A hydraulic butterfly valve is an automated industrial component that utilizes pressurized fluid to rotate a disc 90 degrees, enabling precise regulation or isolation of fluid flow in large-diameter pipelines. Imagine you are managing a high-pressure municipal water network where a manual valve failure could lead to massive flooding and infrastructure damage. This critical pain point often arises when manual gearboxes cannot provide the necessary torque or speed during an emergency. By integrating a hydraulic control butterfly valve, you gain a robust, fail-safe solution that ensures your system remains protected even during total power outages.

What is a hydraulic control butterfly valve?

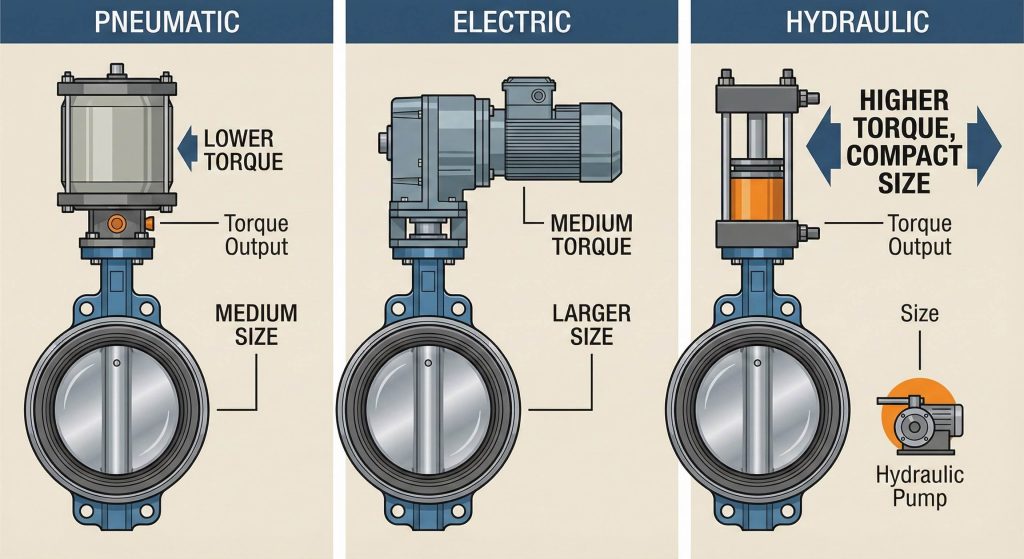

A hydraulic control butterfly valve is a quarter-turn rotary valve equipped with a hydraulic actuator that converts fluid pressure into mechanical torque for automated operation. When you implement a hydraulic control butterfly valve, you are choosing a system designed for the most demanding heavy-duty environments. These valves are essential for large-scale operations where pneumatic or electric actuators lack the necessary force.

What are the primary internal parts?

Think about it: the efficiency of your flow control depends entirely on the synergy between the actuator and the internal sealing components. A high-quality build ensures that the transmission of energy is smooth and repeatable.

