Have you ever faced inefficient system performance, skyrocketing energy costs, or even equipment damage due to an incorrectly sized butterfly valve? These issues often lead to frustrating budget overruns, unexpected operational downtime, and a system you can’t rely on. Mastering the valve coefficient (Cv) is the key to selecting the right butterfly valve, ensuring you achieve optimal flow control and prevent these costly errors from happening.

Unpacking Cv and pressure drop across butterfly valve

Understanding the relationship between the valve coefficient (Cv), flow rate, and pressure drop is the first step toward designing an efficient fluid system. These core concepts dictate how a valve will perform once it’s installed in your pipeline. Let’s explore what Cv means and how it sets the stage for system pressure calculations.

What is the valve coefficient (Cv)?

Let’s break it down: the valve coefficient, or Cv, is a standardized measure of a valve’s capacity to pass fluid. It quantifies how many U.S. Gallons Per Minute (GPM) of water at 60°F will flow through a fully open valve with a pressure drop of one pound per square inch (psi). Think of it as a rating for how “open” a valve’s internal pathway is.

- A higher Cv value indicates a greater flow capacity.

- A lower Cv value signifies more restriction to flow.

How does Cv directly relate to flow rate?

What’s the real story? For a given pressure drop, a valve with a higher Cv will allow a greater flow rate, while a valve with a lower Cv will permit less flow. This direct relationship is fundamental; if you double the Cv, you can expect to double the flow, assuming the pressure drop remains constant. This is why Cv is a critical factor in valve selection.

- Flow rate is directly proportional to the Cv.

- Manufacturers provide Cv charts for different valve opening percentages.

Initial pressure drop considerations

Here’s the deal: every component in a piping system, including valves, creates some resistance to flow, which results in a pressure drop. The butterfly valve’s contribution to this pressure loss is directly tied to its Cv and the flow rate passing through it. Properly accounting for this drop is crucial for sizing pumps correctly and ensuring the system operates as designed.

- Pressure drop is the loss of pressure as fluid moves through the valve.

- It is a necessary trade-off for controlling the flow rate.

| Concept | Description | Implication for Flow |

|---|---|---|

| Valve Coefficient (Cv) | A measure of a valve’s flow capacity at 1 psi pressure drop. | Higher Cv allows more flow. |

| Flow Rate (Q) | The volume of fluid passing through the valve per unit of time. | Directly influenced by Cv and pressure drop. |

| Pressure Drop (ΔP) | The pressure loss incurred as fluid passes through the valve. | Inversely related to Cv for a given flow. |

Key Takeaway: By understanding that Cv is a direct measure of flow capacity, you can begin to see how it forms the foundation for all flow and pressure drop calculations in your system.

Calculating pressure drop across butterfly valve

Once you grasp the concepts, you can move on to the practical calculations that govern your system’s performance. Using established formulas, you can accurately predict the flow rate or the pressure drop across a specific butterfly valve. This empowers you to make data-driven decisions during the design and troubleshooting phases.

The fundamental formula for flow rate

You might be wondering: how do these variables fit together in a formula? The standard equation for liquid flow through a valve is Q = Cv * √(ΔP / SG), where Q is the flow rate, ΔP is the pressure drop, and SG is the specific gravity of the fluid. This formula is the cornerstone of valve sizing and system analysis.

- Q: Flow Rate in U.S. Gallons per Minute (GPM).

- Cv: Valve Coefficient (from manufacturer data).

- ΔP: Pressure Drop in pounds per square inch (psi).

- SG: Specific Gravity of the fluid (water = 1.0).

How to use Cv to find pressure drop

This is where it gets interesting: you can easily rearrange the flow formula to solve for the pressure drop. The new formula becomes ΔP = SG * (Q / Cv)². This is incredibly useful when you know your required flow rate and need to determine how much pressure the valve will consume.

- This calculation helps ensure your pump is sized to overcome the valve’s resistance.

