Yes, butterfly valves can be used for throttling, provided they are designed for flow regulation rather than just simple on/off service. Many engineers struggle with vibrating pipes and persistent leaks when they use standard valves for precise control. By implementing a high-performance butterfly valve throttle setup, you can stabilize system pressure and eliminate the noise associated with turbulent flow.

Can a butterfly valve throttle flow effectively?

Yes, they can regulate flow effectively if you operate them within their optimal angular range and pressure limits. A butterfly valve throttle application requires a deep understanding of how the disc interacts with fluid velocity at various stages.

Look at this:

- They offer high flow capacity in the fully open position.

- Their compact design reduces the overall footprint of your piping system.

- Modern actuators allow for precise positioning across the travel range.

Understanding Flow Control Limits

The effectiveness of the regulation depends on the relationship between the disc angle and the flow coefficient. Most industrial valves provide a modified linear or equal percentage flow characteristic that is suitable for many processes.

Advantages of Quarter-Turn Regulation

The 90-degree movement allows for rapid adjustments compared to multi-turn globe or gate valves. This speed is advantageous in automated systems where quick response to pressure changes is required.

Key Takeaway:

Butterfly valves are capable of effective throttling provided the system pressure and disc angle are maintained within the manufacturer’s recommended operating envelope for the specific media.

| Feature | Throttling Capability |

|---|---|

| Flow Type | Liquid, Gas, Slurry |

| Precision | Moderate |

| Weight | Low |

How does a butterfly valve throttle via disc movement?

