The standard for testing butterfly valves is primarily defined by API 598, which serves as the global industrial benchmark for pressure integrity and leakage rates. You face a significant risk when unverified valves are installed in high-pressure systems, leading to catastrophic leaks and expensive plant downtime. These failures agitate your operational costs and pose severe safety hazards to your onsite personnel. Here’s the deal. Implementing a rigorous butterfly valve standard ensures every component is built for durability and long-term reliability.

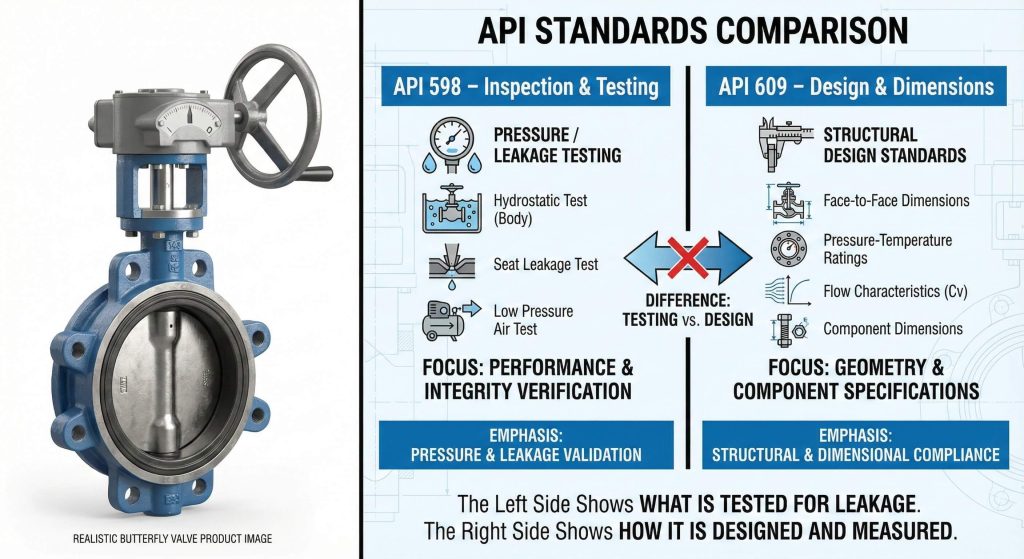

Which API butterfly valve standard applies to pressure tests?

API 598 is the primary butterfly valve standard used for verifying pressure integrity during industrial inspections. This protocol specifies the inspection requirements, test procedures, and acceptable leakage rates for both resilient and metal-seated valves. It covers diameters up to 24 inches for most standard configurations.

Does API 598 cover high-pressure closures?

The standard mandates high-pressure closure tests to ensure the valve seal remains intact under maximum operating conditions. Think about it. You must verify that the seat can hold against the full differential pressure of the system.

- It utilizes hydrostatic or pneumatic pressure media.

- Required hold times vary by the nominal size of the valve.

- Acceptable leakage for soft seats is typically zero bubbles.

Why is API 609 specific to butterfly valve designs?

While API 598 handles testing, API 609 serves as the design code for Category A and Category B valves. Wait, there’s more. This standard ensures that the valve body can withstand rated pressures while maintaining specific face-to-face dimensions for piping compatibility.

- It defines dimensions for wafer and lug styles.

- It classifies valves by performance and offset levels.

- The code ensures structural design meets industrial safety codes.

Key Takeaway: API 598 provides the testing roadmap, while API 609 ensures the structural design is compliant with industrial needs.

| Standard | Primary Function | Scope |

|---|---|---|

| API 598 | Valve Inspection & Testing | Pressure & Leakage Testing |

| API 609 | Butterfly Valve Design | Dimensions & Construction |

This table illustrates the distinct roles of inspection and design frameworks in ensuring valve reliability.