- It is essential for verifying that the system pressure remains within acceptable limits.

What data do you need for this calc?

But what does this mean for you? To perform an accurate calculation, you need a few key pieces of information before you begin. Without these inputs, your results will be nothing more than a guess, potentially leading to incorrect valve selection.

- Target Flow Rate (Q): The desired rate of flow for your process.

- Fluid’s Specific Gravity (SG): A measure of the fluid’s density relative to water.

- Valve Cv: The specific Cv value for your chosen valve at the intended opening angle.

| Variable | Symbol | How to Obtain |

|---|---|---|

| Flow Rate | Q | Determined by system process requirements. |

| Valve Coefficient | Cv | Found in the valve manufacturer’s technical datasheets. |

| Specific Gravity | SG | Available in engineering handbooks or material property data. |

| Pressure Drop | ΔP | Calculated using the formula: ΔP = SG * (Q / Cv)². |

Key Takeaway: With these formulas and the right data, you now have the power to precisely calculate the pressure drop across any butterfly valve, turning guesswork into engineering certainty.

Key factors in pressure drop across butterfly valve

The calculated pressure drop is not just a number; it’s influenced by several dynamic factors in a real-world system. The valve’s opening position, the properties of the fluid, and even the layout of your piping can alter the actual pressure loss. Understanding these factors allows for a more nuanced and accurate system design.

How does valve opening angle matter?

Let’s break it down: a butterfly valve’s Cv is not a single value but changes dramatically with the disc’s opening angle. A valve that is only 30% open has a much lower Cv—and thus creates a much higher pressure drop—than a valve that is 90% open. This is the very principle that allows butterfly valves to throttle or control flow.

- Cv is lowest near the closed position and highest near the fully open position.

- Manufacturers provide Cv curves that plot Cv against the opening percentage.

The role of fluid properties (viscosity)

What’s the real story? While the standard Cv formula works perfectly for water-like fluids, highly viscous liquids like oils or slurries create more internal friction. This increased friction leads to a higher-than-calculated pressure drop. For such applications, a viscosity correction factor must be applied to the calculation.

- Viscosity is a measure of a fluid’s resistance to flow.

- Failing to account for high viscosity can lead to undersized pumps.

Does upstream piping affect pressure drop?

Here’s the deal: the flow profile entering the valve can significantly impact its performance and the resulting pressure drop. Elbows, reducers, or other fittings placed too close to the valve’s inlet can cause turbulence, which disrupts the smooth flow of fluid and increases the pressure loss across the valve.

- Install valves with sufficient straight pipe runs upstream and downstream.

- A common rule of thumb is 5-10 pipe diameters of straight pipe before the valve.

| Influencing Factor | Effect on Pressure Drop | Best Practice |

|---|---|---|

| Valve Opening Angle | Decreasing the angle increases pressure drop. | Operate within the 30-80% open range for stable throttling. |

| Fluid Viscosity | Higher viscosity increases pressure drop. | Apply viscosity correction factors for accurate calculations. |

| Upstream Piping | Close-coupled fittings create turbulence, increasing pressure drop. | Ensure adequate straight pipe runs before and after the valve. |

Key Takeaway: By considering the valve’s opening, fluid properties, and piping layout, you can refine your pressure drop calculations for greater real-world accuracy and avoid unexpected performance issues.

The risks of high pressure drop across butterfly valve

An excessive pressure drop across a butterfly valve is not just a sign of inefficiency; it’s a warning of potentially destructive forces at play. High pressure drops can lead to cavitation, flashing, and severe mechanical damage. Recognizing these risks is crucial for protecting your equipment and ensuring system longevity.

What are cavitation and flashing?

This is where it gets interesting: when a high pressure drop causes the local pressure inside the valve to fall below the fluid’s vapor pressure, bubbles form (cavitation). If these bubbles collapse back into liquid downstream, they create intense micro-jets and shockwaves that can erode the valve disc and body. If the pressure stays low and the bubbles persist, it’s called flashing, which is also highly erosive.

