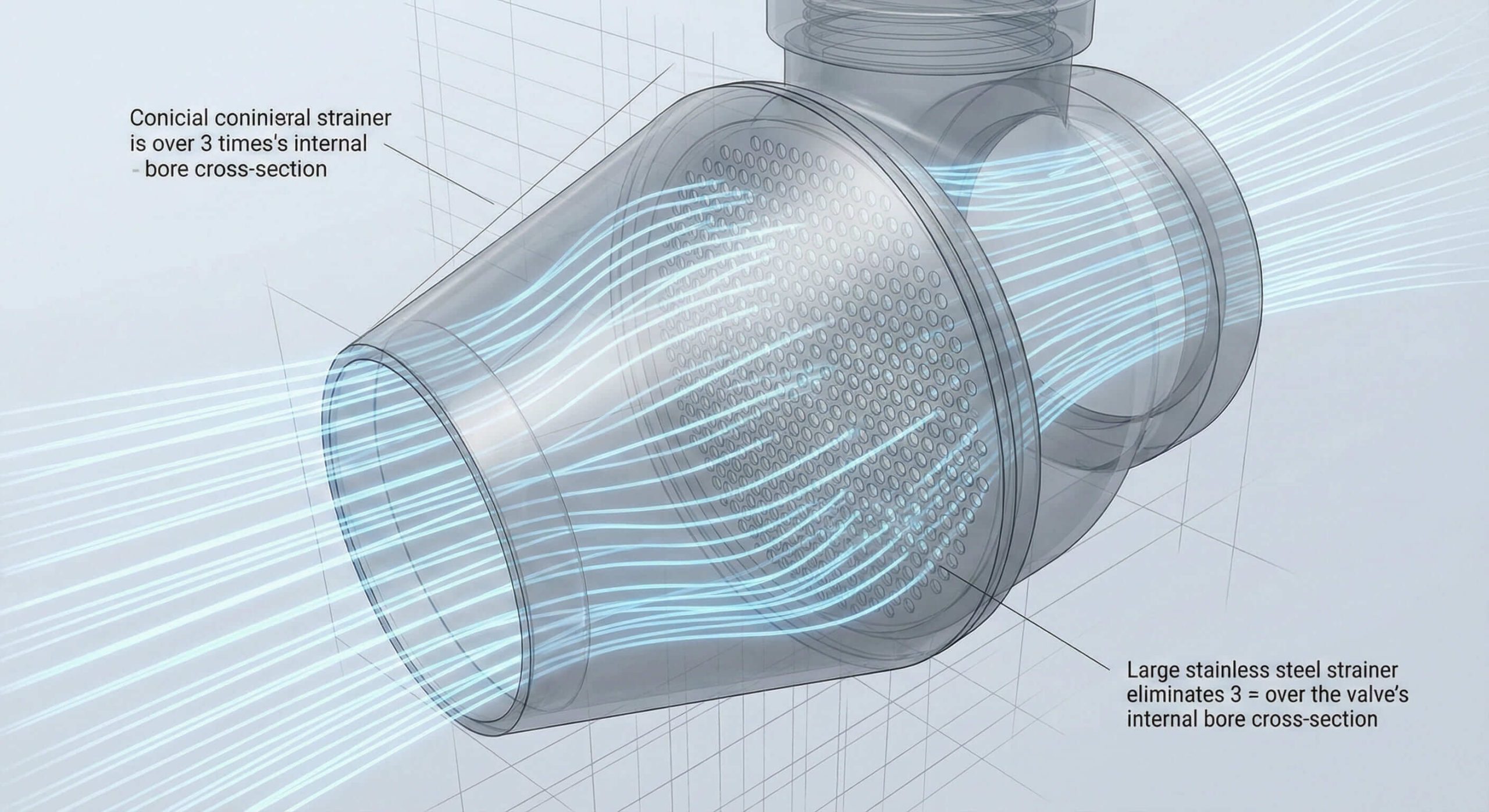

High-Capacity Strainer

Conical strainer with 3× valve bore area. 3mm standard perforation (customizable). Allows 2× design flow at <0.1 bar pressure drop.

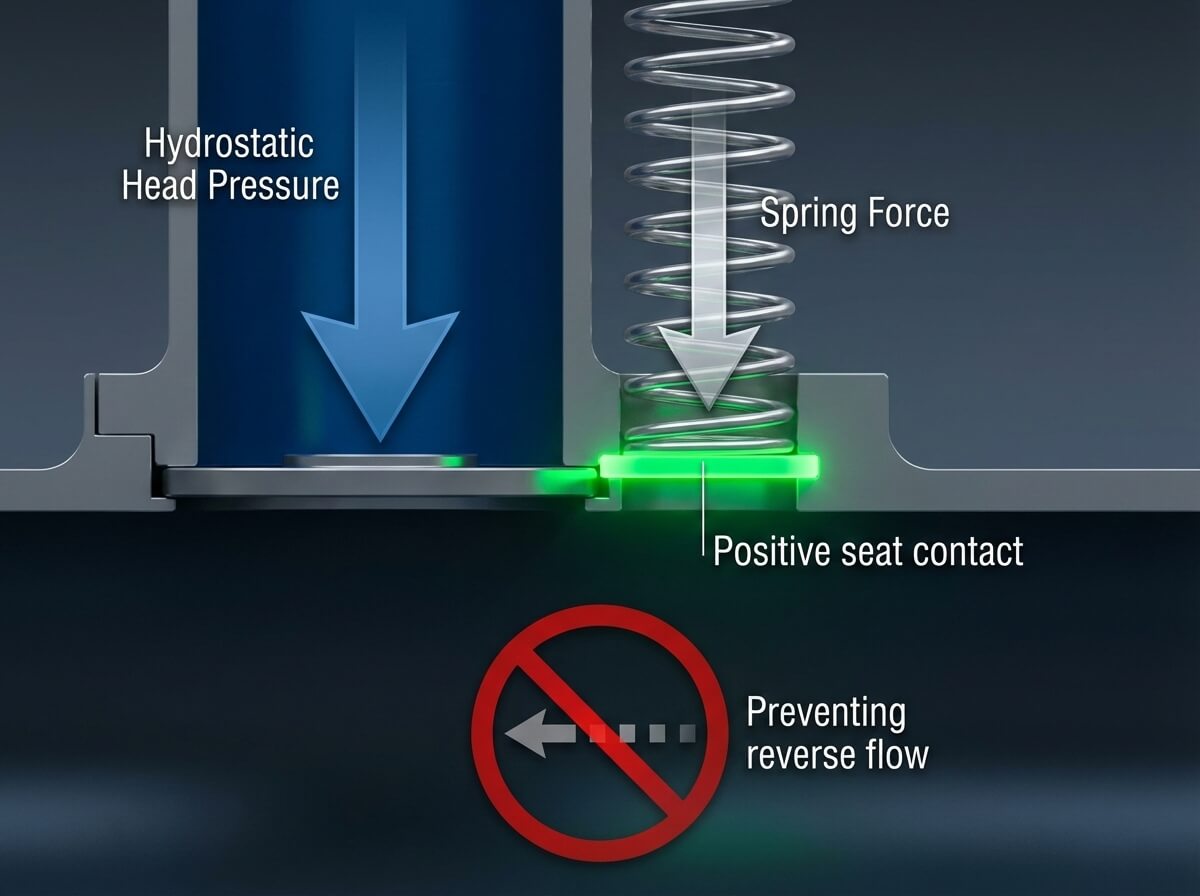

Non-Slam Dynamic Design

Spring-assisted mechanism ensures disc closes at the exact moment of flow reversal (zero velocity), preventing pressure surges and noise.

