The butterfly valve testing standard is primarily defined by API 598 and ISO 5208 to ensure consistent pressure integrity across industrial systems. Pipeline integrity issues frequently haunt industrial engineers during complex commissioning phases, where a single leaky seal can halt massive operations or cause environmental hazards. Adhering to a strict butterfly valve testing standard provides the necessary security required for verifying component quality before installation starts. This guide covers every vital regulation that you must understand today to guarantee that your fluid control systems remain safe and efficient.

1. What defines the primary butterfly valve testing standard?

The primary butterfly valve testing standard relies heavily on API 598 for fundamental pressure verification and shell integrity checks. This protocol dictates how manufacturers evaluate seat tightness to prevent bypass during critical isolation tasks. You must verify that every butterfly valve withstands 1.5 times the maximum working pressure during initial trials to prevent catastrophic failures within your piping infrastructure. Professionals acknowledge that API 598 serves as the primary benchmark for these assessments because it provides specific leakage rates based on valve size and material composition.

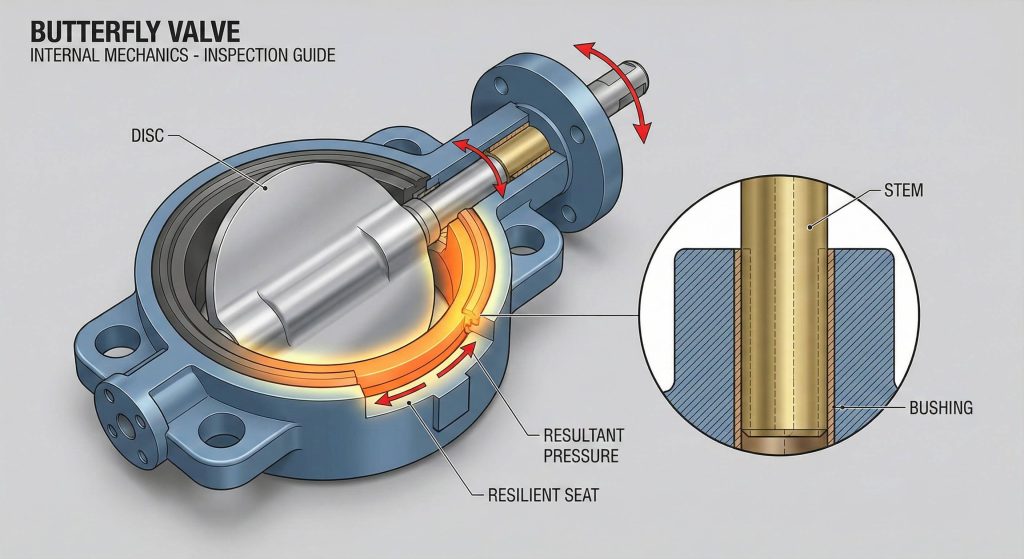

Testing for Different Seat Designs

The standards within API 598 focus on diverse mechanical checks, ranging from visual inspections to high-pressure pneumatic tests. You will notice that the rules apply to both resilient-seated and metal-seated designs, with soft seats generally requiring zero-leakage performance.

| Test Type | Pressure Level | Duration | Acceptance Criteria |

|---|---|---|---|

| Shell Test | 1.5x Rated | 15-120s | No visible leakage |

| Backseat Test | 1.1x Rated | 15-60s | Zero leakage |

| Low-Pressure Seat | 60-100 PSI | 15-60s | Zero for soft seats |

| High-Pressure Seat | 1.1x Rated | 15-60s | Minimal for metal |

Key Takeaway: API 598 acts as the universal baseline for pressure safety and seat reliability in modern industrial environments.

2. How does API 609 affect the butterfly valve testing standard?

The butterfly valve testing standard involves product-specific nuances found in API 609, which addresses design features like disc alignment and operating torque. This regulation specifies how wafer or lug types must behave under mechanical stress, ensuring the disc rotates freely without hitting the body walls. Binding issues often lead to actuator failure or seat damage over time, so API 609 ensures the torque required matches the motor or gear rating. Following these design-focused tests guarantees that the valve fits perfectly into your existing flange connections while matching the performance of a ball valve or other isolation components.

