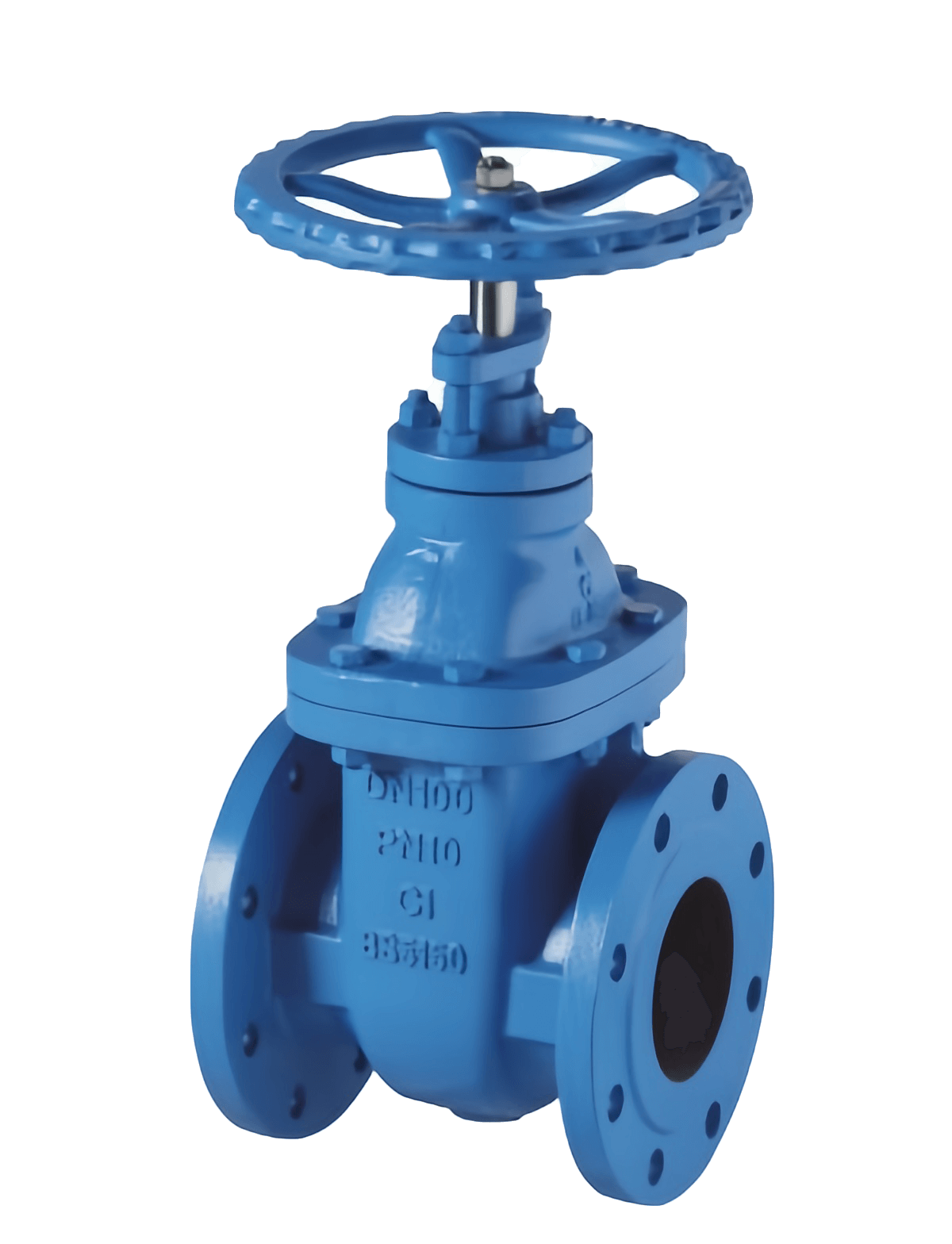

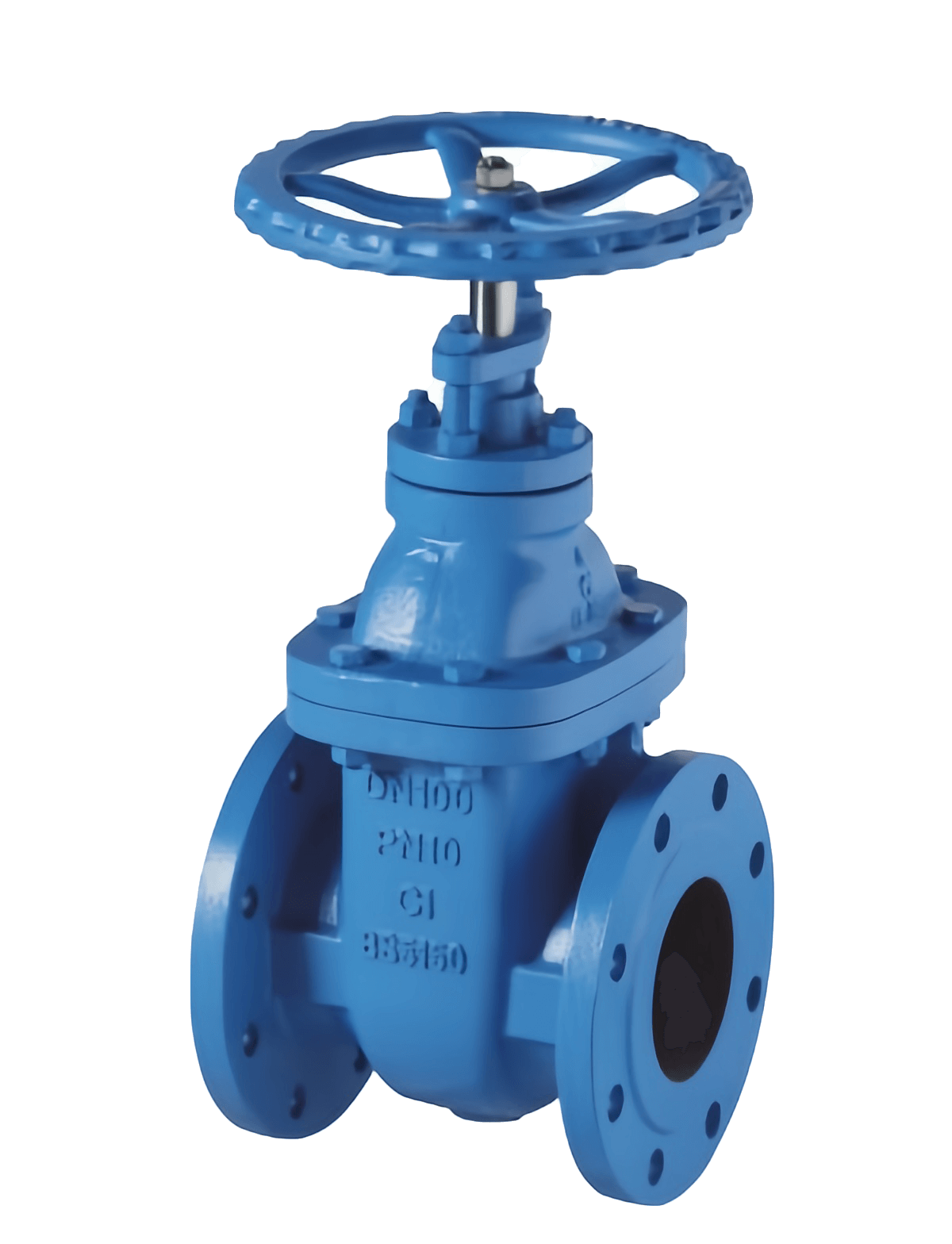

Industrial Gate Valves Built for Reliability

DN25-DN3000 | PN10-PN25 | Full Port Design

DN25-DN3000 | PN10-PN25 | Full Port Design

Leakage appears within 6 months due to poor seat sealing quality or material incompatibility with working media.

