Actuated butterfly valves are quarter-turn flow control devices that utilize external power sources, such as pressurized fluid or electricity, to automate the isolation and throttling of media within a piping system. Industrial facilities often face catastrophic flow control failures during high-pressure operations because standard manual hardware lacks the necessary mechanical strength. These sudden breakdowns result in expensive downtime and hazardous leaks that threaten personnel safety across your entire plant floor. By implementing a high-performance hydraulic actuator butterfly valve, engineers can ensure maximum efficiency and reliability in even the most extreme environments.

What is a hydraulic actuator butterfly valve?

A hydraulic actuator butterfly valve is a specialized assembly where a circular disc is rotated ninety degrees by a piston driven by incompressible fluid pressure. This specific hydraulic actuator butterfly valve configuration allows for the generation of massive torque within a relatively compact footprint. What’s the real story? The design relies on Pascal’s law to convert small amounts of energy into the significant force required to turn large-diameter valve stems against high-velocity flows.

Operating Principles of Fluid Pressure

The actuator functions by directing high-pressure oil into a cylinder, which moves a piston connected to the valve shaft. Unlike other methods, this fluid power provides a stable and consistent torque curve throughout the entire stroke.

- Piston displacement drives the stem rotation.

- Incompressible oil prevents “springy” movement.

- Directional control valves manage the opening speed.

Key Takeaway: Hydraulic actuation offers the highest power-to-weight ratio for automated large-bore valve systems.

| Component | Material | Function |

|---|---|---|

| Valve Body | Ductile Iron | Primary pressure containment |

| Actuator Cylinder | Carbon Steel | Housing for fluid pressure |

| Sealing Disc | Stainless Steel | Primary flow obstruction |

The integration of robust materials with fluid power ensures the valve remains functional under extreme industrial loads.

When to use a hydraulic actuator butterfly valve?

Selecting a hydraulic actuator butterfly valve is the best choice when your application demands frequent cycling or precise modulation under high differential pressures. These units are far superior to manual gate valves when rapid shutdown is required in critical scenarios. Here is the deal. Hydraulic systems allow for infinitely variable speed control, which effectively prevents water hammer and pressure surges in long liquid pipelines.

High-Frequency Cycling Requirements

Industrial processes that require the valve to open and close multiple times per hour benefit from the cooling properties of hydraulic fluid. The oil carries heat away from the moving parts to a reservoir, preventing the overheating common in electric motors.

- Superior duty cycle performance (up to 100%).

- Reduced mechanical fatigue on the valve stem.

- Stable operation in submerged or remote sites.

Key Takeaway: Choose hydraulic actuation when speed control and high-frequency operation are essential for project safety.

| Application | Suitability | Primary Benefit |

|---|---|---|

| Municipal Water | High | Surge prevention |

| Power Plants | Excellent | Rapid shutdown |

| Chemical Lines | High | Precise modulation |

Using the right actuation technology reduces the risk of system-wide failures during peak operational demands.

Why pick a hydraulic actuator butterfly valve for torque?

The primary reason to pick a hydraulic actuator butterfly valve for torque is its ability to generate thousands of foot-pounds of force to unseat large discs against high-velocity media. This mechanical advantage ensures that a hydraulic actuator butterfly valve can operate a sixty-inch valve as easily as a standard manual unit handles a small pipe. But wait, there’s more. High torque capacity allows for the use of stiffer, high-performance seals that prevent leaks in high-pressure steam or chemical applications.

Force Multiplication and Sealing Integrity

The flat torque curve of a hydraulic piston ensures that seating force remains consistent at the critical point of closure. This prevents the “stalling” that often occurs with electric or manual systems when resistance peaks at the end of the rotation.

- Pascal’s Law enables massive force multiplication.

- Consistent seating prevents media bypass.

- Smaller actuator footprints save valuable plant space.

Key Takeaway: Superior torque capacity enables the use of robust sealing materials that smaller actuators cannot effectively operate.

| Actuator Type | Torque Rating | Power Density |

|---|---|---|

| Manual Lever | Low | Minimal |

| Electric Motor | Medium | Moderate |

| Hydraulic Piston | Extremely High | Maximum |

High-density power transmission allows engineers to maintain extreme closing forces while reducing the overall weight load on pipe supports.