Torque and Mechanical Verification

High torque usually indicates poor machining or incorrect seat interference, making torque a vital performance metric in this standard. Testing torque at maximum differential pressure proves that the valve operates reliably under load and allows for the correct sizing of pneumatic or electric actuators.

| Feature | Evaluation Method | Standard Reference |

|---|---|---|

| Dimensions | Caliper Measurement | API 609 Table 3 |

| Disc Clearance | Visual Inspection | Body-to-Disc Gap |

| Operating Torque | Torque Wrench / Sensor | Break-to-Open Values |

| Flange Compatibility | Bolt Pattern Check | ASME B16.5 |

Key Takeaway: API 609 complements pressure testing by focusing on mechanical dimensions and operational torque requirements for system integration.

3. Which butterfly valve testing standard applies globally?

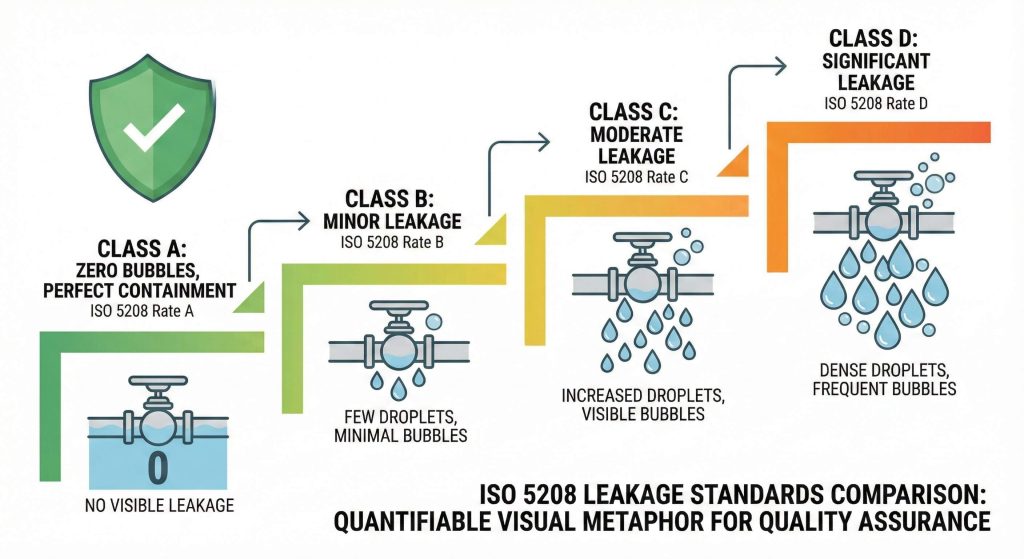

The butterfly valve testing standard known as ISO 5208 serves as the international language for pressure trials, categorizing leakage rates into specific classes. Most European or Asian projects prefer this framework because it ranges from Class A to Class G, letting engineers choose the right cost-to-performance ratio for their application. Class A denotes a bubble-tight seal typically seen in water or gas service, while a check valve might follow different seepage allowances depending on the design. Using an international standard simplifies the procurement process for global companies and builds confidence in the supply chain for large infrastructure projects.

Leakage Class Definitions

ISO 5208 uses liquid or gas as the test medium, with gas tests revealing smaller leaks that liquid might miss due to surface tension. This mathematical approach removes subjectivity from the inspection process by providing clear tables for calculating allowable drops per minute.

| Leakage Class | Test Medium | Allowable Rate | Common Application |

|---|---|---|---|

| Class A | Liquid / Gas | Zero Leakage | Potable Water / Gas |

| Class B | Liquid | 0.01 mm3/s x DN | General Industrial |

| Class C | Liquid | 0.03 mm3/s x DN | Wastewater |

| Class D | Liquid | 0.1 mm3/s x DN | Slurry Handling |

Key Takeaway: ISO 5208 provides a globally recognized classification system for defining exactly how much a valve can leak based on its diameter.

4. What is the European butterfly valve testing standard for metal?

The butterfly valve testing standard for metallic components in Europe is EN 12266-1, which mirrors many ISO requirements while adding specific European directives. You will see it referenced in projects across Germany, France, and the UK to comply with the Pressure Equipment Directive (PED). It mandates a shell test and seat tightness test for every metallic gate valve or butterfly unit produced to catch porosity in the casting. Catching these flaws early prevents the risk of body bursts in the field, particularly in the chemical and power generation industries.