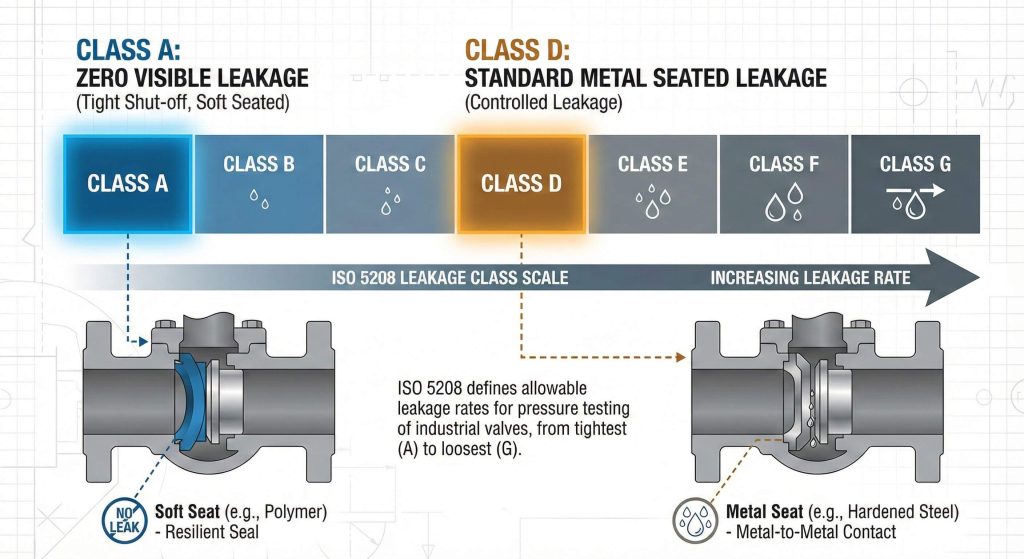

How does the ISO 5208 butterfly valve standard ensure quality?

ISO 5208 establishes international leakage rates from Rate A to Rate G to define the tightness of a butterfly valve standard. This protocol provides a universal language for you to specify exactly how much leakage is permissible in a given application. It is highly valued for international projects where multiple regional standards might clash.

What leakage rates are acceptable under ISO 5208?

Acceptable rates depend entirely on the seat material and the critical nature of your flow media. Ready for the good part? Understanding these rates allows you to specify the exact tightness needed for your specific process requirements.

- Rate A signifies no visible leakage during the test.

- Rate D is commonly used for metal-to-metal seals.

- Tests can be performed with either air or water.

How does shell testing differ from seat testing?

The shell test validates the integrity of the body casting while the seat test checks the disc-to-seal interface. Now we’re getting somewhere. Both tests are mandatory to prevent external environmental leaks and internal process bypass.

- Shell tests typically use 1.5x the rated pressure.

- Seat tests usually use 1.1x the rated pressure.

- Visual inspection ensures no “sweating” occurs on the body.

Key Takeaway: ISO 5208 allows for precise specification of tightness, making it ideal for hazardous chemical or gas service.

| Leakage Rate | Permissible Limit | Typical Seat Type |

|---|---|---|

| Rate A | Zero Leakage | Resilient/Soft Seat |

| Rate B | Low Leakage | High-Performance Metal |

| Rate D | Standard Leakage | General Metal Seated |

The ISO framework categorizes seal performance to match specific application safety and environmental needs.

