A pnuematic butterfly valve is a quarter-turn automated valve that utilizes compressed air to rotate a disc and control fluid flow within a pipeline. Relying on manual labor for large-scale industrial flow control often leads to operational delays, inconsistent pressure management, and increased safety risks. Integrating a high-performance pnuematic butterfly valve solves these challenges by providing rapid, repeatable actuation that integrates seamlessly into modern automation systems.

What is a pnuematic butterfly valve in modern industry?

A pnuematic butterfly valve is an automated flow control device consisting of a valve body, a rotating disc, and a pneumatic actuator. Choosing a pnuematic butterfly valve ensures that your facility can handle high volumes of media with a compact footprint. This valve type is particularly favored in sectors like water treatment and HVAC for its efficiency.

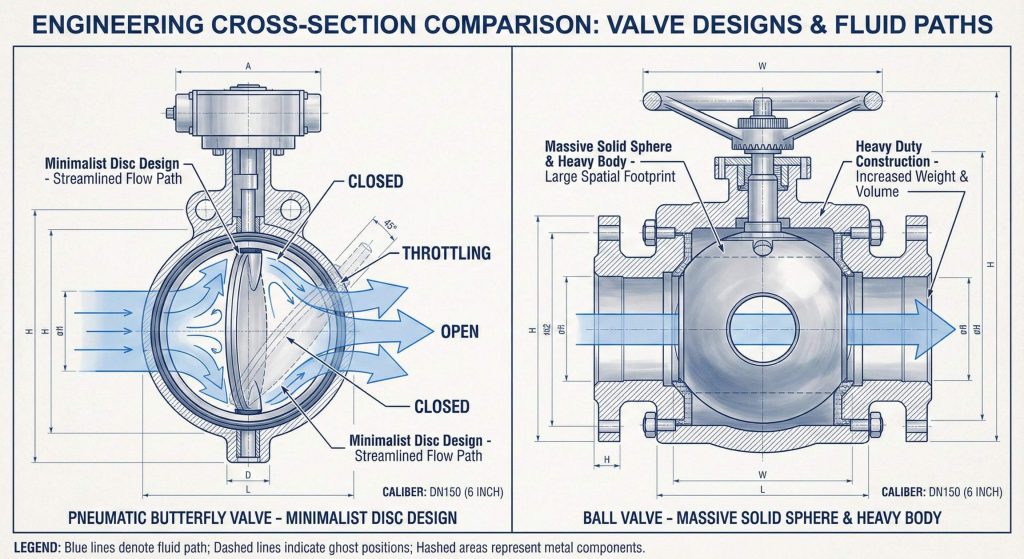

How does the internal disc work?

Think about it: the disc is the heart of the entire mechanism. This component remains in the flow path at all times, rotating on a central axis to either allow or block passage.

- Full Open: The disc sits parallel to the flow for maximum throughput.

- Full Closed: The disc presses against the seat to provide a tight seal.

- Throttling: The disc stays at an intermediate angle to regulate volume.

Key Takeaway: The streamlined design of the disc allows for quick 90-degree transitions between open and closed states.

| State | Disc Orientation | Flow Level |

|---|---|---|

| Open | 0 Degrees (Parallel) | 100% |

| Closed | 90 Degrees (Perpendicular) | 0% |

| Modulating | 1-89 Degrees | Variable |

This mechanical simplicity makes the butterfly design more cost-effective for large diameters than a standard Ball Valve.