Every solution validated through testing protocols and field performance data

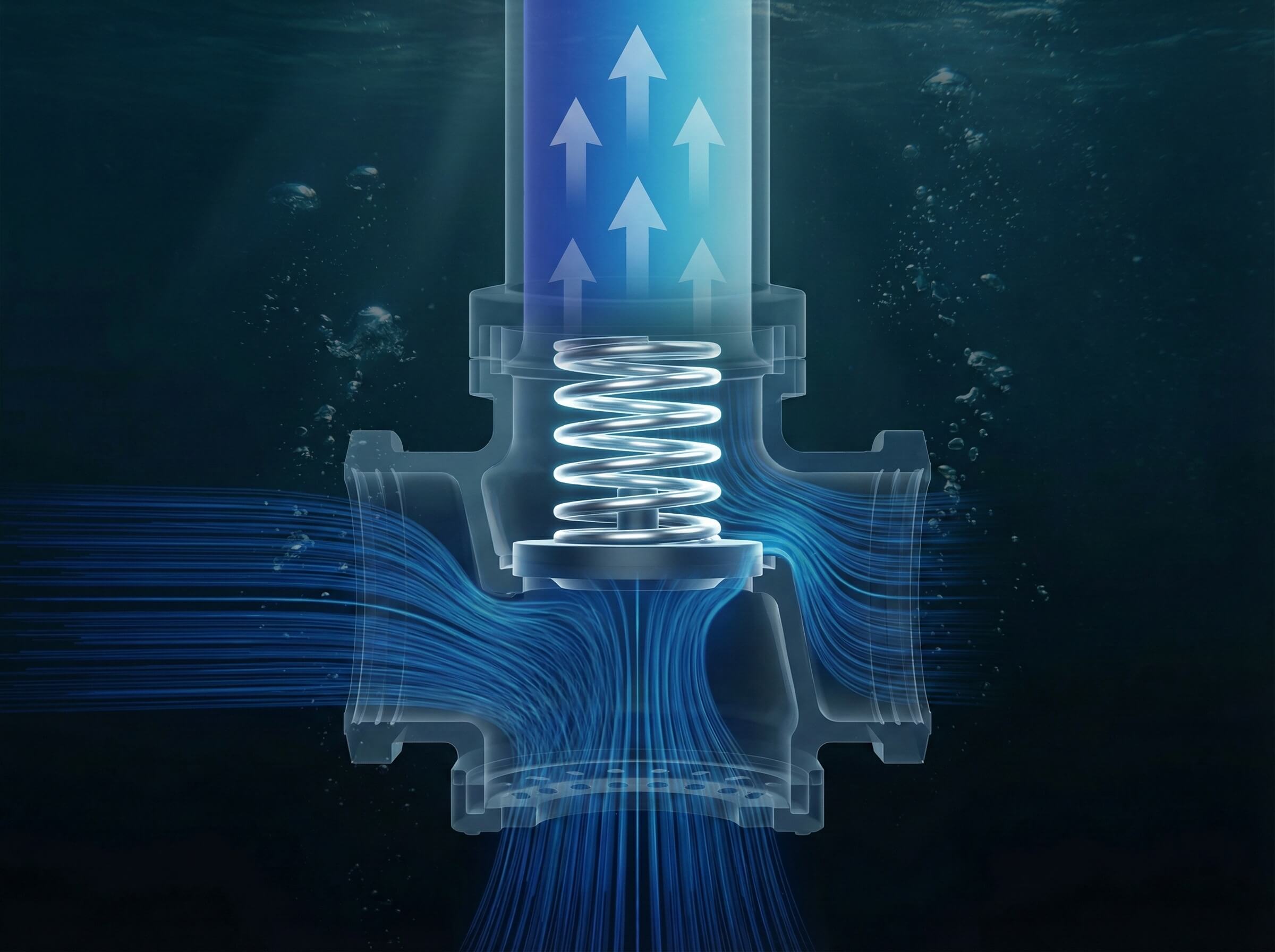

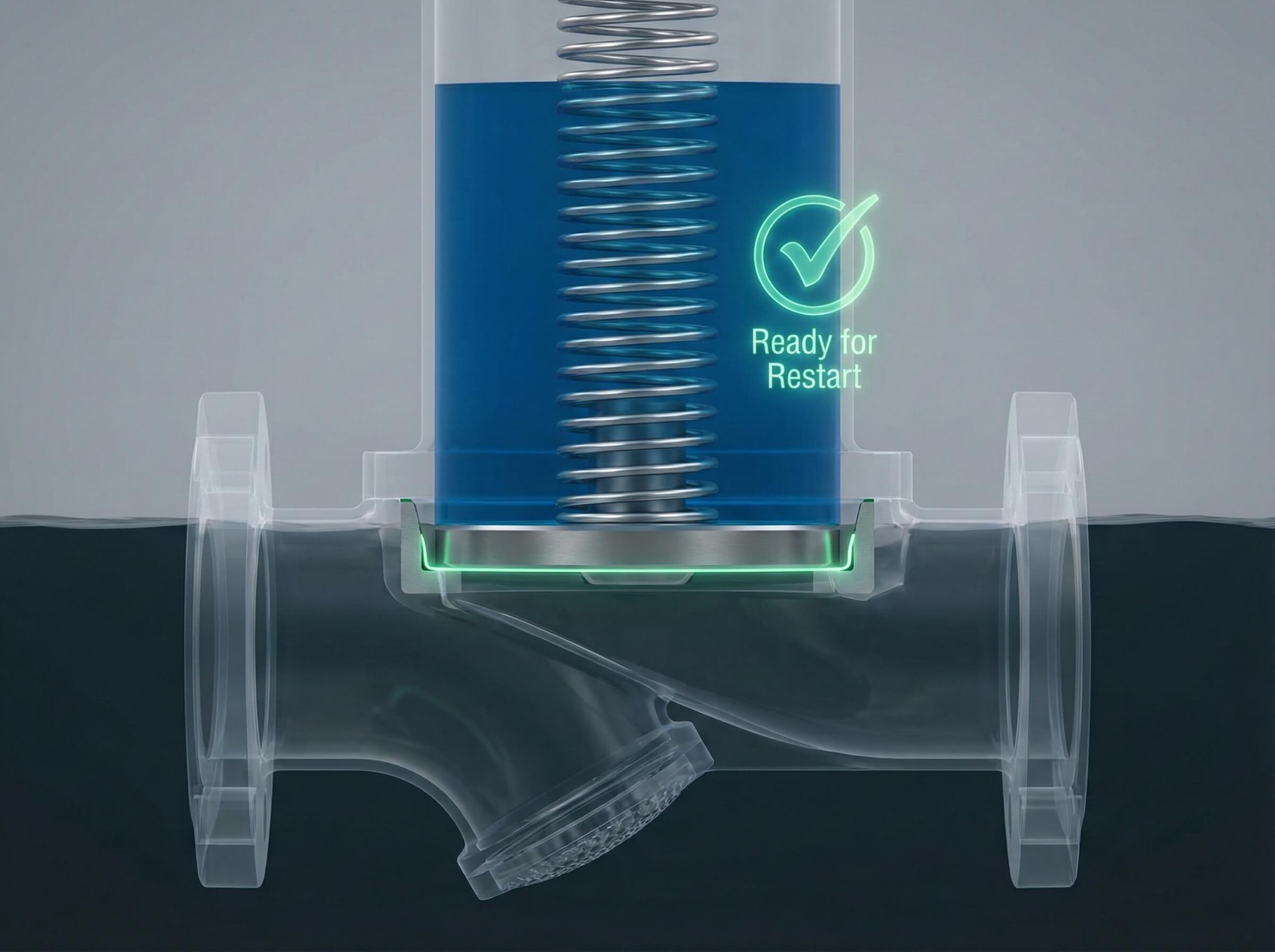

View Technical SpecificationsFoot Valve Operating Sequence

Four-phase operation ensures reliable backflow prevention throughout pump cycles

Startup State

Disc lifts against spring force as pump creates suction. Water flows through strainer and open disc clearance into suction pipe.

