A butterfly valve is a quarter-turn rotational motion valve used to stop, regulate, and start fluid flow within industrial piping systems. Managing fluid dynamics in large-scale piping often feels like a constant battle against bulky equipment and slow response times. Traditional valves frequently occupy excessive space and require significant torque, leading to increased installation costs and potential system bottlenecks that threaten your operational efficiency. When your flow control mechanisms fail to provide rapid shut-off or precise throttling, the resulting pressure drops and maintenance delays can devastate your project’s production schedule. Adopting a versatile application of butterfly valve offers a streamlined, high-performance solution that balances lightweight design with exceptional durability for modern industrial systems.

1. Is the application of butterfly valve ideal for water treatment?

Yes, the application of butterfly valve technology is perfect for water treatment because it offers exceptional corrosion resistance and high-volume handling. You can utilize these valves in both filtration and distribution lines where space is limited but flow demands are high. Their compact nature translates into lower material costs and reduced weight for your infrastructure.

How does filtration aid the application of butterfly valve?

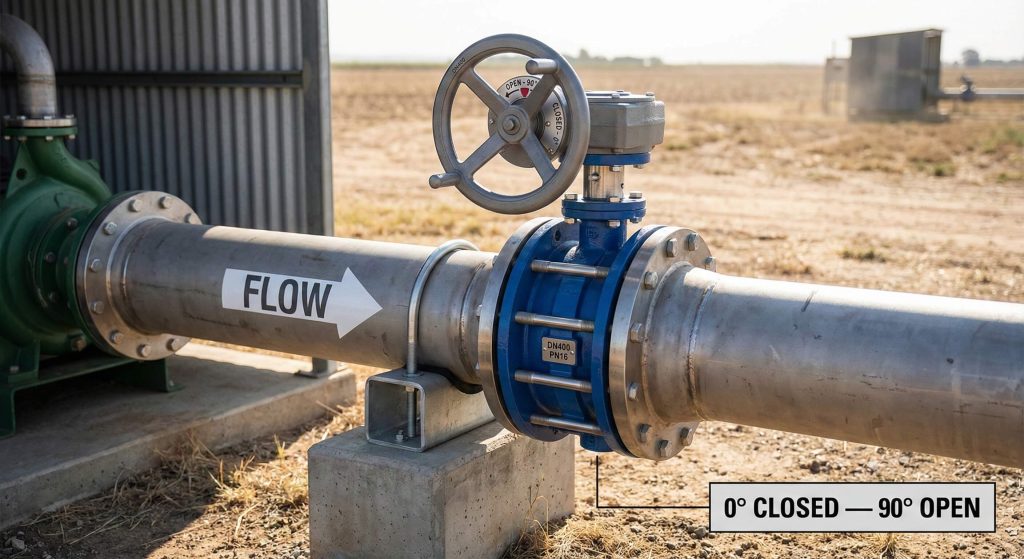

But here is the kicker: the simple design of the rotating disk allows for immediate activation, requiring only ninety degrees of rotation to move from fully open to closed. This speed is vital when you need to isolate sections of a treatment plant for cleaning or emergency repairs. You gain the advantage of a streamlined flow path that minimizes pressure drops across your entire municipal network.

- WRAS-Approved: Ensures materials are safe for potable water.

- Low Pressure Drop: Maximizes the efficiency of your pumping stations.

- Extended Service Life: Reduces your long-term maintenance costs.

- Zero Leakage: Prevents water loss during critical distribution phases.

Key Takeaway: The application of butterfly valve in water treatment ensures a safe, cost-effective, and low-maintenance flow control solution for municipal networks.