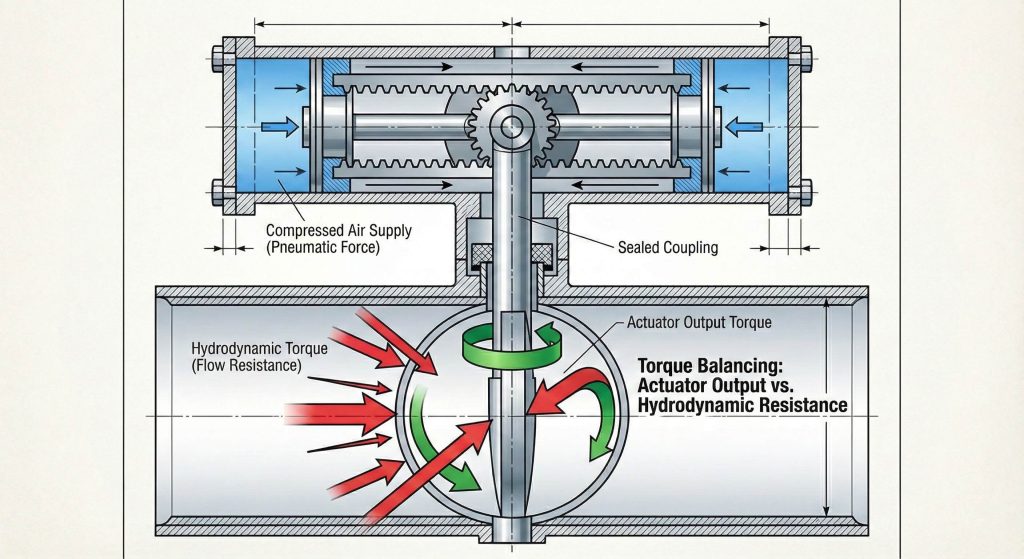

How does a pnuematic butterfly valve improve automation?

A pnuematic butterfly valve improves automation by converting air pressure into mechanical torque to operate the valve without human intervention. The pnuematic butterfly valve responds instantly to electronic signals from a central control system. This rapid response is critical for maintaining process stability in fast-moving production lines.

Why is actuation speed important?

Here is the deal: every second of delay in a safety shutdown or batch process can cost your company thousands. Pneumatic actuators move significantly faster than electric versions or manual gears.

- Instant Response: Air pressure moves the piston in milliseconds.

- Fail-Safe Ready: Spring-return units automatically close if power fails.

- High Cycle Life: These systems are built for millions of operations.

Key Takeaway: Automated speed reduces the risk of human error and ensures consistent cycle times across the plant.

| Benefit | Impact on Production |

|---|---|

| Speed | Reduces downtime during transitions |

| Reliability | Consistent performance over years |

| Safety | Immediate emergency shut-off capability |

Automation allows these valves to perform far more efficiently than a traditional Gate Valve in high-cycle environments.

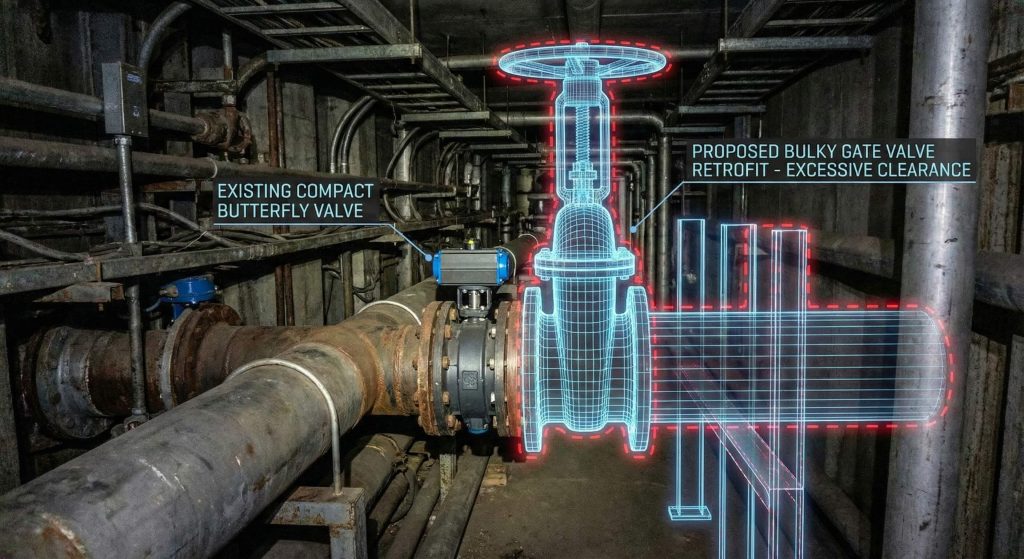

Why choose a pnuematic butterfly valve for large pipelines?

You should choose a pnuematic butterfly valve for large pipelines because it offers a lightweight and space-saving design compared to other heavy-duty valves. Utilizing a pnuematic butterfly valve allows for easier installation in tight spaces where heavy equipment cannot reach. They provide a high flow coefficient while maintaining a very short face-to-face dimension.

