An electric butterfly valve works by utilizing an electric actuator to convert electrical energy into mechanical torque, which rotates a central disc 90 degrees to regulate or obstruct fluid flow.

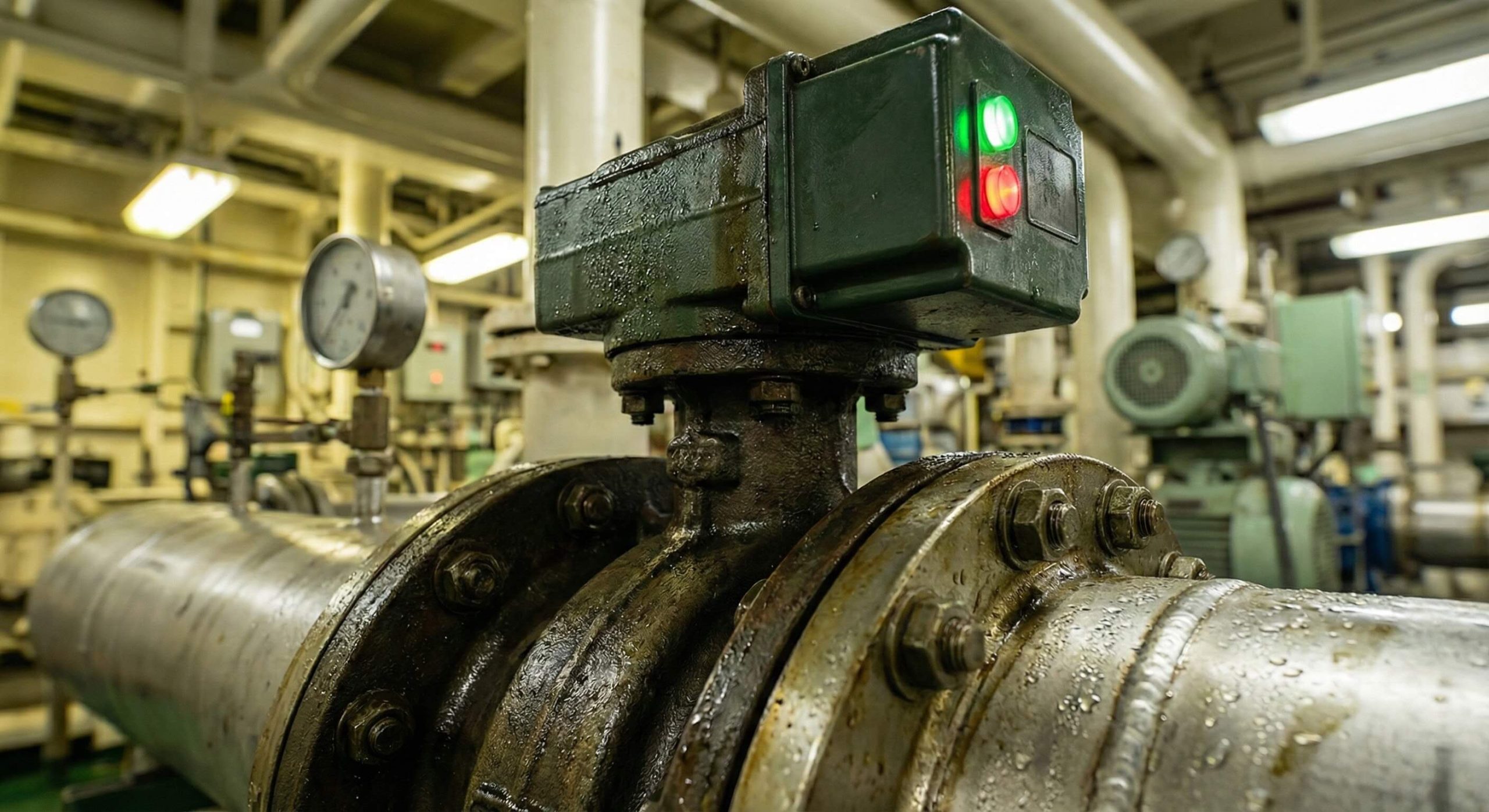

Managing fluid systems manually in high-stakes environments like engine rooms is often labor-intensive and prone to human error. You might face situations where a single delayed valve adjustment leads to pressure surges, equipment damage, or even localized flooding on a vessel. Transitioning to a marine electric butterfly valve provides the automated precision and remote control necessary to safeguard your infrastructure against these operational risks. Using these advanced tools ensures that your crew focuses on navigation rather than fighting stubborn handwheels.