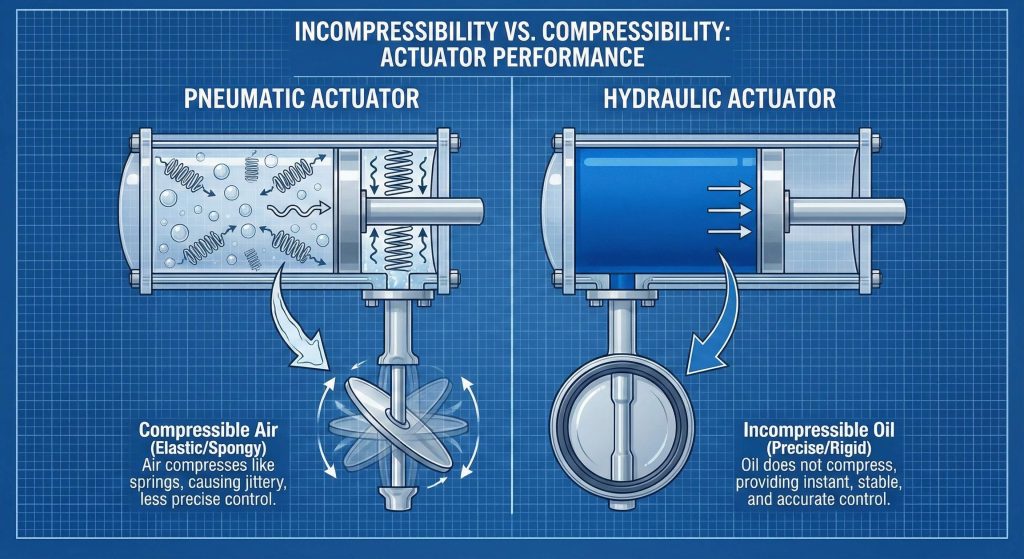

How a hydraulic actuator butterfly valve beats pneumatic power?

A hydraulic actuator butterfly valve outperforms pneumatic alternatives because the working fluid is incompressible, allowing for much higher operating pressures and more precise positioning. While pneumatic ball valves are useful for light-duty tasks, they often suffer from “bouncy” movement in large-bore applications. Check this out. Because hydraulic systems operate at up to 3000 PSI, the physical size of the actuator can be significantly smaller than a 100 PSI air-driven unit.

Fluid Incompressibility and Control

The lack of fluid compression ensures that the valve disc stays exactly where the operator positions it, regardless of flow turbulence. This precision is vital for throttling services where even a slight movement can disrupt the entire process flow.

- Elimination of air system elasticity and lag.

- Compact cylinder design for tight installations.

- Higher internal pressures for increased thrust.

Key Takeaway: Hydraulic systems provide more stable control and a much smaller physical footprint than pneumatic alternatives.

| Feature | Pneumatic | Hydraulic |

|---|---|---|

| Power Fluid | Compressed Air | Hydraulic Oil |

| Max Pressure | ~120 PSI | ~3000 PSI |

| Position Accuracy | Moderate | Precision |

The stability of hydraulic power ensures that your piping system operates without the vibration or oscillation common in air-powered hardware.

Where does a hydraulic actuator butterfly valve work best?

A hydraulic actuator butterfly valve works best in demanding industrial sectors like offshore energy, marine ballast systems, and heavy manufacturing. These environments require a hydraulic actuator butterfly valve that can resist extreme vibration and constant exposure to corrosive saltwater without failing. Think about it. For massive piping projects, the centralized power units of hydraulic systems simplify the control of dozens of remote valves from a single location.

Marine and Offshore Deployment

Marine vessels rely on these valves for ballast control because they offer reliable performance even when submerged at great depths. The robust construction prevents salt spray from damaging the internal mechanics, ensuring a long operational life.

- Offshore oil and gas platform safety.

- Marine ballast and cargo manifold systems.

