Introduction

Valve leakage is a silent budget killer in industrial operations, capable of causing catastrophic unplanned downtime, severe safety hazards, and environmental fines that cripple profitability. Many facility managers underestimate the cumulative impact of fugitive emissions and seat degradation, often realizing too late that the standard valves they installed cannot handle the oscillating temperatures or abrasive media of their specific process. Using the wrong offset design leads to rapid seat degradation and hidden costs that accumulate far faster than the initial savings on a cheaper valve, turning a minor procurement decision into a major operational headache. Understanding the mechanical differences between zero, double, and triple offset valves is the only way to secure your infrastructure against these risks. RUITO offers the precision engineering required for these critical choices, ensuring that your flow control systems deliver reliability where it matters most.

Zero Offset Valves: Basics Before Achieving Zero Leakage in Butterfly Valves

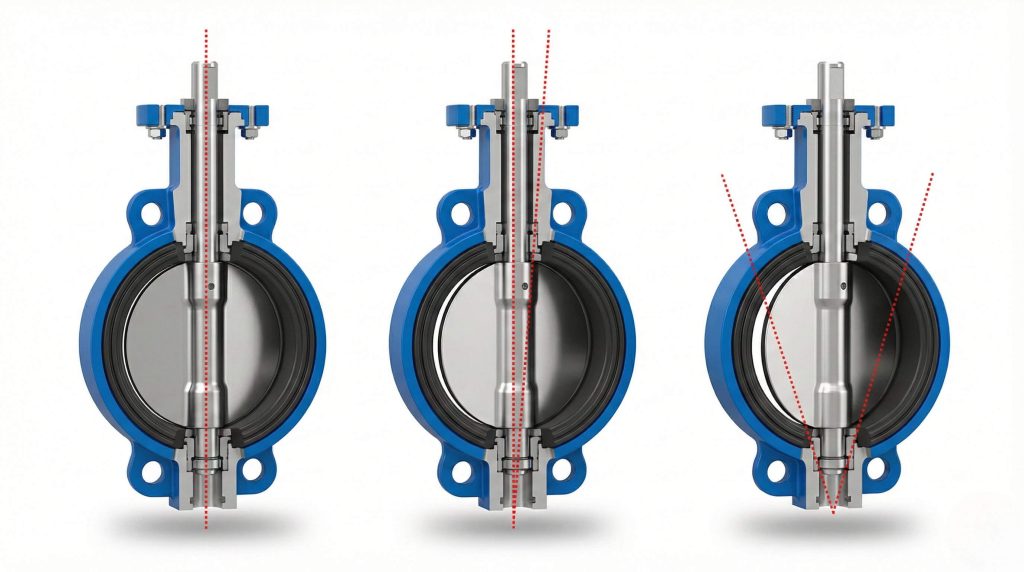

The zero offset valve, often referred to as a concentric butterfly valve, represents the foundational design in flow control technology. In this configuration, the stem passes through the centerline of the disc, and the disc is centered within the valve body bore. This geometry dictates that the disc remains in constant physical contact with the seat throughout the entire 90-degree rotation cycle. While this simplicity makes the valve highly cost-effective and easy to manufacture, the mechanical reliance on interference fit for sealing creates inherent limitations regarding friction and longevity.

What defines the zero offset design?

Zero offset, or concentric valves, feature a stem and disc centered directly within the valve body and seat. You will find the disc remains in constant contact with the seat throughout the entire cycle, relying on the deformation of the rubber to create a seal.

- Key Characteristics:

- Centered stem position relative to the disc and body.

- Constant disc-to-seat friction during the entire stroke.

- Reliance on resilient soft seating (EPDM, NBR, Viton).

- Generally limited to low pressure ratings (up to 250 PSI).

But is simple always better for your specific needs?

Is this design right for you?

While cost-effective, the constant friction means the soft seat wears down faster than other designs, leading to a loss of sealing integrity over time. You might struggle to maintain a perfect seal in high-cycle or abrasive environments where the elastomer can erode or deform permanently.

Key Takeaway: Zero offset valves are economical for low-pressure water or air systems, but they struggle with longevity when achieving zero leakage in butterfly valves under high stress.

Double Offset Valves: A Step Closer to a Zero Leakage Butterfly Valve?

As industrial processes evolved to require higher pressures and temperatures, the limitations of the concentric design became apparent, leading to the development of the double offset valve. This design introduces two distinct eccentricities: the stem is offset from the centerline of the disc seat and sealing surface, and it is also offset from the centerline of the valve bore. This geometry creates a cam action that physically lifts the disc off the seat immediately upon rotation, significantly reducing the duration of contact between the sealing surfaces. This reduction in friction allows for the use of more rigid seat materials, such as PTFE or reinforced heavy-duty elastomers, expanding the valve’s operational envelope.