What components comprise a marine electric butterfly valve?

A marine electric butterfly valve consists of an electric actuator mounted onto a valve body that houses a rotating disc, stem, and sealing seat. The actuator serves as the brain, receiving signals to move the mechanical parts that physically interact with the fluid.

The valve body is typically a wafer or lug style, designed to fit securely between pipe flanges while maintaining a compact profile. Inside, the disc is the primary moving part, which is supported by the stem to ensure it remains centered within the flow path. Heavy-duty seals surround the disc to stop any bypass once you close the unit.

How does the electric actuator function?

The actuator houses a motor and gear train that generates the high torque required to overcome fluid resistance. It translates electrical input into a precise quarter-turn movement that dictates the position of the internal disc.

- The motor initiates rotation upon receiving a voltage command.

- Limit switches stop the motor once the valve reaches the fully open or closed position.

- Internal gears multiply the force to handle high-pressure environments.

- The circuit board manages communication with your central control system.

Think about this:

Without a robust gear ratio, the motor would burn out trying to fight against the rushing water.

Key Takeaway: The synergy between the motorized actuator and the mechanical disc allows for seamless transition between flow states without manual intervention.

| Component | Function | Material Example |

|---|---|---|

| Electric Actuator | Provides rotational torque | Aluminum Alloy / Plastic |

| Valve Disc | Blocks or allows fluid flow | Stainless Steel / Bronze |

| Valve Stem | Transmits motion from actuator to disc | 416 Stainless Steel |

| Resilient Seat | Ensures a bubble-tight seal | EPDM / NBR |

This multi-component assembly ensures that electrical commands are reliably converted into physical flow control under varying maritime pressures.

How does a marine electric butterfly valve open?

A marine electric butterfly valve opens when the internal motor receives a signal to rotate the stem 90 degrees, moving the disc from a perpendicular position to one that is parallel with the flow. This action clears the pipe’s center, allowing the liquid to pass through with minimal obstruction.

As the actuator turns, the torque is applied through the stem directly to the disc. This motion is smooth and controlled, preventing the sudden “water hammer” effect that can sometimes occur with a standard system. You will notice that the flow increases gradually as the disc angle changes from zero to ninety.

What starts the opening sequence?

The process begins at a remote control station or via an automated PLC that sends a specific voltage to the actuator’s terminals. This current energizes the motor, which begins the mechanical reduction process through the gear system.

- Voltage inputs are typically 24V DC, 110V AC, or 220V AC.

- A relay or contactor closes the circuit to initiate motor movement.

- Feedback sensors confirm the initial “closed” status before movement begins.

- Software algorithms prevent accidental opening during high-pressure alerts.

Believe it or not:

The speed of this opening can often be adjusted to suit the specific needs of your piping system.

Key Takeaway: Opening is a precise, motorized transition that minimizes physical strain on the piping while providing remote operational capabilities.

| Feature | Open State Specification | Benefit |

|---|---|---|

| Disc Angle | 0 Degrees (Parallel to flow) | Maximum flow capacity (Cv) |

| Power State | Energized during movement | Automated remote operation |

| Position Feedback | “Open” signal sent to bridge | Real-time system monitoring |

| Flow Resistance | Minimal | Reduced energy consumption for pumps |

The controlled opening sequence is vital for maintaining steady system pressure and protecting downstream equipment from sudden surges.

What controls a marine electric butterfly valve?

An external control system manages the marine electric butterfly valve by sending electrical pulses or continuous signals to the actuator’s control board. You can operate these valves through simple on/off switches or sophisticated modulating controllers that allow for partial flow.