Normal Operation

Disc held fully open by continuous flow. Strainer filters debris while maintaining design flow rate with minimal pressure drop.

Shutdown State

Flow stops, spring force immediately closes disc onto seat. System prime retained in suction line above valve for instant restart.

Backflow Block

Water column weight holds disc sealed. Spring maintains positive seat contact preventing reverse flow during extended standby periods.

Simple, proven mechanism provides decades of reliable service in demanding applications

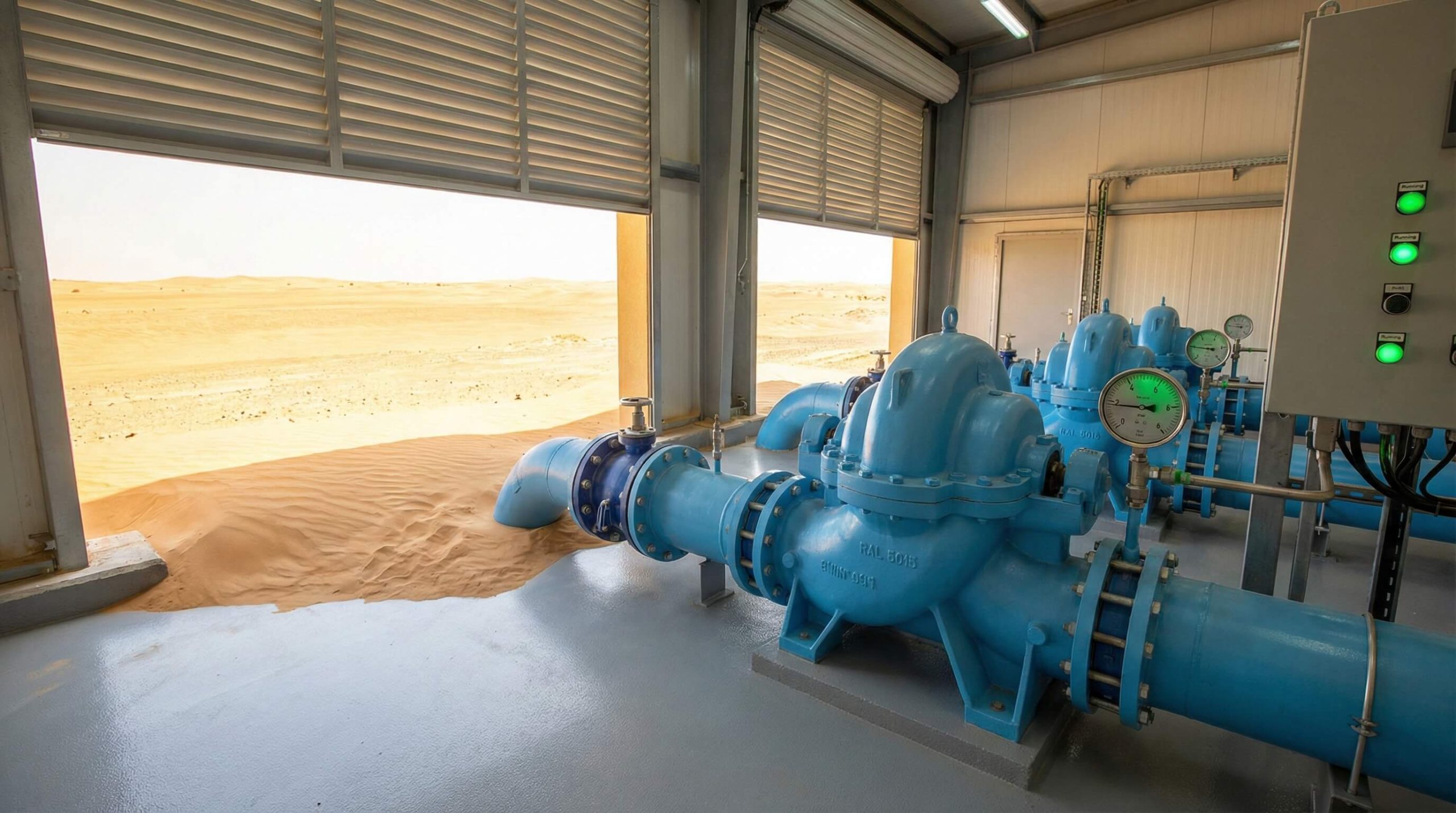

Explore Application ScenariosApplications Where Foot Valves Ensure System Reliability

Critical installations where maintaining prime and preventing backflow directly impacts operational uptime

Municipal Water Distribution

Booster pumps require instant restart capability without repriming delays. Foot valves preserve suction line prime during power interruptions, ensuring immediate pressure recovery.

Agricultural Irrigation

Seasonal installations with intermittent operation need reliable startup after extended standby periods. Strainer prevents debris from well or canal sources from damaging pump impellers.

Industrial Process Water

Cooling towers and process lines cannot tolerate pump dry running. Foot valves prevent water drainage during shift changes, protecting expensive multistage pumps from seal damage.

Fire Protection Systems

Emergency fire pumps must deliver rated flow within seconds. Pre-charged suction lines maintained by foot valves eliminate priming delays that could prove catastrophic.

Construction Dewatering

Temporary wellpoint systems operating in excavations need protection from suspended solids. Large strainer area accommodates high debris loading while maintaining low pressure drop.

Aquaculture Systems

Recirculation pumps in fish farms operate continuously. Foot valves prevent air infiltration that would disrupt biological filtration, blocking debris that could foul downstream sterilizers.

