Many industrial operators struggle with the manual operation of large-diameter valves because the force required to open them under high pressure often leads to operator fatigue and incomplete seating. When a standard lever-handle valve becomes impossible to turn, maintenance teams might resort to unsafe “cheater bars,” which can cause damaged stems or catastrophic leaks. The worm gear wafer butterfly valve provides the mechanical advantage necessary for effortless, high-torque operation through a gear-reduction system.

1. What is a worm gear wafer butterfly valve and how does it work?

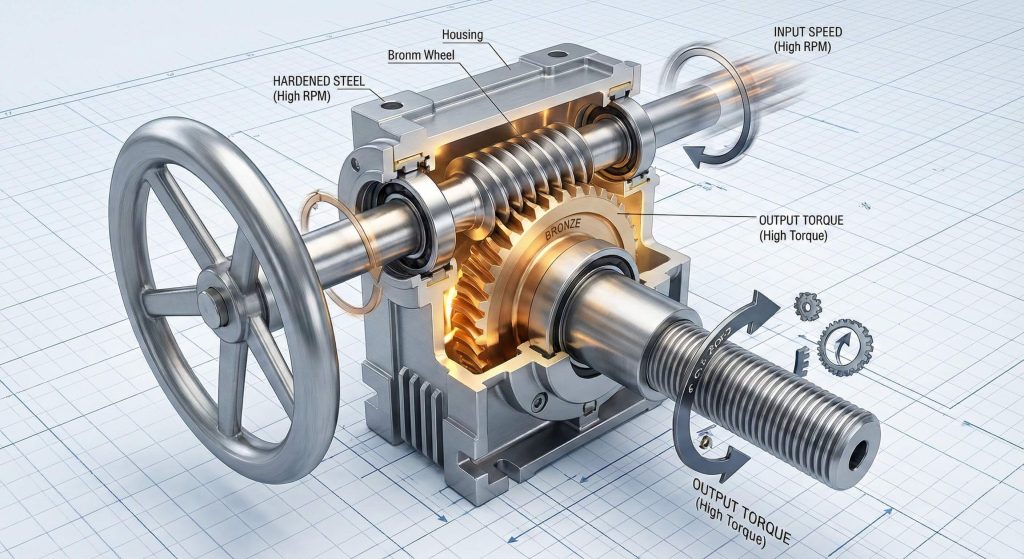

A worm gear wafer butterfly valve is a flow control device that uses a specialized gearbox to multiply the manual force you apply to the handwheel. By turning the handwheel, you rotate a worm screw that meshes with a worm wheel, slowly turning the valve disc to an open or closed position. This mechanism allows you to manage high-pressure systems with significantly less physical effort than a traditional lever.

How does the gearbox amplify torque?

The truth is, the internal gear ratio does all the heavy lifting for you. By using a high reduction ratio, the gearbox converts several rotations of the handwheel into a slow, powerful movement of the stem.

- Converts low-input force to high-output torque.

- Prevents the valve from slamming shut.

- Allows for precise, incremental disc positioning.

What are the main wafer body components?

You might be wondering how such a powerful device remains so compact. The wafer body is designed to sit between two pipe flanges, held in place by long bolts that surround the valve circumference.

- Resilient seat for tight sealing.

- Centrally mounted disc for balanced flow.

- Slim profile to reduce pipeline weight.

Key Takeaway: The worm gear mechanism acts as a force multiplier, allowing a single operator to manage high-pressure flow with minimal physical effort.

| Component | Function | Material Priority |

|---|---|---|

| Worm Gearbox | Amplifies manual torque | Weather-proof Cast Iron |

| Wafer Body | Compact pipe mounting | Ductile Iron / SS316 |

| Valve Disc | Primary flow control | Stainless Steel / Nylon Coated |

2. Why select a worm gear wafer butterfly valve for high-torque systems?

You should select a worm gear wafer butterfly valve for high-torque systems because it eliminates the physical limitations of standard lever handles. Once a valve exceeds a certain diameter, the differential pressure makes a manual lever nearly impossible to move safely. The gear operator provides the steady, controlled force needed to overcome this resistance without straining your equipment.

Can gear operators replace expensive actuators?

But wait, there’s more to consider regarding your budget. If you do not require full automation, a manual gearbox offers a much more affordable way to handle high-torque demands.

- Lower initial investment than pneumatic units.

- Zero energy consumption for operation.

- Reduced complexity in your control system.

How does it improve flow adjustment?