- Centralized control for remote valve networks.

Key Takeaway: Demanding environments like the marine and energy sectors require the specialized durability that only hydraulic actuation provides.

| Industry | Common Application | Environmental Challenge |

|---|---|---|

| Marine | Ballast Control | Saltwater Corrosion |

| Oil & Gas | Pipeline Isolation | High Vibration |

| Mining | Tailings Management | Abrasive Slurries |

Targeted deployment in these harsh sectors maximizes the return on investment by drastically reducing the frequency of unscheduled maintenance.

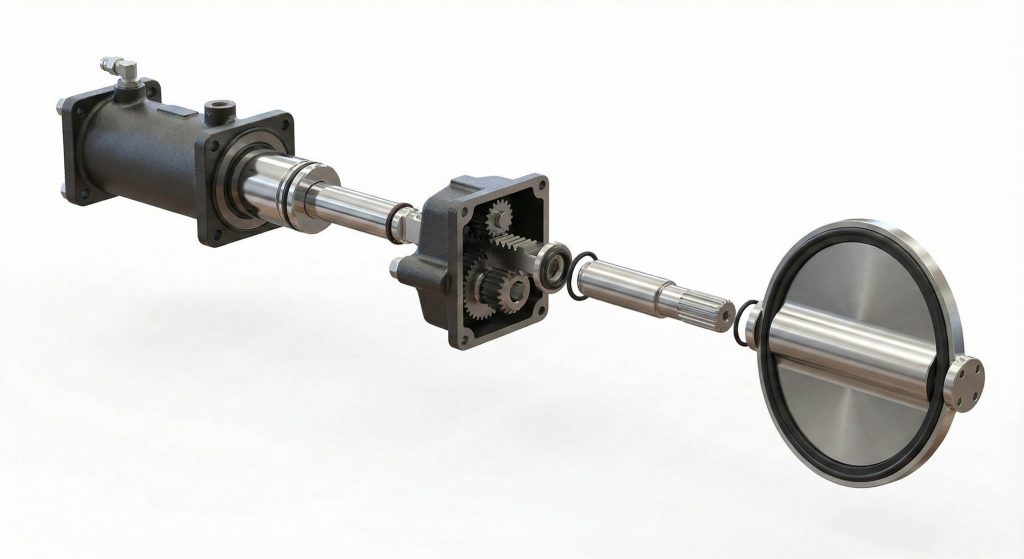

What are the key components of the actuator assembly?