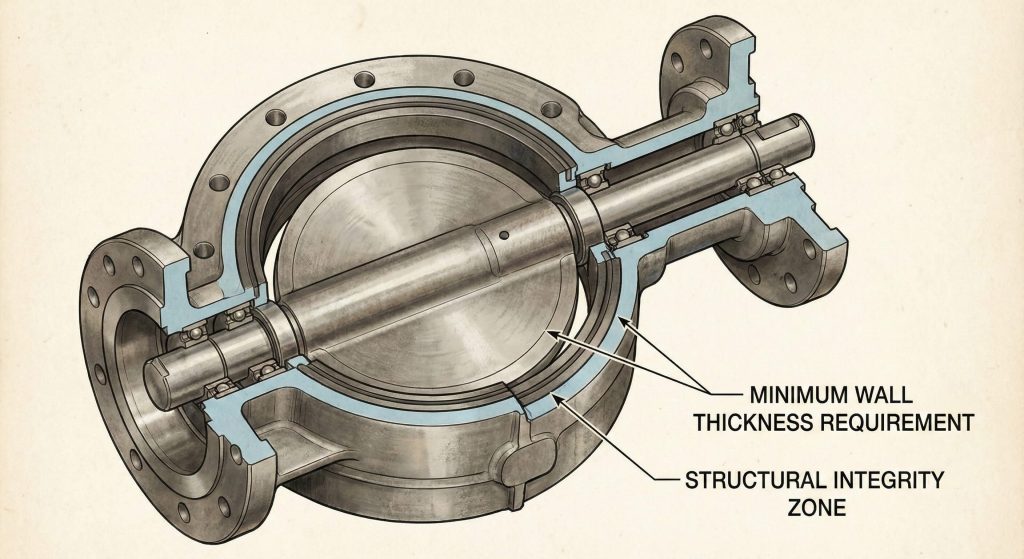

What is the ASME butterfly valve standard for B16.34 compliance?

ASME B16.34 is the overarching butterfly valve standard that mandates minimum wall thicknesses and pressure-temperature ratings for all industrial valves. This standard ensures that your valve body is structurally sound enough to contain high-pressure media without rupture. You can explore compliant options in our full products catalog to ensure your system meets these safety codes.

Does B16.34 define wall thickness requirements?

Yes, it uses mathematical formulas to calculate the minimum metal thickness required for every pressure class. Believe it or not. This protects against body deformation when the valve is under heavy mechanical load.

- It accounts for the different strengths of materials.

- It serves as the baseline for all ASME-rated valves.

- The standard mandates specific hydrostatic test pressures for the body.

How are pressure-temperature ratings calculated?

Ratings are grouped by material class to show the maximum allowable pressure at specific temperatures. It doesn’t stop there. You must ensure that your operational parameters do not exceed these verified curves.

- Stainless steel and carbon steel have different pressure curves.

- Exceeding these ratings leads to immediate safety risks.

- Testing is conducted at 1.5x the rated ambient pressure.

Key Takeaway: ASME B16.34 is a structural safety standard that prevents body failure by mandating material thickness and pressure limits.

| Material Class | Class 150 (PSI @ 100°F) | Class 300 (PSI @ 100°F) |

|---|---|---|

| Carbon Steel | 285 PSI | 740 PSI |

| Stainless Steel | 275 PSI | 720 PSI |

This data confirms that material selection dictates the safe operating pressure limits for industrial piping systems.