The actuator board interprets these signals and determines whether to drive the motor clockwise or counter-clockwise. This level of control is essential for managing complex networks like ballast water systems or fuel transfer lines where precision is mandatory. Feedback loops confirm that the valve has reached its target position.

Can you use modulating signals?

Modulating control allows you to position the disc at any angle between 0 and 90 degrees to throttle the flow rate precisely. This is achieved using a 4-20mA or 0-10V analog signal that corresponds to the desired valve percentage.

- A 4mA signal might represent a fully closed position.

- A 12mA signal would move the disc to a 45-degree angle.

- The actuator’s internal positioner compares the signal to the current disc angle.

- Local displays show the exact percentage of the opening.

You see:

Throttling flow prevents pressure spikes and allows for more delicate temperature control in cooling systems.

Key Takeaway: Control systems range from simple binary switches to complex modulating loops, providing the flexibility needed for diverse marine applications.

| Control Type | Signal Used | Typical Application |

|---|---|---|

| On/Off Control | 220V AC / 24V DC | Ballast tank filling/emptying |

| Modulating Control | 4-20mA Analog | Engine cooling water regulation |

| Bus Communication | Modbus / Profibus | Integrated vessel management systems |

| Manual Override | Mechanical Handwheel | Emergency loss of power scenarios |

Sophisticated control architecture ensures that every valve in the network responds predictably to automated or manual commands.

Why choose a marine electric butterfly valve?

You should choose a marine electric butterfly valve because it offers a significantly more compact and lightweight alternative to a traditional gate valve. In the cramped confines of a ship’s hull, saving space and reducing weight directly translates to better fuel efficiency and easier maintenance.

Furthermore, the integration of electric actuation allows for centralized control of all fluid systems from the bridge. This automation reduces the need for crew members to manually navigate tight corridors to turn heavy handwheels during routine operations. You gain better oversight of your entire fleet’s fluid status.

Is it more efficient than pneumatic?

Electric valves are often more efficient than pneumatic ones because they do not require an expensive air compressor system to be running constantly. You only consume energy when the valve is actually moving, whereas pneumatic systems often suffer from air leaks and maintenance overhead.

- Eliminates the need for extensive air piping throughout the vessel.

- Reduces the noise levels associated with air compressors and exhaust ports.

- Provides more precise positioning than standard pneumatic actuators.

- Saves total vessel power by only drawing current during travel.

But wait, there’s more:

Electric systems are easier to troubleshoot with standard multi-meters compared to hunting for microscopic air leaks.

Key Takeaway: Choosing electric butterfly valves optimizes space, reduces operational energy costs, and ensures long-term reliability in harsh saltwater environments.

| Factor | Electric Butterfly Valve | Benefit to Vessel |

|---|---|---|

| Installation Weight | Low | Higher payload capacity |

| Power Consumption | Only during travel | Reduced fuel for generators |

| Maintenance | Low (No air lines) | Lower long-term operational costs |

| Control Precision | High | Better system stability |

The shift toward electric actuation reflects a broader industry trend toward smarter, leaner, and more automated maritime infrastructure.

Where is a marine electric butterfly valve used?