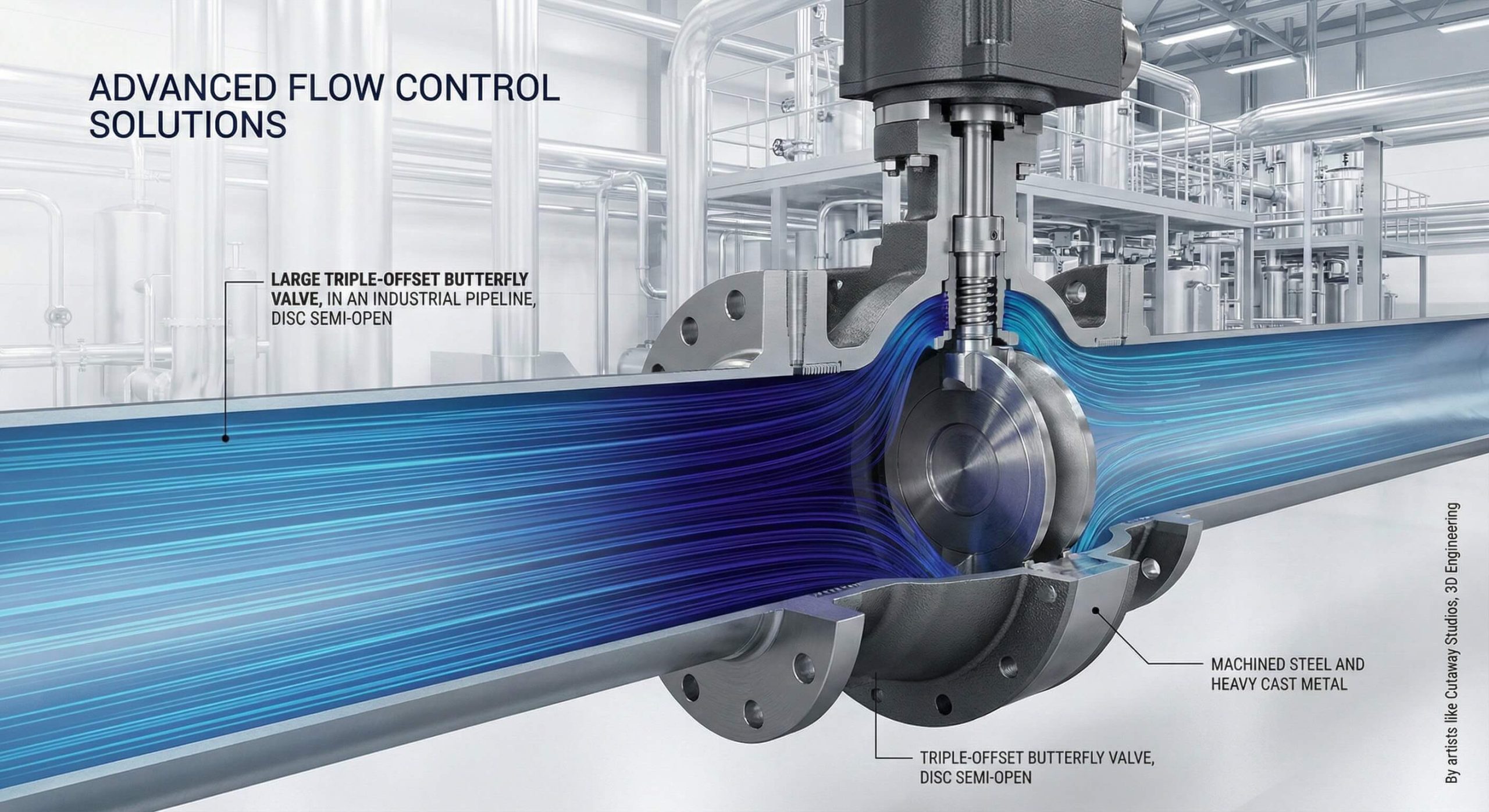

The disc rotates on a central or offset shaft to create a variable opening that restricts fluid volume. Understanding the internal mechanics is vital when deploying a butterfly valve throttle system to ensure the components withstand constant force.

Here is the deal:

- The shaft transmits torque from the handle or actuator to the disc.

- Intermediate positions create two distinct flow paths around the disc edges.

- Flow velocity increases as the opening area decreases.

Mechanical Drive Stability

The connection between the shaft and the disc must be rigid to prevent fluttering during high-velocity flow. Any play in the linkage can cause the disc to shift, leading to inconsistent flow rates.

The Role of Modulating Actuators

For precise throttling, you need a modulating actuator that can hold the disc at specific increments. These actuators often use feedback loops to ensure the disc remains in the requested position despite fluid forces.

Key Takeaway:

The mechanical stability of the disc-to-shaft connection is the foundation of reliable throttling, preventing movement that could lead to flow instability.

| Component | Function in Throttling |

|---|---|

| Shaft | Transmits torque to position the disc |

| Actuator | Holds the disc at a specific angle |

| Disc | Creates the physical flow restriction |

What risks exist when you use a butterfly valve throttle?