| Feature | Water Treatment Benefit | Standard Specification |

|---|---|---|

| Material | Corrosion Resistance | Ductile Iron / SS316 |

| Seal Type | Leak Prevention | EPDM / NBR Resilient Seat |

| Size Range | Large Volume Handling | DN50 – DN3000 |

2. Why choose a high-temp application of butterfly valve?

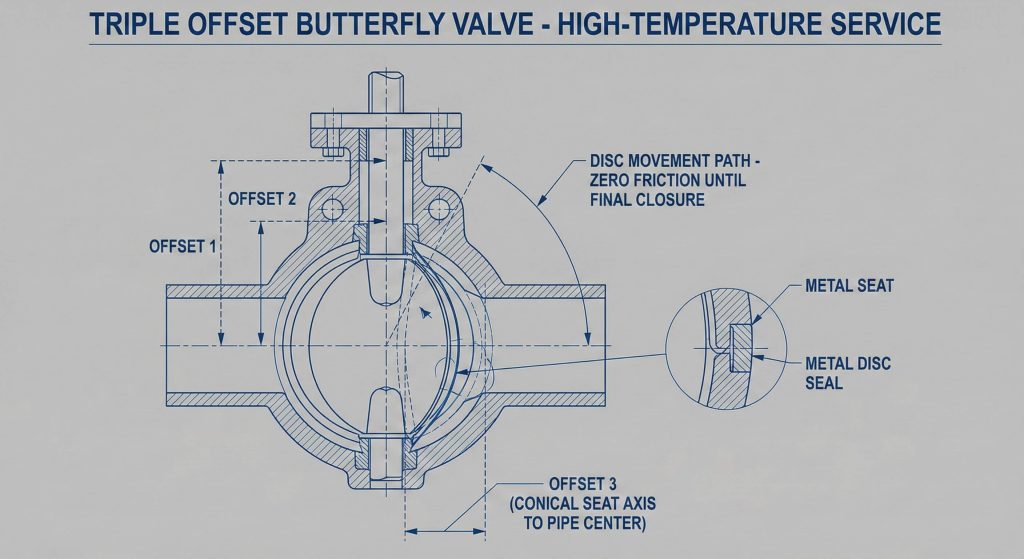

You choose a high-temp application of butterfly valve when your system requires performance under extreme thermal conditions, often exceeding 180°C or even 400°C. Metal-seated designs are specifically engineered to maintain their integrity where standard elastomers would melt or deform. This ensures your steam or thermal oil lines remain secure and operational during peak production cycles.

Does metal seating aid application of butterfly valve in steam?

What is the real story? Triple-offset geometry creates a cam-like motion that eliminates friction until the final moment of closure. This precision engineering protects your hardware from premature wear during high-cycle operations in power generation facilities. You avoid the jamming issues commonly associated with standard centric valves exposed to thermal expansion.

- Stellite Facing: Provides extreme hardness and heat resistance.

- Thermal Expansion Control: Prevents the disk from jamming as heat rises.

- High Pressure Rating: Suitable for PN25 to PN64 industrial environments.

- Fire-Safe Design: Maintains sealing integrity during localized heat events.

Key Takeaway: High-temperature butterfly valves utilize advanced offsets and metal seats to provide reliable shut-off in the most demanding thermal environments.