Think about it: precision is key when you are balancing a system. Unlike a lever that clicks into set notches, the gear operator allows you to stop the disc at any exact angle.

- Infinite adjustment for throttling.

- Eliminates sudden pressure surges.

- Stable positioning under high flow velocity.

Key Takeaway: Gear operators provide a cost-effective bridge between simple manual levers and complex automated actuators.

| Feature | Lever Handle | Worm Gear Operator |

|---|---|---|

| Max Diameter | Generally < DN150 | Up to DN1200+ |

| Precision | Low (Steps) | High (Infinite Adjustment) |

| Cost | Minimal | Moderate |

3. When should you install a worm gear wafer butterfly valve in lines?

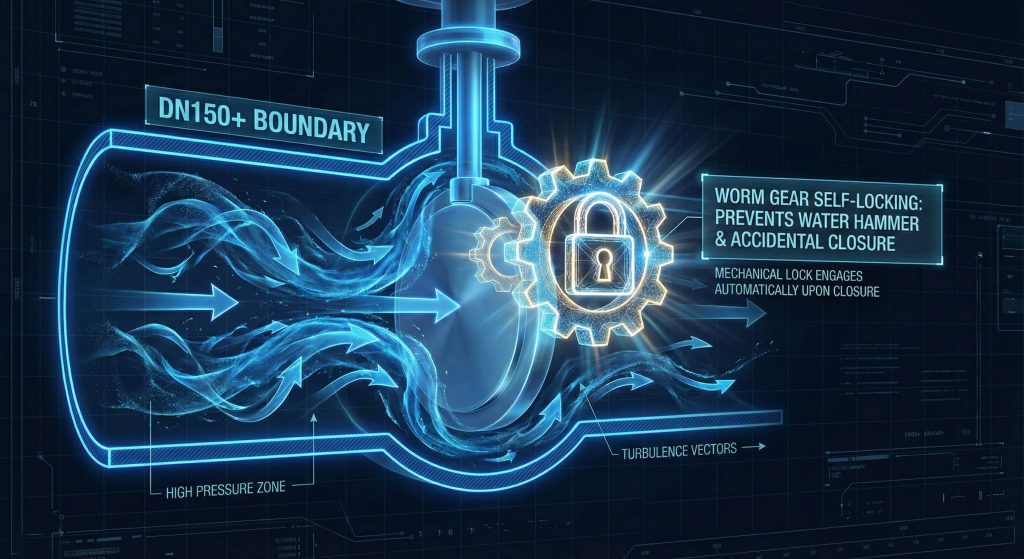

You should install a worm gear wafer butterfly valve whenever your pipeline diameter reaches DN150 or larger to ensure safe operation. At these sizes, the force required to seat the valve properly against the flow is often too high for a manual handle. It is also the ideal choice for any line where you need to prevent water hammer caused by rapid closure.

Is it necessary for high-pressure lines?

Here is the best part: the gearbox acts as a safety buffer against the system’s internal pressure. In high-pressure applications, the gear teeth hold the disc in place, preventing the flow from forcing the valve open or shut unexpectedly.

- Maintains position during pressure spikes.

- Reduces the risk of “handle kickback.”

- Protects downstream sensitive equipment.

When should you consider large diameters?

Check this out: standard industry guidelines suggest moving away from levers once you hit the six-inch mark. Using a gear operator on large lines ensures that any staff member can operate the valve during an emergency.

- Essential for DN150 to DN1200 sizes.

- Best for heavy media like sludge or pulp.

- Facilitates one-person operation on large mains.

Key Takeaway: Always opt for a gear operator when the system pressure or valve size makes manual lever operation physically taxing or unsafe.