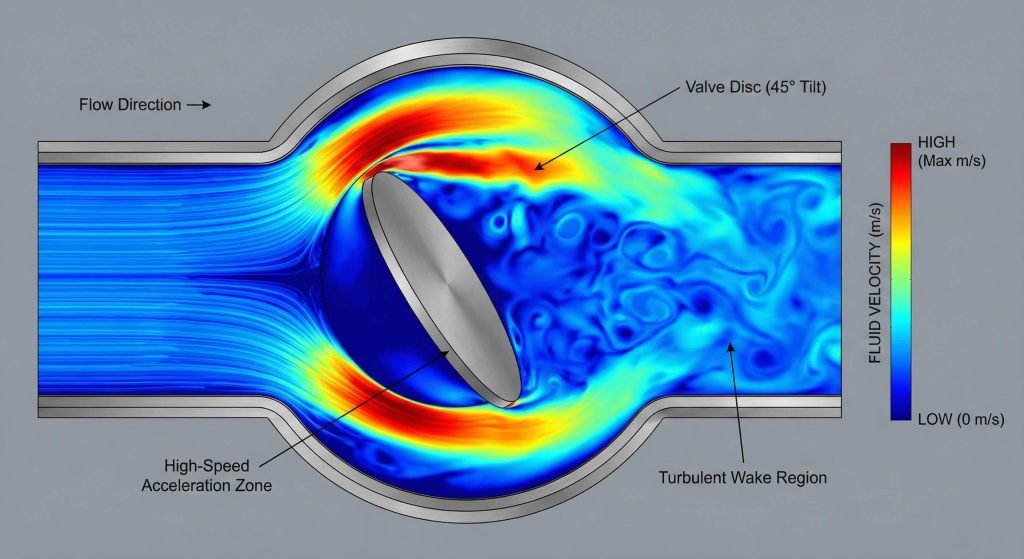

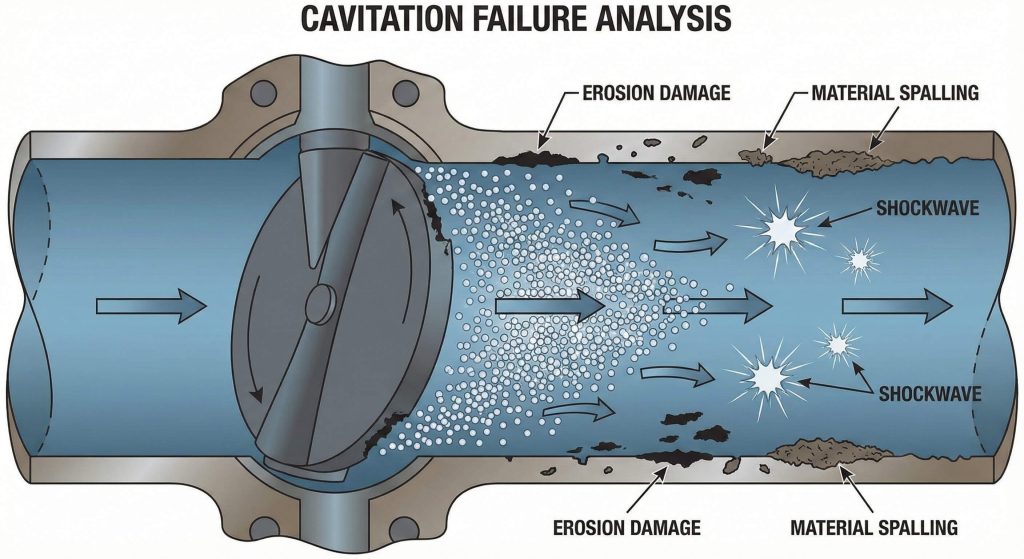

The primary risks include high-velocity seat erosion, cavitation damage, and severe mechanical vibration at low opening angles. Operating a butterfly valve throttle at a very small opening (typically less than 30 degrees) creates high-velocity jets of fluid.

Consider this:

- High-velocity flow can “wash out” soft seat materials.

- Low-pressure zones behind the disc can trigger cavitation.

- Turbulent eddies cause the entire valve body to vibrate.

The Danger of Low Opening Angles

When the valve is nearly closed, the pressure drop is at its highest, which accelerates the fluid to extreme speeds. This concentrated energy can quickly erode the sealing surfaces, making it impossible to achieve a bubble-tight shut-off.

Turbulence and Harmonic Vibration

Fast-moving fluid passing over the disc edges can create harmonic frequencies that match the natural frequency of the piping system. This can lead to loose bolts, cracked welds, and failure of sensitive instruments.

Key Takeaway:

To protect your equipment, you should avoid operating butterfly valves at openings below 30 degrees where fluid velocity and mechanical stress are highest.