How does the cam action work?

This design offsets the stem from both the disc centerline and the pipe centerline, creating a “cam action” during operation. You benefit from the disc lifting off the seat almost immediately, reducing friction during the stroke and minimizing wear points.

- Performance Features:

- Two distinct shaft offsets (eccentricities).

- Reduced seat wear due to minimized contact during opening.

- High-performance sealing capabilities (Class VI).

- Suitable for higher pressures, often up to ANSI Class 600.

However, you might be wondering if this eliminates all wear.

Can you trust high-performance seals?

Double offset valves use robust materials like PTFE or metal backups to handle higher pressures and temperatures than concentric types. While they offer bubble-tight shutoff, they still rely on some deformation of the seat or line pressure assistance for the final seal.

Key Takeaway: Double offset models bridge the gap between cost and performance, offering a reliable zero leakage butterfly valve option for moderate industrial pressures.

Triple Offset Valves: The Ultimate Zero Leakage Butterfly Valve Design

When the application demands absolute isolation in critical services—such as high-pressure steam, lethal gases, or cryogenic fluids—the triple offset butterfly valve (TOV) stands as the premier engineering solution. Building upon the double offset design, the TOV introduces a third offset: the sealing axis of the disc seat is inclined to the axis of the valve bore, creating a conical sealing profile. This geometry transforms the motion of the disc into a non-rubbing, compressive action. The disc acts like a door closing into a frame, contacting the seat only at the precise moment of full closure. This elimination of friction allows for the use of metal-to-metal seats that are fire-safe, wear-resistant, and capable of handling extreme thermal cycling.

Why choose triple offset geometry?

The third offset adds a conical profile to the sealing surface, ensuring the disc and seat only touch at the exact moment of closure. This eliminates rubbing entirely, allowing you to use hard metal seats without wear even in high-cycle applications.

- Superior Design Elements:

- Frictionless stroking mechanism prevents galling.

- True metal-to-metal sealing for durability.

- Extreme temperature capability (-196°C to +900°C).

- True zero leakage performance verified by API 598.

But what makes this truly superior for critical safety?

How is friction eliminated?

The right-angled cone design ensures the seal is achieved through contact pressure (torque) rather than positioning or elastic deformation. This means you get a bi-directional, fire-safe seal that does not degrade over time or rely on fluid pressure to actuate.

| Feature | Specification | Benefits |

|---|---|---|

| Sealing Type | Metal-to-Metal (Frictionless) | Fire safety and extreme durability. |

| Temperature | Cryogenic to >800°C | Suitable for LNG and superheated steam. |

| Leakage Class | API 598 (Zero Leakage) | Prevents fugitive emissions and product loss. |

| Primary Benefit | No wear during operation | Significantly lower lifecycle maintenance costs. |

Expert Analysis: Triple offset valves are the only design where torque generation guarantees the seal, making them indispensable for critical isolation where “almost shut” is not an option.

Key Takeaway: For severe service and harsh media, the triple offset is the definitive zero leakage butterfly valve solution due to its non-rubbing, metal-seated design.

Sealing Science: How Seats Impact Zero Leakage Butterfly Valve Performance

The integrity of any butterfly valve is ultimately dictated by the interaction between the disc and the seat, a relationship defined by material science and mechanical geometry. While the offset design controls how the disc contacts the seat, the material of the seat determines what fluids and temperatures the valve can withstand. Engineers must balance the need for a tight seal against the chemical aggression and thermal stresses of the process fluid. A mismatch here typically results in seat swelling, hardening, or cracking, all of which lead to immediate leakage paths.

Soft vs. metal: Which is better?

Soft seats (EPDM, PTFE) offer excellent sealing at low costs but fail quickly under high heat or abrasive conditions. You need to evaluate if your media will chemically attack the elastomer or degrade it thermally before choosing a soft-seated option.

- Material Classifications:

- Soft Seat: Tight seal, low temp, low cost (Rubber, NBR).

- Metal Seat: Extreme temp, fire-safe, high cost (Stellite, Stainless Steel).

- Laminated Seat: Composite layers (Metal/Graphite) for resilience and tightness.

- Fire-Safe: API 607 certified options typically requiring metal backup.

Yet, there is another factor you cannot ignore.

Why does the seat material matter?

Selecting the wrong material compromises the valve’s pressure rating and lifespan immediately, regardless of the offset design. You must match the seat material not just to the fluid chemistry, but to the mechanical stress exerted by the valve’s specific offset geometry.