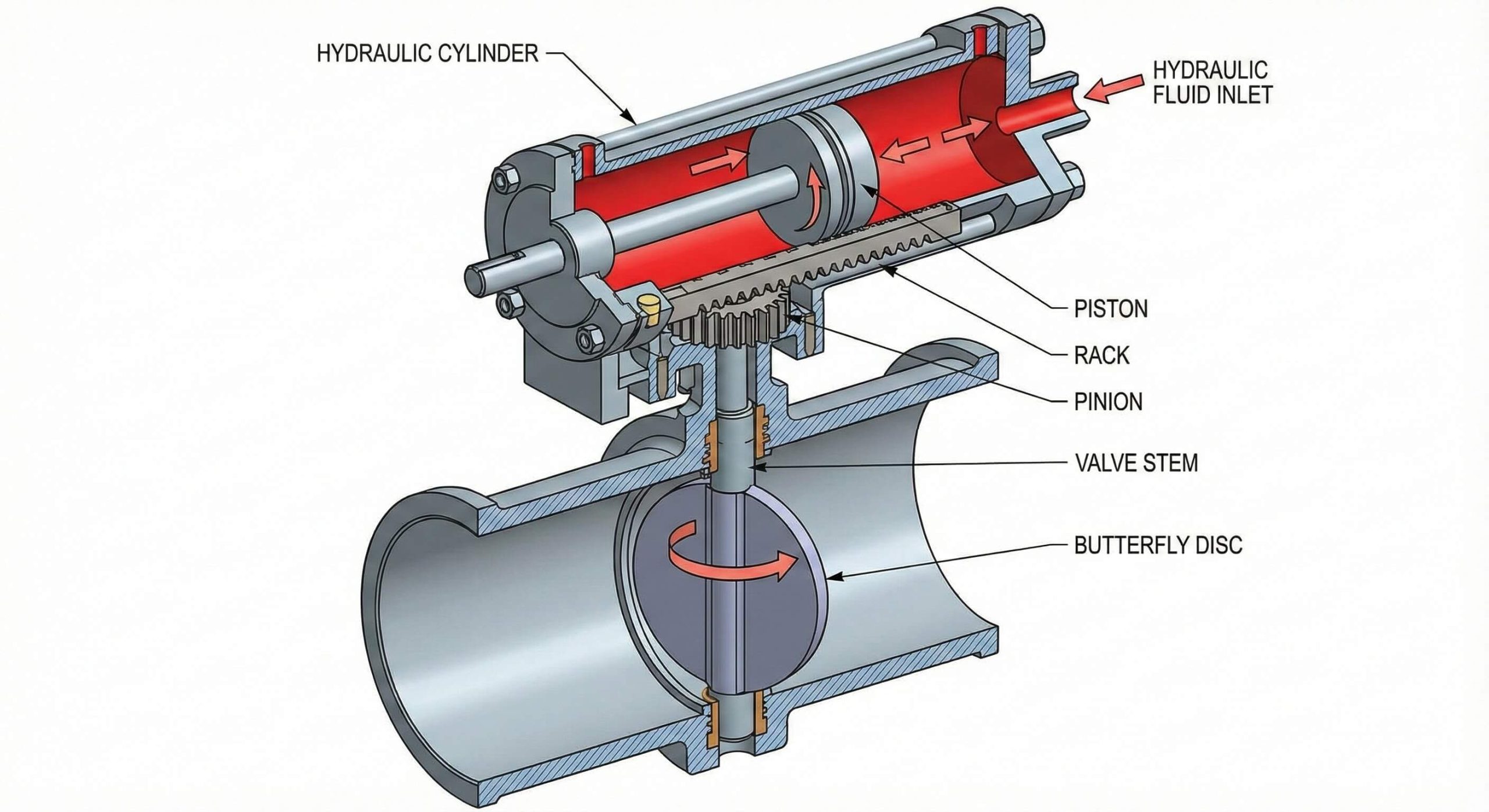

The key components of a hydraulic actuator butterfly valve assembly include the hydraulic cylinder, the internal piston, and the mechanical linkage that converts linear motion into rotation. In every hydraulic actuator butterfly valve, these parts must be precision-machined to ensure that fluid pressure is efficiently translated into shaft movement. It gets better. Advanced models often include integrated limit switches and positioners that provide real-time feedback to the central control room.

Cylinder and Piston Mechanics

The cylinder houses the high-pressure oil, while the piston acts as the primary moving element that generates the required thrust. High-quality seals within the cylinder are essential to prevent internal bypass, which could lead to a loss of torque.

- Precision-ground piston rods for smooth travel.

- Heavy-duty mounting bolts for vibration resistance.

- Internal seals designed for high-pressure oil.

Key Takeaway: Robust internal components are the foundation of a hydraulic actuator’s reliability in high-torque applications.

| Part Name | Role | Material |

|---|---|---|

| Piston Rod | Transmits Force | Chrome Plated Steel |

| Linkage | Converts Motion | Forged Steel |

| Limit Switch | Signals Position | Polymer or Metal |

This hardware configuration ensures that every internal part handles the intense pressures required for heavy-duty industrial automation.

How to maintain a hydraulic actuator butterfly valve?

Maintaining a hydraulic actuator butterfly valve involves regular fluid analysis, seal inspection, and lubrication of the mechanical linkages. It is also important to verify the performance of check valves within the hydraulic circuit to ensure that pressure is maintained during operation. Here is the deal. Contaminated oil acts like liquid sandpaper and can quickly destroy the polished surfaces of the cylinder walls if the filters are neglected.

Fluid Quality and Filtration Monitoring

Monthly fluid checks can prevent thousands of dollars in repair costs by catching metal shavings or moisture before they damage the pump. Ensuring the oil remains within its specified viscosity range is crucial for consistent valve timing.

