Precision Globe Valves for Critical Flow Control

When pressure drop matters and throttling accuracy determines system performance, Globe Valves deliver repeatable control across temperature extremes and demanding industrial conditions.

Engineering Challenges That Demand Globe Valve Solutions

Inaccurate Flow Throttling

Ball valves oscillate between too open and too closed during modulation attempts

Cavitation Damage

Butterfly valves create velocity spikes that erode seats within 6 months

Thermal Expansion Failures

Gate valves seize when temperatures fluctuate beyond 150°C differential

Pressure Drop Instability

Inconsistent pressure curves make PID tuning impossible in automated systems

Designed for applications where control precision outweighs valve cost

Globe Valve: Linear Motion Control for Precise Flow Regulation

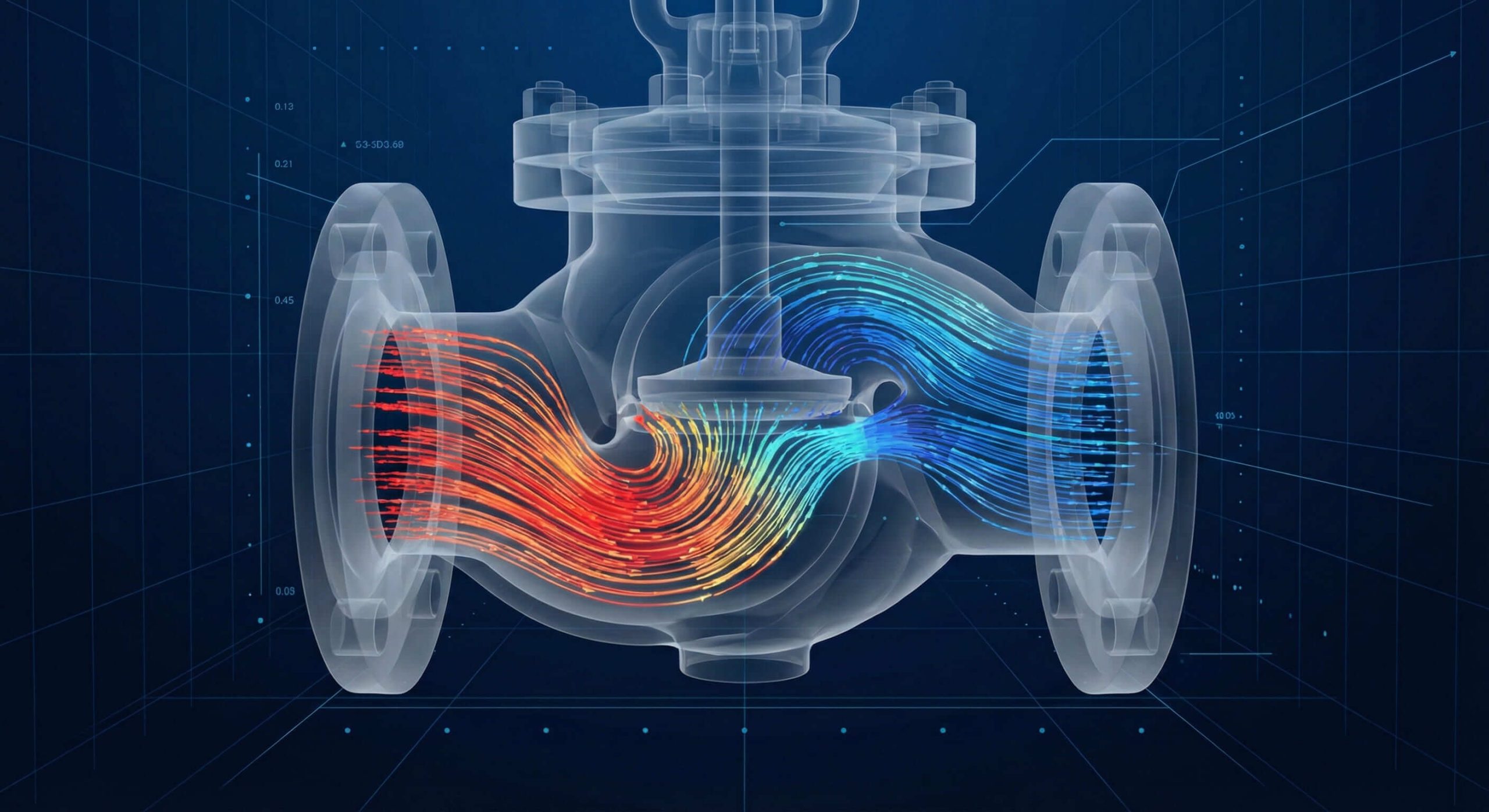

Operating Principle

A movable disc travels perpendicular to the seat, creating a variable orifice. As the stem lifts, flow area increases proportionally. The S-shaped body redirects flow twice, dissipating velocity and converting kinetic energy into controlled pressure drop.