Key Takeaway: The geometric design must work in tandem with the correct seat material to maintain a valid zero leakage butterfly valve rating over time.

Industrial Applications Demanding a Zero Leakage Butterfly Valve Solution

Not all leaks are created equal; in some industries, a leak is a nuisance, while in others, it is a catastrophe. The selection of valve offset type is frequently driven by regulatory compliance, safety standards, and the financial implications of process contamination. High-risk industries have largely migrated toward double and triple offset valves because the cost of failure—ranging from environmental cleanups to plant explosions—far outweighs the initial capital expenditure of premium valve hardware.

Where are these valves critical?

Industries handling hazardous chemicals, high-pressure steam, or volatile hydrocarbons cannot tolerate fugitive emissions or seat failure. You will find triple offset valves are mandatory in Oil & Gas and Power Generation sectors to prevent catastrophic failure and ensure personnel safety.

- Critical Sectors:

- Oil & Gas: Emergency Shut-Down (ESD) systems and pipeline isolation.

- Power Gen: High-pressure steam lines and condensate return.

- Cryogenics: LNG processing and transport (requires frictionless sealing).

- Chemical: Handling corrosive fluids and toxic gases.

But what if your application is less severe?

Are you risking safety?

Even in water treatment, high-pressure lines require the durability of double or triple offset valves to prevent water hammer damage and massive flooding. You jeopardize system integrity and worker safety by forcing a zero offset valve into a high-cycle, high-pressure role it was never designed to handle.

| Industry | Preferred Valve Type | Critical Requirement |

|---|---|---|

| Municipal Water | Zero Offset | Cost-efficiency and corrosion resistance. |

| HVAC | Zero / Double Offset | Modulation control and reliability. |

| Refinery | Triple Offset | Fire safety and zero leakage ESD. |

| Cryogenics | Triple Offset | Thermal stability at -196°C. |

Expert Analysis: While zero offset valves suffice for utilities, using them in hydrocarbon service is a liability; only triple offset valves provide the verifiable isolation required for safety-critical loops.

Key Takeaway: Match the severity of the application to the offset type to ensure you have a functioning zero leakage butterfly valve when emergencies occur.

Comparing Designs: Which Offers the Best Zero Leakage Butterfly Valve Value?

The concept of “value” in industrial procurement is often misunderstood as “lowest sticker price.” However, when analyzing valve performance, Total Cost of Ownership (TCO) is the only metric that matters. A zero offset valve may cost significantly less upfront, but if it requires replacement every six months due to seat abrasion, the labor costs and downtime losses quickly eclipse the price of a more durable double or triple offset valve. Conversely, specifying a titanium triple offset valve for a simple cooling water line is a waste of capital.

How do the three types stack up?

Zero offset wins on initial price, but triple offset wins decisively on Total Cost of Ownership (TCO) due to reduced maintenance intervals and operational lifespan. You have to decide if upfront savings are worth the risk of frequent replacements and potential process interruptions.

- Value Propositions:

- Zero Offset: Low CapEx, High OpEx (Frequent maintenance).

- Double Offset: Moderate CapEx, Good Performance Balance.

- Triple Offset: High CapEx, Lowest OpEx (Zero maintenance, long life).

Let’s look at the data side-by-side.

Is the cost worth the performance?

For critical path operations, the downtime cost of replacing a cheap valve far exceeds the premium price of a triple offset valve. You save substantial money in the long run by investing in durability that matches your production schedule.

| Feature | Zero Offset | Double Offset | Triple Offset |

|---|---|---|---|

| Friction | Constant (High Wear) | Reduced (Cam Action) | Eliminated (Frictionless) |

| Seat Material | Soft (Rubber/EPDM) | Soft (PTFE) / Metal | Metal / Laminated |

| Pressure Rating | Low (<250 PSI) | High (Class 600) | Extreme (Class 2500) |

| Initial Cost | Low | Moderate | High |

| Service Life | Short to Medium | Long | Very Long |

Expert Analysis: While zero offset fits utilities, only double and triple offsets provide the reliability required for process-critical infrastructure where “zero leakage” is a literal requirement.

Key Takeaway: Value is defined by lifecycle costs; a zero leakage butterfly valve that lasts 10 years is cheaper than a cheap valve replaced annually.

Maintenance Tips for Preserving Your Zero Leakage Butterfly Valve

Even the most advanced triple offset valve requires correct installation and occasional monitoring to maintain its zero-leakage certification. Neglect can lead to stem seizing, actuator failure, or debris accumulation that compromises the seal. A proactive maintenance strategy shifts the focus from emergency repairs to scheduled optimization, ensuring that your flow control assets remain reliable for decades rather than years.

How to extend valve service life?