Comparing EN to ISO Standards

While ISO focuses on global trade, EN 12266-1 aligns strictly with regional safety laws and pressure equipment mandates. Test durations are strictly defined to ensure enough time for leaks to appear, and every step must be recorded in a formal test certificate for final handover.

| Feature | EN 12266-1 | ISO 5208 |

|---|---|---|

| Primary Focus | European Compliance | International Trade |

| Shell Test | 1.5x PN | 1.5x PN |

| Seat Test | Mandatory | Mandatory |

| Documentation | PED Compliant | Manufacturer Standard |

Key Takeaway: EN 12266-1 is the definitive European standard for ensuring metallic valves meet regional pressure safety and legal requirements.

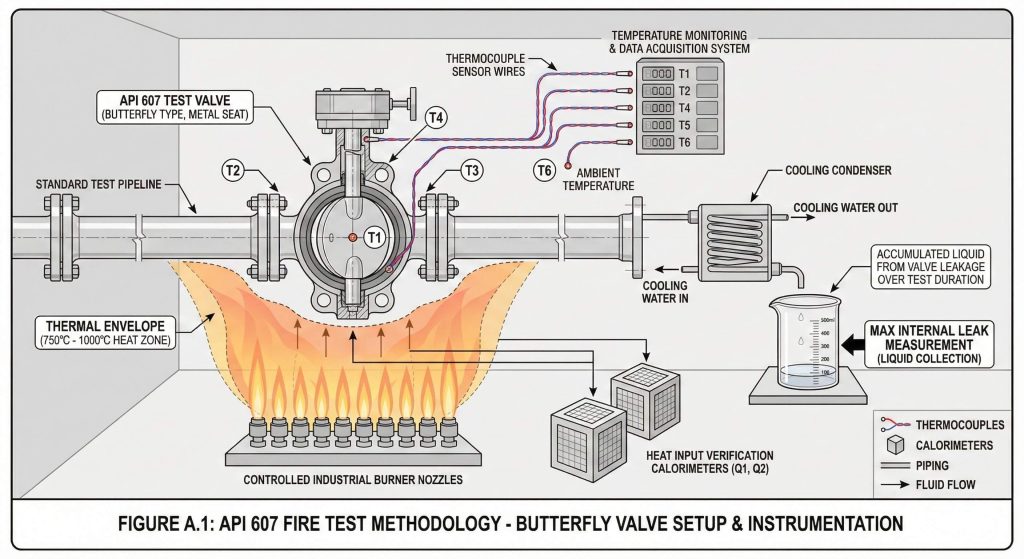

5. How do fire-safe rules impact the butterfly valve testing standard?

The butterfly valve testing standard for fire-prone environments involves API 607 or ISO 10497 to simulate extreme heat conditions. These tests are vital because soft seals melt quickly when temperatures exceed 500 degrees Celsius, forcing the valve to rely on a secondary metal-to-metal contact. During the test, the valve is engulfed in flames for thirty minutes while pressurized, and it must still operate and hold pressure after the fire is extinguished. Fire-safe certification proves that your hardware won’t contribute to a disaster on offshore platforms or in refineries.

Fire Test Procedure Details

Fire safety testing measures both internal and external leakage, as high external leakage can feed a fire and make it impossible to extinguish. The test monitors how much fluid passes through the seat during the burn period and checks the stem packing for signs of failure.

| Parameter | Value | Metric |

|---|---|---|

| Test Temperature | 750 – 1000 | Degrees Celsius |

| Burn Duration | 30 | Minutes |

| Max Internal Leak | 400 | ml/in/min |

| Max External Leak | 100 | ml/in/min |

Key Takeaway: Fire-safe testing ensures that valves provide a critical secondary seal to prevent fuel from feeding a disaster during extreme heat exposure.

6. What water industry butterfly valve testing standard is required?

The butterfly valve testing standard for municipal water systems follows AWWA C504 or C516, prioritizing long cycle life and corrosion resistance. These regulations focus on bubble-tight shutoff at lower pressures typical of city grids rather than high-pressure hydrocarbon service. Unlike a standard check valve, a water industry butterfly valve must survive thousands of open-and-close cycles without losing its sealing ability. Using AWWA standards guarantees that the materials used are safe for contact with potable water, preventing chemical leaching into the public supply.

Cycle Performance and Durability

Larger valves in water mains face massive hydraulic forces, so the test includes a proof-of-design phase to verify structural calculations through physical stress. Cycle tests are performed in both dry and wet conditions to simulate real-world usage over several decades of buried service.

| Test Category | Requirement | Goal |

|---|---|---|

| Performance Test | 3 Cycles | Verify Operation |

| Leakage Test | Zero Bubble | Environmental Safety |

| Hydrostatic Test | 2x Rated | Body Strength |

| Cycle Life Test | 10,000+ Cycles | Long-term Durability |

Key Takeaway: AWWA standards ensure that municipal water valves remain reliable for decades while protecting public health through strict durability trials.