- Cavitation: Bubble formation and violent collapse, causing pitting and damage.

- Flashing: Bubbles form and remain, creating a two-phase flow that acts like an abrasive jet.

The link to system energy inefficiency

You might be wondering: how does this affect my energy bill? A high pressure drop is essentially a measure of energy being wasted to overcome unnecessary resistance. Your pump must work harder and consume more electricity to force the fluid through the restrictive valve, leading directly to higher operational costs.

- Pressure drop is a form of energy loss.

- Minimizing unnecessary pressure drop is key to an energy-efficient system.

How it causes noise and vibration damage

But what does this mean for you? The violent collapse of cavitation bubbles is not silent; it generates significant noise and high-frequency vibration. This vibration can travel through the pipeline, potentially damaging nearby instruments, loosening fittings, and causing premature failure of the valve actuator and seals.

- Loud, rumbling, or “gravel-like” noise is a classic symptom of cavitation.

- Excessive vibration can lead to fatigue failure in mechanical components.

| Risk | Description | Symptom |

|---|---|---|

| Cavitation/Flashing | Formation and collapse of vapor bubbles due to low pressure. | Pitting, erosion, and material loss on valve internals. |

| Energy Inefficiency | Wasted pump energy used to overcome excessive resistance. | High electricity bills and overworked pumps. |

| Noise & Vibration | High-energy shockwaves from bubble collapse. | Loud noise, pipeline vibration, and potential damage to adjacent equipment. |

Key Takeaway: Recognizing that a high pressure drop is a precursor to damaging phenomena like cavitation allows you to proactively design systems that operate within safe, reliable, and efficient parameters.

How to manage pressure drop across butterfly valve

Effectively managing pressure drop is an active process that begins with smart valve selection and extends to system control strategies. By choosing the right size and type of valve and implementing fine-tuning controls, you can balance flow requirements with energy efficiency. This proactive approach ensures your system performs optimally from day one.

How to select the optimal valve size?

Let’s break it down: selecting the “optimal” size is a balancing act. An oversized valve will have a low pressure drop but will offer poor throttling control, as small movements will cause large changes in flow. An undersized valve provides good control but at the cost of a high pressure drop and potential for cavitation.

- Aim for a valve that operates between 30% and 80% open for most of its duty cycle.

- Never size a control valve based on the line size alone; always calculate the required Cv.

When to use a high-performance valve?

What’s the real story? Standard “resilient-seated” butterfly valves are great for on/off service, but for demanding throttling applications with high pressure drops or temperatures, a high-performance butterfly valve (HPBV) is a better choice. These valves feature a more robust design, often with a metal seat, that can better withstand erosive conditions and provide tighter shutoff.

- HPBVs are ideal for high-pressure, high-temperature, or frequent throttling applications.

- Double-offset and triple-offset designs minimize seat wear and reduce operating torque.

Can positioners help fine-tune control?

Here’s the deal: a valve positioner is a device that ensures the valve’s disc moves to the exact position dictated by the control signal, regardless of forces like pressure and friction. For applications requiring precise flow control, a positioner is essential. It translates the control system’s command into an accurate and repeatable valve opening.

- Positioners overcome hysteresis and improve the accuracy of flow control.

- They are critical in systems where precise modulation is needed to maintain a setpoint.

| Management Strategy | Best For | Benefit |

|---|---|---|

| Optimal Sizing | Throttling/Control Applications | Balances control precision with acceptable pressure drop. |

| High-Performance Valves | High-Pressure, High-Temperature, or Erosive Service | Enhanced durability, tighter sealing, and longer service life. |

| Valve Positioners | Precise Flow Modulation | Guarantees accurate and repeatable valve positioning. |

Key Takeaway: By combining proper valve sizing, selecting the right valve type for the service, and using positioners, you can actively manage pressure drop to achieve both precise control and long-term system health.