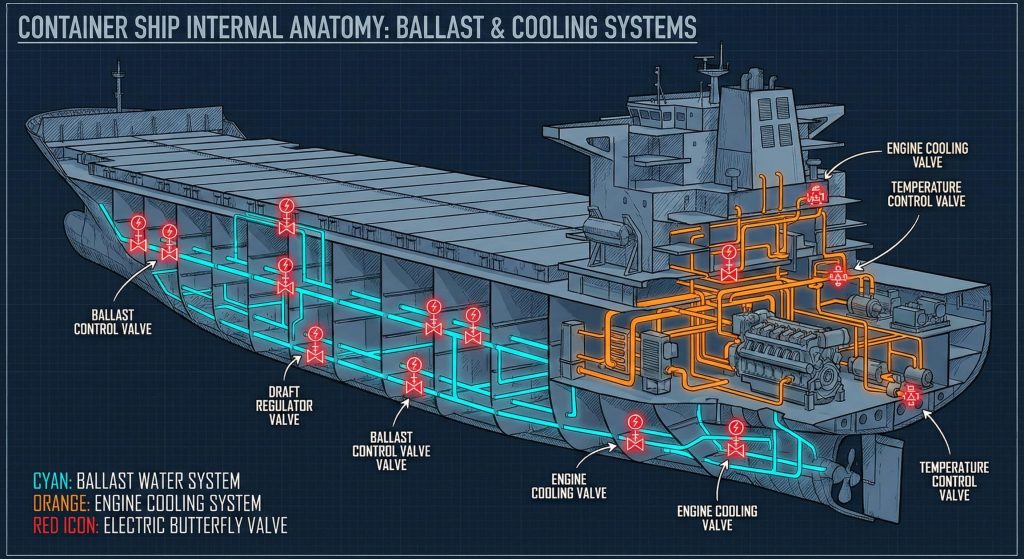

A marine electric butterfly valve is primarily used in large-scale fluid handling systems such as ballast water management, fire protection lines, and engine cooling circuits. Its ability to handle high flow rates with a quarter-turn action makes it ideal for these critical shipboard functions.

You will also find them in wastewater treatment systems and fuel oil transfer lines. Because they can be controlled remotely, they are the preferred choice for valves located in hard-to-reach areas or hazardous zones where manual access is limited. Reliability in these zones protects the ship from unexpected failures.

Why is it vital for ballast systems?

In ballast systems, these valves manage the intake and discharge of seawater to maintain the ship’s stability and trim. Automation allows the crew to balance the ship quickly during loading and unloading operations without leaving the control station.

- Rapidly switches flow between multiple tanks to adjust center of gravity.

- Integrates with ballast water treatment systems to ensure environmental compliance.

- Handles the high volumes of seawater required for large container ships.

- Operates reliably even when submerged in the lower hull areas.

The point is:

Failure in the ballast system during heavy seas can compromise the structural integrity of the entire vessel.

Key Takeaway: Their versatility and reliability make them the backbone of essential marine utility and safety systems.

| System | Primary Function | Valve Requirement |

|---|---|---|

| Ballast Water | Stability and Trim | High volume, fast response |

| Cooling Systems | Engine Temperature Control | Precise modulating capability |

| Fire Main | Emergency Suppression | Immediate opening, high pressure |

| Scrubber Systems | Exhaust Gas Cleaning | Corrosion resistance to acids |

From keeping the engines cool to ensuring the ship stays upright, these valves perform the heavy lifting of fluid management.

How to maintain a marine electric butterfly valve?

You maintain a marine electric butterfly valve by performing regular inspections of the electrical seals, lubricating the gear train, and testing the integrity of the resilient seat. Unlike some other valve types, the butterfly design is relatively simple and easy to access for your maintenance team.

Routine maintenance prevents the common issues of seat degradation and actuator stall, which can lead to system downtime. By following a structured schedule, you ensure that the valve operates smoothly for its entire service life expectancy. Proper documentation of these checks is required for maritime audits.

How often should you check the actuator?

The actuator housing should be opened every 6 to 12 months to check for signs of moisture ingress or loose wiring connections. You should also verify that the limit switches are still triggering at the correct angles to prevent mechanical strain.

- Inspect the O-rings and gaskets for any cracks or dry rot.

- Check terminal blocks for corrosion or heat discoloration.

- Apply fresh marine-grade grease to the drive gears if necessary.

- Verify the heater element is working to prevent internal condensation.

This is where it gets interesting:

A small amount of saltwater inside the actuator can destroy the entire circuit board in days.

Key Takeaway: Proactive maintenance focusing on moisture protection and seat integrity is the most effective way to prevent costly emergency repairs.

| Task | Frequency | Focus Area |

|---|---|---|

| Visual Inspection | Monthly | Leakage, external corrosion, loose bolts |

| Cycle Testing | Quarterly | Smooth movement, limit switch accuracy |

| Electrical Check | Bi-Annually | Voltage stability, wire insulation |

| Internal Overhaul | Every 5 Years | Seat replacement, gear lubrication |

Maintaining these units doesn’t just save money; it ensures the safety of the crew by keeping critical systems operational at all times.