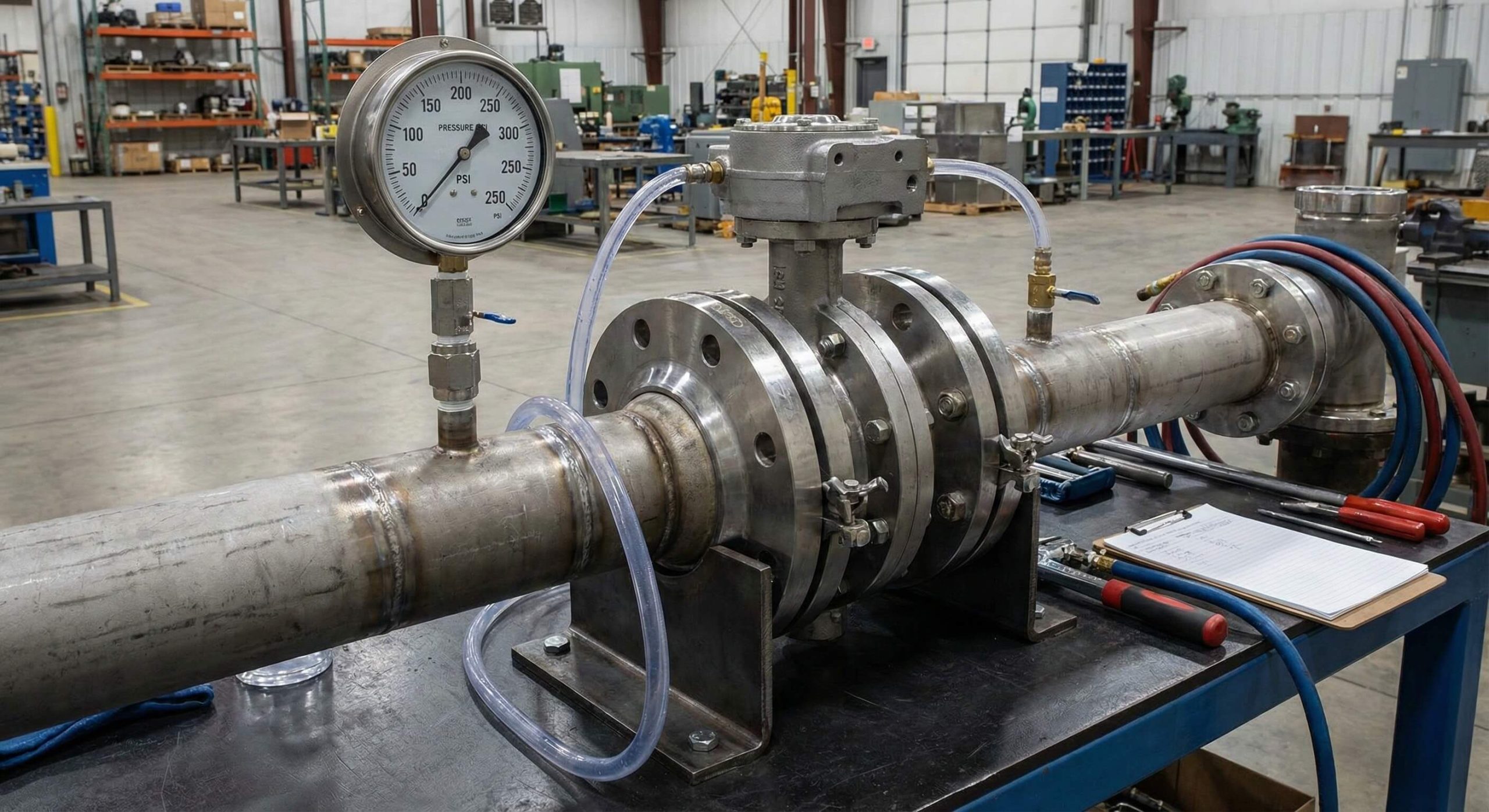

Why is a butterfly valve standard necessary for shell testing?

Shell testing is necessary to confirm that the valve body and its connections are free from porosity or manufacturing defects as per the butterfly valve standard. This process involves filling the valve with water and pressurizing it to significantly higher levels than its normal rating. It is a non-negotiable step for you to prevent external environmental leaks.

What test duration is required for shell integrity?

The duration depends on the valve size to allow you enough time for a thorough visual inspection. But here’s the kicker. Short hold times might miss slow-forming leaks or microscopic “weeping” in the metal.

- Small valves under 2 inches require a 15-second hold.

- Large valves may require up to 5 minutes.

- The exterior surface must remain completely dry during testing.

Can hydrostatic testing reveal casting defects?

Hydrostatic tests are specifically designed to expose microscopic cracks or pinholes in the valve body. What’s the real story? Water is much safer than air for these high-pressure tests because it does not compress.

- Defects appear as distinct drips or surface moisture.

- Failed valves must be scrapped to ensure safety.

- The test ensures the body can handle pressure surges.

Key Takeaway: Shell testing is the “stress test” for the valve body, ensuring it can handle surges without catastrophic failure.

| Valve Size (NPS) | Minimum Duration | Test Pressure |

|---|---|---|

| ≤ 2″ | 15 Seconds | 1.5x Rated |

| 2.5″ – 6″ | 60 Seconds | 1.5x Rated |

| ≥ 8″ | 120+ Seconds | 1.5x Rated |

Visual inspection during these hold times guarantees that the structural integrity of the casting is sound.