Consequence: Emergency shutdown, supplier replacement, additional rework costs

Valve fails pressure test because internal dimensions do not match specifications, or coating quality is substandard.

Consequence: Project delay, penalty clauses triggered, reputation damage

Supplier cannot deliver on time, provides inconsistent lead time estimates, or lacks stock transparency.

Consequence: Production line downtime, expedited shipping costs, lost contracts

Documentation is incomplete, test reports are generic copies, material certificates are missing or fraudulent.

Consequence: Customs clearance failure, compliance audit rejection, project certification blocked

These failures cost more than just money - they cost project timelines, professional reputation, and client trust.

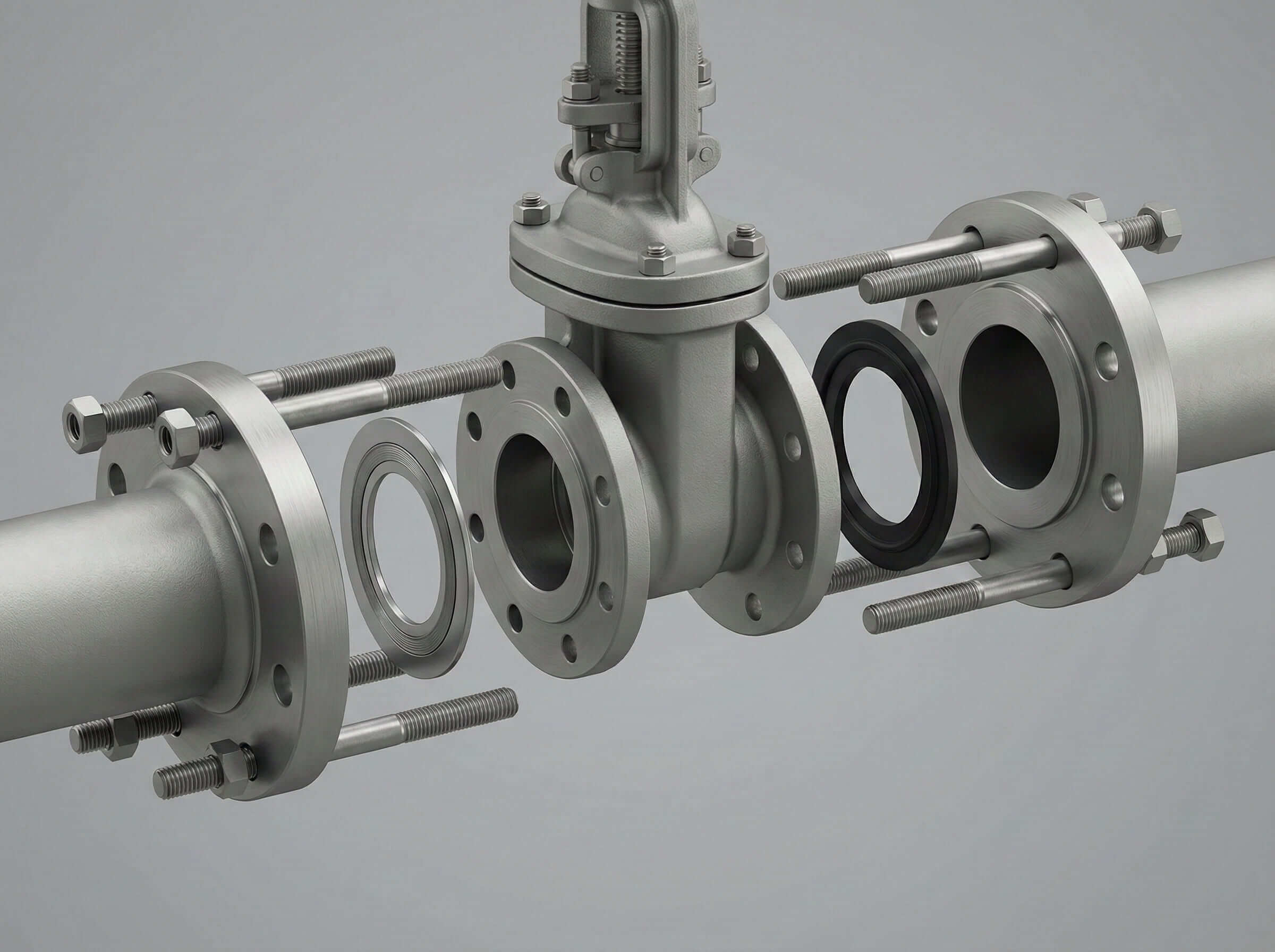

A linear motion valve designed for full-bore, tight shut-off in on-off service applications