Which materials suit a marine electric butterfly valve?

The materials used in a marine electric butterfly valve are specifically chosen for their resistance to galvanic corrosion and mechanical wear in saltwater environments. Typically, you will find bodies made of ductile iron or carbon steel, while the internal discs are often stainless steel or aluminum bronze.

The choice of sealing material is equally critical, with EPDM and NBR being the most common for standard water applications. These materials must maintain their elasticity even when exposed to varying temperatures and chemical treatments used in modern ballast systems. Choosing the wrong alloy can lead to rapid pitting.

Why use aluminum bronze for discs?

Aluminum bronze is highly favored in maritime applications because it forms a protective oxide layer that resists the harsh erosive forces of flowing seawater. It is significantly more durable than standard cast iron and offers better longevity in high-velocity lines.

- Excellent resistance to cavitation and impingement.

- Stronger mechanical properties than many common stainless steels.

- Naturally biocidial, which helps reduce marine growth on the disc.

- Maintains structural integrity under extreme thermal cycling.

What’s the real story?

Reducing biofouling on the disc means you maintain a better seal over time without frequent cleaning.

Key Takeaway: Marine-grade materials like aluminum bronze and specialized elastomers are non-negotiable for valves intended for long-term ocean service.

| Component | Standard Material | Premium Alternative |

|---|---|---|

| Valve Body | Ductile Iron (DI) | Stainless Steel 316 |

| Disc | Aluminum Bronze | Duplex Stainless Steel |

| Stem | 416 Stainless Steel | Monel / K500 |

| Seat | EPDM | Viton / PTFE |

Matching the right material to your specific fluid media prevents premature failure and ensures compliance with maritime classification societies.

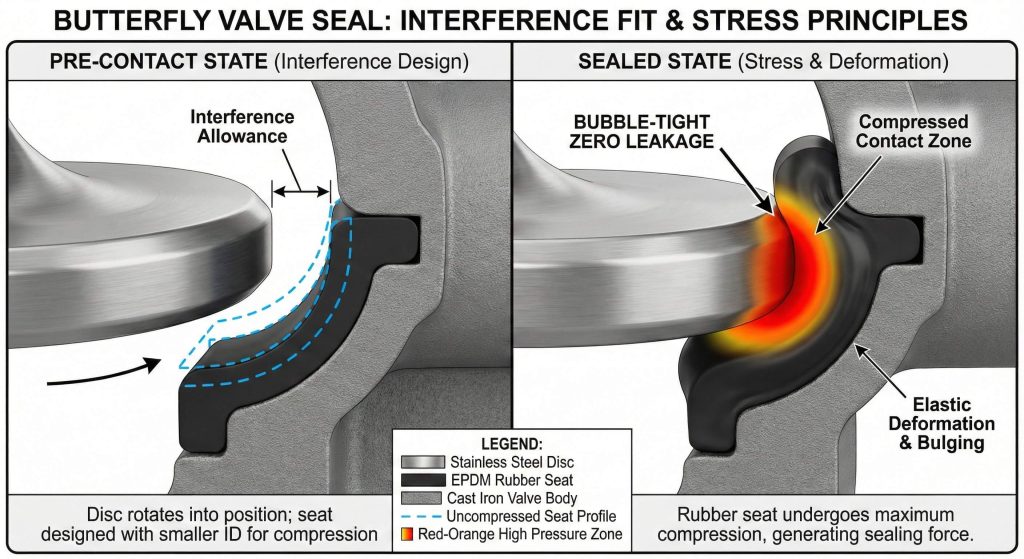

How reliable is a marine electric butterfly valve seal?

The seal of a marine electric butterfly valve is exceptionally reliable, often achieving bubble-tight performance when properly maintained. Unlike other designs, the butterfly valve uses the interference between the disc and the resilient seat to block flow completely.