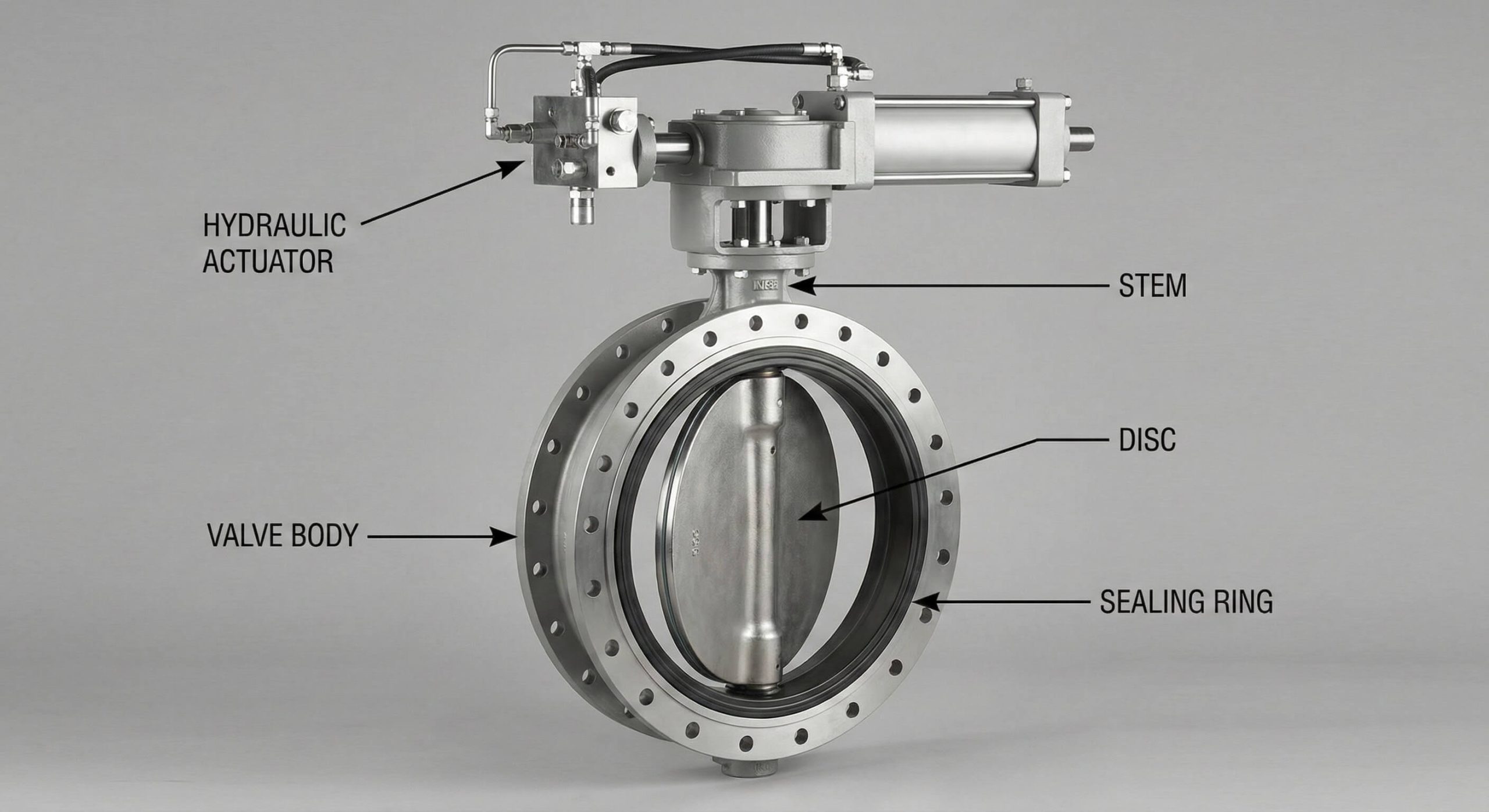

- Hydraulic Actuator: The power source providing high-torque rotation.

- Valve Disc: The central component that rotates to block or allow flow.

- Sealing Ring: Critical for ensuring zero-leakage performance under pressure.

How is the valve construction categorized?

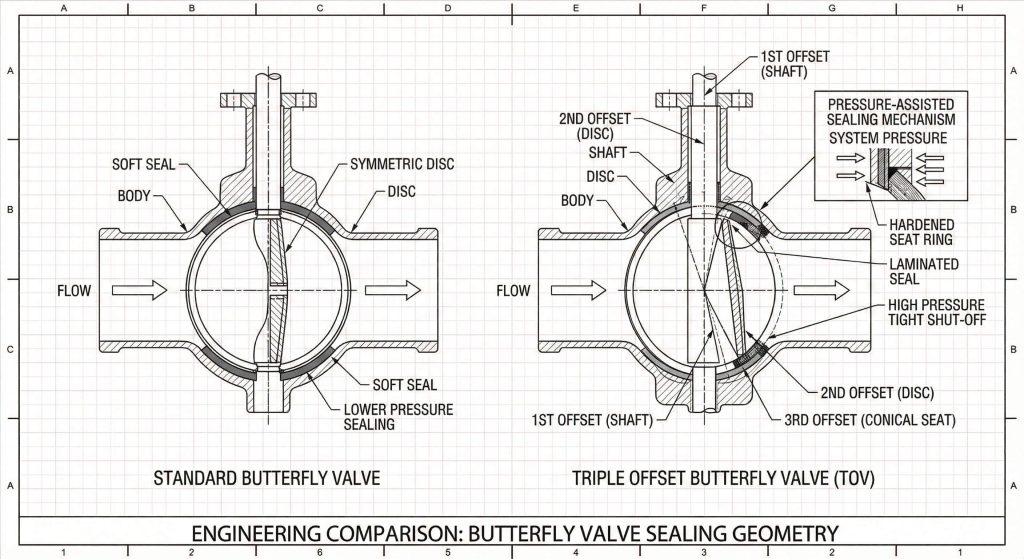

The best part? You can customize these valves with various offsets to suit different pressure ratings and media types. Most industrial versions utilize double or triple offset designs to minimize seat wear and maximize longevity.