- Monthly oil sampling and analysis.

- Quarterly seal and packing inspections.

- Bi-annual lubrication of all external joints.

Key Takeaway: Preventive maintenance focused on fluid purity and seal integrity extends the operational life of the actuator by several years.

| Task | Frequency | Objective |

|---|---|---|

| Oil Sampling | Monthly | Identify Contaminants |

| Seal Check | Quarterly | Prevent External Leaks |

| Linkage Greasing | Bi-Annually | Ensure Smooth Rotation |

Following a strict maintenance regimen prevents small issues from escalating into expensive mechanical failures that stop your entire production line.

Can a hydraulic actuator butterfly valve handle slurries?

A hydraulic actuator butterfly valve is uniquely suited for abrasive slurries because its high torque allows the disc to cut through thick solids that would stall weaker actuators. The massive thrust of a hydraulic actuator butterfly valve ensures that the valve reaches a full-closed position even when rocks or sand build up in the seat area. What’s the catch? You must pair the actuator with a disc made of hardened stainless steel or specialized coatings to survive the constant erosion.

Abrasive Media Resistance Strategies

In mining and wastewater applications, the quarter-turn action of the butterfly design is less prone to clogging than the deep pockets found in gate valves. The hydraulic power provides the necessary “break” force to move the disc through settled sediment after a system shutdown.

- High torque to overcome solid accumulation.

- Clog-free quarter-turn mechanical action.

- Compatibility with erosion-resistant disc materials.

Key Takeaway: Hydraulic power enables the valve to overcome the high friction and resistance typical of slurry and mining applications.

| Media Type | Challenge | Hydraulic Solution |

|---|---|---|

| Tailings Slurry | Abrasion | High Seating Force |

| Wastewater | Debris | Rapid Clearing Action |

| Thick Chemicals | Viscosity | High Constant Torque |

By matching actuator power to media characteristics, plants can achieve reliable flow control in the most difficult fluid environments.

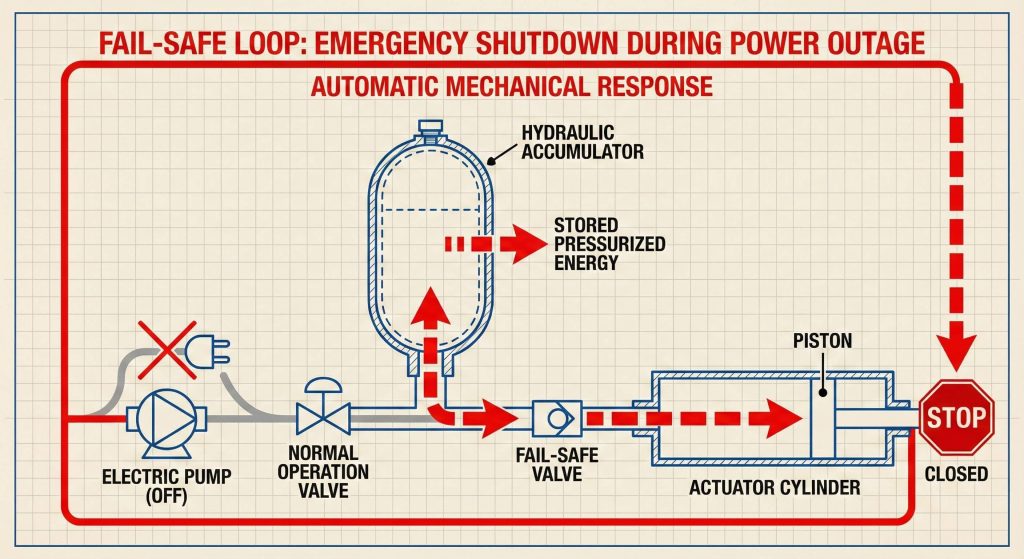

What makes the hydraulic fail-safe mechanism reliable?