| Metric | High-Temp Specification | Standard Service Comparison |

|---|---|---|

| Max Temp | Up to 538°C (Alloy) | 120°C (Standard) |

| Seat Material | Stainless Steel / Stellite | EPDM / NBR |

| Offset Type | Triple Offset | Concentric / Double Offset |

3. How does chemical use aid application of butterfly valve?

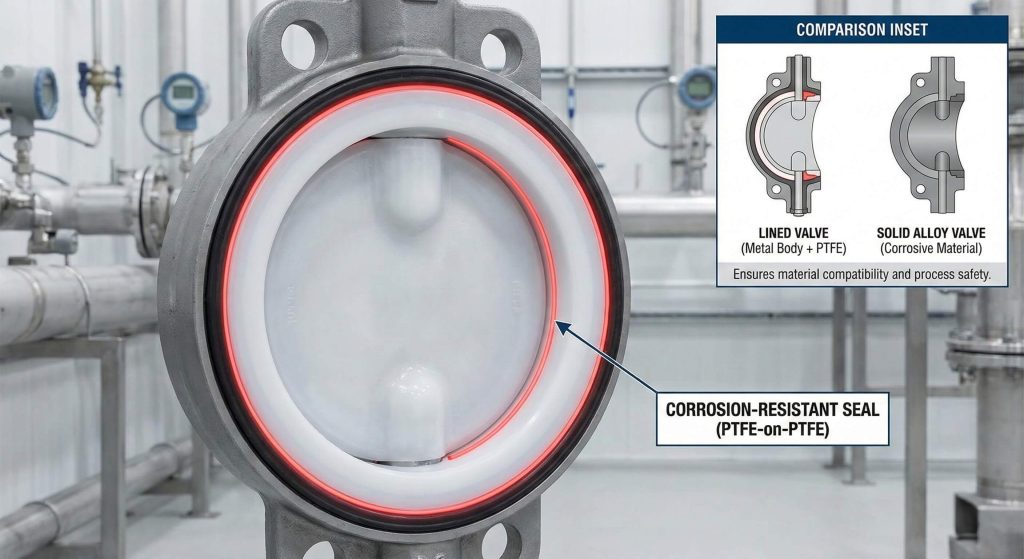

Chemical processing benefits from the application of butterfly valve through the use of PTFE-lined bodies and exotic alloys that withstand aggressive acids. You can integrate these valves into your chemical loops to gain precise control over volatile substances without fearing catastrophic hardware failure. This level of protection is essential for maintaining safety in hazardous production environments where leaks are not an option.

Are linings vital for the application of butterfly valve safety?

Believe it or not, a thin layer of PTFE or PFA can make a standard valve body completely immune to the most corrosive industrial fluids. This allows you to avoid the astronomical costs of solid exotic metal valves while still achieving zero-leakage performance. You ensure that your infrastructure remains compliant with strict environmental regulations regarding hazardous media containment.

- PTFE Sealing: Resists almost all known industrial chemicals.

- Exotic Alloys: Options like Hastelloy for extreme media.

- Zero Leakage: Meets API 598 Class VI standards for containment.

- Lot Traceability: Provides full documentation for every installed component.

Key Takeaway: The application of butterfly valve in chemical plants combines specialized linings with robust design to ensure safe and durable fluid control.

| Lining Type | Chemical Compatibility | Temperature Range |

|---|---|---|

| PTFE | Acids, Bases, Solvents | -20°C to 200°C |

| PFA | Ultra-Pure Chemicals | -20°C to 180°C |

| NBR | Oils and Hydrocarbons | -10°C to 90°C |

4. Is the application of butterfly valve reliable for fire safety?

The application of butterfly valve is highly reliable for fire protection because it allows for rapid, quarter-turn activation during critical emergencies. You gain the advantage of a compact design that fits into tight pump room configurations where traditional gate valves would be too bulky. These valves are often UL-listed or FM-approved to guarantee performance when lives and industrial assets are on the line.

Does speed improve the application of butterfly valve response?

But here is the kicker: in a fire emergency, every second counts, and the 90-degree motion of this valve is built for speed. Unlike a gate valve that requires dozens of turns to open, you can fully activate your suppression system with a single quick movement. You can also integrate supervisory switches to notify your control room of the valve’s status in real-time.

- Visual Indicators: Easily see if the valve is open or closed at a glance.

- Supervisory Switches: Integrated sensors notify your panel of valve status.

- Compact Footprint: Ideal for modular fire pump skids and risers.

- Low Torque: Allows for easy manual operation during power failures.

Key Takeaway: Fire protection butterfly valves provide the speed, visibility, and integration necessary to protect industrial and commercial assets.

| Safety Feature | Benefit | Standard Requirement |

|---|---|---|

| Tamper Switch | Prevents Unintended Closure | UL / FM Approved |

| Indicator | Instant Status Verification | Gear Operator Flag |

| Weight | Easy Installation | Lightweight Wafer/Lug |

5. Can agriculture rely on the application of butterfly valve?

Agriculture can absolutely rely on the application of butterfly valve for irrigation due to its cost-efficiency and ease of manual operation in remote locations. You can manage large-diameter distribution lines with far less weight than traditional alternatives, which simplifies your field infrastructure. These valves are rugged enough to handle the debris and fluctuating pressures common in rural pumping stations across the globe.

Is debris a problem for application of butterfly valve units?

Ready for the good part? The streamlined disk design is engineered to resist buildup from silt or organic matter found in open water sources. Because these valves are significantly lighter than gate valves, your technical teams can install them without needing heavy lifting equipment in remote fields. This reduces your labor costs and speeds up the deployment of your seasonal irrigation network.

- Cost-Effective: Low material usage leads to a lower purchase price.

- Manual Overrides: Easy-to-use levers for quick field adjustments.

- Large Sizes: Available up to DN3000 for massive regional projects.

- Durability: Resistant to UV exposure and harsh outdoor environments.