| Condition | Recommended Operator | Reason |

|---|---|---|

| High Pressure | Worm Gear | Prevents sudden disc snapping |

| Large Diameter | Worm Gear | Reduces operator physical strain |

| Throttling Needs | Worm Gear | Allows for fine-tuned flow |

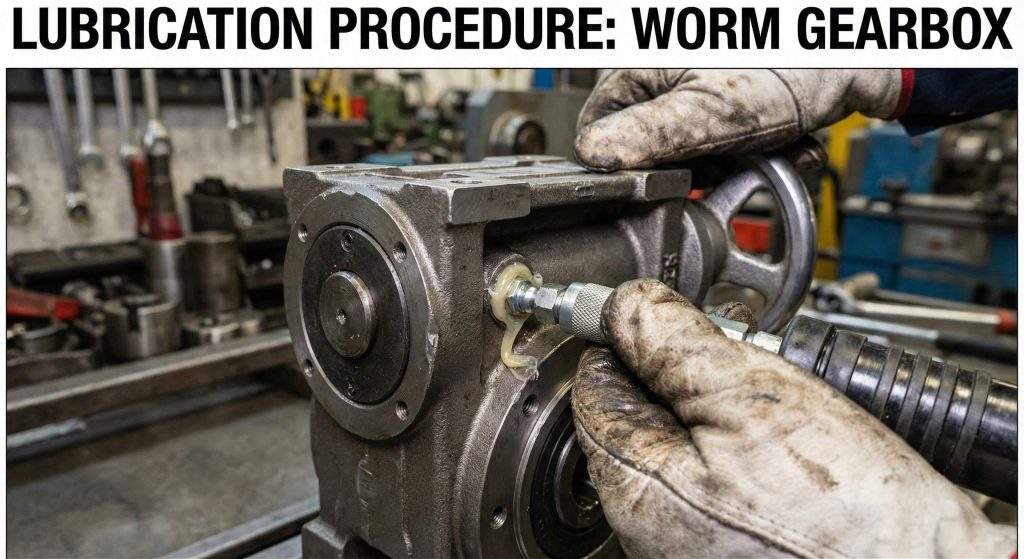

4. How to maintain a worm gear wafer butterfly valve for longevity?

To maintain a worm gear wafer butterfly valve, you must prioritize regular lubrication of the internal gear teeth and the valve stem. Over time, the grease inside the gearbox can dry out or become contaminated, leading to increased friction and potential jamming. A simple maintenance schedule ensures the handwheel remains easy to turn throughout the valve’s service life.

How often should you apply lubricant?

It gets better when you stay ahead of the wear and tear. You should generally inspect and lubricate the gearbox every six to twelve months, depending on the environment.

- Use high-quality lithium-based grease.

- Apply via the grease nipple if provided.

- Rotate the handwheel to spread the grease.

What should you look for during inspections?

Believe it or not, most failures are visible before they become critical. Regularly check for signs of leakage around the stem or any unusual “play” in the handwheel rotation.

- Inspect the stem seal for weeping.

- Tighten any loose mounting bolts.

- Confirm the travel limit stops are secure.

Key Takeaway: Preventive lubrication of the gearbox every 6–12 months is the most effective way to prevent handwheel jamming.

| Maintenance Task | Frequency | Objective |

|---|---|---|

| Gear Lubrication | Bi-annually | Smooth operation/corrosion prevention |

| Stem Seal Check | Quarterly | Prevent external leakage |

| Limit Adjustment | Annually | Ensure 100% bubble-tight shutoff |

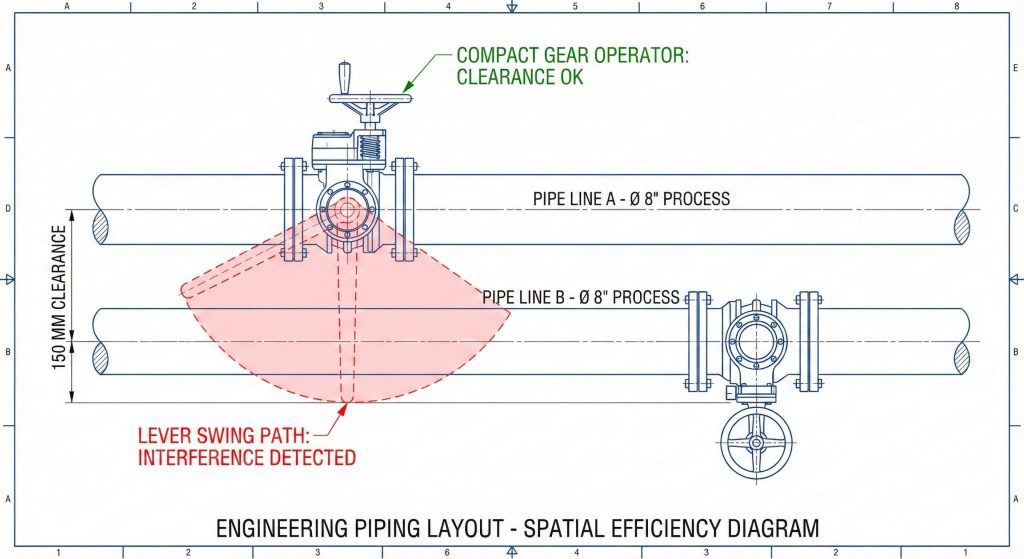

5. Is a worm gear wafer butterfly valve suitable for tight spaces?

A worm gear wafer butterfly valve is highly suitable for tight spaces because its wafer body has an extremely short face-to-face dimension. Additionally, the gearbox is usually oriented vertically, which means the handwheel does not require the wide horizontal clearance that a long lever would. This makes it the perfect solution for crowded mechanical rooms.