Applying pressure drop across butterfly valve data

The data you’ve gathered and the calculations you’ve performed on pressure drop are not just academic exercises. This information is a powerful tool for holistic system design, energy management, and long-term maintenance planning. Applying this knowledge transforms you from a component user into a true system architect.

Better insights for pump and system sizing

This is where it gets interesting: accurate pressure drop data for each component, including the butterfly valve, is critical for creating a system curve. This curve is then used to select a pump that can provide the required flow and head (pressure) efficiently. Without this data, you risk choosing an oversized pump that wastes energy or an undersized one that fails to meet performance goals.

- The sum of all pressure drops determines the total dynamic head the pump must overcome.

- Proper pump sizing is impossible without accurate valve pressure drop information.

For conducting energy efficiency audits

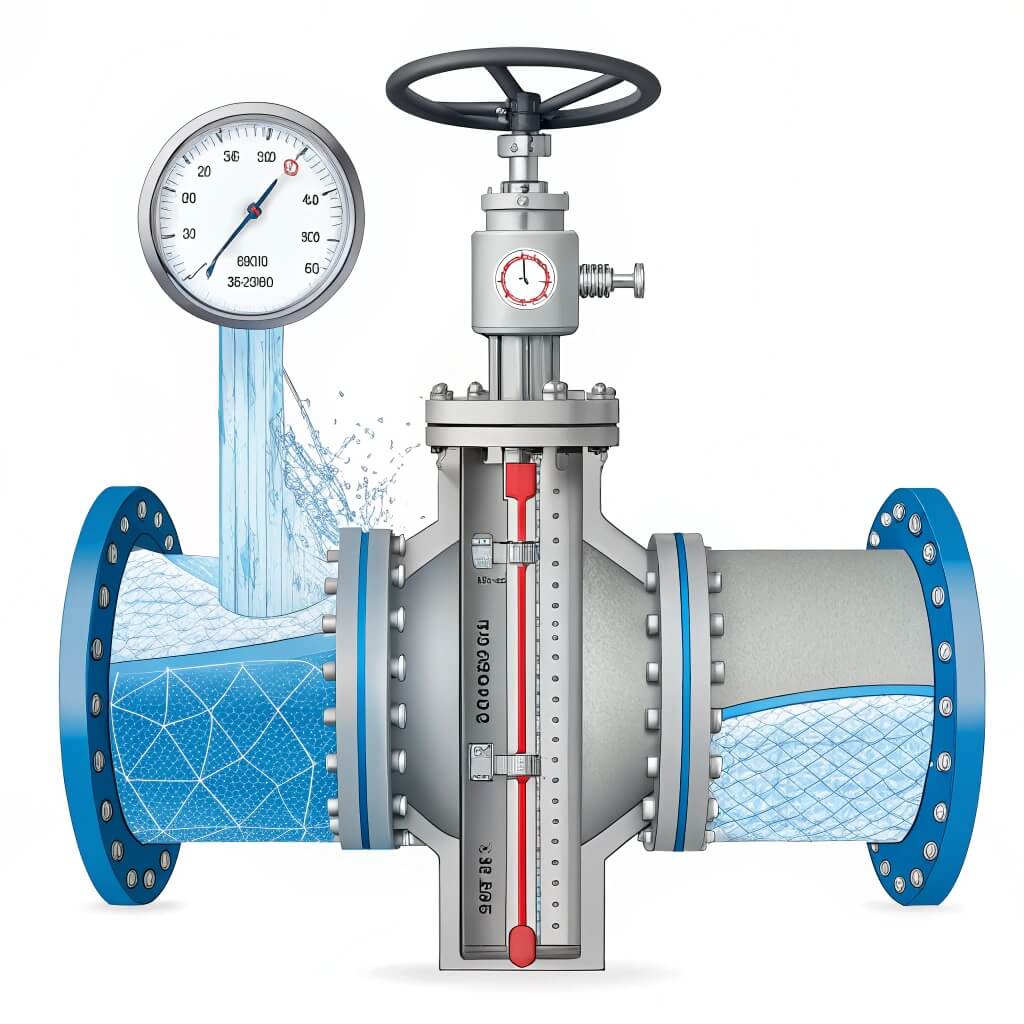

You might be wondering: how can this save money on existing systems? By measuring the actual pressure drop across valves in an operational system and comparing it to design specifications, you can identify sources of inefficiency. A higher-than-expected drop could indicate a partially clogged valve, an incorrectly specified unit, or other issues that are needlessly driving up energy consumption.

- Use differential pressure gauges to measure pressure drop in the field.

- This data provides a quantifiable basis for justifying upgrades or maintenance.

Ensuring long-term system reliability

But what does this mean for you? By designing a system that avoids high pressure drops, you inherently design out the risks of cavitation, noise, and vibration. This proactive approach leads to a system that is not only more efficient but also more reliable, with longer service intervals and fewer unexpected failures. It’s the key to minimizing downtime and ensuring operational continuity.

- Operating within recommended pressure drop limits extends the life of valves and actuators.

- A reliable system is a safe and profitable system.

| Application | How Pressure Drop Data Is Used | Outcome |

|---|---|---|

| Pump & System Sizing | To calculate the total system head loss and create an accurate system curve. | An efficiently sized pump that meets performance needs without wasting energy. |

| Energy Audits | To identify components causing excessive and wasteful energy loss. | Actionable insights for reducing operational costs. |