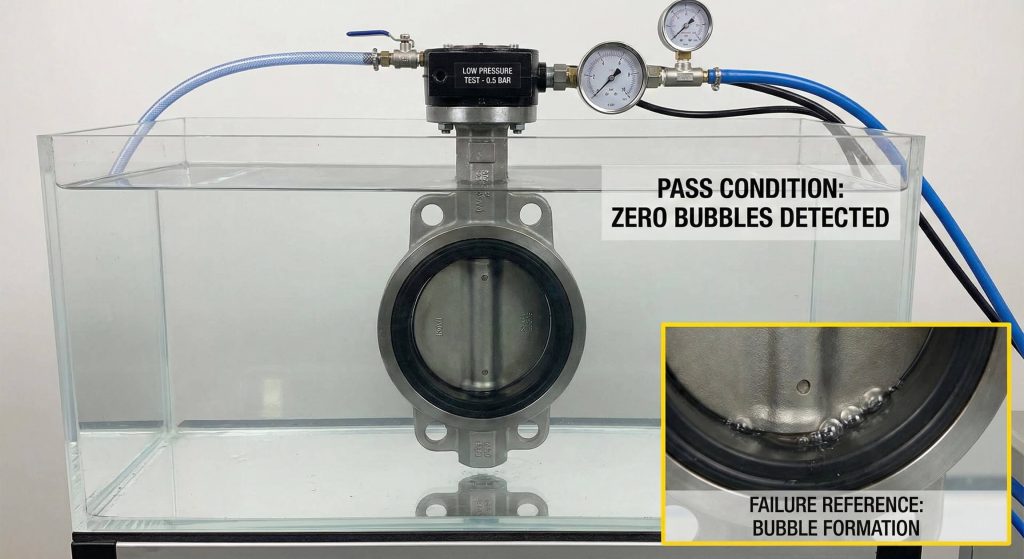

What butterfly valve standard governs low-pressure seat leakage?

The low-pressure seat test is governed by the butterfly valve standard API 598 to ensure bubble-tight shutoff in sensitive systems. This test usually utilizes compressed air at 80 PSI rather than water to find the smallest leak paths. It is particularly critical for you when using a resilient seated design where zero leakage is expected.

Is air or water preferred for seat testing?

Air is the preferred medium for low-pressure tests because its molecules are smaller and more prone to leaking. Let’s dig a little deeper. Air testing detects tiny imperfections that water might hide due to surface tension.

- It is the most sensitive way to verify contact.

- Tests are performed with the valve in the closed position.

- Air pressure is maintained to check for seal displacement.

How many bubbles per minute are permitted?

For resilient-seated valves, the permissible leakage rate is usually zero bubbles during the test period. Here is the deal. Any bubble formation indicates a failing or misaligned seal that could lead to process contamination.

- Zero bubbles are allowed for soft-seated “bubble-tight” designs.

- Metal seats allow for a minimal, regulated bubble count.

- The duration of observation is typically 60 to 120 seconds.

Key Takeaway: Low-pressure air testing is the most sensitive way to guarantee that a butterfly valve provides a complete, bubble-tight seal.

| Test Medium | Pressure Level | Accuracy |

|---|---|---|

| Compressed Air | Low (80 PSI) | High (Bubble Detection) |

| Hydrostatic Water | High (Rated) | Moderate (Drip Detection) |

Using air at low pressure ensures that the seal performs even in low-flow or gravity-fed conditions.