Key Takeaway: The application of butterfly valve in agriculture offers a lightweight, durable, and budget-friendly solution for large-scale irrigation needs.

| Application | Benefit | Recommended Material |

|---|---|---|

| Pump Suction | Low Flow Resistance | Ductile Iron / EPDM |

| Main Headers | High Volume Control | DN300+ Flanged |

| Remote Fields | Portable & Easy Setup | Wafer Style |

6. Does automation improve the application of butterfly valve?

Automation significantly improves application of butterfly valve units by enabling precise remote control plus faster response times within complex industrial environments. Integrated sensors transmit real-time data directly towards central control rooms without human intervention while reducing operational risks during hazardous cycles. Digital positioners ensure your flow remains perfectly balanced throughout production cycles which prevents costly pressure spikes while maximizing hardware longevity.

How do actuators boost application of butterfly valve speed?

Look: modern pneumatic actuators flip your disk inside one second during emergencies whereas manual alternatives require tedious physical labor. You simply connect these units into existing SCADA networks for total oversight regarding every fluid movement across your facility. These automated assemblies reduce risks by providing fail-safe positions which close automatically if power failures strike your plant.

- Remote Monitoring: Track valve status from any central location.

- Variable Speed: Adjust opening rates to prevent water hammer.

- Fail-Safe Logic: Automatic closure during emergency signals.

- Precision Throttling: Achieve exact flow rates with digital feedback.

Key Takeaway: Automating your butterfly valves enhances system safety, provides real-time data, and significantly reduces the labor required for large-scale management.

| Actuator Type | Response Speed | Power Source | Best Use Case |

|---|---|---|---|

| Pneumatic | < 1 Second | Compressed Air | Rapid Emergency Shut-off |

| Electric | 5-15 Seconds | AC/DC Power | Precise Flow Throttling |

| Manual | Manual Speed | Human Labor | Non-Critical Isolation |

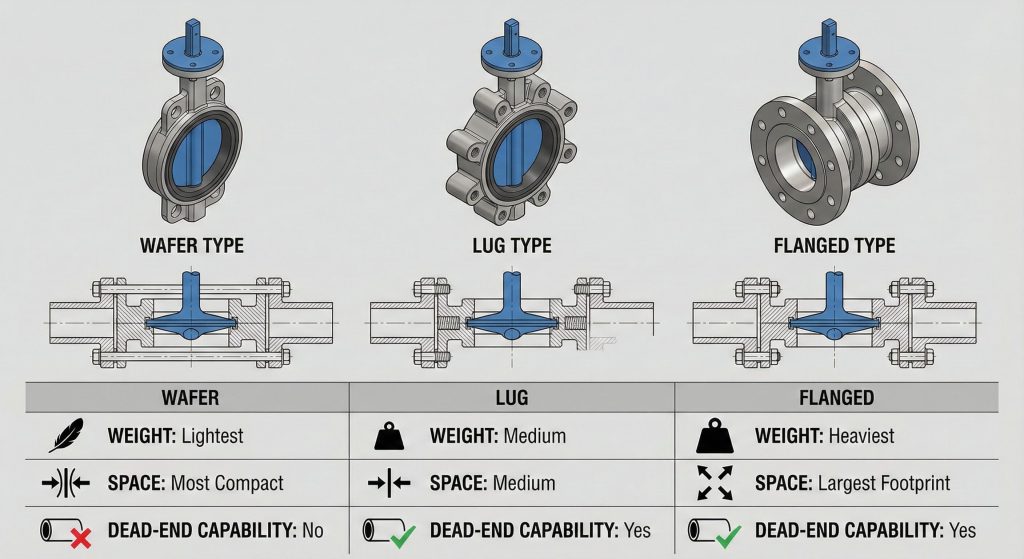

7. Why is wafer body application of butterfly valve popular?

The wafer body application of butterfly valve remains popular because its ultra-slim profile minimizes installation costs within space-constrained piping systems. You sandwich this lightweight component between two flanges using long bolts which reduces overall weight plus structural stress on the pipe. Lower material requirements ensure these units stay affordable for large-scale projects requiring hundreds of individual flow control points.

Does compact design help application of butterfly valve logic?