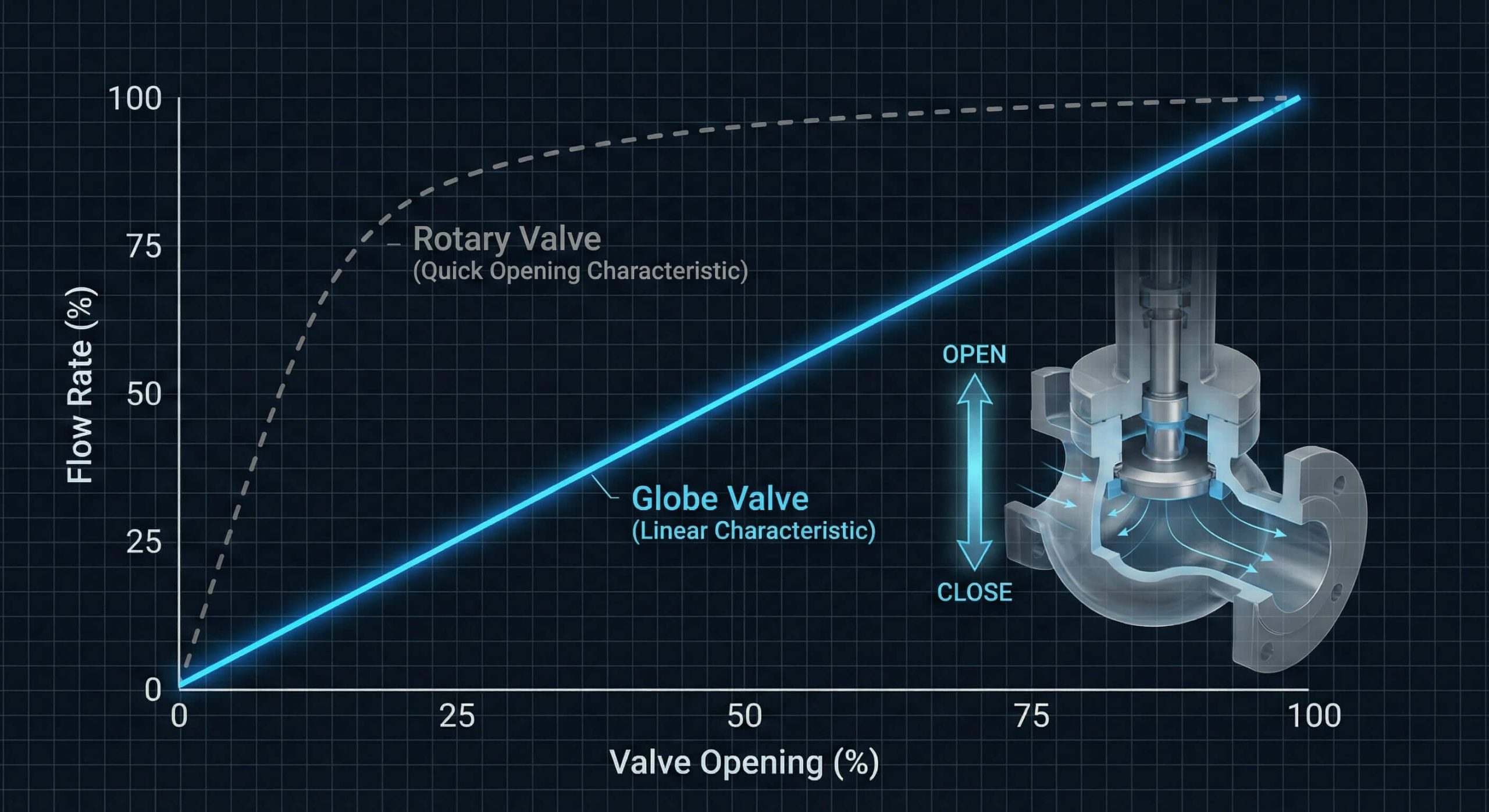

Why Globe Valves Excel

Disc position directly correlates to flow rate with predictable linearity. Unlike rotary valves where 10° of rotation might change flow by 60%, Globe Valves deliver consistent incremental control. Guided disc movement prevents chattering under partial loads.

Valve Type Comparison

Select Globe Valves when throttling frequency exceeds 20 cycles/hour or when CV variation must stay within ±3% across the operating range.

Need help determining if Globe Valves fit your system?

Where Globe Valves Are Non-Negotiable

Mission-critical applications where throttling precision determines operational success

Boiler Feedwater Control

Linear flow response prevents thermal shock during load changes

HVAC Coil Bypass

Maintains differential pressure balance across parallel cooling paths

Chemical Dosing Loops

Repeatable positioning ensures additive concentration stays within ±2%

Condensate Recovery

Prevents backpressure fluctuations that cause steam trap failures

Pump Recirculation

Gradual opening prevents water hammer during minimum flow protection

Hydraulic Test Benches

Fine-tuning capability achieves exact test pressures without overshoot

Match your process conditions to the correct valve architecture

5 Critical Selection Parameters Engineers Must Verify

Flow Coefficient (Cv)

Verify Cv at 70% travel matches your normal operating condition, not just wide-open Cv

Pressure Recovery (FL)

Globe valves have FL of 0.85-0.9; calculate choked flow limits before finalizing sizing

Seat Leakage Class

Specify ANSI Class IV (0.01% Cv) minimum for control service; Class VI for critical isolation

Packing vs. Cycle Frequency

PTFE packing suits <20 cycles/hour; graphite required for frequent modulation or 250°C+

Flow Direction

Flow-to-open reduces actuator thrust but increases seat wear; flow-to-close preferred for control

Get engineering support to validate your selections against actual operating conditions

