A bare shaft butterfly valve is a high-performance valve body manufactured without a manual handle or gear to facilitate the direct installation of automated pneumatic or electric actuators. You often struggle with pre-assembled valves that don’t match your specific automation protocols, leading to expensive hardware waste and project delays. These mismatched components increase the risk of stem leakage and drive failure, which can eventually shut down your entire production line. RUITO solves this problem by providing precision-engineered bare shaft butterfly valve units that feature standardized ISO 5211 mounting pads for effortless integration.

1. What is a bare shaft butterfly valve?

A bare shaft butterfly valve is a modular fluid control component designed with a “headless” configuration to support custom actuation systems. This design allows you to select the exact actuator brand and torque specifications required for your unique piping environment.

Modular Automation Interface

The core purpose of this valve is to provide a clean mechanical interface for automated drives. By removing the manual lever, you eliminate unnecessary parts and reduce the overall weight of the valve assembly.

Here is the deal:

Standardization is the key to minimizing your long-term maintenance inventory.

- ISO 5211 mounting pad for universal fit.

- Extended stem for easy insulation.

- Reduced profile for compact manifolds.

- Direct-drive stem for maximum precision.

Key Takeaway: Bare shaft units are the essential foundation for any modern automated piping system that requires high reliability.

| Feature | Specification |

|---|---|

| Interface Type | ISO 5211 Mounting Pad |

| Stem Design | Square, Flat, or Keyed |

| Primary Use | Automated Systems Only |

| Compliance | API 609 / EN 593 |

Using standardized mounting pads ensures your automation hardware fits perfectly every time.

2. How does a bare shaft butterfly valve function?

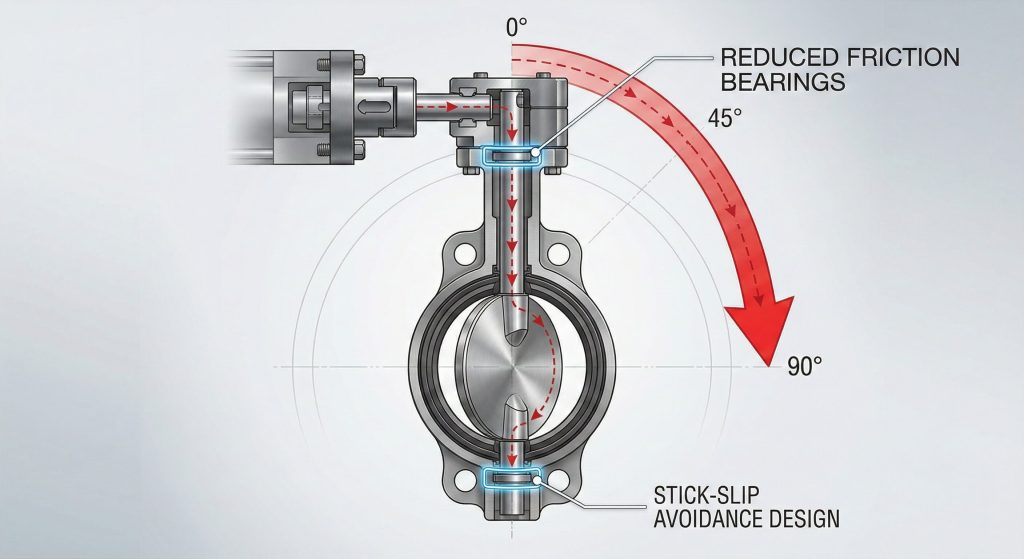

A bare shaft butterfly valve functions by transferring rotational torque from an external actuator through a precision-machined stem to the internal sealing disc. When the actuator rotates the shaft 90 degrees, the disc moves from a closed position to a fully open state within the pipeline.

Torque Transmission Process

The mechanical efficiency of the valve depends on the smoothness of the stem’s rotation within the body bearings. You will find that high-quality machining prevents the “stick-slip” effect that can interfere with sensitive modulating control.

Look at this:

Precise stem alignment is what prevents lateral stress from destroying your actuator seals.

- Actuator converts energy to torque.

- Force travels through the coupling.

- The disc rotates into position.

- Sealing occurs at 90 degrees.

Key Takeaway: Smooth torque transmission is vital for maintaining the accuracy of your process control loops.

| Operational Metric | Performance Level |

|---|---|

| Rotation Stroke | 0° to 90° |

| Control Logic | On-Off or Modulating |

| Drive Efficiency | Direct Coupling |

| Sealing Speed | Depends on Actuator |

The direct-drive mechanism provides a more responsive control experience than manual gearboxes.