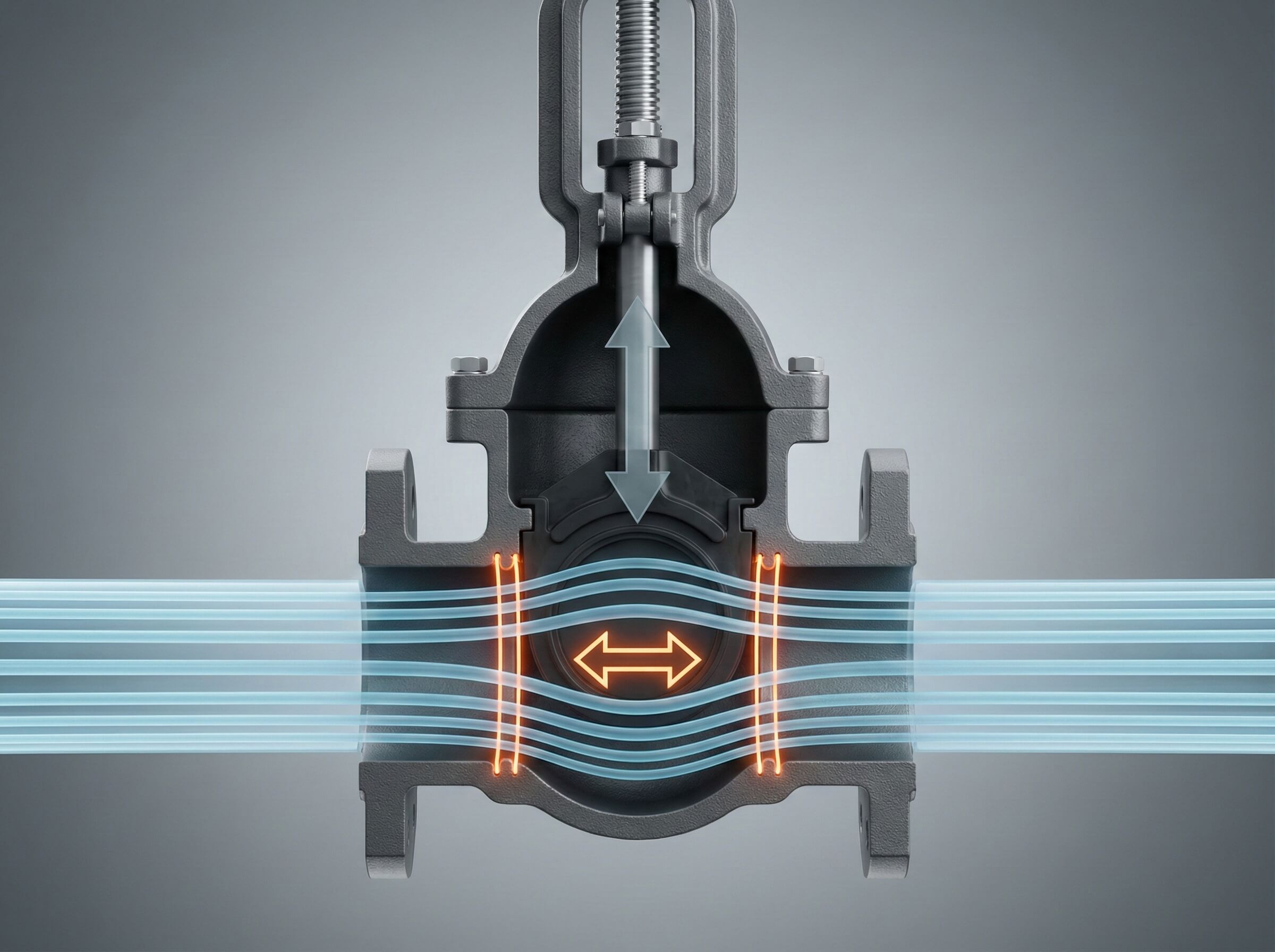

Gate moves perpendicular to flow path, providing unrestricted flow when fully open. Zero pressure drop minimizes pumping energy consumption and prevents sediment accumulation.

Wedge or parallel disc design creates metal-to-metal or resilient seat contact under system pressure. Suitable for applications requiring absolute leak-tightness in both flow directions.

Designed for infrequent operation in fully open or fully closed positions. Simple internal structure reduces wear parts and extends service life to 15-20 years in proper conditions.

Critical infrastructure systems that demand zero pressure drop and absolute shut-off reliability

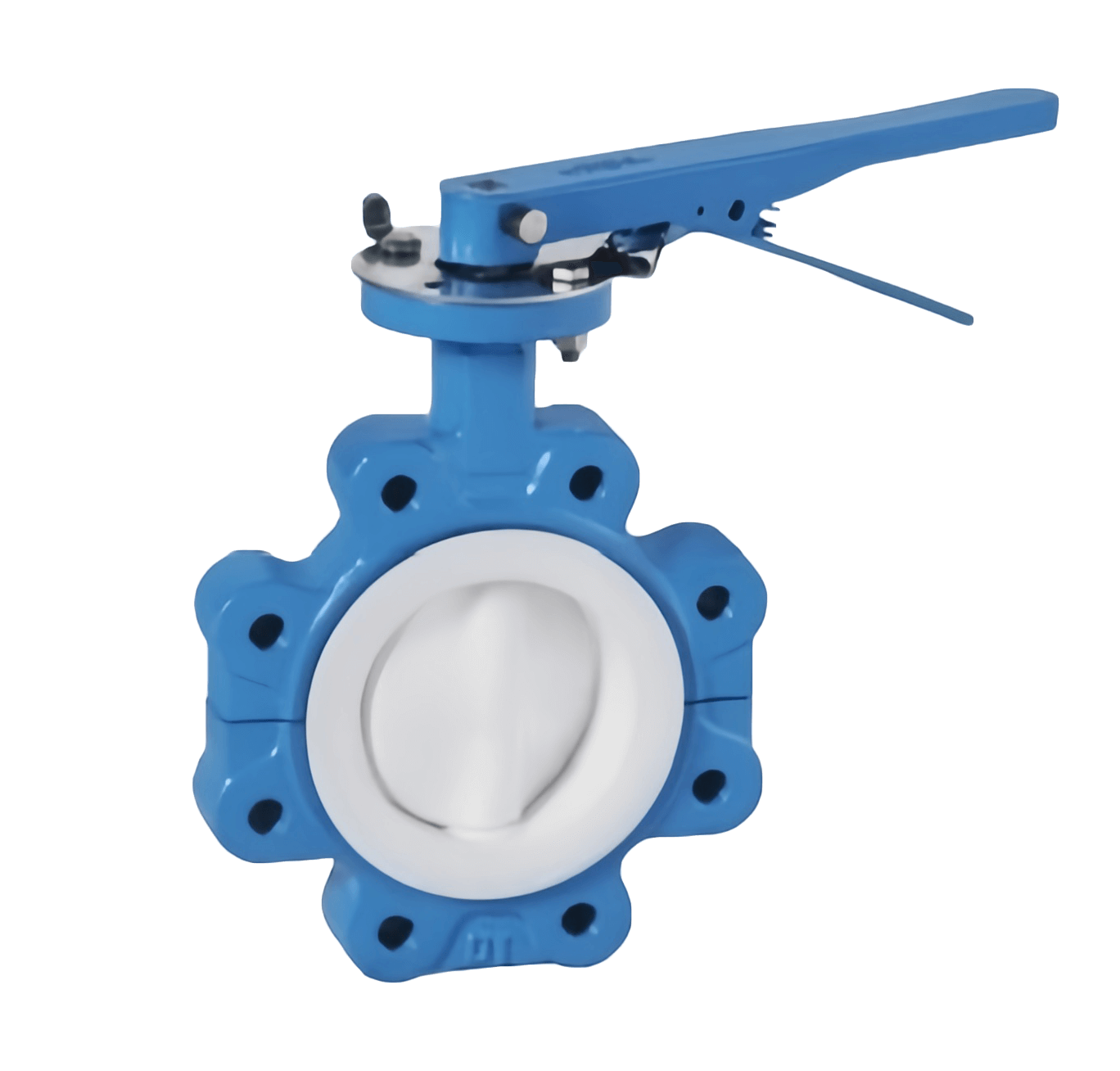

Technical comparison based on actual operating characteristics and lifecycle costs

| Selection Criteria |

|

|

|

|---|---|---|---|

|

Sealing Method

|

Metal-to-metal or resilient seat, bidirectional tight shutoff, suitable for absolute leak prevention | Elastomer liner contact, soft sealing, acceptable minor leakage in some applications | Spherical surface contact, excellent sealing, but limited by seat material temperature range |

|

Pressure Loss

|

Zero pressure drop when fully open, full bore design maintains original pipe flow area | Disc remains in flow path, creates 15-30% pressure loss even when fully open | Minimal pressure loss, but reduced bore design may increase velocity |

|

Operation Frequency

|

Optimized for infrequent operation, 10-50 cycles per year, not suitable for throttling service | Suitable for frequent operation and modulating control, fast opening/closing response | Medium frequency operation, quick quarter-turn action, limited cycle life in high-pressure systems |

|

Cost Level

|

Moderate initial cost, lowest lifecycle cost in large diameter applications due to extended service life | Lowest initial cost for large sizes, but higher maintenance frequency increases TCO | Higher initial cost especially in large diameters, expensive replacement parts |

|

Maintenance

|

15-20 year service life, simple internal structure, accessible components, low spare parts inventory | 5-10 year seat replacement cycle, actuator maintenance required for automated systems | Seat replacement every 3-7 years, entire ball assembly may require replacement |

|

Typical Applications

|

Water distribution, power plants, wastewater, oil & gas transmission, isolation service | HVAC systems, ventilation, low-pressure water systems, flow regulation | Chemical processing, gas service, high-purity systems, quick shutoff requirements |