Match valve specifications to your system requirements

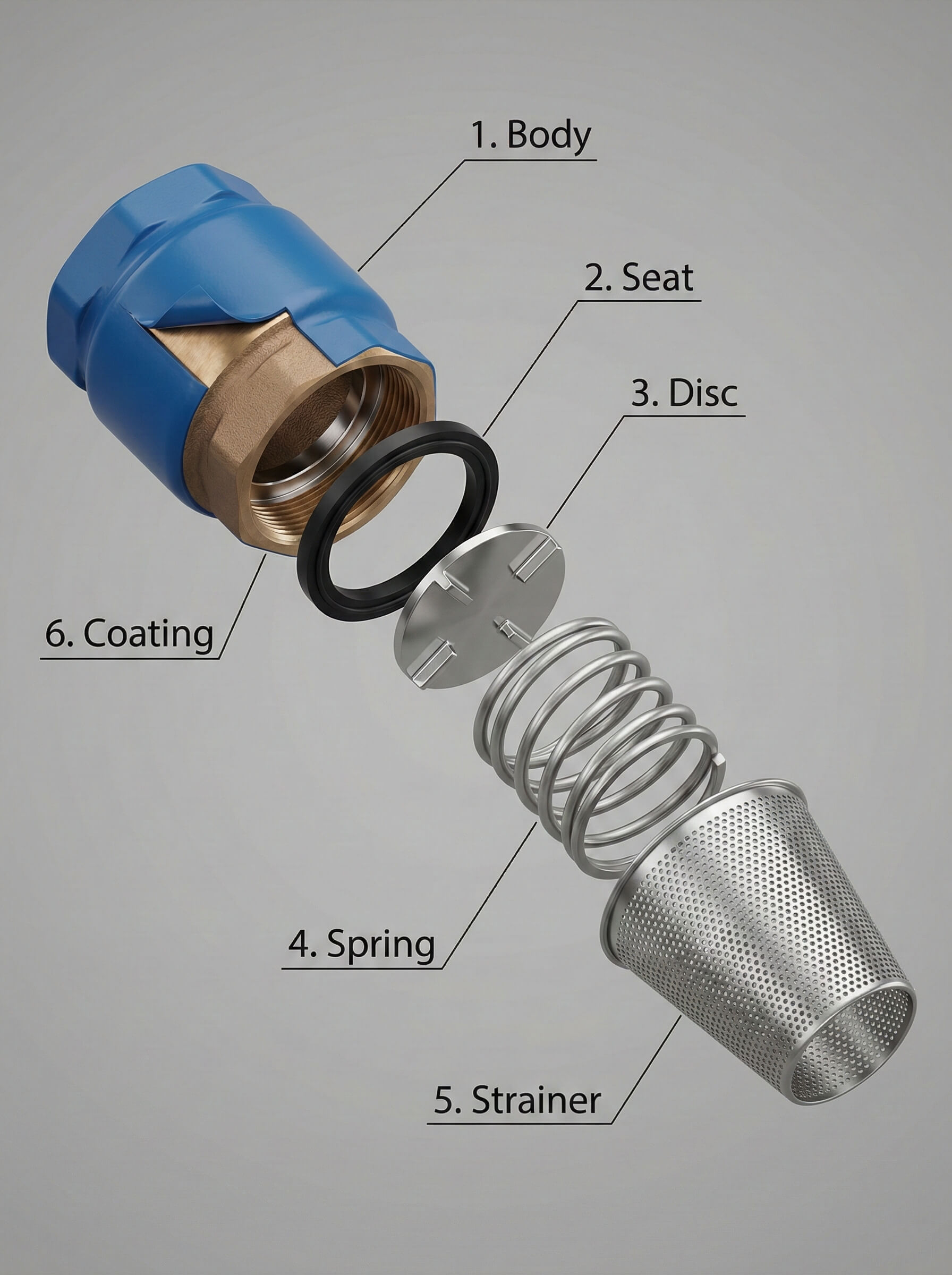

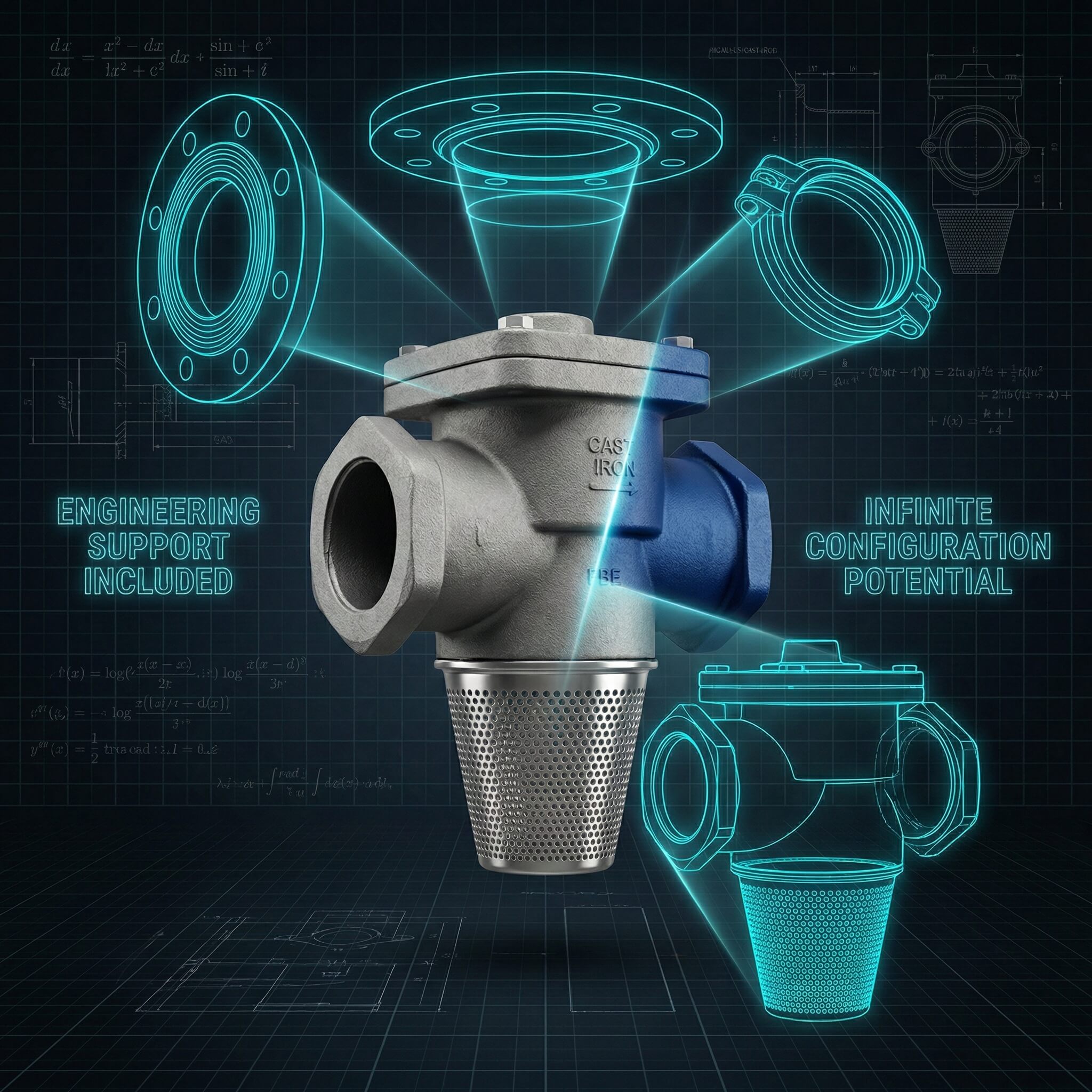

Request Application ReviewComponent Breakdown and Engineering Details

Every part specified for durability and field serviceability in demanding installations

