Introduction

Are you still calculating the hidden costs of manual flow control in your facility? While manual valves have served industries for decades, they introduce variables that modern production lines simply cannot afford: inconsistent flow rates caused by human estimation, the risk of valve positioning errors during critical changeovers, and the significant physical strain placed on operators managing large-diameter pipelines. Furthermore, relying on pneumatic systems often means maintaining complex, leak-prone air compression infrastructure that drives up energy bills and maintenance hours.

These inefficiencies create a dangerous domino effect in your operations. A valve left partially open due to operator fatigue can compromise an entire batch of product, leading to waste and missed deadlines. Unplanned downtime caused by “sticking” pneumatic actuators or frozen air lines in winter disrupts your yield, while the safety risks associated with manually accessing valves in hazardous or hard-to-reach locations expose your workforce to unnecessary danger. Ask yourself: how much energy and capital are you wasting maintaining auxiliary systems for valves that lack true precision?

The solution lies in upgrading to the electric butterfly valve, the modern standard for industrial automation. This is not merely a component replacement; it is a strategic upgrade that combines the compact, high-flow efficiency of a quarter-turn butterfly mechanism with the intelligent, programmable precision of electric actuation. By transitioning to motorized control, you eliminate the variables of human error and the overhead of compressed air, securing a streamlined, automated, and safer future for your pipeline infrastructure.

1. Anatomy of Efficiency: Understanding Electric Butterfly Valve Components

To understand how these valves revolutionize flow control, you must first understand the engineering behind them. The device is not a single unit but a synergy of two distinct technologies: a rugged, high-capacity valve body and a sophisticated electromechanical actuator. This combination allows you to handle high-pressure drops and corrosive media with a compact footprint that larger gate or globe valves cannot match.

What defines the structural integrity of the body?

First, let’s look at the exterior to understand durability. The valve body, typically cast from ductile iron or stainless steel, acts as the pressure boundary and houses the internal disc. Whether you choose a Wafer style (sandwiched between flanges) or Lug style (bolted directly to flanges), the body’s material strength ensures it can withstand the mechanical stress of pipeline expansion and fluid pressure.

How does the electric actuator drive performance?