Now it gets better: choosing a wafer design allows you to install multiple valves in tight rows where bulky flanged models simply cannot fit. This compactness is a major advantage for skid-mounted systems or modular factories that prioritize high equipment density. Because the valve lacks its own bolt holes, alignment becomes faster for your technicians which further lowers project labor expenses.

- Low Profile: Fits into narrow gaps between existing pipes.

- Lightweight: Requires minimal support brackets or heavy rigging.

- Cost-Effective: Uses significantly less metal than flanged alternatives.

- Universal Fit: Compatible with various standards like ANSI or DIN.

Key Takeaway: Wafer body butterfly valves are the ideal solution for budget-conscious projects that require reliable flow control in restricted physical spaces.

| Body Style | Weight Class | Installation Difficulty | Dead-end Service? |

|---|---|---|---|

| Wafer | Ultra-Light | Very Easy | No |

| Lug | Medium | Moderate | Yes |

| Flanged | Heavy | High | Yes |

8. Is the application of butterfly valve suitable for slurries?

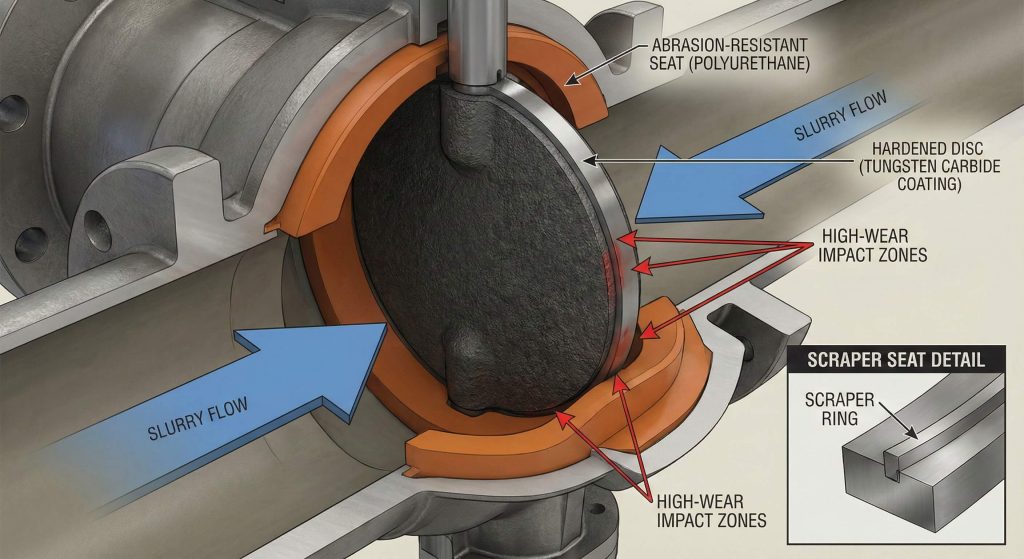

The application of butterfly valve units works for heavy slurries when you specify hardened disk materials plus specialized abrasive-resistant seats. Robust construction prevents premature failure when managing thick liquids that would normally destroy standard elastomer components within weeks. You should choose reinforced shafts designed for high-torque environments where debris might obstruct moving parts during the final closure sequence.

Can coatings protect the application of butterfly valve parts?

What’s the catch? Standard disks will pit quickly under high-velocity sediment, but specialized coatings like tungsten carbide protect internal surfaces from erosive grit. Hardened metal seats provide a rugged interface that resists the scraping action of rocks or concentrated chemicals found in mining operations. This durability extends your service intervals and prevents the frequent leaks associated with softer materials in high-wear scenarios.

- Hardened Disks: Resist pitting from high-velocity abrasive particles.

- Scraper Seats: Clear debris from the sealing surface during rotation.

- Oversized Shafts: Prevent bending under heavy sediment loads.

- Polyurethane Linings: Offer extreme resistance against erosive slurry.

Key Takeaway: High-performance butterfly valves with specialized coatings are highly effective at managing abrasive media while maintaining a compact footprint.

| Media Type | Recommended Disk | Seat Material | Wear Resistance |

|---|---|---|---|

| Fine Silt | Stainless Steel | EPDM / NBR | Medium |

| Coarse Sand | Chrome Plated | Polyurethane | High |

| Heavy Slurry | Tungsten Carbide | Stellite Metal | Extreme |

9. How does the application of butterfly valve support dam safety?

Large-scale application of butterfly valve technology supports dam safety by providing reliable emergency shut-off for massive penstock lines. Hydroelectric plants require immense valves capable of stopping millions of gallons instantly to prevent catastrophic flooding. Heavy-duty gearboxes provide the necessary mechanical advantage so technicians can operate these giants during power failures or maintenance shutdowns.