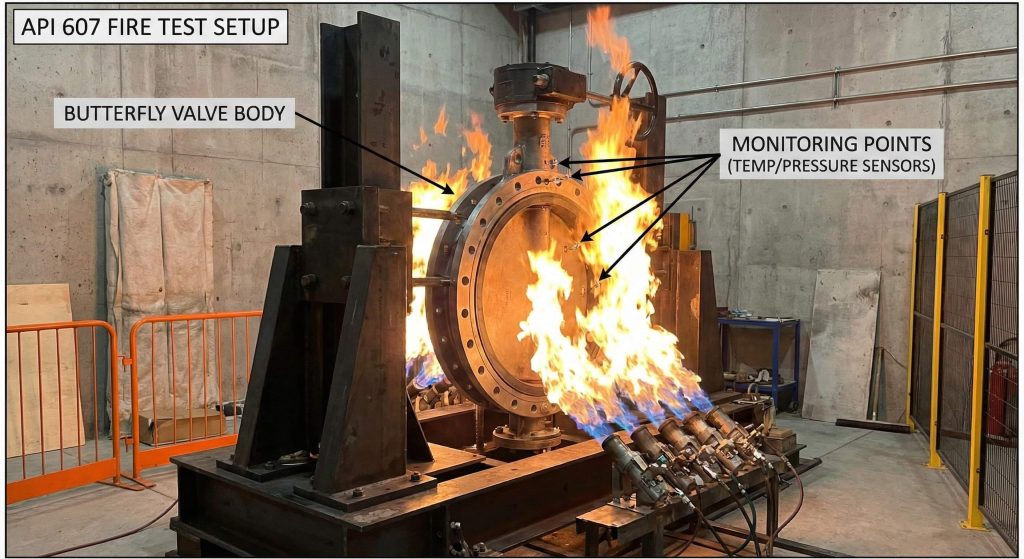

Which fire-safe butterfly valve standard is most recognized?

API 607 is the industry-standard fire test for a butterfly valve standard used in the oil and gas sector. This test determines if a valve can maintain its seal after its soft components have been completely destroyed by fire. It ensures that even in an emergency, your valve prevents flammable media from fueling a disaster.

Does API 607 apply to soft-seated designs?

Yes, it is specifically designed to test valves with non-metallic seats that would melt in a fire. Think about it. The valve must maintain a secondary metal-to-metal seal to stop the flow of fuel.

- The valve must survive 30 minutes in direct flames.

- A secondary metal seal must take over automatically.

- Leakage is measured after the fire has been extinguished.

How is burn-through resistance measured?

Burn-through resistance is measured by monitoring the internal leakage while the valve is engulfed in 1400°F flames. It doesn’t stop there. External leakage at the stem and flanges is also strictly monitored for compliance.

- The valve must remain operable after it has cooled.

- Leakage rates must remain within very strict limits.

- Certification is vital for refinery and offshore safety.

Key Takeaway: API 607 certification is a prerequisite for any valve installed in environments where fire risk is high.

| Test Parameter | Required Value | Goal |

|---|---|---|

| Flame Temperature | 1400°F – 1800°F | Simulate Real Fire |

| Burn Duration | 30 Minutes | Test Material Survival |

| Operability | Must Open/Close Post-Test | Emergency Shutdown |

Rigorous fire testing ensures that valves provide a final line of defense during industrial accidents.

How does the AWWA butterfly valve standard affect water service?

AWWA C504 is the primary butterfly valve standard for municipal water treatment and distribution systems. Unlike industrial standards, it focuses on the long-term cycle life and corrosion resistance required for public utilities. Implementing a double offset design often meets these high-longevity requirements for your water service.

What is the AWWA C504 testing cycle requirement?

AWWA C504 requires proof-of-design tests that cycle the valve thousands of times to prove its durability. The real story? These valves are often buried or installed in remote areas, so they must function without maintenance for decades.

- Valves must withstand 10,000 cycles for Class 150B.

- Tests are conducted under full differential pressure.

- Cycle testing ensures the seat doesn’t wear out early.

Why are torque tests performed on AWWA valves?

Torque tests verify that the actuator can always open the valve, even after months of inactivity. Wait, there’s more. Sediment buildup or mineral scaling can significantly increase the force needed to move the disc.

- Actuators must have a verified safety margin.

- The test prevents failures during emergency water main breaks.

- Torque data helps you size the correct automation package.