Does the vertical handwheel help?

Keep this in mind: space is often at a premium in modern industrial plants. By utilizing a vertical wheel, you can install multiple valves side-by-side without handles interfering with each other.

- Reduces the required footprint.

- Allows for easier access in galleries.

- Minimizes overhead clearance issues.

Why is the wafer design more compact?

The bottom line is that the wafer design is built for efficiency between flanges. Because it is essentially a thin disc in a frame, it takes up far less room than a traditional gate or globe valve.

- Fits between standard existing flanges.

- Significantly lighter for easier installation.

- Requires fewer supports in the piping run.

Key Takeaway: The combination of a thin wafer body and a vertically oriented handwheel makes this valve ideal for high-density piping arrays.

| Space Constraint | Wafer Gear Solution | Benefit |

|---|---|---|

| Horizontal Gap | Wafer Body | Fits between existing flanges |

| Side Clearance | Vertical Handwheel | No handle swing radius needed |

| Overhead Room | Compact Gearbox | Minimal vertical footprint |

6. Where is a worm gear wafer butterfly valve used in HVAC projects?

In HVAC projects, the worm gear wafer butterfly valve is primarily used for balancing chilled water and condenser water systems. Because these systems require precise flow regulation to maintain building temperatures, the incremental control offered by the gearbox is invaluable. You will often find them installed at the discharge side of pumps or near large heat exchangers.

How does it help with throttling?

The truth is, HVAC efficiency depends on fine-tuning. The gear operator allows you to make micro-adjustments to the flow rate, ensuring your cooling or heating is perfectly balanced.

- Prevents temperature fluctuations.

- Reduces wear on pump motors.

- Enhances overall energy efficiency.

Can it be used for system isolation?

But wait, there’s more than just throttling to consider. These valves also serve as reliable isolation points when you need to take a chiller or pump offline for seasonal maintenance.

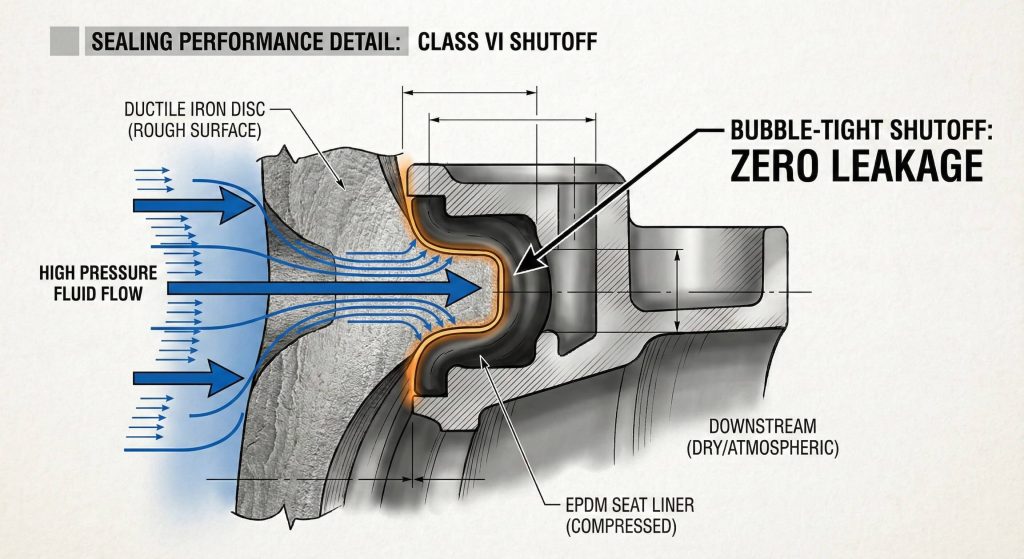

- Provides bubble-tight shutoff.

- Reliable for long-term dormancy.

- Easy to operate after months of sitting.