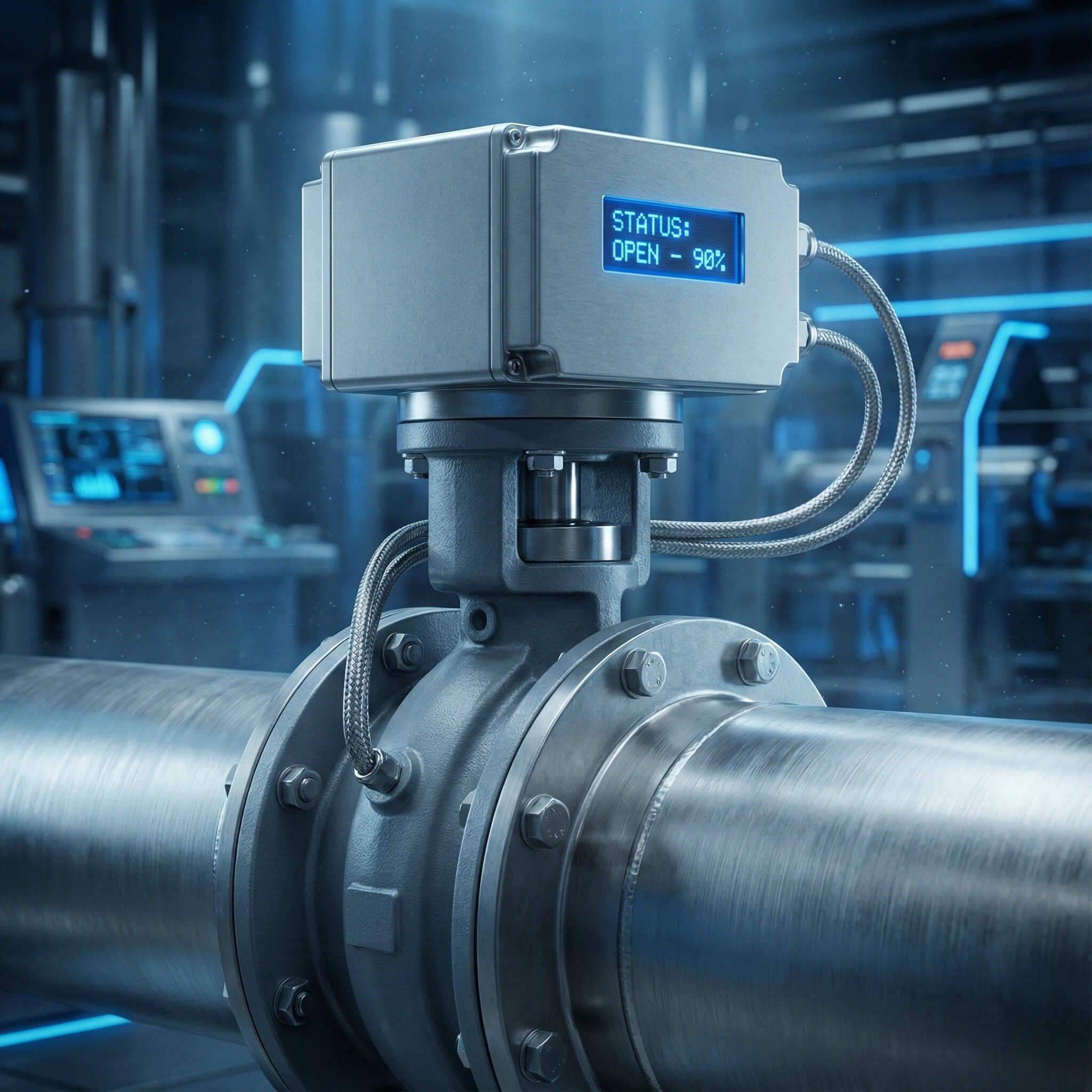

The actuator serves as the “brain and muscle” of the unit, sitting atop the valve and replacing the manual handwheel. Inside its protective housing—often rated IP67 or IP68 for weather resistance—sits an electric motor coupled with a reduction gear train that converts high-speed electrical energy into the immense low-speed torque required to turn the valve stem.

What ensures a leak-proof seal during operation?

The sealing capability relies entirely on the precision interface between the disc and the resilient seat. The seat, commonly made from EPDM for water or PTFE for chemicals, lines the internal body diameter; when the disc rotates into the closed position, it presses into this seat to create a bubble-tight shutoff that prevents downstream leakage.

Core Material Specifications:

- Valve Body: Ductile Iron (general use), Stainless Steel 304/316 (corrosive environments), PVC (chemical processing).

- Disc: Stainless Steel (standard), Nickel-plated Ductile Iron (cost-effective), Hastelloy (extreme corrosion).

- Seat: EPDM (Water/Glycol, -20°C to 120°C), NBR (Oil/Gas), PTFE (Acids/Alkalis, high temp).

- Stem: 416 Stainless Steel, 17-4 PH (high strength).

Summary of Component Functions

| Component | Primary Function | Critical Characteristic |

|---|---|---|

| Actuator Motor | Generates kinetic energy | High-torque, reversible induction motor |

| Reduction Gears | Multiplies torque | Worm gear design to prevent back-driving |

| Valve Disc | Obstructs or permits flow | Streamlined profile to minimize pressure drop |

| Resilient Seat | Seals the pipeline | Elasticity to compensate for pressure changes |

Expert Analysis: The synergy between a rigid, dimensionally stable body and a high-torque actuator is what allows these valves to maintain a tight seal even under fluctuating pipeline pressures.

Key Takeaway:

The reliability of an electric butterfly valve comes from the integration of a robust physical barrier (the disc and seat) with a high-precision driver (the actuator). Understanding these materials ensures you select a valve that can survive your specific chemical and thermal environment.

2. The Mechanics of Motion: From Signal to Action

The operation of an electric butterfly valve is a study in transforming electrical energy into mechanical control. Unlike linear valves that require multiple turns to close, the butterfly valve is a quarter-turn device, meaning it requires only a 90-degree rotation to move from fully open to fully closed. This mechanical efficiency translates to faster cycle times and reduced wear on moving parts.

How does the quarter-turn mechanism operate?

The fundamental principle relies on the stem transmitting torque to the disc to execute a precise 90-degree rotation. At 0°, the disc is perpendicular to the flow, fully engaging the seat to stop all fluid movement; at 90°, the disc aligns parallel to the flow, presenting a slim profile that allows fluid to pass with minimal resistance.

But what starts the process of motorized butterfly valve function?

The sequence begins when the actuator receives an electrical command, triggering the internal motor to spin at high speed. This rotational energy is instantly fed into the gear train, which slows the speed down while exponentially increasing the force, eventually turning the output drive and the connected valve stem.

How do gears amplify torque for heavy flow?