Regular actuation prevents the stem from seizing in static applications, particularly in lines that remain open or closed for months. You should also monitor actuator torque output, as changes often indicate internal seat wear or debris buildup before a leak actually occurs.

- Maintenance Protocols:

- Cycle valves periodically (partial stroke testing).

- Flush lines before closing to remove debris.

- Monitor actuator torque profiles for anomalies.

- Check packing glands regularly for external leaks.

But what happens when a leak starts?

When should you replace the seat?

For soft-seated valves, any visible damage, tearing, or hardening requires immediate replacement to restore sealing integrity. Triple offset valves often allow for seat ring replacement without discarding the entire valve body, offering a repairable solution for long-term assets.

Key Takeaway: Proactive maintenance protocols are essential to ensure your zero leakage butterfly valve retains its bubble-tight certification throughout its intended lifespan.

Selection Guide: Finding the Perfect Zero Leakage Butterfly Valve for You

Selecting the correct valve is an exercise in matching technical constraints with operational goals. It requires a holistic view of the piping system, including potential pressure spikes, thermal shocks, and the chemical nature of the fluid. Over-specifying leads to wasted budget, while under-specifying invites disaster. RUITO recommends a data-driven approach to selection, ensuring that every valve installed is optimized for its specific location in the plant.

What specs define your ideal valve?

Start with the pressure class and temperature range, then analyze the media for abrasiveness and corrosiveness. You must consult the manufacturer’s torque charts to size your actuator correctly, as offset valves have different torque requirements than concentric ones.

- Critical Specification Criteria:

- Operating Pressure & Temperature (Min/Max).

- Media type (Slurry, Gas, Liquid, Corrosive).

- Required Shutoff Class (e.g., API 598, ISO 5208).

- Actuation method (Pneumatic, Electric, Manual).

One final summary to help you decide.

Comparison of Specs

Reviewing the technical limits ensures you don’t under-spec your system and create a weak link in your piping infrastructure.

| Valve Type | Max Temp | Max Pressure | Leakage Standard |

|---|---|---|---|

| Concentric | ~200°C | ~17 Bar | Standard Seal |

| Double | ~538°C | ~100 Bar | Class VI (Soft Seat) |

| Triple | ~900°C | ~420 Bar | Zero Leakage (Metal) |

Expert Analysis: Always select a valve rating that exceeds your system’s maximum spike pressure, not just the steady-state operating pressure, to ensure safety during upsets.

Key Takeaway: Accurate specification is the first step to installing a zero leakage butterfly valve that performs safely and efficiently.

Conclusion

The difference between zero, double, and triple offset butterfly valves is not merely a matter of geometry; it is the difference between basic containment and absolute isolation. While zero offset valves serve well in benign utility applications, the demanding environments of modern industry require the advanced engineering of double and triple offset designs to ensure safety and efficiency. The Triple Offset Valve, in particular, stands as the pinnacle of this technology, offering frictionless operation and verifiable zero leakage for the most critical services.

RUITO specializes in custom-engineered zero, double, and triple offset valves designed to meet stringent industry standards for zero leakage. Our commitment to precision manufacturing ensures that whether you are managing a municipal water plant or a high-pressure petrochemical refinery, you have the technology required to maintain control.

Contact RUITO today to optimize your systems with valves engineered for safety, longevity, and performance.

FAQs

- Can a zero offset valve achieve zero leakage?

Yes, a zero offset valve can achieve zero leakage, but typically only at low pressures and temperatures using new soft seats. However, due to the constant friction between the disc and seat, the seal degrades much faster than in offset designs, leading to leaks over time.

- Why is a triple offset valve so expensive?

The cost reflects the high-precision machining required to create the elliptical conical seat geometry and the use of high-grade alloys (like Stellite or Duplex steel) necessary for frictionless, metal-to-metal sealing. This initial investment pays off through zero maintenance and extended longevity.

- Is a double offset valve fire-safe?

A double offset valve is only fire-safe if specifically specified as such. Standard models often use soft seats (PTFE) that melt in a fire; however, fire-safe versions include a secondary metal backup seat to maintain a seal if the primary soft insert is destroyed.

- Which valve handles abrasive slurry best?

The triple offset valve is superior for abrasive slurry because its cam action prevents the seat from rubbing against abrasive particles trapped on the disc. The “torque seating” nature also allows the valve to cut through sludge to form a seal, unlike soft seats that would be torn apart.

- Can I use a butterfly valve for throttling?

Yes, double and triple offset valves are excellent for throttling applications due to their stable flow characteristics and robust design. Their offset geometry reduces the torque required to hold the disc in an intermediate position, providing precise flow control.