| Component | Standard Material | Purpose |

|---|---|---|

| Body | Ductile Iron | Structural Integrity |

| Disc | 316 Stainless Steel | Corrosion Resistance |

| Actuator | Steel Cylinder | Force Generation |

Key Takeaway: These valves provide the highest torque-to-size ratio of any automated valve type, making them ideal for massive infrastructure projects.

How does a hydraulic control butterfly valve work?

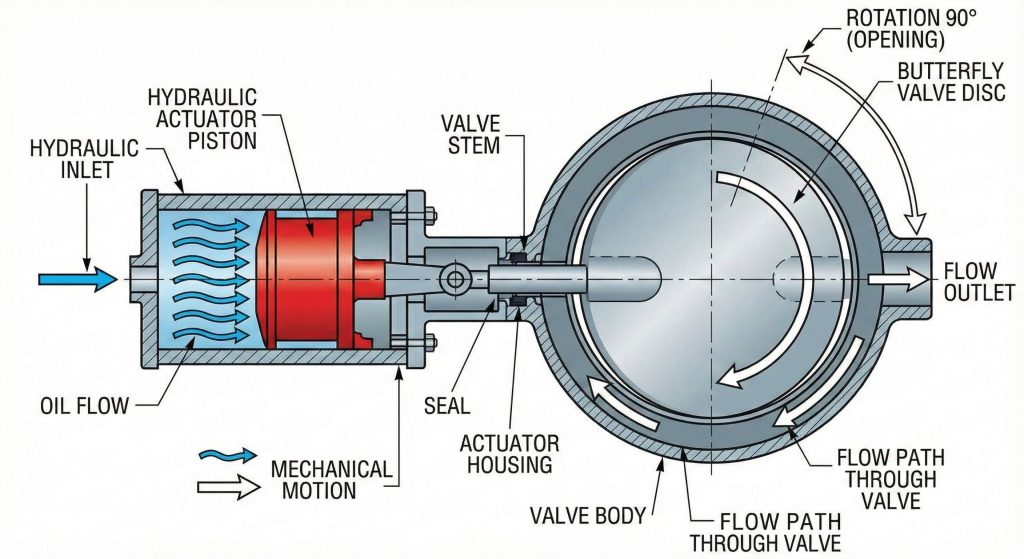

The hydraulic control butterfly valve functions by pumping pressurized oil into a cylinder which pushes a piston to rotate the valve stem and disc. This mechanism allows you to achieve precise 90-degree movement for either full isolation or varied throttling. Because oil is incompressible, the movement is incredibly stable compared to pneumatic systems.

Does it support fail-safe operations?

Here is the deal: safety is non-negotiable in critical industrial processes. Hydraulic actuators are often equipped with spring-return or accumulator systems to ensure the valve closes automatically if power is lost.

- Single-Acting: Uses a spring to return the valve to a safe position.

- Double-Acting: Uses hydraulic pressure for both opening and closing cycles.

- Manual Override: Allows you to operate the valve during a hydraulic system failure.

How is the motion controlled accurately?

You might be surprised by the level of precision these systems offer. Advanced hydraulic positioners allow for incremental adjustments, which is vital when you need to manage sensitive pressure levels in a process line.

| Actuation Type | Motion Style | Precision Level |

|---|---|---|

| Hydraulic | Rotary 90° | High (Incremental) |

| Manual | Gear-Driven | Low (User-Dependent) |

| Pneumatic | Quarter-Turn | Moderate (Air Compressibility) |

Key Takeaway: The use of incompressible hydraulic fluid translates to unmatched stability and precision in flow regulation.

Why use a hydraulic control butterfly valve?