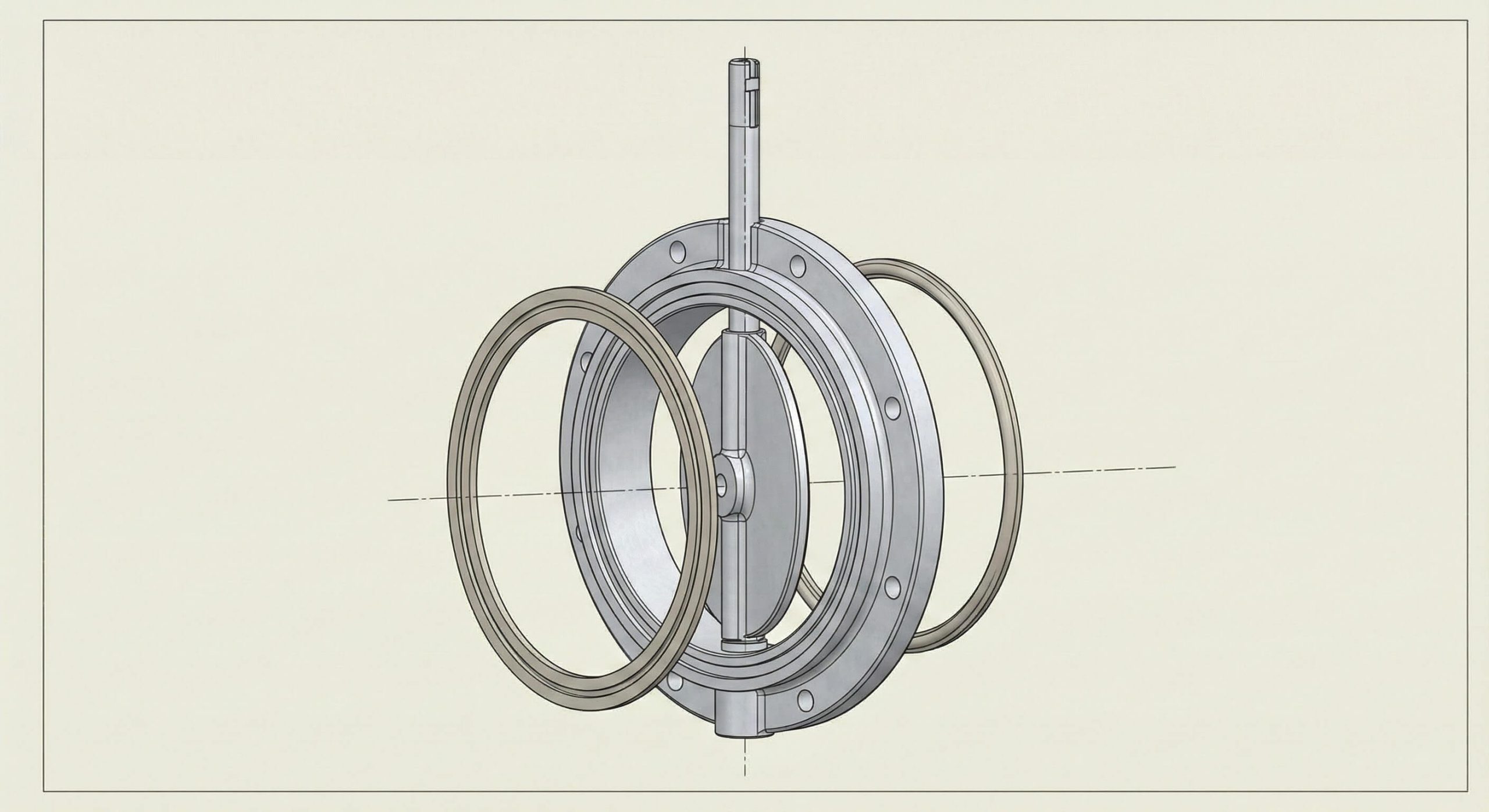

3. What are the parts of a bare shaft butterfly valve?

The parts of a bare shaft butterfly valve include a rugged outer body, a precision-contoured disc, a resilient seat liner, and a high-strength stainless steel stem. Each component is engineered to withstand the specific chemical and thermal stresses of your industrial application.

Critical Sealing Components

The stem acts as the bridge between your expensive actuator and the fluid media inside the pipe. RUITO uses blow-out proof shaft designs to ensure maximum safety for your plant personnel under high-pressure conditions.