In high-pressure marine environments, the pressure of the fluid actually helps to push the disc tighter against the seat in some designs. This ensures that the more pressure you have behind the valve, the more secure the seal becomes. This prevents dangerous leaks in the hull during deep-sea voyages.

How does the resilient seat work?

The resilient seat is slightly smaller in diameter than the disc, creating a press-fit when the valve closes. This deformation of the rubber material fills any microscopic gaps, ensuring that no liquid can seep through the interface.

- The seat is often reinforced with a rigid phenolic backer.

- Interference fit compensates for minor thermal expansion.

- Elastic memory of the rubber ensures the seal returns to shape.

- Friction between the disc and seat is minimized by polished surfaces.

Ready for the good part?

Some high-performance valves use a double-offset design that lifts the disc out of the seat immediately upon opening.

Key Takeaway: The combination of an interference-fit resilient seat and high-torque actuation provides a reliable, zero-leakage seal suitable for critical hull penetrations.

| Seal Rating | Description | Application |

|---|---|---|

| Class VI | Bubble-tight, zero visible leakage | Fuel lines, hull valves |

| Class IV | Metal-to-metal, minimal leakage | High-temp steam or exhaust |

| Bi-directional | Seals from both directions | Ballast manifolds |

| Fire-Safe | Maintains seal during extreme heat | Fire-fighting supply lines |

Reliability is built into the geometry of the seat, ensuring that the valve remains a dependable barrier against the ocean.

How to install a marine electric butterfly valve correctly?

You install a marine electric butterfly valve by sandwiching it between two pipe flanges and securing it with long bolts or studs. It is crucial to ensure the disc is in the partially open position during installation to prevent the disc edge from being crushed.

Proper alignment is the most important factor; if the valve is tilted, the seat will not compress evenly. This can lead to localized leaks or increased torque that might cause the electric actuator to trip its thermal overload protection. You must check the flange faces for cleanliness before tightening any bolts.

What is the correct orientation?

While butterfly valves can be installed in any orientation, it is generally recommended to install them with the stem horizontal. This prevents sediment or debris from settling in the bottom stem bearing, which can lead to sticking and corrosion over time.

- Horizontal stems allow debris to pass through the bottom.

- Ensure there is enough overhead clearance for actuator service.

- Avoid installing the valve too close to pumps or elbows.

- Support the weight of the actuator if the pipe is thin.

Make no mistake:

Installing with the actuator hanging underneath the pipe increases the risk of water damage if a leak occurs nearby.

Key Takeaway: Careful physical alignment and watertight electrical connections are the dual pillars of a successful valve installation.

| Installation Step | Critical Action | Consequence of Failure |

|---|---|---|

| Pre-fitting | Keep disc 10% open | Damage to seat/disc edge |

| Bolting | Use cross-pattern tightening | Uneven seal, body stress |

| Wiring | Seal all cable entries | Actuator electronics failure |

| Testing | Run 3 complete cycles | Undiscovered mechanical binding |

A correct installation ensures the valve starts its service life without unnecessary mechanical or electrical stress.