Are large sizes vital for application of butterfly valve power?

This is where it gets interesting: isolating a penstock requires a valve that can handle high velocities without vibrating or losing structural integrity. The streamlined disk design minimizes turbulence which protects your turbines from cavitation damage over long operational periods. These units act as the final line of defense for the facility by providing a bubble-tight seal that holds back entire reservoirs.

- High Pressure Rating: Designed to withstand deep-water head pressure.

- Emergency Closure: Works independently of external power using weights.

- Massive Scale: Available in diameters exceeding three thousand millimeters.

- Durability: Engineered for a fifty-year operational lifespan.

Key Takeaway: In hydroelectric applications, butterfly valves provide the massive scale and fail-safe reliability required to protect surrounding communities and infrastructure.

| Metric | Specification | Safety Benefit |

|---|---|---|

| Max Diameter | Up to 4000mm | Handles High Penstock Flow |

| Pressure Class | PN25 – PN64 | Withstands Deep Reservoir Loads |

| Operation | Hydraulic / Gravity | Works During Grid Failure |

10. Can ships trust the application of butterfly valve systems?

Marine vessels rely heavily on application of butterfly valve units for ballast management because they offer superior resistance against saltwater corrosion. Engine rooms contain limited space so compact quarter-turn designs offer a perfect solution for modern shipbuilders. Aluminum bronze disks withstand harsh maritime environments while preventing biofouling that often clogs traditional piping systems over long voyages at sea.

Is biofouling a risk for application of butterfly valve metal?

The truth is: managing ship stability requires moving thousands of tons of water quickly between various internal tanks. The low-torque requirement of these valves allows for small actuators that save valuable weight on the vessel’s upper decks. You can integrate these units with automated hull monitoring systems to ensure your ship remains perfectly level in rough seas and unpredictable weather.

- Bronze Alloys: Resist the corrosive nature of seawater.

- Compact Footprint: Fits into cramped bilge areas easily.

- Quick Actuation: Allows for rapid weight distribution adjustments.

- Vibration Resistance: Withstands the constant movement of the vessel.

Key Takeaway: The maritime industry trusts butterfly valves for their corrosion resistance, space savings, and ability to handle high-volume ballast water.

| Ship System | Benefit | Material Requirement |

|---|---|---|

| Ballast Water | Fast Leveling | Aluminum Bronze |

| Fuel Transfer | Precise Control | Viton Sealing |

| Fire Main | Emergency Speed | Ductile Iron / SS |

Conclusion

Managing complex fluid dynamics should not result in bulky equipment or operational bottlenecks. By adopting the versatile butterfly valve, you gain a streamlined, quarter-turn solution that maximizes space while ensuring rapid shut-off across diverse industrial applications. Our vision focuses on delivering precision-engineered flow control that empowers global projects to operate with unmatched reliability and efficiency. To optimize your infrastructure and prevent costly system failures, contact us today for a professional technical consultation.

FAQ

Can I use a butterfly valve for high-pressure steam?

Yes, but you must specify a triple-offset model with a metal seat. These specialized designs handle extreme thermal expansion and high velocities that would destroy standard resilient seats during operation.

What’s the best material for a corrosive chemical application?

You should utilize PTFE-lined bodies or exotic alloys like Hastelloy. These materials provide a complete barrier against aggressive acids while maintaining a bubble-tight seal during hazardous production cycles.

How do I know if a wafer or lug style fits my project?

Choose a wafer style for simple, space-saving installations between flanges. If you need to perform maintenance on downstream piping while the system is pressurized, select a lug style for dead-end service.

Can I install these valves in a vertical orientation?

Yes, butterfly valves function perfectly in both horizontal and vertical pipelines. You must ensure the shaft is oriented correctly to prevent sediment from accumulating in the lower bearing over time.

What’s the best way to prevent seat leakage over time?

Regularly inspect the valve for torque increases and utilize a double-offset design to minimize disk-to-seat friction. This geometry prevents the scuffing that typically causes wear in concentric models.