| Reliability Engineering | To design systems that avoid cavitation and other damaging phenomena. | Increased equipment lifespan and reduced maintenance costs. |

Key Takeaway: By applying your knowledge of pressure drop, you can make more intelligent decisions in everything from initial pump selection to long-term energy management, ultimately building more efficient and reliable systems.

Conclusion

You now have the tools to calculate Cv, understand the factors influencing pressure drop across a butterfly valve, and recognize the risks of getting it wrong. This knowledge empowers you to prevent system inefficiencies, avoid equipment damage, and design robust, reliable fluid control systems.

At our company, we provide high-performance butterfly valves engineered for precise flow control and minimal pressure drop. With international certifications (ISO 9001, CE, WRAS) and a commitment to a 24-hour technical response, our expert team is ready to help you select the perfect valve for your application, whether it’s a standard order or a custom ODM solution. We’re not just selling valves; we’re building the future of fluid control, one efficient system at a time.

Frequently Asked Questions (FAQ)

Q: How do I know if the pressure drop across my butterfly valve is too high?

A: You’ll know if you observe symptoms like excessive pump energy consumption, lower-than-expected flow rates, or loud noise and vibration from the valve. These signs indicate the valve is creating too much resistance for your system’s needs.

Q: Can I use a butterfly valve for flow throttling?

A: Yes, you can, but it requires careful consideration. Butterfly valves are most effective for throttling when opened between 30 and 80 degrees, but prolonged use near the closed position can cause disc erosion and sealing issues.

Q: What’s the best way to get an accurate Cv value for a specific valve?

A: The best way is to refer to the manufacturer’s technical datasheet. Manufacturers provide Cv values tested at various opening percentages, which is far more accurate than relying on generic estimations.

Q: Can I ignore a small, unexpected pressure drop?

A: No, it’s not recommended. Even a small, unaccounted-for pressure drop can lead to significant energy waste over time and may indicate underlying issues like partial clogging or incorrect valve installation.

Q: Does a larger valve always guarantee a lower pressure drop?

A: Not necessarily. While a larger valve generally has a higher Cv and thus lower pressure drop at full opening, an oversized valve can lead to poor control and instability, especially in throttling applications. Proper sizing is crucial.