| Issue | Impact |

|---|---|

| Erosion | Destroys the sealing surface |

| Noise | Indicates turbulence and stress |

| Vibration | Can loosen fasteners and supports |

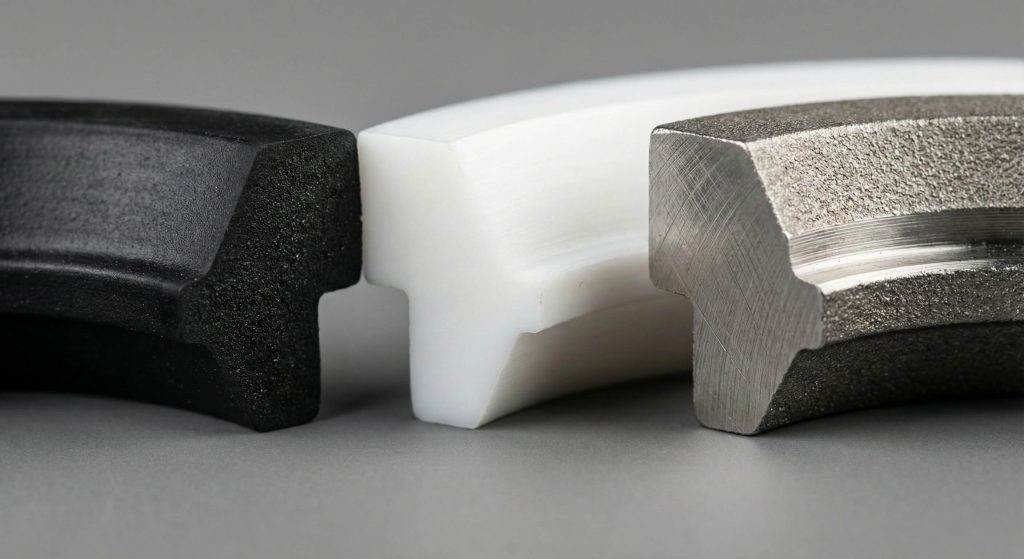

Why select a specific butterfly valve throttle seat?

Seat material is critical because the constant friction and turbulent flow during regulation can degrade soft seals rapidly. The longevity of a butterfly valve throttle depends heavily on the chemical and thermal resistance of the chosen material.

The reality is:

- Soft seats like EPDM offer excellent sealing but have temperature limits.

- PTFE provides chemical inertness for corrosive throttling applications.

- Metal seats are required for high-temperature or abrasive services.

Material Temperature Thresholds

As temperatures rise, many elastomeric materials lose their structural rigidity. In a throttling application, a softened seat can be torn or “rolled” out of its groove by the high-velocity fluid.

Resilient vs. Metal Seating

Resilient seats are perfect for general water or air service at moderate pressures. However, for critical throttling where the valve is constantly adjusting, metal-to-metal seats in high-performance designs offer much higher durability.

Key Takeaway:

Your choice of seat material directly dictates the maintenance interval and the overall service life of a valve used for constant flow regulation.

| Material | Best Use Case | Temperature Limit |

|---|---|---|

| EPDM | Water, HVAC | 120°C |

| PTFE | Chemicals | 200°C |

| Metal | High Temp/Steam | 450°C+ |

Which butterfly valve throttle designs perform best?