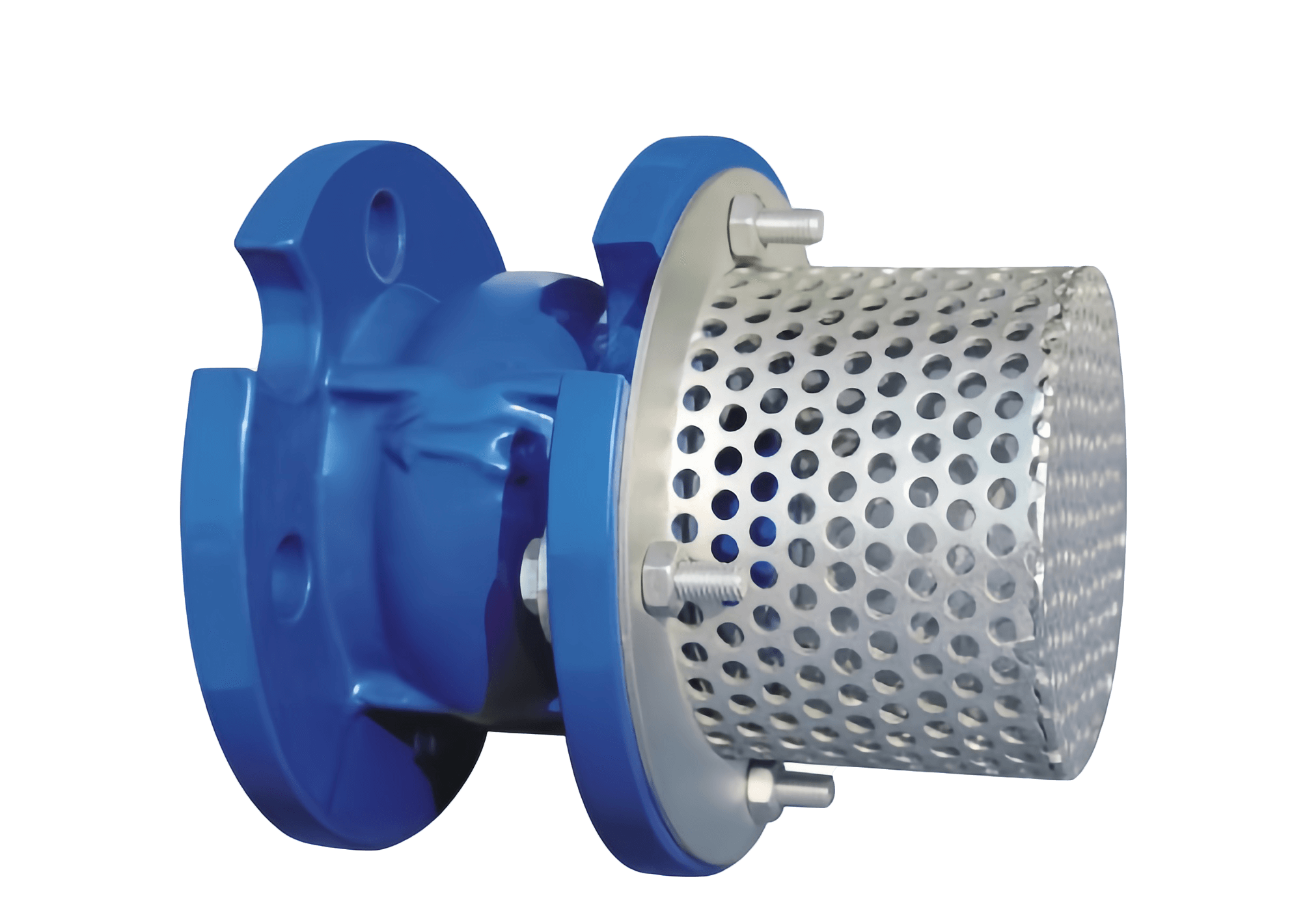

Axial component arrangement showing assembly sequence

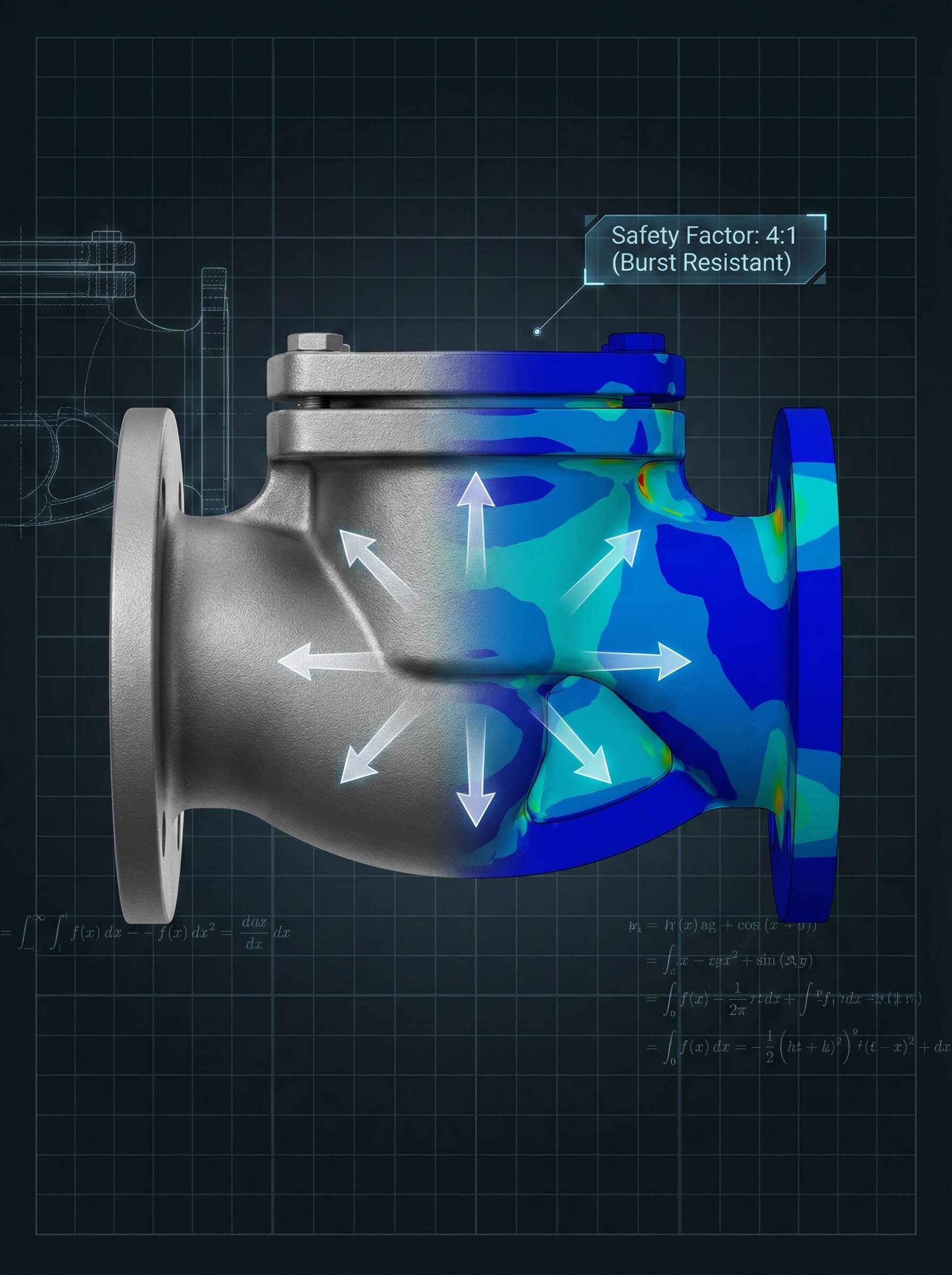

Body

Cast bronze (ASTM B584 C83600) or ductile iron (ASTM A536 Grade 65-45-12) construction. Threaded or flanged end connections per ANSI B16.1. Wall thickness sized for PN16 working pressure with safety factor 4:1 against burst.