Engineered solutions for different pressure classes and application requirements

Comprehensive specifications meeting international standards for industrial applications

| Parameter | Range | Notes / Standard |

|---|---|---|

|

Nominal Size

|

DN25 – DN3000 (1" – 120") | DIN, EN, ANSI dimensional standards. Large diameter valves DN1000+ manufactured upon confirmed order specifications |

|

Pressure Rating

|

PN6 / PN10 / PN16 / PN25 / PN40 Class 125 / 150 / 300 |

Per EN 1092-2, DIN 2501, ASME B16.5. Higher pressure ratings available with engineered-to-order body designs |

|

Temperature Range

|

-29°C to 425°C (-20°F to 800°F) | Dependent on body and seat material selection. Resilient seats limited to -10°C to 80°C for EPDM, -20°C to 90°C for NBR |

|

Body Material

|

GG25 / GGG40 / GGG50 WCB / WC6 / WC9 CF8 / CF8M / CF3M |

Cast iron per EN-GJL-250, ductile iron per EN-GJS-400, carbon steel per ASTM A216, stainless steel per ASTM A351 |

|

Bonnet Design

|

Bolted / Pressure Seal Union / Welded |

Bolted bonnet standard for PN≤25. Pressure seal design for PN40+ or high-temperature applications above 300°C |

|

Seat Material

|

EPDM / NBR (Resilient) Bronze / Stellite (Metal) |

Resilient seats for water service. Metal seats for steam, thermal oil, or temperatures exceeding 100°C |

|

Stem Material

|

SS410 / SS416 / SS304 / SS316 | Martensitic stainless for freshwater. Austenitic SS316 mandatory for seawater or chloride-containing media |

|

Connection Type

|

Flanged (DIN / ANSI / JIS) Wafer / Grooved / Weld End |

Flange drilling per EN 1092-2, ASME B16.5, JIS B2220. Grooved ends per AWWA C606 for municipal water |

|

Operation Mode

|

Handwheel / Gear Operator Electric / Pneumatic Actuator |

Manual operation standard for DN≤300. Gear operator recommended for DN350+. Actuators configured per site specifications |

|

Face-to-Face

|

EN 558-1 Series 14 / 15 ASME B16.10 / API 6D |

Series 14 for PN10/16 flanges. Series 15 for PN25/40. ASME dimensions for ANSI Class flanges |

|

Test Standard

|

EN 12266-1 / API 598 MSS SP-61 |

Shell test at 1.5× PN. Seat test at 1.1× PN for metal seats, 1.0× PN for resilient seats. Zero leakage per Rate A |

|

Design Standard

|

DIN 3352 / EN 1074 AWWA C509 / C515 API 600 / API 6D |

DIN 3352 for European markets. AWWA C509/C515 for North American water utilities. API 600 for oil & gas applications |