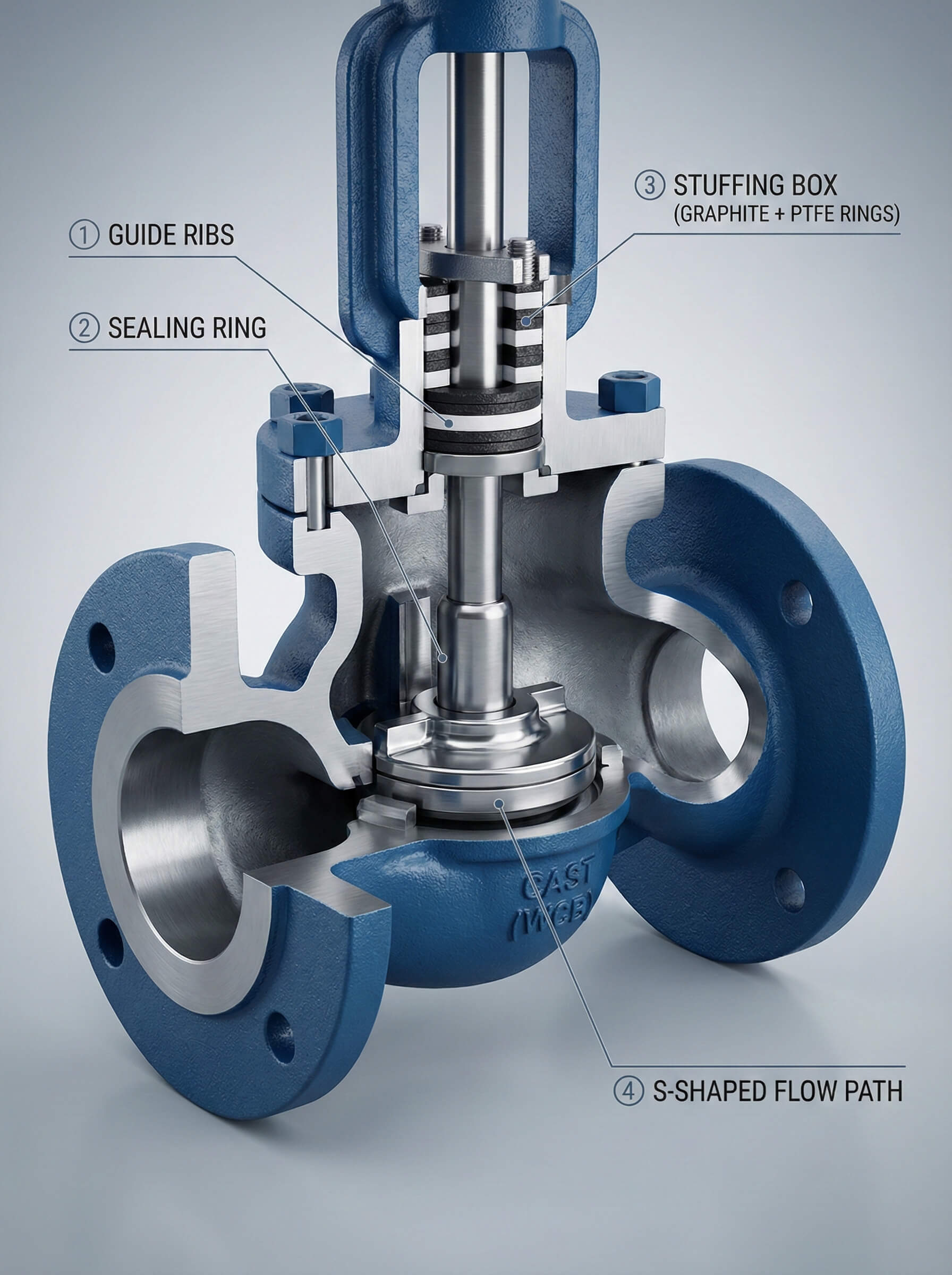

Engineered Structure for Extended Service Life

Disc Guided Design

Top and bottom guides prevent lateral movement during throttling

Hard / Soft Seat Options

Metal-to-metal for high temp; PTFE/RPTFE for bubble-tight shutoff

Low-Leakage Packing

Multi-layer graphite or PTFE reduces fugitive emissions to <50 ppm

Optimized Flow Path

S-curve geometry dissipates energy without creating turbulence zones

Request detailed assembly drawings with material specifications

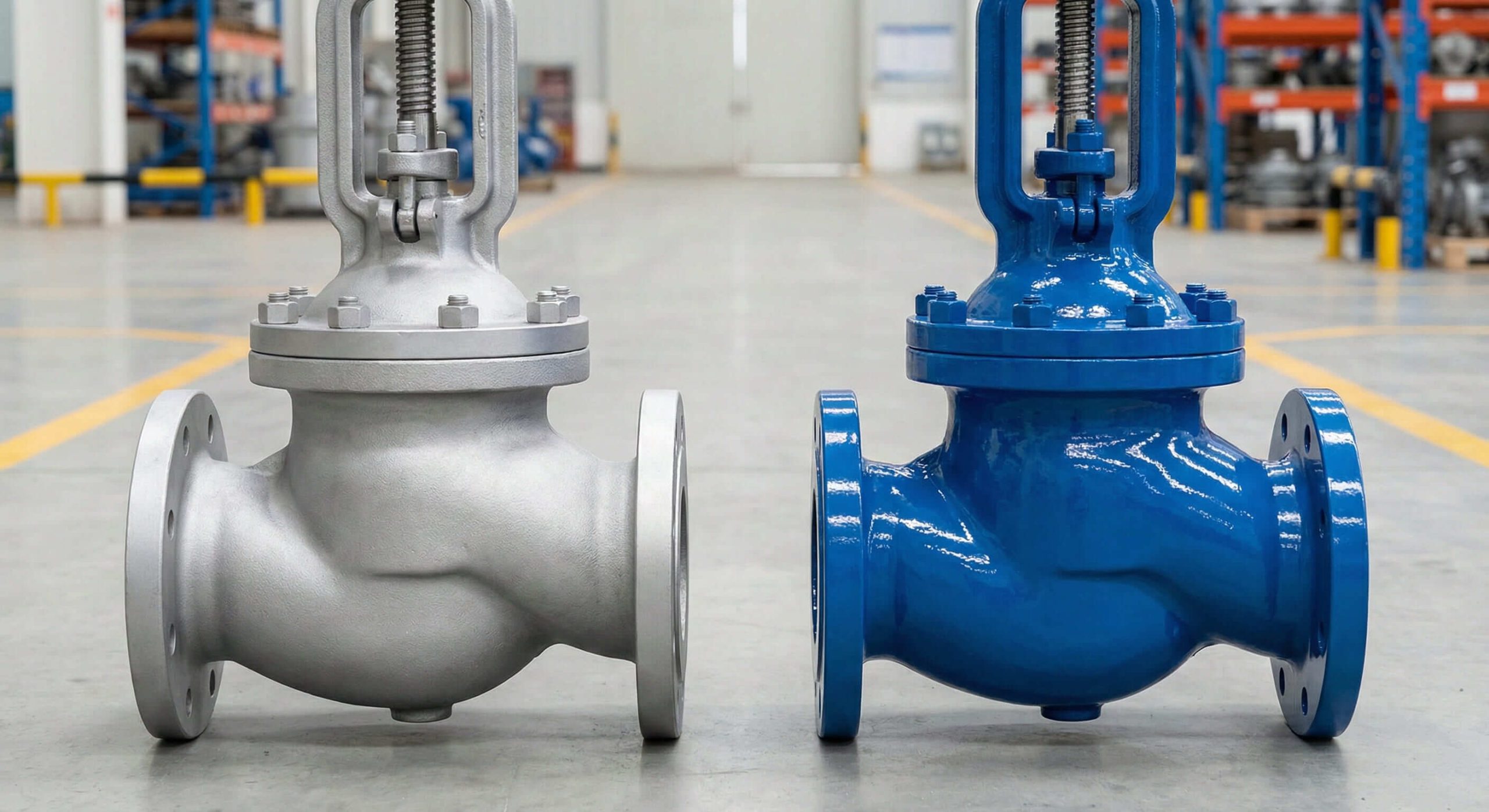

Material Selection Determines Service Life

Match metallurgy to actual operating conditions, not just nameplate ratings

Ambient Water Systems

Carbon steel provides cost efficiency while 13Cr resists erosion from suspended solids

High Temperature Systems

Chrome-moly alloy maintains strength at elevated temps; Stellite prevents galling