How does weight affect your system?

Look: a heavy valve puts unnecessary stress on your pipe supports and structural frames. The butterfly design uses less metal than most alternatives, which simplifies your entire engineering layout.

- Lower Costs: Less material means a lower purchase price for you.

- Easy Handling: Smaller crews can install these without heavy cranes.

- Minimal Stress: Reduces the risk of pipe sagging or flange leaks.

Key Takeaway: Choosing lightweight valves reduces both initial capital expenditure and long-term infrastructure maintenance.

| Valve Type | Relative Weight | Installation Ease |

|---|---|---|

| Butterfly | Light | High |

| Ball | Medium | Moderate |

| Gate | Heavy | Low |

Compared to a bulky Globe Valve, the butterfly design significantly lowers the total weight of your piping network.

Can a pnuematic butterfly valve handle corrosive chemicals?

Yes, a pnuematic butterfly valve can handle corrosive chemicals when equipped with specific liners and high-grade alloy discs. The pnuematic butterfly valve is often lined with PTFE or PFA to prevent the metal body from contacting aggressive media. This makes them ideal for chemical processing and pharmaceutical applications where purity is paramount.

Which liner materials are best?

Best of all: you can customize the internal materials to match the exact pH and temperature of your chemicals. Choosing the right polymer ensures that the valve remains leak-proof throughout its service life.

- PTFE: Offers nearly universal chemical resistance for acids.

- Viton: Excellent for high temperatures and oil-based media.

- EPDM: The standard choice for water and mild chemicals.

Key Takeaway: Material selection for the seat and disc is the most critical factor in chemical durability.

| Material | Chemical Resistance | Temperature Range |

|---|---|---|

| PTFE | Excellent | -20°C to 200°C |

| EPDM | Good | -30°C to 120°C |

| Viton | Very High | -15°C to 200°C |

Using a lined butterfly valve is often a more practical solution for chemical flow than using a metal-seated Check Valve.

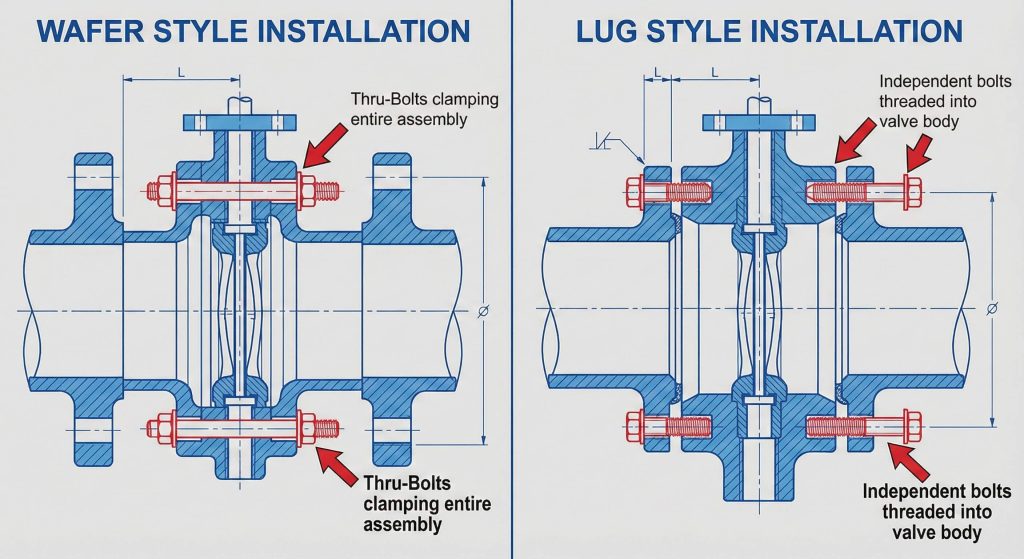

What defines the body of a pnuematic butterfly valve?

The body of a pnuematic butterfly valve is defined by its outer casing which houses the disc and provides the connection points for the pipeline. A high-quality pnuematic butterfly valve body is typically made from ductile iron, stainless steel, or carbon steel. The body must withstand the internal pressure of the media while supporting the weight of the pneumatic actuator.