Wait, there is more:

The choice of seat material is what determines the ultimate lifespan of your valve in corrosive service.

- High-strength stainless steel stems.

- Precision disc for low torque.

- Blow-out proof shaft security.

- Machined ISO mounting pads.

Key Takeaway: Using premium materials for internal components significantly reduces the frequency of your unplanned maintenance cycles.

| Valve Component | Material Options |

|---|---|

| Body | Ductile Iron / SS316 |

| Sealing Disc | SS304 / Nylon Coated |

| Stem Shaft | 410SS / 17-4PH |

| Seat Liner | EPDM / NBR / PTFE |

Component material synergy is the secret to achieving a bubble-tight shutoff in every cycle.

4. Why choose a bare shaft butterfly valve for projects?

You choose a bare shaft butterfly valve to gain complete freedom over your plant’s automation architecture and brand standards. This modularity allows you to source actuators from local suppliers while maintaining a consistent valve body standard across your entire facility.

Cost and Customization Benefits

Purchasing bare shaft units reduces your initial capital expenditure by eliminating the cost of manual handles you never intended to use. It also simplifies your spare parts management because you can swap actuators without removing the valve from the line.

Think about it:

Independence from manufacturer-specific actuators gives you more leverage during the procurement process.

- Independent component replacement.

- Lower initial hardware pricing.

- Simplified inventory management.

- Brand-agnostic actuator pairing.

Key Takeaway: Modularity leads to a lower total cost of ownership by allowing for independent actuator and valve maintenance.

| Project Advantage | Business Impact |

|---|---|

| Procurement | 20% Lower Initial Cost |

| Maintenance | Faster Repair Cycles |

| Flexibility | Global Brand Support |

| Logistics | Lower Shipping Weight |

A modular strategy ensures your plant stays adaptable as new automation technologies emerge.

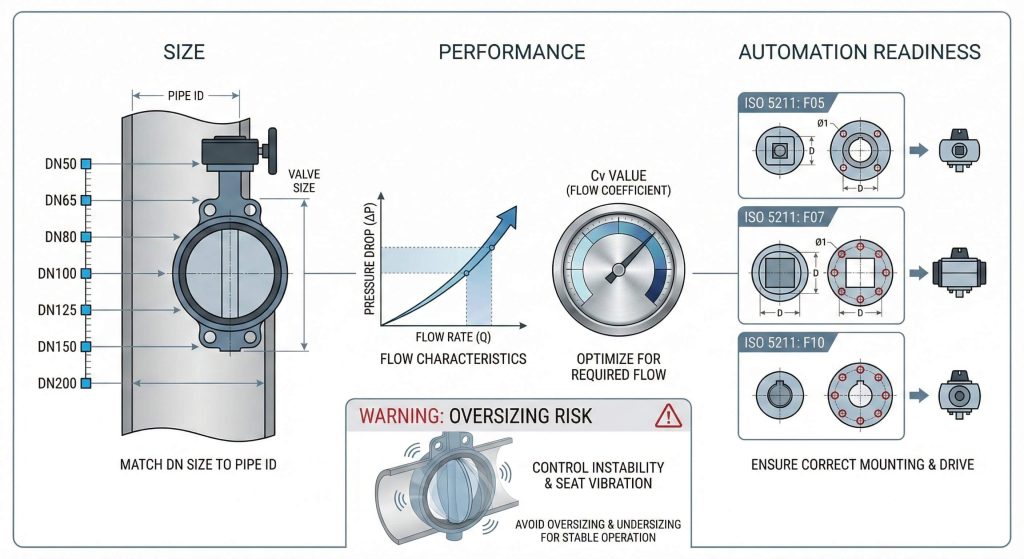

5. How do you size a bare shaft butterfly valve?

Sizing a bare shaft butterfly valve involves calculating the required flow coefficient (Cv) and the maximum torque demand of the media at peak pressure. You must ensure that the pipe diameter matches the valve size to prevent excessive turbulence and seat erosion.