The gearbox is essential because it converts the motor’s low-torque, high-RPM output into the high-torque, low-RPM movement needed to overcome the resistance of the fluid pressing against the disc. This mechanical advantage allows a relatively small electric motor to control massive volumes of water or gas that would otherwise require immense physical strength to move.

Operational Sequence:

- Signal Input: Operator or PLC sends a command (e.g., “Open”).

- Motor Excitation: The electric motor windings energize, creating magnetic fields that spin the rotor.

- Torque Conversion: The rotor drives a worm gear set, reducing speed and multiplying torque.

- Stem Rotation: The gearbox output turns the valve stem.

- Disc Positioning: The stem rotates the disc 90 degrees to the open position.

- Limit Switch Termination: Cams hit internal limit switches, cutting power to the motor at the exact end-of-travel point.

Key Takeaway:

Gear reduction is the “secret sauce” of motorized valve operation; it allows compact electric motors to generate the massive torque required to fight hydraulic pressure, ensuring the valve opens and closes reliably every time.

3. Intelligent Control: Signal Input and Positioning

The true power of the electric butterfly valve lies in its intelligence. While manual valves are “dumb” devices, electric actuators are “smart” components that can integrate seamlessly into your Industrial Internet of Things (IIoT) or SCADA systems. This allows you to move beyond simple Open/Close functionality into the realm of precise flow modulation and real-time data acquisition.

How do control signals dictate valve position?

The actuator interprets specific electrical inputs to determine its behavior, distinguishing between simple power signals and complex data streams. For isolation, a standard supply voltage (AC or DC) drives the valve to fully open or close limits; for throttling, the actuator utilizes an internal positioner card to interpret analog signals (like 4-20mA), moving the disc to a proportional angle (e.g., 12mA = 50% open).

Why is real-time feedback crucial for automation?

Feedback mechanisms, such as auxiliary limit switches or potentiometers, close the communication loop by telling your control system exactly where the valve is. Instead of guessing, your PLC receives a return signal confirming that the valve has actually reached its commanded position, which is vital for preventing system errors and ensuring safety interlocks function correctly.

How does the system handle position errors?

If the valve fails to reach the target position due to an obstruction, torque switches detect the resistance spike and cut power to the motor. This intelligent self-protection prevents the motor from burning out and sends an error alarm to your dashboard, allowing for immediate troubleshooting.

Signal Types and Capabilities

| Signal Type | Typical Application | Precision Level | Function |

|---|---|---|---|

| On/Off (Power) | Isolation / Emergency Shut-off | Low (Binary) | Fully Opens or Fully Closes the valve. |

| 4-20mA Analog | Flow Modulation / Temperature Control | High (Continuous) | Adjusts disc angle proportionally to current. |

| 0-10V Analog | HVAC Dampers / Light Industrial | Medium | Voltage-based proportional control. |

| Modbus/Profibus | Complex Automation Networks | Very High (Digital) | Bidirectional data: control + diagnostics. |

Expert Analysis: Regulating type valves utilizing 4-20mA signals are critical where flow variance directly impacts product consistency, such as in chemical dosing or temperature mixing loops.

Key Takeaway:

The ability to convert analog signals into precise mechanical angles makes these valves essential for automated feedback loops, allowing your system to self-correct flow rates without human intervention.

4. Strategic Applications in Modern Industry

Electric butterfly valves are chameleons of the industrial world, capable of adapting to a vast array of environments. Because they combine high flow capacity with a compact design, they are often the preferred choice over bulky gate valves in facilities where space is at a premium. From the basement of a skyscraper to the heart of a refinery, their applications are diverse and critical.

Why are they essential for HVAC systems?

In heating and cooling infrastructure, these valves regulate the flow of chilled and hot water to air handling units and cooling towers. Their precise modulation capabilities allow building management systems to maintain exact temperature setpoints, ensuring occupant comfort while maximizing energy efficiency by preventing over-pumping.

How do they handle aggressive industrial fluids?

For chemical processing and wastewater treatment, electric butterfly valves utilize specialized liners like PTFE to resist corrosion from acids, alkalis, and slurries. The electric actuator is particularly valuable here because it keeps operators safely inside a control room, far away from potentially toxic or hazardous leaks during valve adjustment.

Where does the electric butterfly valve function shine?

They are indispensable in the Oil & Gas and Power Generation sectors for fire-safety shutoffs and cooling water circuits. In these high-stakes environments, the reliability of the electric torque ensures that large-diameter lines can be shut down remotely and instantly in the event of an emergency, protecting both personnel and infrastructure.