What are the main body styles?

In fact: the way the valve connects to your pipes determines how easy it will be to maintain your system later. Most industrial setups use either wafer or lug configurations depending on the location of the valve.

- Wafer: Slides between two flanges for the most compact fit.

- Lug: Features threaded holes for independent bolting to each flange.

- Flanged: Used for very large diameters and high-pressure ratings.

Key Takeaway: Wafer bodies are the most economical, while lug bodies allow for downstream piping removal.

| Style | Installation Type | Best For |

|---|---|---|

| Wafer | Clamped between flanges | General applications |

| Lug | Bolted to each flange | Dead-end service |

| Flanged | Double bolted flanges | Heavy industrial use |

A lug-style body provides more versatility for maintenance than a standard Ball Valve during system shutdowns.

Which pnuematic butterfly valve style fits your installation?

The wafer style pnuematic butterfly valve usually fits best in standard installations where space and cost are the primary concerns. The pnuematic butterfly valve in a lug configuration is better suited for end-of-line service where you may need to disconnect one side of the pipe. You must evaluate your system’s vibration levels and maintenance schedule before selecting a style.

Is the wafer style right for you?

Think about it: the wafer design is essentially a thin disc that “sandwiches” between your existing pipe flanges. This reduces the footprint of the valve to just a few inches even for large pipe diameters.

- Low Profile: Fits into extremely narrow pipe gaps.

- Universal Alignment: Centering holes ensure proper disc placement.

- Cost Savings: Uses the least amount of raw material for the body.

Key Takeaway: Wafer valves are the ideal choice for weight-sensitive and budget-conscious projects.

| Comparison | Wafer | Lug |

|---|---|---|

| Face-to-Face | Shortest | Moderate |

| Maintenance | Requires system shutdown | Allows partial pipe removal |

| Price | Economical | Slightly Higher |

These styles offer significantly more installation flexibility than a heavy-duty Gate Valve.

How to size a pnuematic butterfly valve actuator correctly?

Sizing a pnuematic butterfly valve actuator correctly requires calculating the torque needed to overcome the friction of the valve seat under pressure. Choosing a pnuematic butterfly valve with an undersized actuator will lead to incomplete sealing or the valve getting stuck. You must always include a safety factor to account for seat wear or debris buildup over time.

How do you calculate torque?

Look: the pressure of the fluid pushes against the disc, making it harder to turn as the PSI increases. You must match the actuator’s output torque at your available air pressure to the valve’s “break-away” torque.

- Media Type: Slurries require more torque than clean water.

- Frequency: Rarely used valves may “stick” and need extra force.

- Air Pressure: Most actuators are rated at 80 PSI for peak performance.

Key Takeaway: Proper sizing ensures the valve operates smoothly without straining the mechanical components.

| Sizing Factor | Impact on Torque | Recommendation |

|---|---|---|

| Higher Pressure | Increases Friction | Use larger actuator |

| Abrasive Media | Increases Resistance | Add 30% safety factor |

| Clean Fluid | Lower Friction | Standard sizing is safe |

Accurate sizing is just as vital here as it is when selecting an actuator for a Globe Valve in a control loop.

What is the pnuematic butterfly valve sealing mechanism?

The sealing mechanism of a pnuematic butterfly valve relies on the interference fit between the outer edge of the disc and the resilient seat. In a pnuematic butterfly valve, this seal must be tight enough to prevent bypass while allowing the disc to rotate smoothly. Modern designs often use a “double-offset” or “triple-offset” to reduce seat wear during the opening and closing cycles.

How does the resilient seat work?

Here is the deal: the seat is usually a flexible ring that deforms slightly when the disc presses against it. This deformation creates a “bubble-tight” seal that stops even the smallest gas molecules from leaking through.

- Interference Fit: The disc is slightly larger than the seat opening.

- Self-Cleaning: The rotation of the disc wipes away light debris.

- Replaceable Parts: Most seats can be swapped out without replacing the whole valve.

Key Takeaway: Resilient seats provide the best sealing for low-to-medium pressure industrial liquids.

| Seal Type | Closing Style | Application |

|---|---|---|

| Concentric | Centered disc | General purpose |

| High Performance | Offset disc | High pressure/Heat |

| Metal Seated | Metal-to-metal | Steam and abrasives |

This sealing efficiency is often superior to the metal gates found in a traditional Gate Valve.