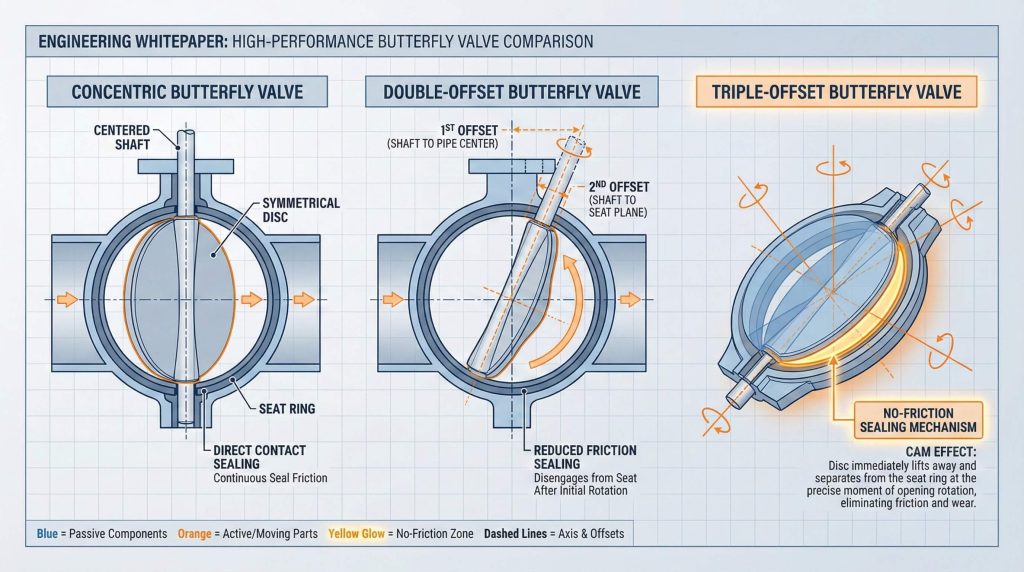

High-performance eccentric designs, specifically double and triple offset valves, offer the best throttle control and longevity. Not all designs are equal for a butterfly valve throttle application in demanding industrial environments.

The fact is:

- Concentric valves have the disc centered in the seat, causing constant rubbing.

- Double offset designs lift the disc off the seat to reduce friction.

- Triple offset designs use a cam-like motion for a non-rubbing seal.

Concentric vs. Offset Configurations

In a concentric valve, the disc remains in contact with the seat for much of its travel, which leads to wear. Offset designs move the shaft behind the disc, allowing it to “cam” away from the seat almost immediately.

Triple Offset Precision

The triple offset design is the premier choice for high-pressure throttling because it eliminates rubbing entirely. This geometry allows for high-cycle regulation without degrading the sealing surfaces, making it ideal for critical process control.

Key Takeaway:

For critical applications requiring high reliability and precise control, eccentric designs are superior to standard concentric valves due to reduced seat wear and better flow characteristics.

| Design Type | Throttling Performance | Seat Wear |

|---|---|---|

| Concentric | Basic/Occasional | High |

| Double Offset | Good | Moderate |

| Triple Offset | Excellent | Minimal |

How do you calculate sizing for a butterfly valve throttle?

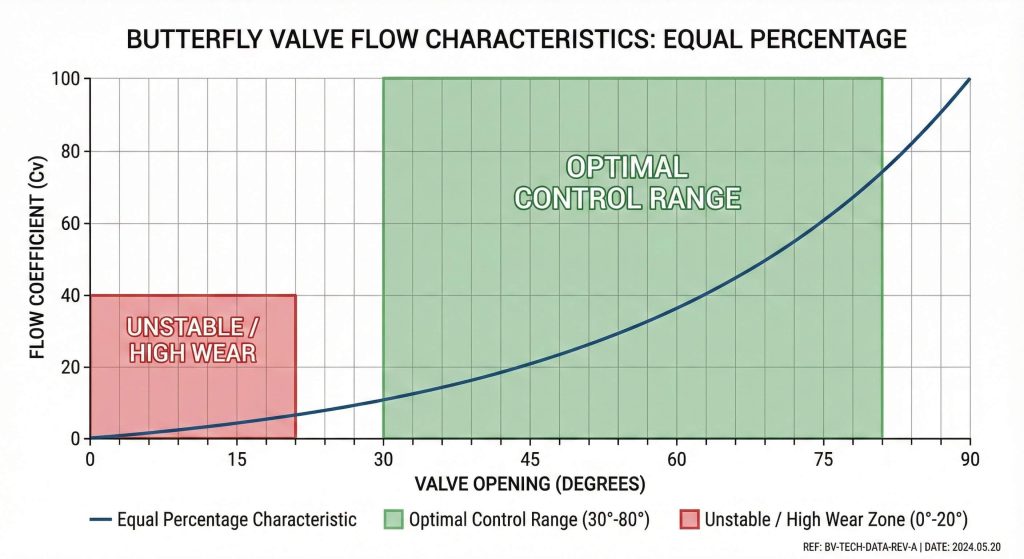

Calculating sizing involves determining the Flow Coefficient (Cv) and K-factor relative to specific disc angles to ensure the valve meets system demands. To achieve precise regulation, your butterfly valve throttle must be sized so that the required flow rate falls within the 30 to 80-degree opening range.

Here is the point:

- Sizing based on pipe diameter alone often leads to oversized valves.