Disc

316 stainless steel (ASTM A276) for corrosion resistance. Precision-guided with four contact points maintaining alignment within 0.3mm throughout travel. Surface hardness 200+ HV resists erosion from particulate impact.

Spring

304 stainless steel compression spring (ASTM A313) designed for 50% maximum deflection. Pre-stressed to eliminate settling. Maintains minimum 15N closing force after 200,000 cycles verified per EN 13906 fatigue testing protocol.

Seat

Nitrile rubber (NBR) Shore A 70 for clean water, EPDM for chlorinated systems, or metal-to-metal for slurries. Machined seat pocket with 1.6μm Ra surface finish ensures consistent seal contact pressure across full circumference.

Strainer

316L stainless steel (ASTM A240) conical basket with open area 3× valve bore. Standard 3mm perforations, available in 5mm or 8mm for high-debris applications. Pressure drop <0.1 bar at 2× design flow rate verified by Cv testing.

Coating

Fusion-bonded epoxy interior coating (250-300μm dry film thickness) for corrosive media. Applied after machining and prior to assembly. Coating adhesion verified per ISO 8501, providing 20+ year corrosion protection in chlorinated or brackish water service.

Component specifications and material certificates available upon request

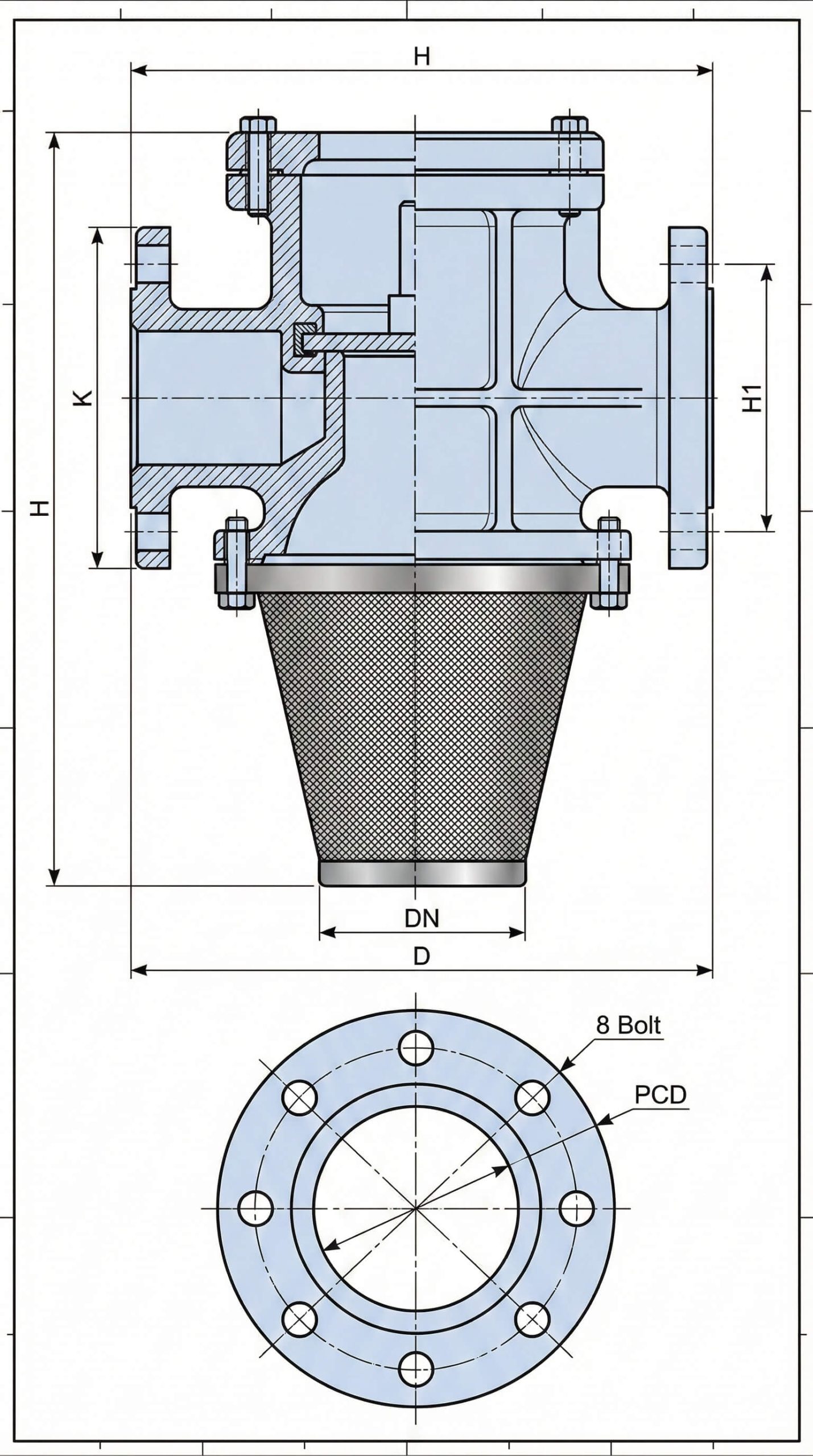

Request Material CertificationsKey Technical Specifications

Performance envelope and compliance standards for system integration

Complete dimensional drawings and performance curves available for engineering review

Download Full DatasheetMaterial and Seal Selection Matrix

Match component materials to operating conditions for maximum service life

| Material / Seal Config | Municipal Water | Suspended Solids | Brackish / Seawater | Chlorinated Systems | High Cycle Rate |

|---|---|---|---|---|---|

| Bronze Body + NBR Seat | |||||

| Bronze Body + EPDM Seat | |||||

| Ductile Iron + Epoxy + NBR | |||||

| Ductile Iron + Epoxy + EPDM | |||||

| 316 Stainless Body + EPDM | |||||

| Bronze Body + Metal Seat |

Uncertain about material selection for your specific water chemistry? Consult our application engineers

Get Material RecommendationFour Critical Factors That Determine Service Life

Engineering decisions that separate reliable valves from premature failures

Design Life Calculation

Components sized for initial functionality without fatigue analysis. Performance often degrades within 12-18 months.

Components engineered for 10-year service life. Body stress analysis ensures 4:1 safety factor against burst.

QA: Every production batch undergoes 10,000-cycle endurance testing to verify retention of design specifications.