Corrosive Media

Molybdenum in 316 resists chloride pitting; RPTFE handles chemical attack

High-Frequency Modulation

Precipitation-hardened stainless withstands repetitive impact without work hardening

Unsure which material combination suits your process chemistry?

Compliance Built Into Manufacturing, Not Added Afterwards

Design Standards

ANSI B16.34

Pressure-temperature ratings for North American markets

DIN 3356

European dimensional and material requirements

EN 13709

CE-marked valves for EU industrial installations

API 600 / 602

Oil & gas industry bolted/threaded bonnet specifications

Third-Party Certifications

CE Marking

Pressure Equipment Directive compliance for EU projects

ISO 9001:2015

Quality management system certification for consistent output

WRAS Approved

UK drinking water contact materials verification

DNV Type Approval

Marine and offshore classification society acceptance

Need certificates for customs clearance or project approval?

Manufacturing Transparency: Every Step Documented

Casting

Ultrasonic testing for internal defects before machining

Machining

CNC tolerance verification at seat and bonnet interfaces

Assembly

Torque-controlled bolting per assembly specification sheets

Pressure Test

Shell test at 1.5× rated pressure, seat test at 1.1× for 60 sec

Painting

Epoxy coating after sandblasting to Sa 2.5 surface profile

Packing

Individual plywood crates with desiccant and tamper-evident seals

100% Pressure Tested

No sampling—every valve tested to standard

Traceable Batch ID

Heat numbers linked to mill certificates

In-House QC Team

Independent inspection at each process gate

Want to see our factory processes in detail?