Flow and Interface Matching

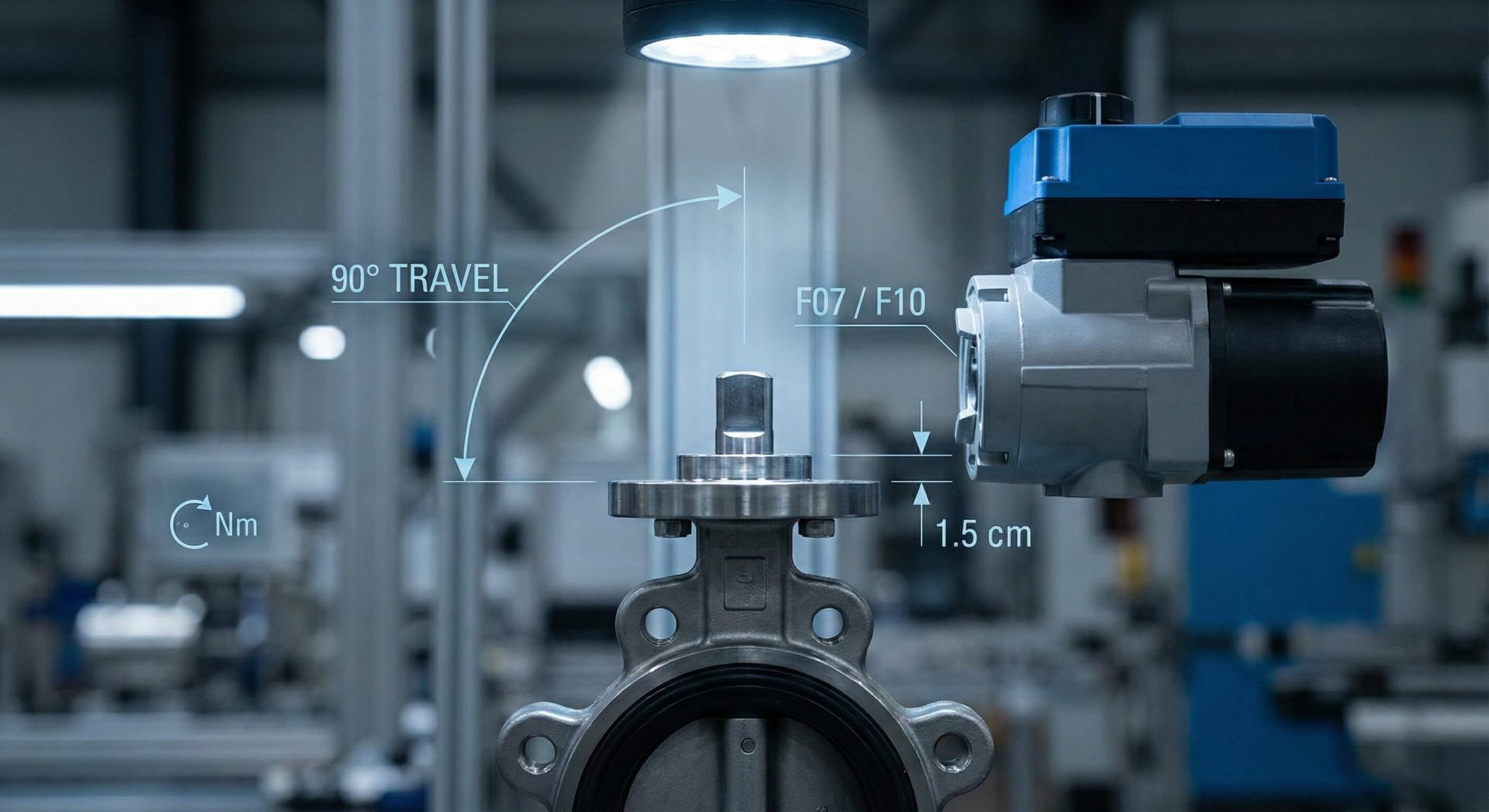

You must also verify that the stem diameter and mounting pad code (e.g., F07) match the drive socket of your actuator. A minor mismatch here will result in mechanical play that eventually ruins the actuator’s drive teeth.

Here is the kicker:

Oversizing your valve is just as dangerous as undersizing because it leads to poor control and seat “chatter.”

- Accurate Cv value calculations.

- Media velocity assessments.

- Dynamic torque measurements.

- Pressure drop optimizations.

Key Takeaway: Precise mechanical and hydraulic sizing is the only way to ensure your automated system operates efficiently.

| Sizing Variable | Unit of Measure |

|---|---|

| Nominal Diameter | DN / Inches |

| Required Torque | Newton-Meters (Nm) |

| Mounting Code | ISO 5211 (F-series) |

| Flow Rate | GPM / m³/h |

Correct sizing protects your actuator investment from being overworked and failing prematurely.