You should use a hydraulic control butterfly valve because it offers the highest torque output in a compact footprint, ensuring reliable operation for valves up to DN3000. These units are specifically engineered to handle the massive hydrodynamic forces found in large-diameter pipelines. By using a hydraulic control butterfly valve, you eliminate the need for oversized electric motors that are prone to burnout.

What are the main efficiency benefits?

The real kicker? These valves significantly reduce your system’s energy consumption during the holding phase. Once the valve reaches its position, the hydraulic lock maintains it without requiring continuous power.

- High Torque: Easily overcomes friction in high-pressure seals.

- Compact Size: Saves valuable space in tight plant rooms.

- Damping Effect: Prevents water hammer by controlling closing speeds.

Is reliability guaranteed in harsh conditions?

Consider this: hydraulic systems are self-lubricated by the operating fluid, which naturally reduces internal wear. This makes them significantly more durable than electric actuators in corrosive or humid environments.

| Feature | Hydraulic Benefit | System Impact |

|---|---|---|

| Power Density | High PSI Capability | Reduced Actuator Weight |

| Response Time | Rapid Actuation | Improved Safety Margins |

| Maintenance | Self-Lubricating | Longer Service Life |

Key Takeaway: Selecting hydraulic automation minimizes the risk of torque stall and ensures reliable performance in high-stress environments.

Where is a hydraulic control butterfly valve applied?