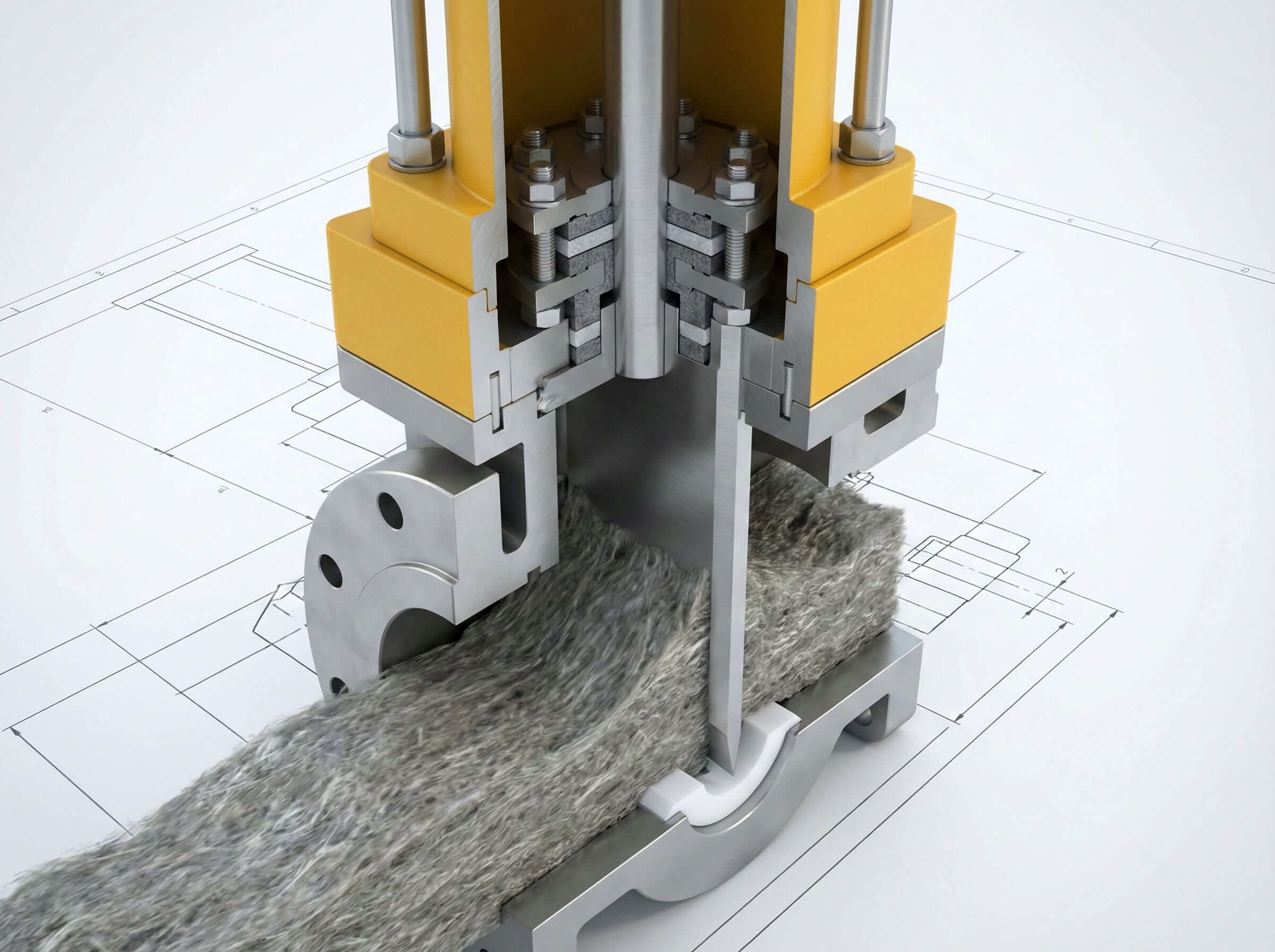

Critical zones engineered for leak-tight performance and extended service life

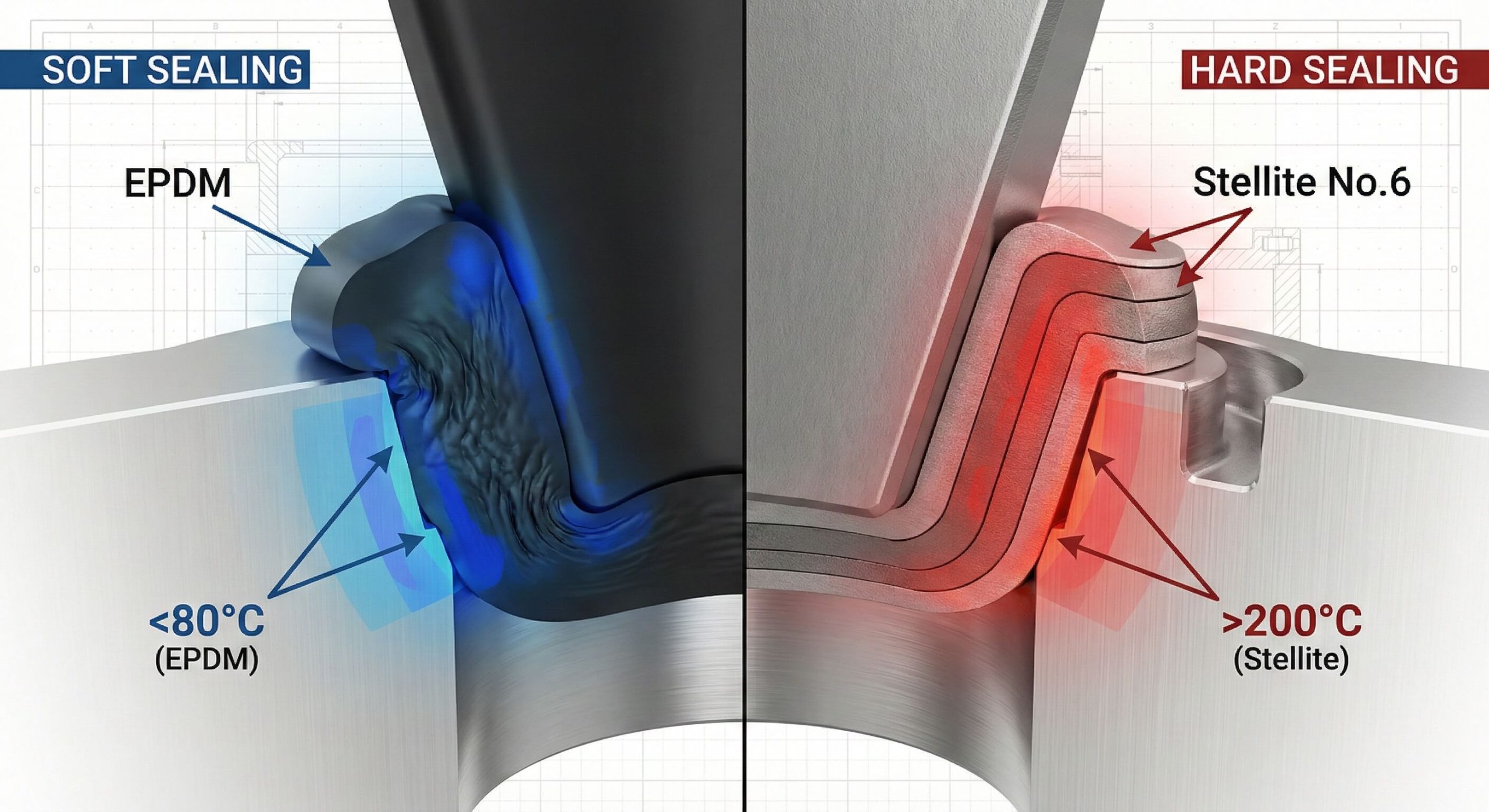

Resilient seats (EPDM/NBR) vulcanized directly onto ductile iron body provide bubble-tight shutoff in potable water systems at temperatures below 80°C. Metal seats (bronze or Stellite-faced) used when fluid temperature exceeds 100°C or media contains abrasive particles.

Municipal water systems require NSF-61 certified EPDM for drinking water contact. Steam applications above 200°C mandate Stellite No.6 hardfacing to resist thermal cycling and erosion. Seawater service requires bronze seats.

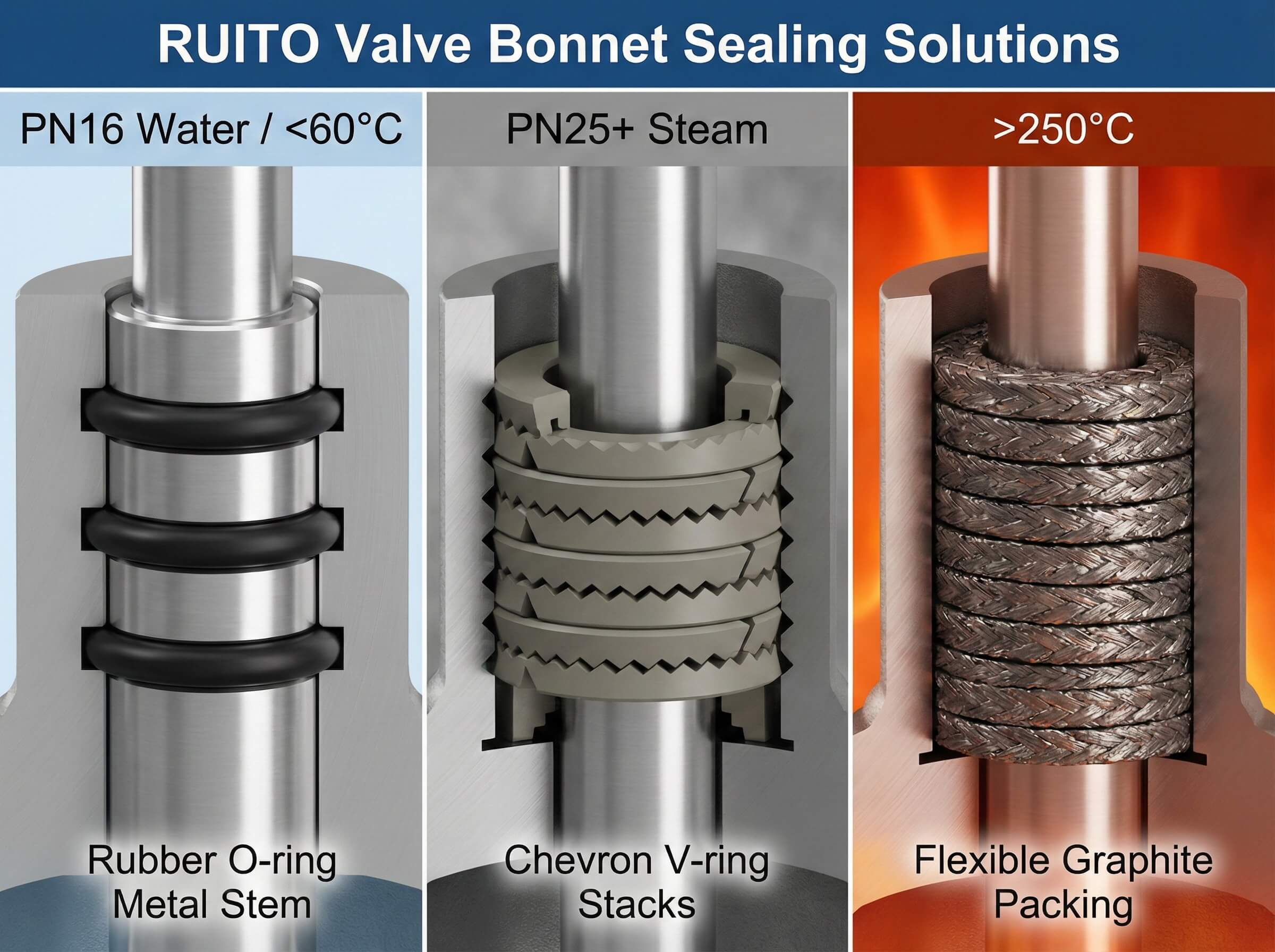

O-ring seals (NBR/EPDM) standard for water service up to PN16 and 60°C. Chevron V-ring packing stacks used for PN25+ or steam applications where higher stuffing box pressure is required. Graphite packing mandatory for temperatures above 250°C.