6. Which materials suit a bare shaft butterfly valve?

The materials for a bare shaft butterfly valve must be selected based on the pH levels, temperature, and abrasiveness of your process fluid. Ductile iron with EPDM seats is the industry standard for HVAC and municipal water systems due to its durability and low cost.

Corrosion Resistance Strategies

If you are dealing with aggressive chemical processing, upgrading to a 316 stainless steel disc and PTFE seat is mandatory for safety. RUITO offers specialized coatings like epoxy and nylon to protect the valve body from harsh external environments like salt spray.

It gets interesting:

A small investment in material upgrades today prevents a catastrophic environmental leak tomorrow.

- Ductile Iron for water/HVAC.

- Stainless Steel for chemicals.

- PTFE for corrosive acids.

- Bronze for marine environments.

Key Takeaway: Strategic material matching is the most effective method for extending the operational life of valves in harsh media.

| Environment | Body Material | Seat Material |

|---|---|---|

| Potable Water | Ductile Iron | EPDM |

| Sea Water | Bronze | NBR |

| Strong Acids | SS316 | PTFE |

| High Temp | Carbon Steel | Viton |

Selecting the right materials ensures that your automated valves remain functional even in the most demanding settings.

7. Where to install a bare shaft butterfly valve properly?

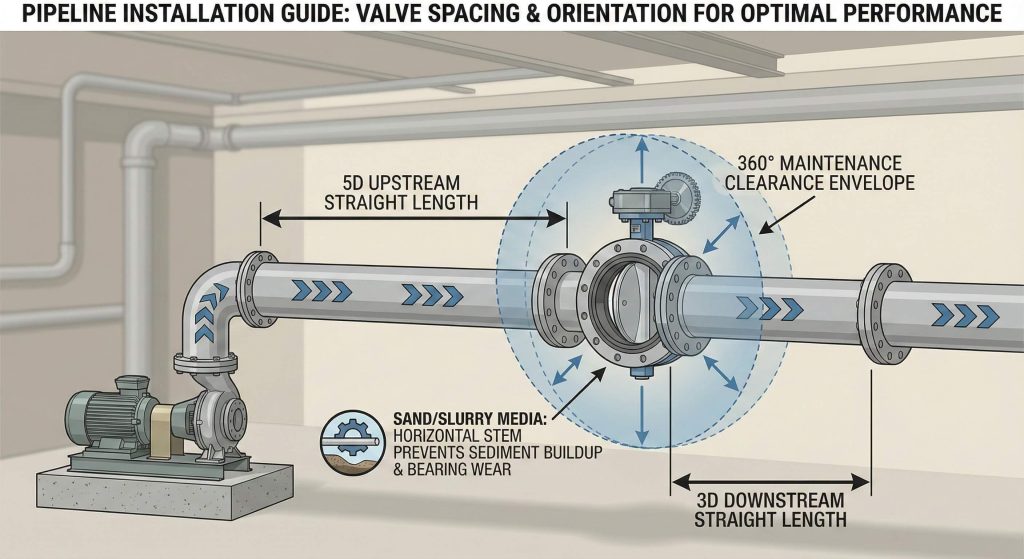

Proper installation of a bare shaft butterfly valve requires a straight run of pipe to ensure uniform flow distribution across the disc surface. You should position the valve so the stem is horizontal when handling fluids that contain sand or other abrasive solids.

Orientation and Clearance Planning

You must also plan for sufficient overhead clearance to allow for actuator removal and electrical wiring access. Installing the valve too close to a pump or elbow will create turbulent flow that causes the disc to vibrate and wear out the seat.

Believe it or not:

Most premature seal failures are caused by improper installation distance from turbulent pipe fittings.

- Horizontal stems for slurries.

- 360-degree actuator clearance.

- Distanced from turbulent elbows.

- Secure mounting bolt torque.

Key Takeaway: A well-planned installation protects the valve internals and makes future maintenance significantly easier for your team.

| Installation Factor | Recommendation |

|---|---|

| Upstream Straight | 5x Pipe Diameter |

| Downstream Straight | 3x Pipe Diameter |

| Stem Position | Horizontal (Dirty Media) |

| Access Space | 1 Meter Radius |

Following these guidelines ensures that your automation system performs with the highest level of stability.

8. How to maintain a bare shaft butterfly valve?

Maintaining a bare shaft butterfly valve is exceptionally simple because there are no complex manual gearboxes to lubricate or repair. Your primary focus should be on inspecting the stem packing for signs of moisture and verifying the tightness of the actuator mounting bolts.