Key Takeaway: HVAC efficiency relies on precise flow control, which the worm gear provides through its incremental adjustment capability.

| HVAC Application | Valve Function | Typical Media |

|---|---|---|

| Cooling Tower | Flow Balancing | Water/Glycol |

| Pump Discharge | Isolation | Chilled Water |

| Heat Exchanger | Throttling | Treated Water |

7. Can a worm gear wafer butterfly valve prevent backflow effectively?

A worm gear wafer butterfly valve is not a dedicated backflow preventer, but it provides a very effective seal against back-pressure when closed. Unlike a check valve that operates automatically, you must manually close this valve to stop the flow. However, the gear operator ensures the disc is squeezed tightly into the resilient seat, stopping any reverse leakage.

How does the seat ensure a seal?

You might be wondering how the seal stays so tight over time. The gearbox allows you to apply consistent pressure to the seat, ensuring the disc fully compresses the rubber liner for a leak-proof finish.

- Resilient seats like EPDM provide tight closure.

- Gear ratio ensures maximum seating force.

- Durable against moderate back-pressures.

Is it a substitute for a check valve?

Think about it: a check valve responds to flow, while this valve responds to you. While it can hold back fluid, it should not be your only line of defense in a dynamic backflow situation.

- Best used for maintenance isolation.

- Requires manual intervention to close.

- Excellent as a secondary safety barrier.

Key Takeaway: While not a check valve, the worm gear operator ensures a superior, bubble-tight seal that prevents leakage when the system is closed.

| Feature | Butterfly Valve + Gear | Standard Check Valve |

|---|---|---|

| Primary Use | Flow Control/Isolation | Backflow Prevention |

| Manual Override | Full Control | None |

| Sealing Type | Resilient Seat (Tight) | Gravity/Spring (Variable) |

8. Which accessories enhance a worm gear wafer butterfly valve setup?

You can enhance your worm gear wafer butterfly valve by adding limit switches or locking devices to improve system safety. Limit switches are particularly useful because they send an electronic signal to your control room to confirm if the valve is open or closed. This bridges the gap between manual operation and digital monitoring.

Why are limit switches important?

Here is the best part: you don’t have to walk to the valve to check its status. Integrating these sensors allows your PLC to monitor manual valves as part of a larger automated process.

- Provides remote position feedback.

- Improves facility safety protocols.

- Enables system-wide synchronization.

Should you use locking devices?

Check this out: in fire safety or critical chemical lines, you cannot afford accidental changes to the valve position. Locking tabs allow you to padlock the handwheel in place, ensuring it stays exactly where you set it.

- Prevents unauthorized tampering.

- Essential for “lock open” fire systems.

- Adds an extra layer of operational security.

Key Takeaway: Accessories like limit switches and locking tabs transform a simple manual valve into an integrated part of a smart industrial system.

| Accessory | Purpose | Industry Context |

|---|---|---|

| Limit Switch | Position Feedback | PLC/Automation |

| Locking Device | Security | Fire Protection |

| Extension Stem | Accessibility | Underground/Deep Well |

9. Why does a worm gear wafer butterfly valve offer better safety?

The worm gear wafer butterfly valve offers better safety because the worm gear mechanism is inherently self-locking due to high internal friction. This means the valve disc cannot be forced open or closed by the movement of the fluid alone. You can step away from the valve knowing that vibration or pressure surges won’t cause the disc to drift.

How does self-locking protect you?

It gets better when you consider the risks of manual handles. If a lever handle is bumped or if the flow is too strong, the handle can swing violently and cause injury; a gearbox prevents this entirely.

- Eliminates mechanical “kickback.”

- Holds position without external locks.

- Resists movement from pipe vibrations.

Does it prevent sudden disc movement?

Believe it or not, the slow movement of the gears is actually a safety feature. Because it takes many turns to move the disc, you are forced to adjust the flow gradually, which protects your pipes from hydraulic shock.

- Prevents catastrophic water hammer.

- Protects downstream gaskets and seals.

- Ensures controlled startup of systems.

Key Takeaway: The inherent self-locking nature of worm gears provides a secondary layer of safety against accidental valve opening or closing.