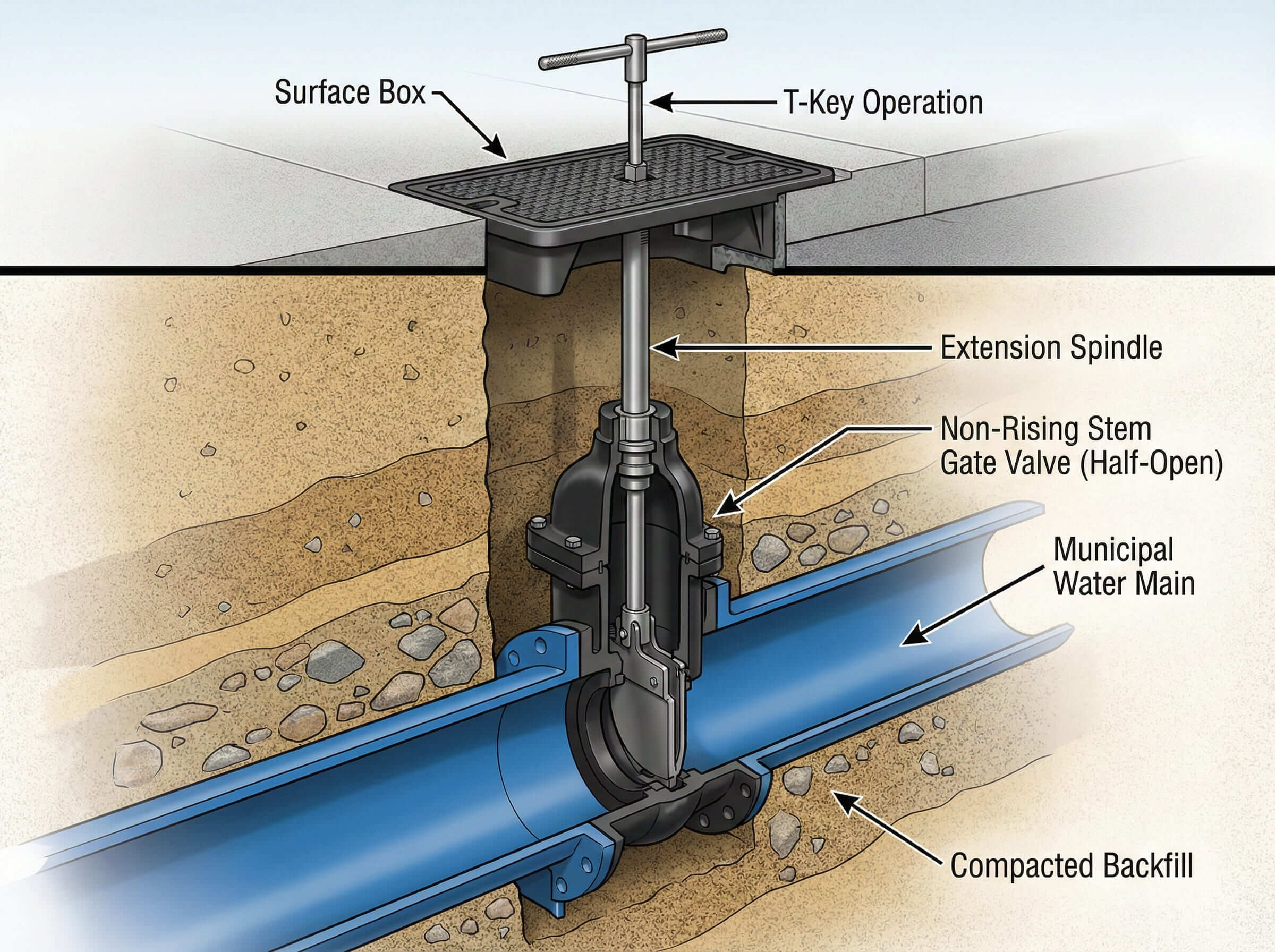

Buried valve installations require extended stuffing boxes with additional packing rings to accommodate underground corrosion protection. Chemical process systems may specify live-loaded packing glands to compensate for thermal expansion.