Preventive Care and Inspections

You should cycle the valve at least once a month to prevent the seat from bonding to the disc during long periods of inactivity. Tightening the packing gland occasionally will stop minor leaks before they can damage the sensitive electronics in your actuator.

Now look:

Consistent maintenance is the only thing standing between you and a multi-thousand dollar repair bill.

- Quarterly bolt inspections.

- Monthly leak observations.

- Bi-annual seat testing.

- Annual actuator calibration.

Key Takeaway: A proactive approach to stem seal integrity is the most important part of your valve maintenance program.

| Task | Frequency |

|---|---|

| Visual Inspection | Every 30 Days |

| Bolt Torque Check | Every 90 Days |

| Seat Leak Test | Every 12 Months |

| Actuator Calibration | Every 2 Years |

Regular maintenance ensures that your automated flow control system never becomes a liability for your operation.

9. Who is a top bare shaft butterfly valve manufacturer?

RUITO stands out as a top manufacturer by providing ISO 9001-certified valves that meet the strict quality and documentation standards of global EPC projects. We perform 100% hydrostatic and pneumatic pressure testing on every single unit to guarantee absolute reliability in the field.

Engineering Excellence Standards

Our factory utilizes advanced CNC machining to ensure that every ISO 5211 mounting pad is perfectly flat and precisely aligned for your actuators. We provide full material traceability and all necessary international certifications like CE, WRAS, and DNV for your peace of mind.

The best part?

Our engineering team provides 24-hour technical support to help you solve any integration challenges on-site.

- ISO 9001:2015 QC systems.

- 100% Hydrostatic testing.

- Full material traceability.

- Global market certifications.

Key Takeaway: Partnering with a manufacturer that prioritizes technical transparency ensures your project stays on schedule and in compliance.

| RUITO Capability | Standard |

|---|---|

| Testing Pressure | 1.5x Working Pressure |

| Traceability | Full Batch MTCs |

| Lead Time | 5-25 Working Days |

| Certifications | CE, WRAS, DNV, ISO |

Choosing a manufacturer with proven export experience reduces your risk in complex international projects.

10. What is a bare shaft butterfly valve cost?

The cost of a bare shaft butterfly valve is primarily influenced by the body material, the nominal size, and the precision level of the stem machining. While these units are less expensive than manual versions, you must consider the total system cost including the actuator and mounting kit.

Total Ownership Calculations

You will find that investing in high-quality stainless steel internals pays for itself by reducing the frequency of seat and stem replacements. RUITO offers competitive bulk pricing that allows you to maximize your project budget without sacrificing the mechanical integrity of your system.

Here is the bottom line:

Don’t be fooled by the lowest price; a cheap mounting pad will cost you far more in damaged actuators and downtime.

- Material grades (DI vs. SS).

- Nominal size expansions.

- Seat upgrade requirements.

- Volume purchase discounts.

Key Takeaway: Evaluating the total cost of ownership is the most effective way to justify a high-quality valve procurement strategy.

| Cost Component | Price Influence |

|---|---|

| Body Alloy | High (Up to 300%) |

| Size | Moderate (Linear) |

| Seat Material | Low (Up to 50%) |

| QC Documentation | Minimal |

Focusing on the quality of the automation interface provides the greatest long-term return on your hardware investment.

Conclusion

Precision-engineered bare shaft units are the backbone of efficient industrial automation. RUITO is committed to manufacturing valves that meet the highest standards of reliability and modular flexibility. By choosing our ISO-compliant designs, you ensure that your automated systems perform with maximum uptime and safety. If you are ready to streamline your procurement and optimize your plant’s performance, contact us today for an expert technical consultation and quote.

FAQ

Can I use a manual handle on a bare shaft valve if my automation fails?

You can usually mount a manual override gear or a temporary lever if the stem profile is standard, but these valves are specifically optimized for permanent actuator mounting.

What’s the best way to prevent stem leakage?

The best way is to ensure that your actuator is perfectly aligned with the ISO pad and that the packing nut is adjusted to the manufacturer’s specified torque.

How do I know which ISO 5211 size I need?

You should refer to the technical drawing of your actuator to find its mounting code (like F05 or F10) and match it to the valve’s pad specification.

Where can I find the torque data for my bare shaft valve?

RUITO provides a complete technical datasheet with every order that includes the breakaway, running, and seating torque values for different media types.

What is the standard lead time for a bulk order?

Standard models are usually ready in 5-10 days, while custom alloy bodies or large-diameter units typically require 15-25 days to complete production and testing.