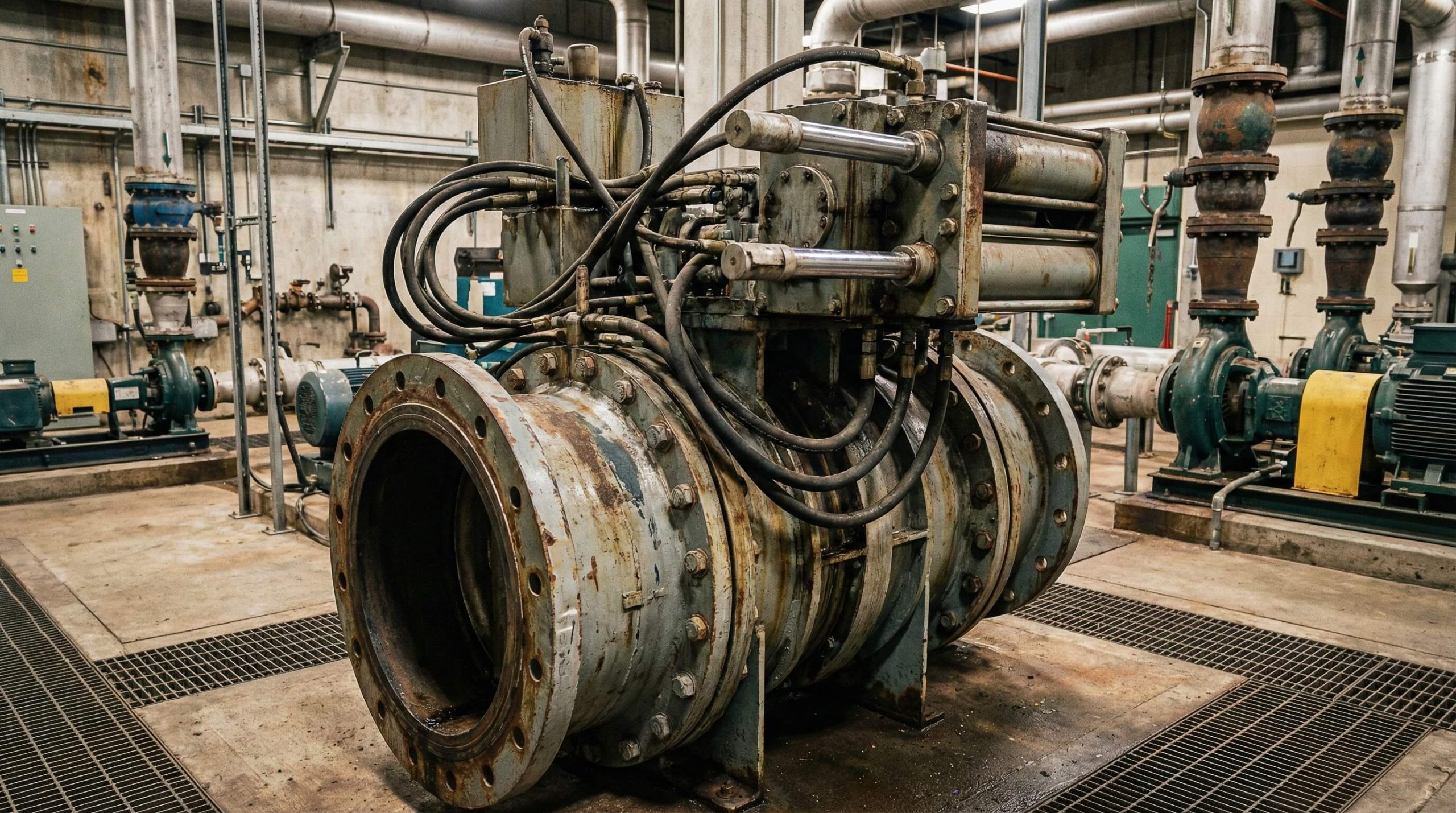

A hydraulic control butterfly valve is most effective in heavy industries like shipbuilding, hydropower, and municipal water management where massive flow volumes require automated precision. You will frequently find these valves in ship ballast systems where space is at a premium but reliability is life-critical. They are also standard in dam safety systems for emergency turbine shut-offs.

Which industries rely on this technology?

Believe it or not, these valves are the backbone of modern global infrastructure. They handle everything from crude oil transport to the cooling water of nuclear power plants.

- Marine & Offshore: Essential for ballast and cargo handling.

- Oil & Gas: Used in midstream pipelines for high-pressure control.

- Power Generation: Critical for cooling water systems and steam regulation.

How are they used in municipal water?

In large cities, the water distribution network depends on these valves to prevent catastrophic leaks. They are often installed in underground vaults where their compact size and submersible capabilities are mandatory.

| Industry Sector | Primary Use Case | Media Handled |

|---|---|---|

| Hydropower | Turbine Protection | High-Pressure Water |

| Shipbuilding | Ballast Management | Saltwater/Seawater |

| Municipal | Main Line Isolation | Potable Water |

Key Takeaway: These valves are indispensable for any application requiring high force and absolute fail-safe reliability.

Which materials suit a hydraulic control butterfly valve?

Materials such as ductile iron for the body and stainless steel or aluminum bronze for the disc are best for a hydraulic control butterfly valve to ensure longevity. When you browse the hydraulic control butterfly valve material options, you must match the metallurgy to your specific chemical media. Improper selection can lead to rapid corrosion and total system failure.

What are the best sealing options?

The secret is in the seat: the material of your valve seat determines the leakage class and the temperature range. For chemical processing, you should always look for high-grade synthetic elastomers or metal-to-metal seals.

- EPDM: Best for water and steam up to 120°C.

- PTFE: Excellent for aggressive chemical handling.

- Metal-to-Metal: Required for extreme temperatures and abrasive slurries.

Why is body material so important?

Don’t overlook the housing: while the internal parts handle the fluid, the body must withstand external environmental stress. Ductile iron is standard, but stainless steel 316L is necessary for offshore platforms where salt spray is constant.

| Component | Standard Option | Severe Service |

|---|---|---|

| Body | GGG50 Ductile Iron | CF8M Stainless Steel |

| Disc | Nylon Coated DI | Aluminum Bronze |

| Stem | 420 Stainless Steel | 17-4PH High Strength |

Key Takeaway: Material compatibility with the media and environment is the single most important factor for valve lifespan.

How to size a hydraulic control butterfly valve?

Sizing a hydraulic control butterfly valve requires calculating the required flow coefficient (Cv) and the breakaway torque needed to open the valve under maximum differential pressure. You must ensure the valve diameter matches your pipe size to prevent turbulence and excessive pressure drops. An undersized valve will restrict flow, while an oversized one will lead to poor control during throttling.