The reliability of a hydraulic actuator butterfly valve fail-safe mechanism stems from the use of nitrogen-charged accumulators or heavy-duty internal springs that store energy for emergency shutdowns. This ensures that the hydraulic actuator butterfly valve can reach its safe position even during a total loss of electrical power at the facility. This is where it gets interesting. These systems act as a “hydraulic battery,” providing the critical force needed to isolate hazardous pipelines during a turbine trip or seismic event.

Energy Storage and Redundancy

Nuclear and thermal power plants trust this technology because it offers a predictable and independent power source for safety functions. The robust construction of the accumulator ensures that the stored pressure is ready for use even after months of inactivity.

- Accumulators provide emergency closing power.

- Spring-return models offer mechanical fail-safety.

- Redundant valves prevent accidental movement.

Key Takeaway: Hydraulic systems provide independent energy storage for critical safety functions during total plant power loss.

| Fail-Safe Type | Mechanism | Best Application |

|---|---|---|

| Spring Return | Mechanical Spring | Small to Medium Valves |

| Accumulator | Compressed Nitrogen | Large Bore Valves |

| Lock-Up | Fluid Logic | Process Security |

Integrated safety features ensure that the valve remains a reliable guardian of plant integrity during unforeseen disasters or equipment failures.

How do you size a hydraulic actuator butterfly valve?

Sizing a hydraulic actuator butterfly valve correctly requires calculating the “break-to-open” torque, which includes the friction of the seals and the dynamic force of the flowing media. Every hydraulic actuator butterfly valve must be matched to the specific pressure drop (Delta P) of the system to ensure smooth operation without jerky movements. You might be wondering. To avoid over-sizing, engineers use precise flow coefficient (Cv) data and torque curves to select the ideal cylinder bore and stroke.

Torque Calculation Factors

Accounting for the weight of the disc and the viscosity of the fluid is essential for determining the required thrust. An undersized actuator may stall before the valve is fully open, while an oversized unit adds unnecessary cost and weight to the system.

- Accurate calculation of seating friction.

- Evaluation of dynamic flow forces on the disc.

- Selection of proper cylinder stroke for 90° rotation.

Key Takeaway: Precise torque calculations prevent the installation of undersized actuators that might stall during critical operations.

| Sizing Factor | Impact on Actuator | Engineering Check |

|---|---|---|

| Delta P | Increases Thrust Requirement | Max System Pressure |

| Media Velocity | Changes Dynamic Torque | Cv/Kv Data Analysis |

| Disc Diameter | Affects Lever Arm Force | Valve Geometry Review |

Properly sized hardware guarantees that your piping system operates efficiently with the lowest possible energy consumption and mechanical wear.

Frequently Asked Questions

Q1: Can I use a hydraulic actuator in sub-zero temperatures?

Yes, as long as you select a low-temperature hydraulic oil that maintains its viscosity in freezing conditions. Unlike pneumatic systems, hydraulic oil does not suffer from frozen condensation in the lines.

Q2: What’s the best way to handle a pump failure?

Most hydraulic systems include a manual override, such as a hand-operated pump or a mechanical screw-jack. This allows operators to close the valve safely even without electrical power.

Q3: Can I integrate these valves with my existing PLC?

Yes, modern hydraulic actuators are compatible with standard control systems through the use of solenoid valves and electronic positioners. These components allow for seamless automation within your plant’s digital network.

Q4: What’s the best fluid for food-grade applications?

For food and beverage lines, you must use H1-certified food-grade hydraulic fluid. This ensures that any accidental leak does not contaminate the product stream.

Q5: Can I replace my electric actuators with hydraulic ones?

Yes, though you will need to install a hydraulic power unit (HPU) to provide the necessary fluid pressure. The increased torque and durability often justify the infrastructure upgrade in high-cycle applications.

Summary

Modern industrial piping demands the extreme power and precision that only an automated butterfly valve can provide. We have explored how these units generate massive torque, offer superior safety through fail-safe mechanisms, and outperform pneumatic alternatives in compact spaces. Here’s the deal, choosing high-quality automated valves is an investment in the long-term safety and productivity of your facility. If you are ready to optimize your flow control systems, please contact us today to speak with our senior engineering staff about your project requirements.