Industry-Specific Use Cases:

- Water Treatment: Controlling sludge lines and aeration airflow where obstruction leads to system imbalance.

- Food & Beverage: Managing clean-in-place (CIP) cycles where sanitary stainless steel valves must cycle frequently and reliably.

- Marine/Shipbuilding: Ballast systems where compact, lightweight valves are necessary to save fuel and space.

- Fire Protection: Automated sprinkler zones that require immediate remote activation.

Key Takeaway:

The versatility of the electric butterfly valve lies in its interchangeable seat and disc materials, allowing a single mechanical design to serve sectors ranging from ultra-clean potable water to highly corrosive chemical slurries.

5. Installation and Maintenance Best Practices

Even the most robust equipment will fail if installed incorrectly. Experience shows that the majority of valve “failures” are actually installation errors—specifically, gasket misalignment or improper torque application. To protect your investment, you must treat the installation process as a precision operation, not just a plumbing task.

What are the critical steps for proper installation?

Before you bolt it down, you must ensure the pipeline is completely free of weld slag, rust, and debris that could scar the soft valve seat. You must also align the flanges perfectly; forcing the valve into a misaligned gap creates stress on the body that causes leaking, and the valve disc should always be slightly open (about 10°) during installation to prevent the seat from deforming under flange pressure.

How can routine maintenance prevent system failure?

While electric actuators are generally low-maintenance, you cannot ignore them entirely; a “set it and forget it” mentality leads to seized stems. You should implement a schedule of visual inspections to check for seal integrity and, most importantly, “exercise” inactive valves by cycling them fully at least once a month to keep the seals flexible and the gears lubricated.

How do you protect the electronics during setup?

Ensure that the cable entries on the actuator are sealed with proper glands immediately after wiring. Leaving the housing open to the humid plant environment allows condensation to form on the circuit board, which is the leading cause of premature electrical failure in actuators.

Pre-Installation Checklist:

- Clean the Line: Flush the pipe to remove weld slag and scale.

- Check Orientation: Confirm flow direction arrows on the body match the pipeline flow.

- Disc Position: Ensure disc is slightly OPEN (not closed, not fully open) to protect the sealing edge.

- Flange Spacing: Verify the gap is sufficient to insert the valve without scraping the seat faces.

- Wiring Check: Confirm supply voltage matches the actuator label (e.g., don’t hook 240V to a 24V unit).

Key Takeaway:

90% of valve failures stem from improper installation torque or debris left in the pipeline; taking ten extra minutes to align flanges and clean the pipe can add ten years to your valve’s lifespan.

6. Comparative Analysis: Electric vs. Pneumatic

When designing a system, engineers often face the choice: electric or pneumatic? While pneumatic valves are faster, motorized butterfly valve function offers superior precision and lower infrastructure requirements. The decision ultimately depends on your specific priorities regarding speed, control, and available utilities.

How does it compare to pneumatic alternatives?

Pneumatic valves use compressed air to actuate, offering lightning-fast closing speeds (often under 1 second) which is ideal for emergency shutdowns. However, electric valves provide significantly smoother and more precise control for modulation, eliminating the “stick-slip” effect common in air-driven cylinders and removing the need for complex air filtration systems.

Is the investment worth the motorized valve operation?

When you look at the Total Cost of Ownership (TCO), electric valves often win despite a higher upfront purchase price. Pneumatic systems carry hidden costs: air leaks are expensive energy wasters, and the maintenance of compressors, dryers, and lubricators adds up year over year, whereas electric valves consume electricity only when moving.

What about fail-safe requirements?

Pneumatic valves have a natural advantage in fail-safe applications (spring return is simple), but modern electric actuators now offer battery backup or super-capacitor return options. While electric fail-safe units are more expensive, they allow you to achieve safety compliance in remote areas where running an air supply line is logistically impossible.

Feature Comparison: Electric vs. Pneumatic

| Feature | Electric Butterfly Valve | Pneumatic Butterfly Valve | Manual Valve |

|---|---|---|---|

| Power Source | Electricity (AC/DC) | Compressed Air | Human Effort |

| Motion Speed | Slow/Controlled (10-60s) | Fast/Instant (<2s) | Variable/Slow |

| Precision | High (Modulating) | Low (On/Off mostly) | Low |

| Maintenance | Low (Gearbox) | Medium (Air leaks, seals) | Very Low |

| Infra. Needs | Electrical Wiring | Compressor + Tubing | None |

Expert Analysis: Choose electric for precision modulation and remote sites with only power access; choose pneumatic for explosive environments or where high-speed fail-safe shutdown is the primary safety requirement.