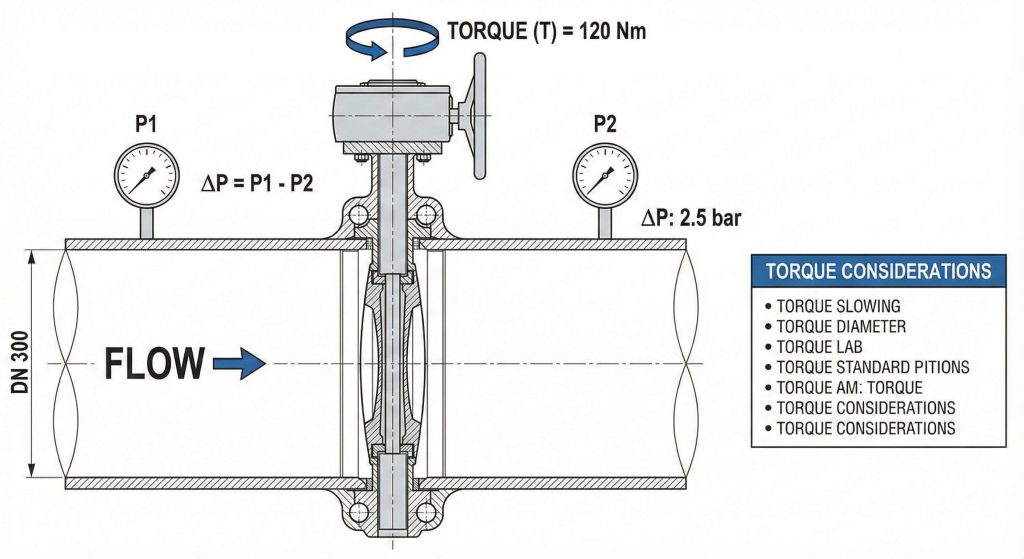

How do you calculate torque requirements?

Let’s look at the facts: the actuator must overcome the friction of the seals and the hydrodynamic force of the flowing media. If your actuator is undersized, the valve may fail to close during a high-velocity surge.

- Dynamic Torque: The force required while the fluid is moving.

- Seating Torque: The force needed to compress the seal at shut-off.

- Safety Factor: Always add a 20-30% margin to your calculations.

What parameters are most critical?

When you submit your requirements to an engineering team, you must provide the full operating profile. This includes the minimum and maximum flow rates as well as the specific gravity of the fluid.

| Parameter | Unit of Measure | Importance |

|---|---|---|

| DN Size | Millimeters (mm) | Pipe Compatibility |

| Kv/Cv | Flow Capacity | System Efficiency |

| Max ΔP | Bar / PSI | Actuator Sizing |

Key Takeaway: Accurate sizing prevents premature seal wear and ensures the actuator has sufficient power for all conditions.

Is a hydraulic control butterfly valve high-pressure?

Yes, a hydraulic control butterfly valve is specifically designed for high-pressure service, often rated for PN25, PN40, or even ANSI Class 300 applications. You can rely on these valves for systems reaching pressures up to 740 PSI when using high-performance triple offset designs. By choosing a hydraulic control butterfly valve, you gain the massive force needed to maintain a bubble-tight seal against high line pressure.

How does the valve maintain sealing?

The good news? Triple offset geometry allows the disc to “wedge” into the seat, creating a seal that tightens as the pressure increases. This eliminates the rubbing motion that destroys soft seats in standard valves.

- Standard Seal: Suitable for HVAC and general water lines.

- High-Performance: Used for steam and industrial process fluids.

- Zero-Leakage: Achieved through precision machining and high seating force.

Is it safe for high-pressure steam?

You should be aware that high-pressure steam requires specialized metal-seated valves. Hydraulic actuators are preferred here because they are not affected by the high ambient temperatures that often degrade electric motor insulation.

| Pressure Rating | Typical PSI | Application |

|---|---|---|

| PN16 | 232 | Municipal Water |

| PN25 | 362 | Fire Protection |

| Class 300 | 740 | Petrochemical |

Key Takeaway: Hydraulic actuation is the most reliable method for controlling butterfly valves in high-pressure industrial environments.

What maintenance does a hydraulic control butterfly valve need?

Maintenance for a hydraulic control butterfly valve focuses on inspecting the actuator seals, checking the hydraulic fluid levels, and verifying the integrity of the disc seals. You must perform these checks annually to prevent oil leaks and ensure the valve responds immediately when triggered. Most failures are caused by contaminated hydraulic oil or worn-out piston seals in the actuator.

How to troubleshoot common issues?

Now it gets interesting: if your valve moves sluggishly, it is likely that air has entered the hydraulic lines. Bleeding the system and checking the pump pressure can resolve most operational delays without removing the valve.