Key Takeaway: AWWA standards prioritize the extreme durability and cycle life needed for municipal infrastructure that must last decades.

| AWWA Class | Cycle Test Limit | Application |

|---|---|---|

| Class 150B | 10,000 Cycles | Potable Water |

| Class 250B | 5,000 Cycles | High-Pressure Lines |

Focusing on cycle life allows water utilities to minimize costly excavation and replacement projects.

Does the MSS SP-67 butterfly valve standard cover lug types?

MSS SP-67 is the specific butterfly valve standard that defines the design and testing of wafer and lug-style valves. It ensures that the lugs on your valve are strong enough to support the weight of the piping during dead-end service. This standard is the go-to reference for general-purpose valves in commercial buildings.

What testing criteria apply to wafer vs lug valves?

The testing criteria focus on structural integrity under the pressure of flange bolting. Think about it. Lug valves must be able to hold pressure on one side while the downstream pipe is removed.

- Lug valves are specifically tested for dead-end pressure.

- Wafer valves rely on the compression of pipe flanges.

- Dimension checks prevent the disc from hitting the pipe.

How are face-to-face dimensions standardized?

Standardized dimensions ensure that valves from different manufacturers can be interchanged without you having to modify the piping. Believe it or not. This simplifies your maintenance schedules and replacement part procurement.

- MSS SP-67 aligns with international sizing standards.

- It covers both narrow and wide body patterns.

- Consistency reduces installation errors in the field.

Key Takeaway: MSS SP-67 is essential for ensuring that wafer and lug valves fit properly and perform safely in light-duty systems.

| Feature | Wafer Style | Lug Style |

|---|---|---|

| Support | Clamped between flanges | Bolted directly to flange |

| Dead-end Service | Not Recommended | Fully Supported |

This standard provides the necessary engineering guidelines for universal fit and structural safety in building services.

What butterfly valve standard handles cryogenic testing?

The BS EN 12266-1 and BS 6364 standards provide the butterfly valve standard framework for testing valves in sub-zero temperatures. These tests are essential for you when using a triple offset valve in liquefied natural gas (LNG) applications. At temperatures as low as -320°F, standard seals can shatter, making specialized testing mandatory.

Are BS 6364 guidelines relevant for LNG applications?

Yes, BS 6364 is the definitive guide for validating valve performance in cryogenic environments. Believe it or not. The valve is submerged in liquid nitrogen to simulate real-world cold conditions.

- Helium is used to detect leaks at -320°F.

- The thermal contraction of all parts is carefully monitored.

- Valves must remain operable despite the extreme freezing.

How is seat tightness verified at sub-zero temperatures?

Tightness is verified using helium gas because its tiny molecules can find leak paths created by material shrinkage. Now we’re getting somewhere. You need this level of precision to ensure hazardous LNG stays contained during transport.

- Helium sniffing detects leaks at the parts per million level.

- The valve must demonstrate a Class A or B leakage rate.

- Tests prove the seal material remains flexible when frozen.

Key Takeaway: Cryogenic testing proves that the valve’s materials and seals can withstand the extreme thermal stress of super-cooled liquids.

| Test Parameter | Medium | Temperature |

|---|---|---|

| Cryogenic Leakage | Helium Gas | -320°F (-196°C) |

| Ambient Leakage | Nitrogen/Air | 70°F (21°C) |

Validating performance at extreme temperatures is the only way to ensure safety in the cryogenic supply chain.