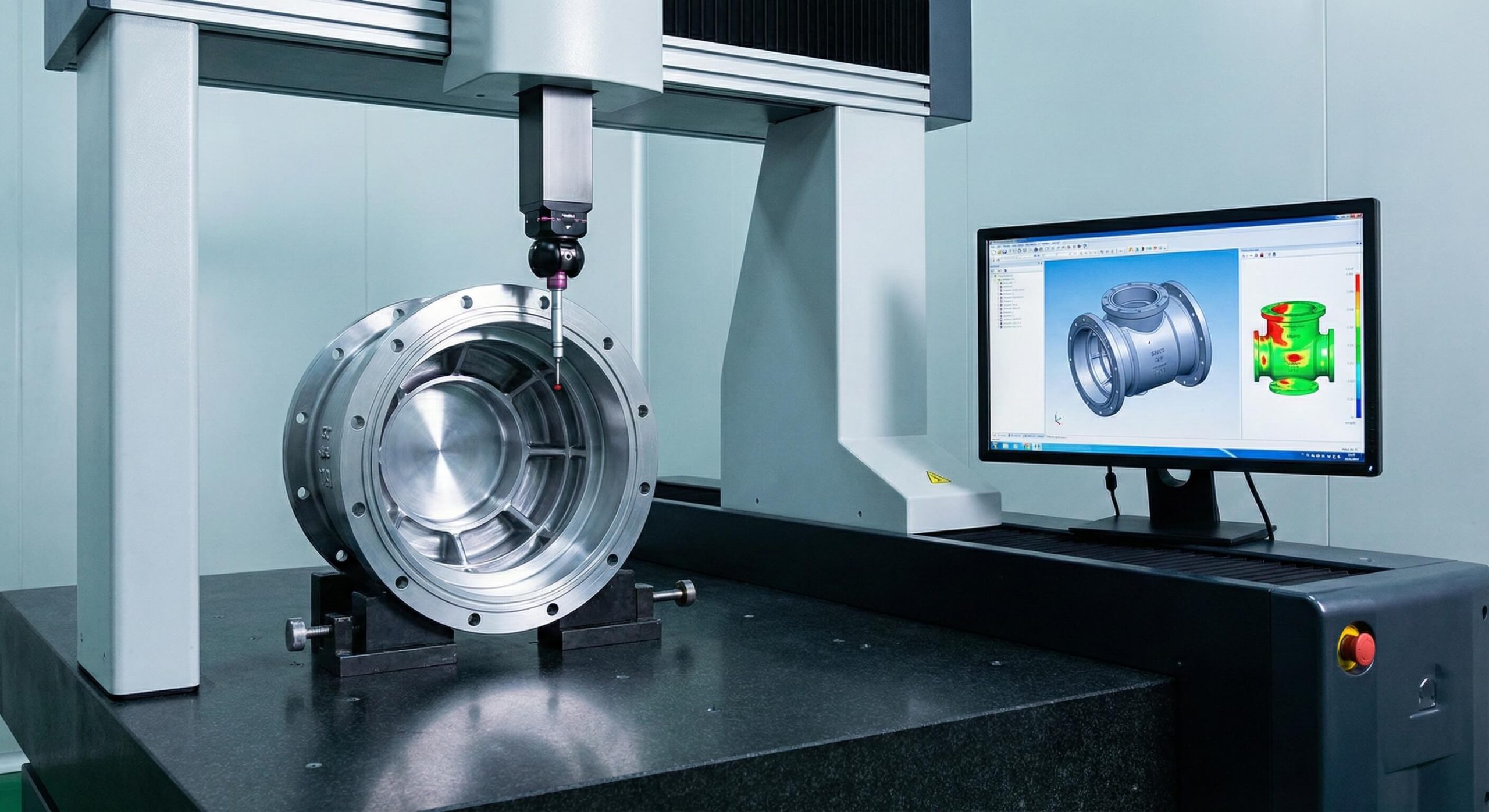

Machining Precision

Loose tolerances allow disc wobble during closure. Rough seat surfaces create uneven contact pressure and leakage.

CNC machining maintains alignment within 0.3mm. Seat pockets are finished to Ra 1.6μm for perfect sealing.

QA: Critical dimensions verified with CMM inspection. Surface finish measured with contact profilometer on 5% samples.

Spring Fatigue Resistance

Undersized springs operate near stress limits. They settle and lose preload force within 30,000 cycles.

304 Stainless springs designed for 50% max compression. Pre-stressed to maintain >15N force after 200k cycles.

QA: Load retention verified via EN 13906 protocol. Accelerated fatigue testing performed on random wire samples.

Corrosion Protection

Standard paint fails in 2-3 years. Rust accumulation jams moving parts and delamination accelerates pitting.

Fusion-bonded epoxy coating (250-300μm). Adhesion verified per ISO 8501 for 20+ years of protection.

QA: Holiday detection at 200V identifies defects. Coating thickness checked with magnetic gauge at 6 points.

These engineering commitments result in measurably longer field service life

Review Quality Control ProcessQuality Control Process from Materials to Shipment

Six-stage verification protocol ensures consistent product quality and performance reliability