- Oil Leaks: Check all fittings and the actuator cylinder.

- Stem Packing: Ensure there is no media leakage around the shaft.

- Cycle Test: Operate the valve fully to check for smooth travel.

What is the recommended service schedule?

Routine care is the key to a 25-year service life. By following a structured maintenance plan, you can reduce unplanned downtime by as much as 40%.

| Interval | Action Item | Goal |

|---|---|---|

| 3 Months | Visual Inspection | Identify External Leaks |

| 6 Months | Functional Test | Verify Response Time |

| 12 Months | Seal Replacement | Ensure Internal Tightness |

Key Takeaway: Proactive maintenance of the hydraulic power unit and actuator seals is essential for long-term reliability.

How to install a hydraulic control butterfly valve?

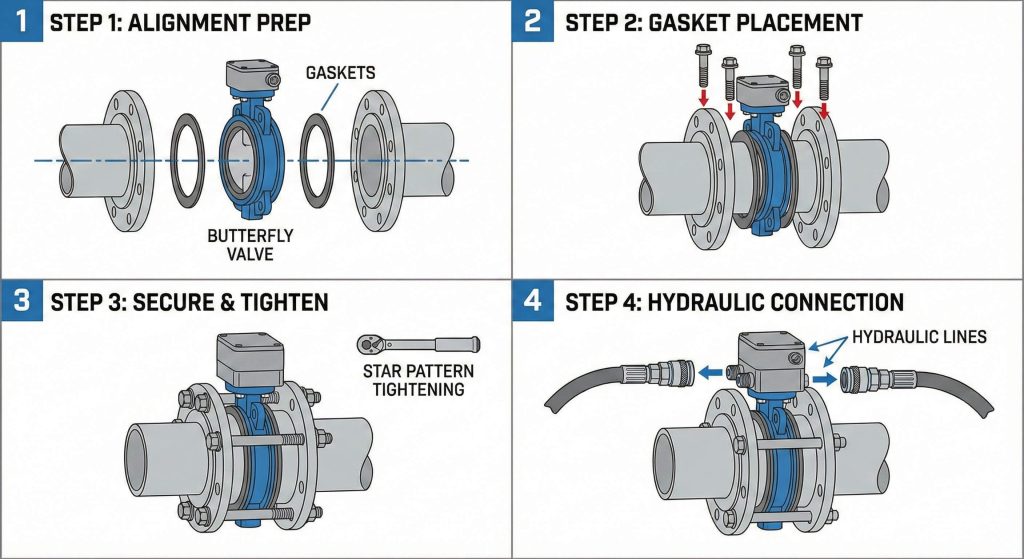

To install a hydraulic control butterfly valve, you must align the valve body precisely between the pipe flanges and secure the hydraulic power lines to the actuator ports. When you partner with an expert for hydraulic control butterfly valve solutions, you receive detailed GA drawings to guide your installation team. Improper alignment can cause the disc to hit the pipe wall, leading to catastrophic damage upon the first cycle.

What are the critical installation steps?

Keep this in mind: the valve should ideally be installed with the stem in a horizontal position if the media contains solids. This prevents sediment from collecting in the lower bearing and seizing the valve.

- Flange Cleaning: Remove all rust and debris before assembly.

- Gasket Centering: Ensure the gasket does not obstruct the disc path.

- Bolt Torquing: Use a star pattern to apply even pressure to the seals.

How to connect the control system?

Once the valve is physically mounted, you need to calibrate the limit switches and connect the hydraulic fittings. You must ensure the lines are clean and free of metal shavings that could damage the actuator’s internal pistons.

| Step | Focus Area | Success Metric |

|---|---|---|

| Alignment | Flange Centering | No Disc Obstruction |

| Connection | Hydraulic Hoses | Zero Leakage at Fittings |

| Calibration | Limit Switches | Accurate 0-90° Feedback |

Key Takeaway: Precise physical alignment and clean hydraulic connections are the foundations of a successful valve installation.