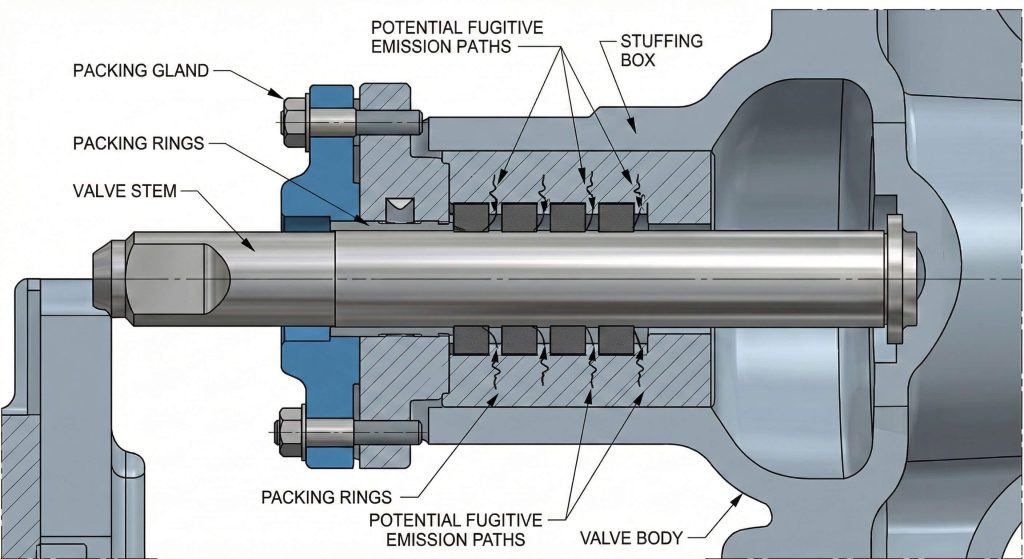

Why follow a butterfly valve standard for fugitive emissions?

ISO 15848-1 is the global butterfly valve standard used to measure and limit the release of hazardous vapors from the stem packing. This standard is vital for your environmental compliance and protecting air quality around chemical plants. Following these guidelines helps you avoid heavy fines and reduces the loss of valuable process media.

Does ISO 15848-1 apply to stem packing?

The standard specifically targets the stem seal area, which is where most fugitive emissions occur. Here is the bottom line. You must ensure the packing is designed for thermal cycling to maintain a tight seal.

- It categorizes valves into different “Tightness Classes.”

- Class AH is the most stringent level for toxic gases.

- Valves undergo repeated opening and closing during tests.

What is the helium sniffing method?

The helium sniffing method uses a mass spectrometer to detect tiny traces of helium escaping the stem. Think about it. This provides a quantitative measurement that is much more accurate than a simple soap-bubble test.

- It provides a parts-per-million (ppm) leakage reading.

- The test ensures the packing material is correctly compressed.

- It validates the valve for use in “Low-E” applications.

Key Takeaway: Fugitive emission standards are the key to environmental sustainability and operational safety in modern chemical plants.

| Tightness Class | Helium Leak Rate | Performance Level |

|---|---|---|

| Class AH | ≤ 10^-6 | Exceptional (Low-E) |

| Class BH | ≤ 10^-4 | Standard Industrial |

| Class CH | ≤ 10^-2 | Basic Compliance |

Following emission standards allows plants to meet global sustainability targets while protecting worker health.

Conclusion

Understanding and applying these testing standards is the only way for you to guarantee the safety, efficiency, and longevity of your fluid control systems. At RUITO, we are dedicated to providing precision-engineered valves that exceed these international benchmarks, ensuring your operations remain uninterrupted and secure. Our brand vision is to lead the industry through transparent quality and unwavering reliability in every component we deliver. To secure the most dependable solutions for your facility, contact us today for a technical consultation.

Frequently Asked Questions

- Can I use API 598 for every butterfly valve?

Generally yes, because it is the most common standard for all industrial valves, but high-performance designs may require the more specific ISO 5208 or API 609 criteria. - What’s the best way to verify zero leakage in resilient seats?

A low-pressure air seat test is the best method because it reveals microscopic leak paths that hydrostatic water testing might hide. - How do I choose between API 607 and API 6FA for fire testing?

API 607 is the preferred choice for soft-seated butterfly valves, while API 6FA is more commonly applied to check valves and specific gate designs. - Why should I care about shell test hold times?

The hold time ensures that slow-forming drips or “weeping” through porous metal are caught before the valve is put into active service. - Does a standard cover the testing of plastic-lined butterfly valves?

Yes, these are typically tested under modified API 598 protocols that use lower pressures to avoid damaging the sensitive lining material.