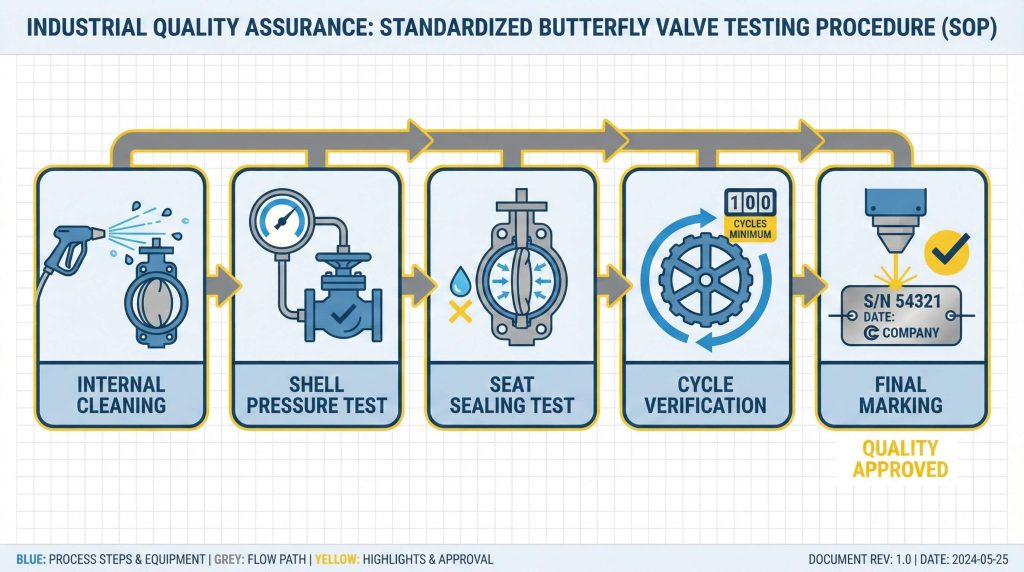

7. What are the main steps in a butterfly valve testing standard?

The butterfly valve testing standard follows a logical sequence starting with a shell test for checking the integrity of the casting. You fill the body with liquid and apply high pressure to ensure there is no weeping or sweating on the metal surface. After the body is verified, you perform a seat leakage test by closing the disc and pressurizing one side to see if the seal effectively blocks flow. Every step is meticulous and documented to create a complete quality history for the unit before it leaves the factory.

Execution of the Shell Test

The shell test requires the valve to be in a partially open position to allow the pressure to reach every part of the internal body and stem area. It is critical to bleed all air out of the system before reaching test pressure to avoid dangerous sudden failures during the evaluation.

| Order | Step Name | Primary Action | Key Indicator |

|---|---|---|---|

| 1 | Cleaning | Remove debris | Clean surfaces |

| 2 | Shell Test | Apply 1.5x PN | No body leaks |

| 3 | Seat Test | Apply 1.1x PN | Zero/Low Leakage |

| 4 | Cycling | Open/Close 3x | Smooth Motion |

| 5 | Marking | Apply Tag | Visual ID |

Key Takeaway: A systematic testing process from shell trials to final marking guarantees the overall quality and safety of industrial valves.