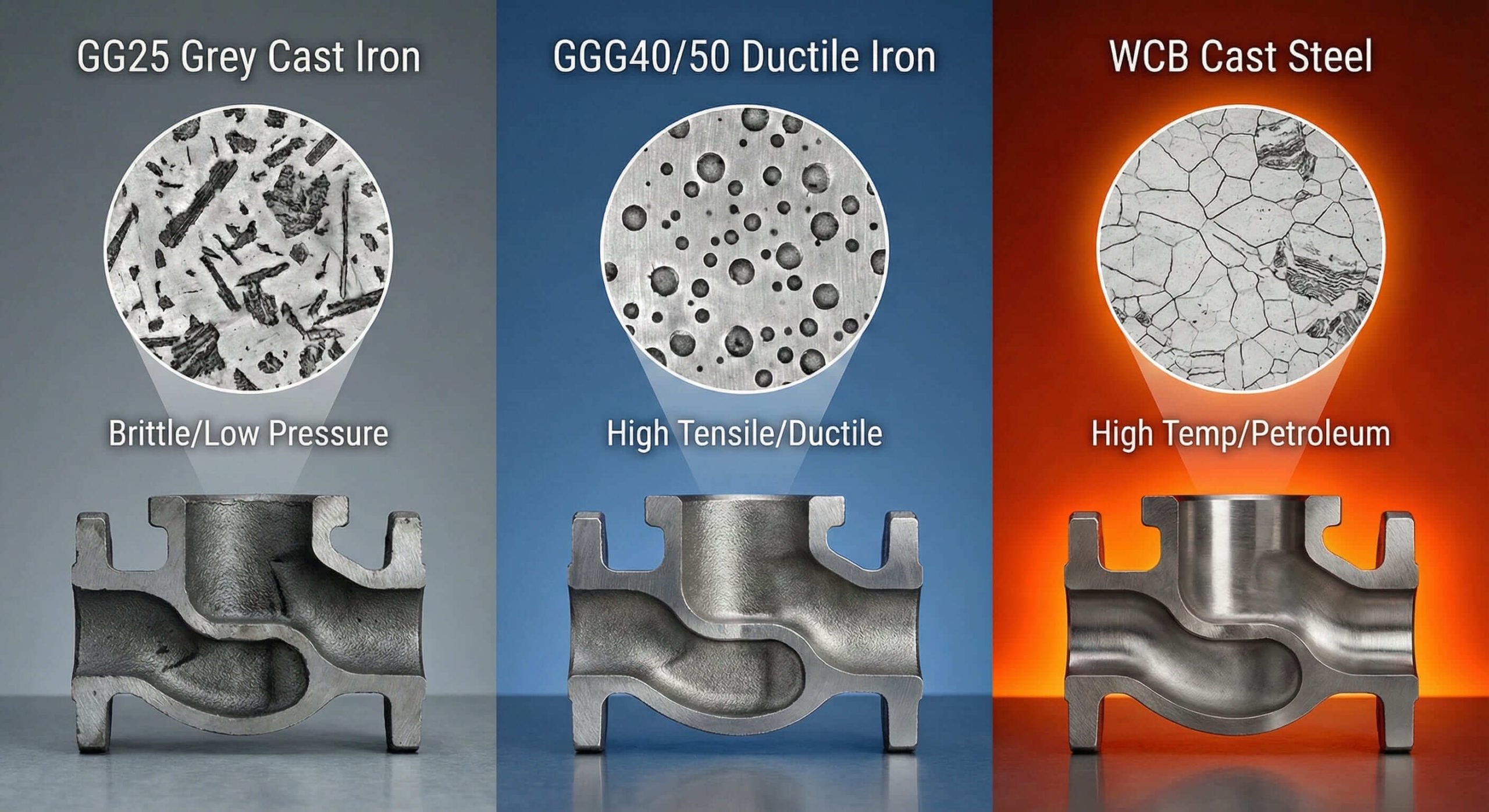

GG25 cast iron sufficient for freshwater systems below PN10. GGG40/50 ductile iron provides higher tensile strength for PN16/25 applications. WCB carbon steel body required for steam or petroleum service above 120°C.

Offshore platforms and desalination plants require CF8M (316 stainless steel) bodies to withstand chloride pitting. Food-grade systems mandate CF8 (304 stainless) with electropolished surfaces. Severe corrosion environments may necessitate nickel alloys.

Six controlled stages from raw casting to final inspection ensure consistent quality

Sand molding process for ductile iron bodies ensures uniform wall thickness distribution and eliminates porosity defects. Spectroscopic analysis verifies carbon content, silicon ratio, and nodular graphite structure meet EN-GJS-400 requirements before pouring. X-ray inspection on critical pressure-containing sections detects internal flaws larger than 1.5mm prior to machining.

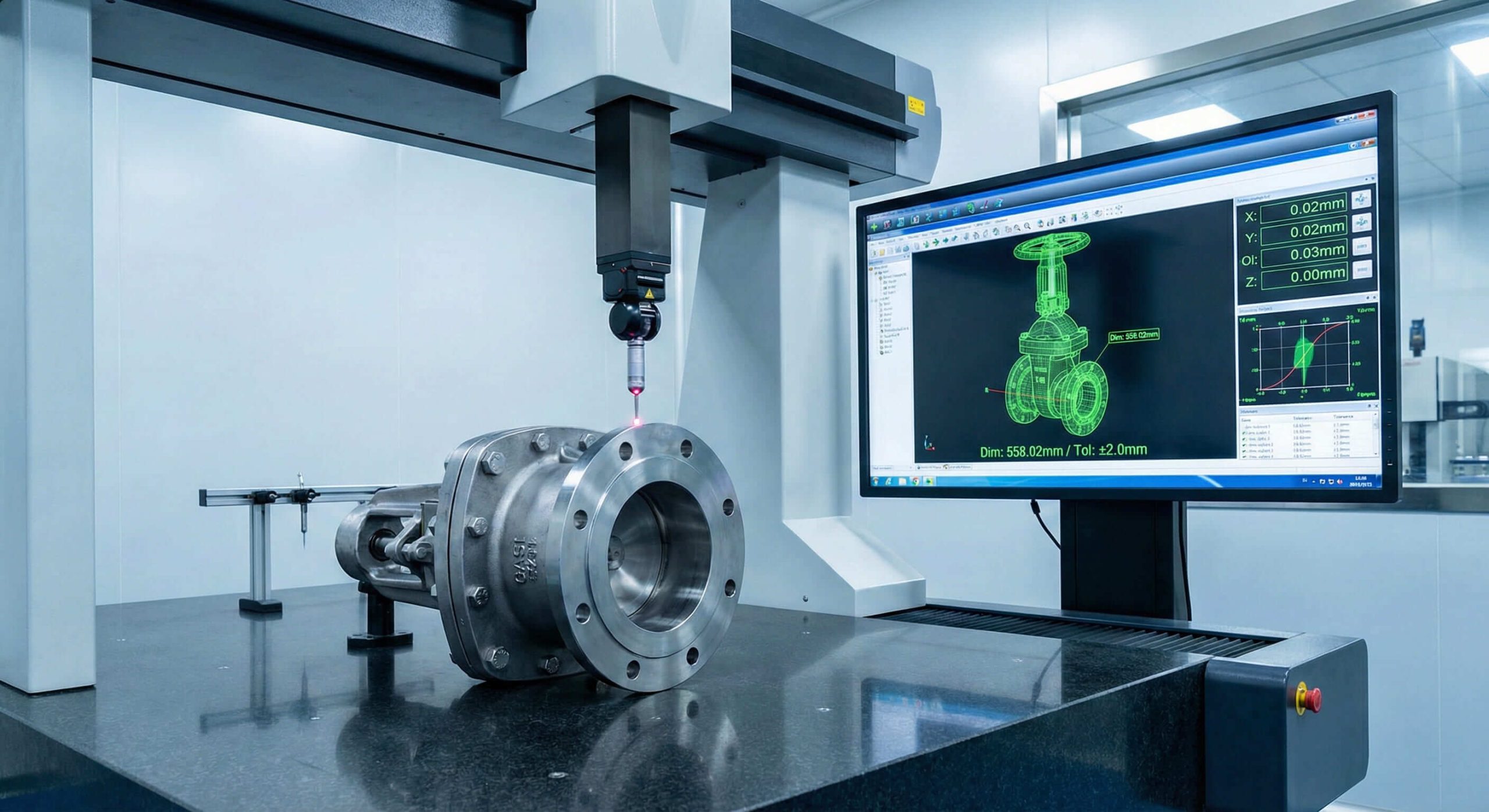

Computer-controlled lathes maintain sealing surface flatness within 0.02mm tolerance across entire seat contact area. Thread milling operations produce ACME stem threads with dimensional accuracy per ISO 2904 Class 7H/7e, ensuring smooth operation over 50,000 cycles. Flange face machining achieves Ra 3.2 surface finish to prevent gasket embedding and maintain leak-tight bolted connections.

Clean room environment prevents contamination during resilient seat vulcanization process, which bonds EPDM compound to body at controlled temperature and pressure cycles. Torque wrenches calibrated per ISO 6789 Class A ensure bonnet bolts reach specified preload without overstressing threads. Gate-to-seat alignment verified using feeler gauges to confirm uniform contact pressure across full circumference.

Grit blasting to Sa 2.5 cleanliness standard removes mill scale and creates anchor pattern for coating adhesion. Fusion-bonded epoxy powder coating applied electrostatically achieves 250-300 micron dry film thickness, providing ISO 12944 C5-M corrosion protection rating for 15+ year service life. Internal surfaces receive NSF-61 certified epoxy coating when specified for potable water contact.