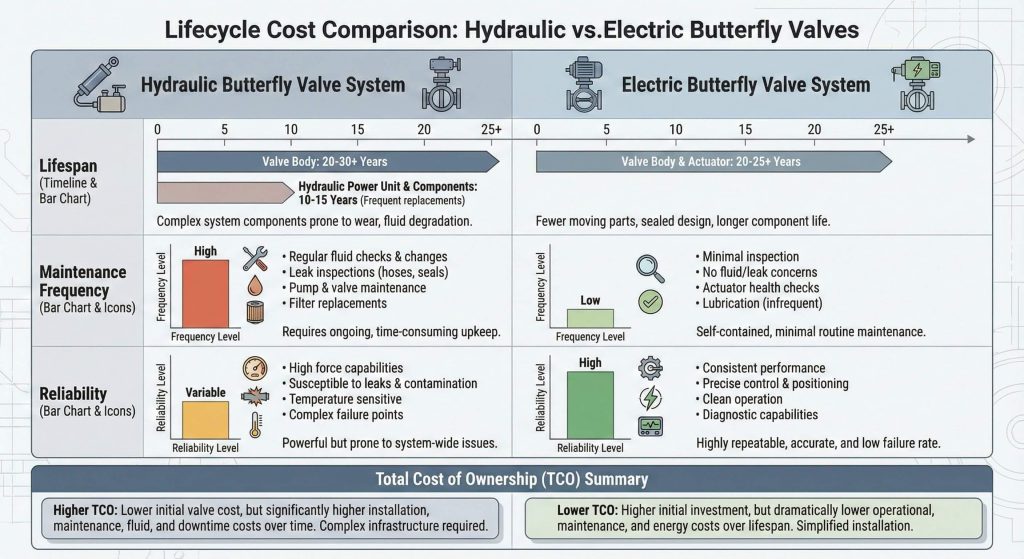

Is a hydraulic control butterfly valve cost-effective?

Yes, a hydraulic control butterfly valve is highly cost-effective because its 20-year service life and low maintenance requirements result in a lower total cost of ownership than complex electric alternatives. While the initial investment for the hydraulic power unit may be higher, you save significantly on energy and replacement costs. These valves are built for hundreds of thousands of cycles without needing major overhauls.

How does the lifecycle cost compare?

The bottom line is simple: if you choose a cheaper manual or pneumatic valve for a high-torque application, you will pay more in repairs and downtime. Hydraulic systems provide the durability needed for critical infrastructure where failure is not an option.

- Energy Efficiency: No power is required to hold the valve in position.

- Durability: Self-lubricating parts reduce the frequency of parts replacement.

- System Safety: Prevents expensive pipe bursts through controlled closing.

Is the investment worth it for your plant?

When you analyze your budget, consider the cost of one hour of plant downtime. If a hydraulic valve prevents even one emergency shutdown, it has likely paid for itself several times over.

| Factor | Hydraulic Valve | Electric Valve |

|---|---|---|

| Lifespan | 20+ Years | 10-15 Years |

| Maintenance | Low (Robust) | Moderate (Electrical) |

| Performance | High Torque | Limited Torque |

Key Takeaway: Despite higher upfront costs, the long-term reliability and low maintenance make hydraulic valves the best financial choice.

FAQ Section

Q1: Can I use a hydraulic control butterfly valve for seawater?

Yes, you can use them effectively if the disc is made of aluminum bronze or high-grade stainless steel to resist saltwater corrosion.

Q2: What’s the best way to handle emergency closures?

The best way is to utilize a hydraulic accumulator or spring-return actuator that provides independent power to close the valve during a total system outage.

Q3: Can I operate the valve manually if the hydraulic pump fails?

Yes, most systems include a manual hand pump or a mechanical handwheel override so you can still operate the valve during a power failure.

Q4: What’s the maximum size available for these valves?

Standard industrial sizes go up to DN3000, which is over 118 inches in diameter, suitable for the largest water mains and dam projects.

Q5: Can I install these valves in underwater applications?

Yes, hydraulic actuators are naturally suited for submersible environments because they are sealed units that do not rely on external air or electrical venting.

Conclusion

Selecting a high-performance hydraulic control butterfly valve is a strategic move that protects your facility from the risks of manual failure and slow response times. By leveraging high-torque actuators, specialized material selection, and robust engineering standards, you ensure that your fluid control systems remain reliable for decades. These valves solve the critical problems of low power density, high maintenance costs, and operational instability in large-scale pipelines. Our brand vision at RUITO is to provide precision-engineered solutions that empower global infrastructure with safety and efficiency. To optimize your specific system requirements and ensure 99.5% reliability, please contact us today for a technical consultation.