How We Guarantee Batch-to-Batch Consistency

Defect Rate Tracking

Real-time SPC monitoring keeps rejection rate below 0.8% across all product lines

Batch Archive System

Digital records retained for 10 years with material certs, test reports, and dimensional data

Fixed Supply Chain

Sole-source agreements with steel mills prevent material variation between production runs

Dedicated QC Team

8 full-time inspectors independent from production, each certified to Level II NDT standards

Review our quality control procedures and inspection points

Flexible Delivery Engineered for Real Project Timelines

Inquiry & Check

Technical review within 24 hours

Engineering Review

Sizing & drawing approval

Production

Lead time: 15-25 days

Testing

Pressure test & reports

Partial Delivery

Split shipments available

Final Delivery

Complete documentation

Coordinate delivery schedule with your construction milestones

Proven Performance in Real Industrial Applications

Validated solutions from actual installations, not theoretical claims

Steam Pressure Reduction Station

Refinery desuperheater application in Malaysia

Challenge

Existing ball valves couldn't maintain ±0.2 bar stability during load swings; steam temperature varied 15°C

Solution Provided

DN80 PN40 Globe Valve with linear trim, WC9 body, Stellite seat for 480°C service

Measured Result

Pressure stability improved to ±0.05 bar; 18 months zero maintenance record

District Cooling Balancing Loop

Commercial complex secondary pump system in Dubai

Challenge

Butterfly valves created 30% flow imbalance between zones; remote floors over-cooled while lobbies under-served

Solution Provided

DN150 PN16 Globe Valves with characterized disc; CF8M body for glycol compatibility

Measured Result

Flow distribution variance reduced to <5%; energy consumption dropped 12% from reduced pump head

Chemical Dosing Control

Municipal water treatment plant in Thailand

Challenge

Chlorine dosing overshoots caused non-compliance with WHO limits; manual adjustment required every 2 hours

Solution Provided

DN25 PN16 Globe Valve with RPTFE seat; equal percentage trim for low-flow accuracy

Measured Result

Chlorine residual held within 0.5-0.8 ppm automatically; operator intervention eliminated

Share your application challenge for a customized engineering analysis

Why Engineering Teams Partner With RUITO

Not a Trading Company

We manufacture every valve in our own foundry—no middleman markup, no supply chain blackbox

Not Price-Only Supplier

Budget matters, but we optimize total cost of ownership through material selection and design longevity

Not Catalog-Only Support

Standard products available, but 40% of orders involve engineering modifications for specific conditions

Engineering-First Mindset

Sales discussions start with system parameters, not just order quantities—because correct sizing prevents callbacks

Experience the difference of working with a manufacturer who understands valve applications

Complete Technical Documentation Ready for Approval

All documents ready for approval—no waiting, no excuses

GA Drawing (General Arrangement)

Dimensional verification and installation planning

Material Certificate (EN 10204 3.1)

Customs clearance and quality audits

Pressure Test Report

Project commissioning approval and FAT evidence

O&M Manual (Operation & Maintenance)

Handover documentation and maintenance planning

Datasheet (English)

Technical submittal for engineering review

Request full documentation package in editable format

Engineering Support Process: From Inquiry to Delivery

Send Parameters

Provide flow rate, pressure, temperature, media type, and pipe size

Engineer Review

Calculate Cv, check velocity limits, verify pressure drop and cavitation risk

Proposal

Recommend valve size, trim type, materials, and actuation if needed

Drawing Approval

Review GA drawing and confirm flange rating, connection type

Production

Manufacturing with progress photos sent at casting, machining, and testing stages

Delivery

Shipment with complete documentation package and packing list

Start your project with a free technical consultation

Frequently Asked Questions

What is your Minimum Order Quantity (MOQ)?

What is the standard delivery lead time?

Do you provide pressure test reports?

Can you produce valves with special materials?

Do you offer OEM or private labeling?

What certifications do you hold?

How do you handle spare parts?

Do you provide installation manuals?

What is your warranty period?

Can you help with valve sizing?

What NDT testing methods are available?

What are your payment and shipping terms?

Still have questions about your specific project requirements?

Ready to Solve Your Flow Control Challenge?

Our engineering team is ready to analyze your system parameters and provide a guaranteed solution within 24 hours. Stop settling for catalog replacements—get a valve engineered for your process.