Is pnuematic butterfly valve maintenance simple to perform?

Yes, pnuematic butterfly valve maintenance is relatively simple because the design has few moving parts and allows for easy access to the seals. Maintaining your pnuematic butterfly valve usually involves inspecting the actuator air lines and checking the seat for signs of wear. Because the disc is easily accessible once the valve is removed from the line, repairs can be finished quickly.

What are common maintenance steps?

Look: a proactive maintenance schedule can extend the life of your automated valves by several years. Regular checks prevent small air leaks from turning into major system failures.

- Visual Inspection: Check for leaks at the valve stem.

- Air Quality: Ensure the pneumatic air is dry and lubricated.

- Cycle Testing: Periodically operate the valve to prevent sticking.

Key Takeaway: Simple routine checks on the actuator and seat integrity can prevent 90% of valve failures.

| Component | Task | Frequency |

|---|---|---|

| Actuator | Check air seals | Quarterly |

| Valve Seat | Inspect for tears | Annually |

| Stem | Lubricate bearings | Bi-Annually |

Compared to the complex internal packing of a Globe Valve, these maintenance tasks are much faster.

Where to source a high-quality pnuematic butterfly valve?

You should source a high-quality pnuematic butterfly valve from an established manufacturer that provides full material traceability and performance testing. A reliable pnuematic butterfly valve vendor will offer certifications that guarantee the valve meets international safety standards. Investing in quality from the start ensures that your automated system operates without unexpected interruptions.

What certifications should you look for?

Best of all: quality certifications prove that the valve has been tested under extreme conditions before it reaches your site. This gives you peace of mind that the hardware will not fail during a critical production run.

- ISO 9001: Ensures consistent manufacturing quality.

- CE/API: Guarantees the valve meets pressure and safety ratings.

- Material Reports: Confirms the chemistry of the metal alloys used.

Key Takeaway: Always verify manufacturer credentials to ensure long-term reliability and site safety.

| Quality Indicator | Importance | Result |

|---|---|---|

| Pressure Testing | Critical | Prevents onsite leaks |

| Material Grade | High | Ensures corrosion resistance |

| Warranty | Moderate | Protects your investment |

Sourcing from a trusted partner is just as important for these valves as it is for high-precision components like a balancing valve.

Strategic Summary and Conclusion

The pnuematic butterfly valve remains one of the most versatile and efficient tools for industrial automation. By combining a lightweight design with the power of pneumatic actuation, you can achieve precise flow control across a wide variety of applications, from water treatment to chemical processing. At our core, we believe that high-quality engineering and robust materials are the foundation of any successful pipeline system. We are committed to providing durable flow control solutions that help you maximize productivity and minimize downtime.

Ready to upgrade your pipeline automation?

Our team is standing by to help you select the perfect valve configuration for your specific industrial needs. To receive a custom quote or technical consultation, please contact us today.

Frequently Asked Questions

Can I install a pnuematic butterfly valve in any orientation?

Yes, you can, but installing the valve with the stem in a horizontal position is generally recommended. This prevents debris from settling in the bottom of the valve body and damaging the shaft seals over time.

What’s the best way to determine if my actuator is failing?

The best way is to check for sluggish movement or audible air leaks during a cycle. If the valve fails to reach the fully open or closed position despite adequate air pressure, the internal actuator seals likely need replacement.

Can I use these valves for high-pressure steam?

No, you shouldn’t use standard resilient-seated butterfly valves for steam because the heat will melt the EPDM or PTFE seat. For steam applications, always select a high-performance metal-seated version designed for extreme temperatures.

How do I know which size valve I need for my pipe?

You should match the valve’s nominal diameter (DN) to the inner diameter of your existing piping. Selecting a valve smaller than the pipe can cause excessive turbulence and pressure drop across the system.

What’s the best air pressure for operating the actuator?

The best air pressure is typically between 60 and 80 PSI (4 to 5.5 bar). While most actuators can handle up to 120 PSI, operating at a consistent 80 PSI provides the ideal balance of torque and seal longevity.