Shell test conducted at 1.5× nominal pressure rating for minimum 5 minutes while inspecting all pressure-containing joints for leakage. Seat closure test performed at 1.1× PN for metal seats, 1.0× PN for resilient seats with zero visible leakage meeting EN 12266-1 Rate A criteria. Third-party witnessed testing available upon request with certified test reports traceable to individual valve serial numbers.

Protective caps installed on all port openings prevent contamination during transportation and storage. Valves secured in wooden crates with internal bracing to prevent movement damage during ocean freight or truck transport. Documentation package includes material certificates per EN 10204 3.1, dimensional inspection reports, pressure test records, and operation & maintenance manuals in customer-specified language.

Mandatory inspection protocols verify performance before shipment

Shell test at 1.5× PN for 5 minutes minimum, seat test at 1.1× PN (metal) or 1.0× PN (resilient) for 2 minutes with valve in closed position. Test medium is clean water with temperature between 5-40°C, pressurized using calibrated pneumatic intensifier pumps.

Zero visible leakage from shell (Rate A per EN 12266-1), seat closure leakage not exceeding 0.005 L/min per inch of nominal diameter for resilient seats, absolute zero leakage for metal seats in critical service applications.

CMM measurement of face-to-face dimensions per EN 558-1 or ASME B16.10 with ±2mm tolerance. Flange drilling pattern verification using precision pin gauges to confirm PCD, bolt hole diameter, and raised face dimensions match drawing specifications.

All critical dimensions within drawing tolerances. Flange face flatness not exceeding 0.05mm across any 25mm span. Concentricity between flange bore and body bore within 0.5mm to prevent gasket crushing during installation.

PMI (Positive Material Identification) analysis using handheld XRF spectrometer on body, bonnet, gate, and stem to verify alloy composition matches material certificates. Hardness testing on sealing surfaces confirms heat treatment effectiveness and wear resistance properties.

Chemical composition within limits of ASTM A216 WCB, ASTM A351 CF8M, or EN-GJS-400 standards as specified. Brinell hardness values between HB 150-220 for ductile iron bodies, HB 180-240 for carbon steel, maintaining adequate ductility.

Electromagnetic induction gauge measurements at minimum 5 points per square meter of coated surface, including critical areas prone to thin coverage such as threaded connections and weld seams. Holiday detection at 3kV DC voltage identifies coating discontinuities.

Minimum 250 microns DFT (dry film thickness) for fusion-bonded epoxy coatings in C5-M corrosion environments. No coating holidays larger than 2mm diameter. Adhesion strength minimum 10 MPa when tested per ISO 4624 pull-off method.

Full stroke cycling from closed to open and back 20 times minimum while measuring operating torque at 25%, 50%, 75%, and 100% travel positions. Stem packing adjusted to achieve fugitive emission levels below 100 ppm when tested per ISO 15848 protocol.

Operating torque values within calculated range based on valve size and pressure rating. No binding, galling, or abnormal resistance throughout stroke. Handwheel rotation force not exceeding 250N rim pull for manual operation per EN 12570.

Quality assurance team verifies material certificates trace to original mill test reports, pressure test records contain witnessed signatures and serial number correlation, dimensional inspection reports include calibration dates of measurement equipment used.

Complete documentation package includes: EN 10204 3.1 material certificates, hydrostatic test certificates, dimensional inspection reports, coating records, and traceability matrix linking serial numbers to all test documents.

International approvals ensuring product acceptance across global markets

Full compliance with EU Pressure Equipment Directive (Module H). Certified for high-pressure industrial applications and safety.

License No. 6D-1438. Designed and manufactured in strict accordance with API 600 & API 6D standards for oil & gas pipelines.

Certified for use in UK potable water supply systems. Ensures material safety and compliance for drinking water projects.

Type approved for marine vessels and offshore platforms. Verified for structural integrity and reliability in harsh sea environments.

Fire safe design tested to API 607 / ISO 10497 standards. Witnessed and verified by Bureau Veritas.

Quality management system certified by LRQA. Guaranteeing consistent manufacturing excellence and complete material traceability.

Real applications demonstrating our capability to solve complex technical challenges

Existing knife gate valves failing after 18 months due to seal degradation in contact with chlorinated effluent.

Specified chlorine-resistant EPDM compound with extended vulcanization cycle, increased shore hardness from 65A to 75A for better abrasion resistance.

42 valves operating for 4+ years with zero seal replacements, client extended contract for Phase II expansion with 60 additional units.

Seawater intake system required corrosion-resistant valves with 25-year design life in high-salinity environment at 45°C ambient temperature.

Full SS316 construction with super duplex steel (2507) stem, HNBR seat material tested to 5000 ppm chloride exposure, internal epoxy coating.

28 valves commissioned in 2018, annual inspection reports show zero pitting corrosion, client specified RUITO for three subsequent projects.

Abrasive slurry (40% solids by weight) eroding standard valve seats, causing closure failure and production downtime every 6 months.

Stellite No.12 hardfacing on gate and seat rings (HRC 52-58 hardness), increased seat contact width from 4mm to 8mm to distribute load.

18 valves operating for 3+ years without seat refurbishment, client calculated $2.3M savings from eliminated unplanned maintenance shutdowns.

API 600 compliance mandatory, required full traceability documentation, 6-week delivery deadline for scheduled turnaround maintenance window.

Mobilized dedicated production line, arranged third-party API 600 witnessing inspection, air-freighted valves to meet critical path schedule.

32 valves delivered in 38 days with complete API monograms and MTRs, client avoided $500K penalty for turnaround delay.

Factual comparison based on verifiable performance metrics and client feedback

Transparent lead times with realistic constraints clearly stated

Common configurations in DN50-DN300, PN10/PN16 ratings with resilient seats available for immediate dispatch from warehouse inventory.

Limited to standard DIN/EN flange drilling patterns, GGG40 bodies with EPDM seats

Priority manufacturing slot for sizes DN25-DN600 when specifications match existing tooling and material is available in raw material inventory.

Requires confirmed technical drawings and PO within 24 hours of quotation acceptance

Standard lead time for non-stock configurations including special materials, large diameters DN800+, API 600 compliance, or third-party inspection requirements.

Timeline starts after drawing approval and material procurement

Flexible manufacturing partnerships for valve distributors and engineering companies

Manufacture valves to your existing designs and specifications, apply your brand nameplate and logo, package in your branded cartons with custom documentation format.

Established valve distributors with existing product catalogs, companies requiring consistent supply under their brand name, minimum order typically 50-100 units per production run.

Engineering team designs valve solution based on your application requirements, you receive exclusive rights to resulting design within your market territory, we handle manufacturing to finalized specifications.

Companies entering new market segments, system integrators needing application-specific valves, projects requiring unique configurations not available from standard catalogs.

Produce valves to customer-provided detailed engineering drawings, maintain dimensional accuracy per specified tolerances, source special materials or components as drawing requires.

EPC contractors with project-specific designs, end users replacing obsolete equipment requiring dimensional interchangeability, engineering firms with proprietary valve designs.

Invest in dedicated casting patterns and tooling for your exclusive use, lock in specific design features and dimensional requirements, amortize tooling cost across committed production volumes.

High-volume buyers committing to multi-year contracts, companies requiring proprietary design protection, projects justifying tooling investment through total order quantity.

Transparent five-step process from initial inquiry to order fulfillment

Direct answers to common procurement and technical inquiries

Engineering team responds to qualified inquiries within 24 hours

Our application engineers review your requirements and provide technical recommendations tailored to your specific operating conditions.