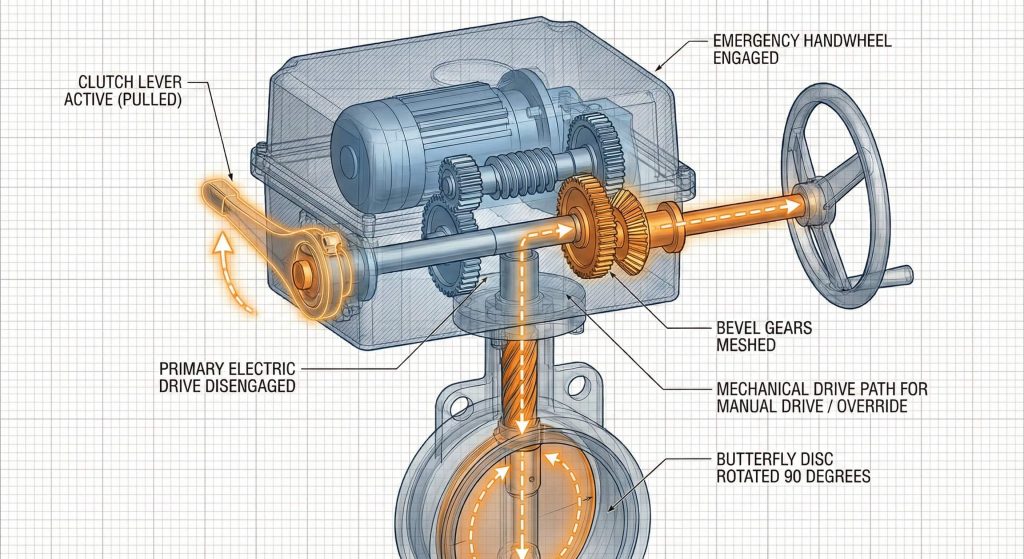

Can a marine electric butterfly valve fail safely?

Yes, a marine electric butterfly valve can fail safely by using either a manual override handwheel or a battery-backup system. In the event of a total shipboard power loss, you can still operate the valve to ensure the safety of the vessel.

Modern actuators often include an internal spring or a super-capacitor that stores enough energy to move the valve to a safe position automatically. This is a critical safety feature for hull valves and fuel systems where an unmanaged open line could be catastrophic. You can rely on these systems during emergency blackouts.

How does the manual override work?

The manual override usually involves a declutching lever and a handwheel that allows you to bypass the motor and turn the gears directly. Once engaged, you can manually crank the valve to the desired position to manage flow during emergencies or maintenance.

- Pull the lever to disconnect the motor drive.

- Rotate the handwheel clockwise to close the valve.

- Check the mechanical pointer to see the disc position.

- Re-engage the clutch for future automated operation.

The bottom line:

Always remember to re-engage the clutch after manual use, or the remote control system will not work.

Key Takeaway: Multiple fail-safe mechanisms—ranging from mechanical handwheels to electrical backups—ensure that you never lose control of your fluid systems.

| Fail-Safe Method | Power Source | Operational Speed |

|---|---|---|

| Manual Handwheel | Human power | Slow, manual effort |

| Battery Backup | Internal Battery | Normal actuator speed |

| Spring Return | Mechanical Spring | Very fast, automatic |

| Super-Capacitor | Stored Electrical Charge | Moderate, automatic |

Reliable fail-safe options are what separate professional-grade marine valves from standard industrial equipment.

Conclusion

As the maritime industry pushes toward autonomous shipping and higher efficiency, the role of automated fluid control becomes even more pivotal. By integrating advanced electric butterfly valves into your vessel’s infrastructure, you are not just upgrading hardware; you are investing in a future of predictable, safe, and cost-effective operations. To learn more about how our precision-engineered solutions can optimize your next project, contact us today.

FAQ

Q1: Can I manually operate an electric butterfly valve if the power goes out?

Yes. Most marine-grade electric actuators are equipped with a manual override handwheel or a hexagonal wrench socket that allows you to physically rotate the valve disc even without electrical power.

Q2: What’s the best way to prevent the motor from burning out?

Verify the torque. You must ensure that the actuator’s rated output torque is at least 20-30% higher than the valve’s maximum break-away torque, and always use limit switches to prevent the motor from straining against mechanical stops.

Q3: How do I know if the valve is truly closed from the control room?

Check the feedback signals. You should rely on the auxiliary limit switches or a 4-20mA position transmitter that sends a confirmed signal back to your control interface, rather than just assuming the command was executed.

Q4: Can I install these valves in a vertical pipe?

Yes. You can install them vertically, but it is highly recommended to keep the stem in a horizontal orientation to prevent sediment buildup in the lower bearings, which extends the life of the seals.

Q5: What’s the best material for a valve used in raw seawater?

Aluminum Bronze. This material offers the best balance of corrosion resistance and mechanical strength for seawater applications, significantly outperforming standard stainless steel in long-term submerged or high-flow scenarios.