- An oversized disc causes “hunting” where the actuator cannot maintain a steady flow.

- Precise Cv mapping prevents the valve from operating in the high-wear 0-20% range.

What is the importance of the Cv value?

The Cv value represents the volume of water in gallons per minute that will flow through a wide-open valve with a 1 psi pressure drop. In a throttling application, you must calculate the Cv at various intermediate angles.

How does the K-factor impact sizing?

The K-factor represents the physical resistance the valve introduces into the piping system as the disc obstructs the path. As you close the valve to throttle flow, the K-factor increases exponentially, requiring more pump energy.

Key Takeaway:

Proper sizing requires matching the system’s required Cv to the valve’s performance curve between 30 and 80 degrees to prevent premature wear and control instability.

| Opening Angle | Flow Capacity (Cv) | Resistance (K-Factor) |

|---|---|---|

| 90° (Full Open) | 100% | Lowest |

| 45° (Mid-Throttle) | 30% – 50% | Moderate |

| 15° (Low Flow) | <10% | Very High |

How can you manage cavitation with a butterfly valve throttle?

Managing cavitation requires installing the valve in lower-temperature zones or utilizing high-performance trim to dissipate pressure energy. When you use a butterfly valve throttle for high-pressure drops, vapor bubbles form and collapse violently.

The result?

- Higher pump energy is required to maintain flow.

- Fluid velocity spikes at the disc edges.

- Pressure recovery must be calculated to avoid downstream turbulence.

What causes excessive noise during throttling?

Noise is often the first indicator that the fluid velocity is too high or that cavitation is occurring. The sound of “marbles” in the line indicates that vapor bubbles are imploding against the internal surfaces.

How can you prevent vapor bubble collapse?

You can mitigate the damage by ensuring the pressure drop across the valve remains below the cavitation index threshold. Installing the valve further upstream, where the static pressure is higher, can also prevent the fluid from reaching its vapor pressure.

Key Takeaway:

Cavitation is a physical reality in high-pressure throttling; it must be managed through specialized disc designs or by optimizing the valve’s position in the process line.

| Cavitation Level | Physical Effect | Recommended Action |

|---|---|---|

| Incipient | Minor Pitting | Monitor noise levels |

| Constant | Surface Erosion | Install anti-cavitation trim |

| Severe | Structural Failure | Reduce pressure differential |

Is a butterfly valve throttle better than a globe valve?

A butterfly valve is typically better for high-volume applications where space, weight, and initial cost are the primary decision drivers. While a butterfly valve throttle may not offer the extreme precision of a globe valve, its compact design provides significant installation advantages.

Look at the facts:

- They weigh up to 70% less than equivalent globe valves.

- Installation requires fewer man-hours and lighter lifting equipment.

- The simple design has fewer moving parts to maintain.

What are the footprint advantages?

Butterfly valves have a very short face-to-face dimension, allowing them to fit into tight manifold spaces. This makes them ideal for retrofit projects where you are adding flow control to an existing system.

When should you choose a globe valve?

If your application requires micro-adjustments or involves extremely high-pressure drops that would destroy a standard disc, a globe valve is the safer choice. They offer a more linear flow characteristic and better handle severe service conditions.

Key Takeaway:

Select a butterfly valve for economical, large-scale flow regulation; reserve globe valves for small-bore systems requiring high-precision control.

| Feature | Butterfly Valve | Globe Valve |

|---|---|---|

| Precision | Moderate | High |

| Pressure Drop | Low to Medium | High |

| Space Required | Minimal | Substantial |

What maintenance does a butterfly valve throttle require?

High-cycle throttling demands regular inspections of the seat integrity and actuator calibration to prevent control drift. Because a butterfly valve throttle is constantly moving to adjust flow, the friction between the disc and seat is higher than in on/off service.

The bottom line?

- Check for abrasive wear on the disc edges.

- Verify the tightness of the shaft seals to prevent external leaks.

- Lubricate the actuator linkage to ensure smooth movement.

How often should you inspect the seat?