Stage 1

Stage 1

Incoming Material Inspection

Stage 2

Stage 2

Machining Process Control

Stage 3

Stage 3

Assembly Verification

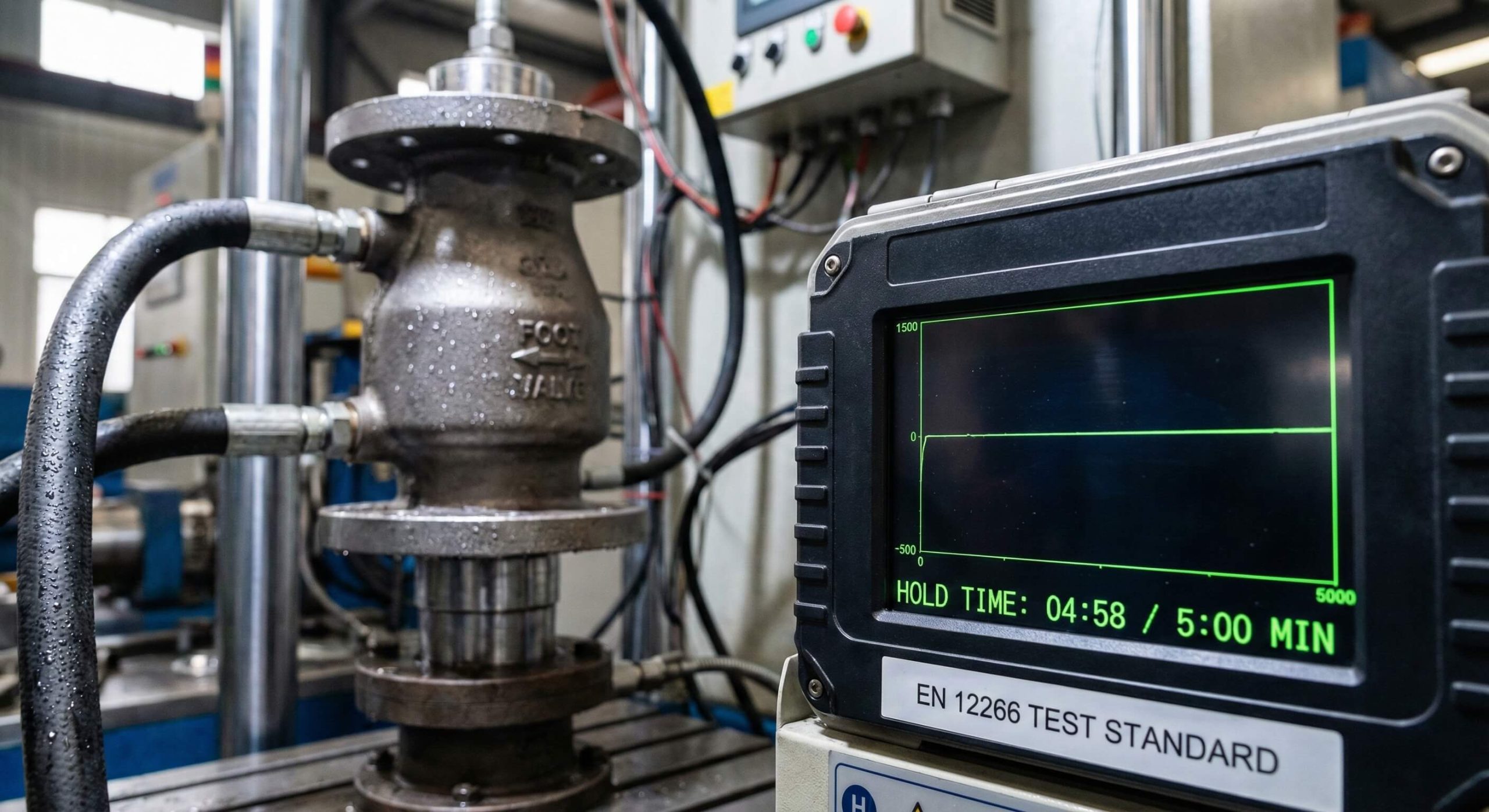

Stage 4

Stage 4

Hydrostatic Testing

Stage 5

Stage 5

Final Inspection

Stage 6

Stage 6

Documentation Package

Every valve ships with complete traceability from raw materials through final testing

Request Sample Test ReportsCertifications and Standards Compliance

Third-party verification ensures product conformity for regulated markets and critical applications

CE Marking (PED)

Full compliance with EU Pressure Equipment Directive (2014/68/EU) Module H.

WRAS Approved

Certified for UK potable water supply systems. Safe for drinking water.

DNV Type Approval

Certified for marine, offshore, and critical industrial applications.

ACS Compliance

French sanitary conformity certification (Attestation de Conformité Sanitaire).

ISO 9001:2015

Quality management system certified by LRQA. Ensuring consistent excellence.

ABS Type Approval

Product Design Assessment (PDA) for marine and offshore vessels.

Environment & Safety

Environmental management system certified by TÜV Rheinland.

Material Verification

Critical materials and components inspected and verified by SGS.

All certifications maintained current through annual audits and ongoing compliance verification

Download Certification CopiesCustomization Capability: Your Project Specifications Met Exactly

Engineering flexibility to modify standard designs for unique application requirements without tooling delays

Base Standard Platform

Most customizations deliverable within standard lead times without premium pricing

Submit Custom SpecificationEngineering Case Studies from Field Installations

Documented problem-solution-result sequences demonstrating performance in critical applications

System maintains prime for 48+ hours. Cleaning intervals extended from weekly to quarterly. Zero startup failures in 18 months.

Startup time reduced to 90 seconds. No corrosion after 24 months. Maintenance interventions reduced by 75%.

Pump achieves rated flow in 18 seconds. Suction line retains prime for 72+ hours. Passed NFPA 25 inspection with zero deficiencies.

Cleaning interval extended to 14 days (85% reduction). Zero impeller damage in 2 seasons. Saved $12,000 annually in labor.

Additional case studies available covering specialized applications and custom engineering solutions

Request Full Case Study LibraryWhy Engineering Teams and Procurement Departments Select RUITO

Operational capabilities that reduce project risk and ensure on-time delivery to specification

Production Stability

Dedicated manufacturing lines eliminate dependency on external foundries. Buffer inventory ensures immediate availability for urgent orders.

Engineering Support

Technical team provides sizing calculations, material selection guidance, and installation recommendations during specification phase.

Water Expertise

Two decades supplying municipal and industrial systems globally. Deep understanding of regulatory compliance across different markets.

Global Coverage

Established logistics partnerships enable efficient shipping to project sites worldwide. Streamlined customs clearance processes.

Rapid Response

Preliminary quotes provided within 48 hours. Custom modifications evaluated and priced within one week without commitment obligations.

Delivery Reliability

Documented on-time delivery performance exceeds 95%. Real-time scheduling provides order status visibility for project managers.

Ready to evaluate RUITO for your upcoming project requirements

Start Vendor Qualification ProcessDecision Framework: RUITO vs Generic Suppliers

Comparative analysis of procurement risk factors that impact project success and total cost of ownership

| Risk Evaluation Criteria | RUITO | Typical Generic Supplier |

|---|---|---|

| Engineering Design Support |

In-house engineering team provides sizing calculations, material selection recommendations, and installation guidance during specification phase. |

Limited or no technical support beyond catalog dimensions. Buyer responsible for all application engineering and material selection decisions. |

| Quality Testing Methods |

100% hydrostatic testing at 1.5× rated pressure with documented test certificates per EN 10204 Type 2.2. Batch sampling for dimensional verification. |

Testing protocols vary by batch. May rely on visual inspection or statistical sampling only. Test documentation often unavailable. |

| Documentation Completeness |

Material certificates, hydrostatic test reports, dimensional inspection records, and installation instructions shipped with every order. |

Documentation frequently incomplete or generic. Mill certificates may not match actual batches. Test reports often require extra fees. |

| Delivery Reliability |

Documented 95%+ on-time delivery. Production scheduling provides order status visibility. Standard lead time 3-4 weeks. |

Delivery dates frequently missed due to capacity constraints. Limited visibility into production status. Lead times extend without notice. |

| Customization Response |

Custom modifications evaluated within one week. Engineering drawings provided. Most customizations deliverable within standard lead times. |

Custom requests require high MOQs and extended lead times. Modifications incur significant tooling charges and limited flexibility. |

| Supply Chain Risk |

Vertically integrated production eliminates dependency on external foundries. Buffer inventory for standard sizes ensures availability. |

Dependent on third-party suppliers for components. Supply disruptions directly impact delivery. Limited inventory creates vulnerability. |

Evaluate supplier capabilities against your project risk tolerance and quality requirements

Request Detailed Capability StatementFrequently Asked Questions

Common technical and procurement questions organized by stakeholder perspective

Engineering Questions

How do I determine the correct foot valve size for my pump system?

What material combination should I specify for brackish water or seawater?

Can the foot valve handle suspended solids or does it require upstream filtration?

What is the maximum suction lift this valve can maintain without losing prime?

How often does the strainer require cleaning in municipal water applications?

Procurement Questions

What is your standard lead time and can you accommodate expedited delivery?

What documentation is included with shipment and what costs extra?

Do you accept small quantity orders or require minimum order values?

What warranty coverage is provided and how are claims processed?

Can you support special packaging or consignment inventory?

Additional questions not covered here? Our technical and commercial teams respond within 24 hours

Submit Your QuestionChoose the Fastest Path to Move Your Project Forward

Three direct pathways to access technical information, pricing, or engineering consultation based on your current project stage

Get Technical Datasheet

Best for: Specification Review

Receive comprehensive technical documentation including dimensional drawings, performance curves, material specifications, and pressure ratings within 10 minutes.

Download DatasheetRequest Quote & Lead Time

Best for: Budget Estimation

Submit your quantity, size, and delivery requirements to receive detailed pricing, confirmed lead times, and shipping options within 48 business hours.

Get Pricing QuoteConsult Engineering Team

Best for: Custom Requirements

Connect directly with application engineers for sizing verification, material compatibility analysis, custom design feasibility, or installation troubleshooting.

Contact Engineering