| Safety Factor | Lever Handle Risk | Worm Gear Advantage |

|---|---|---|

| Vibration | Disc can drift | Self-locking friction |

| Accidental Bump | Can fully open/close | Requires manual rotation |

| Pressure Surge | Handle can kick back | Mechanical lock-in |

10. How to troubleshoot a worm gear wafer butterfly valve gear box?

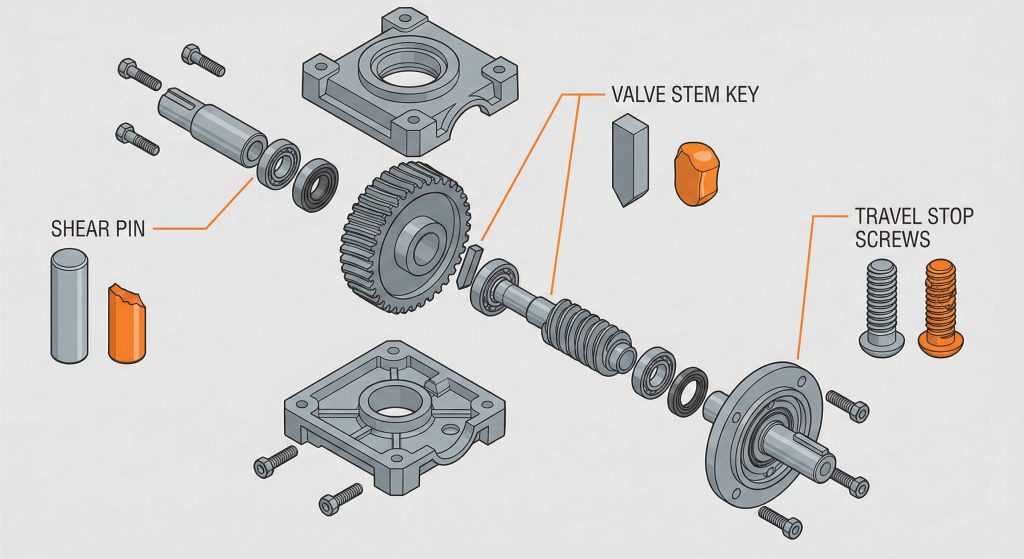

To troubleshoot a worm gear wafer butterfly valve, you should first check for dried lubricant or external obstructions if the handwheel becomes difficult to turn. If the wheel turns but the valve disc doesn’t move, you likely have a sheared pin or a broken key in the drive assembly. Most issues can be resolved with basic tools and a fresh application of grease.

What causes a jammed handwheel?

Keep this in mind: environmental factors are usually the culprit. If the valve is outdoors, rust or debris can enter the gearbox if the seals are worn, causing the gears to bind.

- Check for internal corrosion.

- Verify the stem isn’t bent.

- Ensure the travel stop screws aren’t loose.

How do you fix rattling noises?

The bottom line is that noise usually means something is loose. Check the mounting bolts that secure the gearbox to the valve flange to ensure they haven’t vibrated loose over time.

- Tighten the gearbox mounting bolts.

- Check the mesh between worm and wheel.

- Adjust travel limits to stop fluttering.

Key Takeaway: Most gear issues stem from lack of lubrication or loose mounting; always verify the travel limits before assuming a gearbox is broken.

| Symptom | Potential Cause | Immediate Action |

|---|---|---|

| Hard to Turn | Dried Grease | Inject fresh lubricant |

| Handwheel Idling | Key/Pin sheared | Replace drive pin |

| Valve Leaks (Closed) | Stop limit incorrect | Re-adjust close-limit screw |

Conclusion

Navigating the complexities of manual flow control doesn’t have to be a challenge for your maintenance and engineering teams. By choosing a gear-driven solution, you resolve the issues of operator strain and improve the precision of your entire fluid system. Our mission is to provide high-quality, reliable valving solutions that stand up to the most demanding industrial environments. We invite you to explore our comprehensive catalog and contact us today to see how we can optimize your project with the right equipment and expert support.

Frequently Asked Questions

Can I automate this valve later?

Yes, most of these valves come with an ISO 5211 mounting pad. This means you can simply remove the manual gearbox and bolt on an electric or pneumatic actuator when your budget or system requirements change.

What’s the best material for high-pressure seats?

For general water and HVAC use, EPDM is the industry standard for durability. However, if you are dealing with higher temperatures or aggressive chemicals, you should opt for PTFE or Viton to ensure the seal doesn’t degrade under pressure.

Can I install this valve in a vertical pipeline?

Absolutely, the wafer design is perfectly functional in any orientation. The only thing you need to consider is the accessibility of the handwheel for your operators once the valve is in place.

What’s the best way to lubricate the gears?

A high-quality, water-resistant lithium grease is usually the best choice. Regularly injecting grease through the gearbox fitting ensures the worm screw and wheel mesh smoothly without wearing down the metal surfaces.

Can I use this for gas applications?

Yes, provided the seal materials like NBR or PTFE are compatible with the specific gas you are transporting. Always check the pressure rating and safety certifications to ensure the valve meets local gas handling standards.