In high-cycle applications, you should perform a visual inspection of the seat every six months to check for signs of tearing. Any deformation in the seat material will lead to leakage when the valve is closed for isolation.

Why is actuator calibration vital?

As the valve components wear, the original calibration points may shift, leading to “offset” errors in your flow control. Regular recalibration ensures that a signal from your controller actually results in the correct disc angle.

Key Takeaway:

Preventive maintenance should focus on seat wear and actuator synchronization to ensure the valve remains a reliable tool for process regulation.

| Task | Frequency | Objective |

|---|---|---|

| Seat Inspection | Bi-annually | Prevent internal leakage |

| Actuator Calibration | Annually | Maintain control accuracy |

| Shaft Seal Check | Quarterly | Prevent environmental leaks |

When should you replace a butterfly valve throttle?

You should replace the valve when it shows signs of persistent seat leakage, shaft binding, or severe cavitation pitting on the body. Using a butterfly valve throttle in a high-quality control system can extend hardware life, but mechanical stresses will eventually exceed structural limits.

Here is the kicker:

- Pitting on the body wall can lead to a catastrophic burst.

- Increased torque requirements suggest the bearings are failing.

- Uncontrollable flow at low angles indicates a washed-out seat.

What are the signs of mechanical fatigue?

Fatigue often manifests as cracks in the disc near the shaft connection or a “wobble” during rotation. This indicates that the constant agitation of the fluid has weakened the primary structural components of the valve.

Is seat leakage a terminal indicator?

While some seats are replaceable, repeated failures suggest the disc or the body seating surface is warped. In these cases, replacing the entire valve is more cost-effective than continuous, unsuccessful repairs.

Key Takeaway:

Replacement is necessary when the physical integrity of the disc or body prevents accurate flow regulation or poses a safety risk to the facility.

| Symptom | Cause | Recommendation |

|---|---|---|

| Inconsistent Flow | Disc/Seat Erosion | Replace Valve |

| High Operating Torque | Bearing Failure | Inspect or Replace |

| External Leaks | Shaft Seal Failure | Repair Seal |

Conclusion

Successfully implementing a butterfly valve for throttling requires a balance of engineering precision and practical maintenance. By selecting the correct offset design, sizing the valve for the 30-80 degree window, and choosing seat materials that match your media, you can transform a simple quarter-turn valve into a powerful tool for flow regulation.

We are committed to helping you navigate these complex technical decisions with ease. Our expertise in high-performance valve design ensures that your systems operate at peak efficiency with minimal downtime. To optimize your flow control infrastructure and ensure the long-term reliability of your project, contact us today. We look forward to engineering a solution that powers your industrial success.

Frequently Asked Questions

Can I use a standard wafer butterfly valve for high-pressure throttling?

No, because standard wafer designs often lack the structural rigidity and offset geometry required to handle the turbulence and seat friction of constant regulation. For high-pressure throttling, a double or triple offset flanged valve is the safer and more durable choice.

What’s the best opening angle for a butterfly valve throttle?

The 30 to 80-degree range is the best because it provides the most predictable flow response while protecting the seat from high-velocity erosion. Operating below 30 degrees creates high-speed fluid “jets” that can quickly destroy elastomeric seals.

Can I throttle abrasive slurries with a butterfly valve?

Yes, but only if you use specialized hardened discs and heavy-duty liners like polyurethane or ceramic. Standard stainless steel discs will be eroded quickly by the “sandblasting” effect of the slurry during the throttling process.

What is the main cause of noise in a throttling butterfly valve?

Turbulence and cavitation are the primary causes because the disc creates a significant obstruction that forces fluid to accelerate and then expand rapidly. This creates pressure fluctuations and vapor bubble collapses that generate loud, vibration-inducing noise.

Can I automate a manual butterfly valve for throttling?

Yes, provided you replace the manual handle with a compatible mounting pad and a modulating actuator. You must ensure the new actuator has sufficient torque to overcome the dynamic forces of the fluid pushing against the disc during mid-stroke positions.