Key Takeaway:

Electric actuators eliminate the “energy bleed” of compressed air systems, offering a greener operational footprint and a lower long-term operating cost for facilities focused on energy efficiency.

7. Troubleshooting Common Operational Issues

Despite their reliability, issues can arise in harsh industrial environments. Being able to quickly diagnose whether the problem lies in the pipeline (the valve) or the control room (the actuator) can save hours of downtime. Most issues boil down to power supply problems, environmental wear, or mechanical obstructions.

What causes unexpected valve leakage?

If the valve passes fluid when closed, the culprit is usually a damaged seat or debris trapped between the disc and the liner. Over time, abrasive fluids can wear down the rubber seat, or chemical incompatibility can cause the liner to swell or crack, preventing the disc from making a perfect seal.

How do you diagnose actuator connection errors?

If the actuator is humming but not moving, you likely have a “single-phasing” issue (bad connection on one wire) or a jammed valve requiring more torque than the motor can provide. Check your voltage at the terminals while under load; a voltage drop of more than 10% indicates undersized wiring that is starving the motor of power.

Why might the valve fail to change direction?

Failure to reverse or stop often points to limit switch miscalibration or a stuck internal relay. If the limit switches are not set to trigger exactly at 0° and 90°, the motor may continue pushing against a physical stop until the thermal overload protection trips to save the motor from burning out.

Quick-Fix Troubleshooting Guide:

- Motor Hums, No Movement: Check for debris blocking the disc; verify voltage is stable; check for seized stem.

- Valve Leaks Through: Inspect seat for cuts/wear; cycle valve to dislodge trapped solids.

- Actuator Overheats: Check duty cycle (don’t exceed the rated starts per hour); check for high ambient temp.

- No Position Feedback: Tighten connections on the limit switch terminals; check cam alignment.

- Moisture in Housing: Check conduit entry seals; ensure heater (if equipped) is working to prevent condensation.

Key Takeaway:

Regular monitoring of motor current and position feedback allows for predictive maintenance; a spike in motor amperage is often an early warning sign of seat wear or debris buildup before total failure occurs.

Conclusion

The transition from manual or pneumatic systems to electric butterfly valves represents a shift toward smarter, safer, and more efficient industrial operations. By solving the core problems of inconsistent flow control, high maintenance overhead, and operator safety risks, these valves prove themselves not just as hardware, but as critical assets in modern infrastructure. They deliver the precision required for quality product output and the reliability necessary to prevent costly downtime.

Whether you are managing a municipal water plant, a high-tech chemical facility, or a commercial HVAC system, the integration of motorized actuation ensures your processes run smoothly and predictably. Do not let outdated flow control methods bottleneck your efficiency.

Ready to optimize your pipeline efficiency? Contact our engineering team today for custom valve sizing and actuation solutions that fit your specific operational needs.

Brand Vision: Committing to innovative automation for safer, more efficient industries worldwide.

FAQ

- Can I use an electric butterfly valve in corrosive environments?

Yes, but material selection is critical. You must select a valve with a Stainless Steel or plastic (PVC/CPVC) body and a chemically resistant seat like PTFE (Teflon). Using a standard ductile iron or NBR rubber valve in corrosive media will lead to rapid degradation and dangerous leaks. - What happens to the valve during a power failure?

Standard electric valves stay in their last position (fail-in-place) because the gears prevent back-driving. However, fail-safe options exist. You can specify actuators equipped with internal battery backups or spring-return mechanisms if your safety protocols require the valve to automatically close or open upon loss of power. - What is the best way to maintain a motorized butterfly valve?

Regular cycling is the most important step. Even if the valve is rarely used, you should cycle it fully at least once a month. This prevents the rubber seat from bonding to the disc (“taking a set”) and keeps the grease in the actuator gears distributed, ensuring it is ready to operate when needed. - Why is my electric actuator humming but not moving?

This usually indicates a jammed valve or insufficient torque. Check for debris blocking the disc in the pipeline. If the line is clear, verify that the actuator size provides a safety factor of at least 1.25x the valve’s torque requirement; an undersized actuator will stall against the fluid pressure. - Can electric butterfly valves be installed outdoors?

Yes, provided they have the correct IP rating. You need an actuator rated IP65, IP67, or IP68 to withstand rain and dust. Additionally, for outdoor installations, it is highly recommended to install a sunshield to prevent UV damage to the display and to prevent internal overheating from direct sunlight.