8. Does ASME B16.34 set a butterfly valve testing standard?

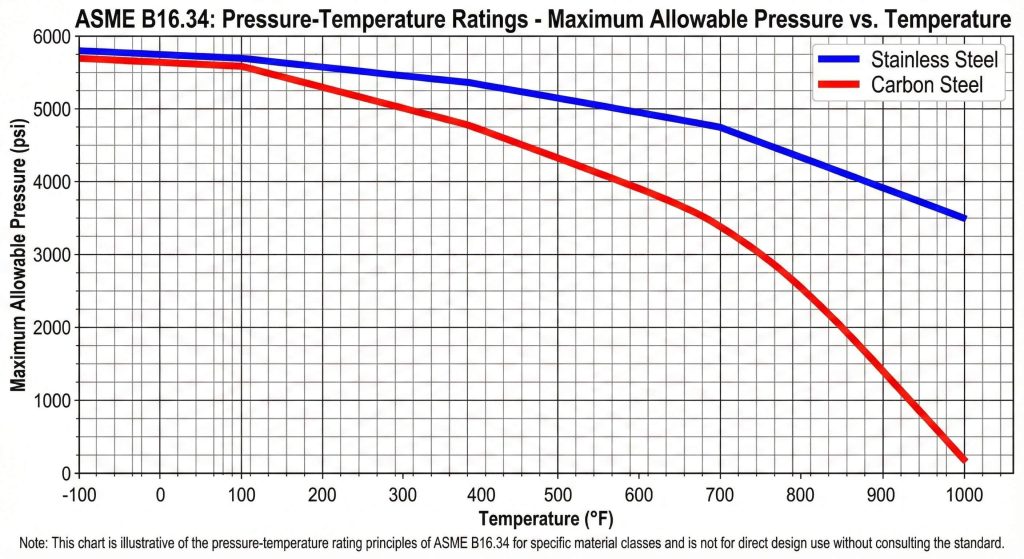

The butterfly valve testing standard is fundamentally influenced by ASME B16.34, which defines the relationship between pressure, temperature, and material strength. You must use these tables to determine the maximum allowable working pressure for your specific valve, whether it is a butterfly unit or a globe valve. While it doesn’t provide the step-by-step test procedure, it sets the limits that the tests must verify and specifies minimum wall thicknesses. Engineers use this standard for selecting the right hardware for high-pressure steam or volatile chemical lines.

Pressure-Temperature Application

The safety envelope of a valve changes significantly as temperature increases because the strength of the metal decreases. You must check the rating charts to ensure your valve is safe for the intended operating conditions, as a Class 150 valve has different limits than a Class 300 unit.

| Material Group | Class | 100°F (PSI) | 400°F (PSI) |

|---|---|---|---|

| Carbon Steel | 150 | 285 | 200 |

| Stainless 316 | 150 | 275 | 195 |

| Stainless 316 | 300 | 720 | 515 |

Key Takeaway: ASME B16.34 provides the pivotal pressure-temperature data that defines the safe operating limits for all industrial valves globally.

9. Why follow a consistent butterfly valve testing standard?

The butterfly valve testing standard exists for protecting your investment and your people through predictable performance. Consistency in testing means you won’t have to worry about one unit failing while others work fine, allowing technicians to learn one set of repair procedures. Standardized tests allow for easier maintenance and parts replacement, which improves efficiency and reduces human error during maintenance turnarounds. Following these benchmarks also makes it easier to pass safety audits and proves your company takes quality and site safety seriously.

Ensuring Long-term Reliability

Standardized testing reveals hidden flaws like casting cracks or poor seal bonding that are often invisible to the naked eye. By eliminating these weak links, you create a more resilient pipeline system where you know exactly how the hardware will behave in an emergency.

| Advantage | Impact | Result |

|---|---|---|

| Risk Mitigation | Fewer Leaks | Lower Liability |

| Interchangeability | Easy Replacement | Fast Repairs |

| Cost Control | Less Downtime | Higher ROI |

| Compliance | Audit Success | No Fines |

Key Takeaway: Consistent testing standards build a foundation of safety and reliability that protects both corporate assets and personnel.

10. How to pick the right butterfly valve testing standard?

The butterfly valve testing standard selection depends on your industry and geographic location to ensure you meet all legal and technical requirements. If you are in the oil and gas sector, you will likely stick with API 598, whereas water utilities in the United States will almost always require AWWA C504. For global projects, specifying ISO 5208 is often the most flexible choice for ensuring a wide range of suppliers can comply with your needs. You should also consider the media being handled; flammable fluids require fire-safe testing, similar to what you would expect for a ball valve in the same service.

Final Selection Criteria

Choosing the right standard ensures you don’t over-specify and waste budget or under-specify and risk safety. Talk to your engineering team about the specific safety requirements of your process to reach the best technical and economic outcome for your infrastructure project.

| Industry | Primary Standard | Secondary Standard |

|---|---|---|

| Oil & Gas | API 598 | API 607 (Fire) |

| Water Works | AWWA C504 | ISO 5208 |

| Chemical | EN 12266-1 | API 598 |

| Power Plant | ASME B16.34 | ISO 5208 |

Key Takeaway: Matching the testing standard to your specific industry and application is the best way to ensure safety and cost-effectiveness.

Conclusion

In summary, the butterfly valve testing standard remains the cornerstone of industrial safety and operational efficiency. I have discussed the primary frameworks like API 598 and ISO 5208, which define the limits for pressure integrity and leakage. Following these established rules prevents catastrophic failures and reduces long-term maintenance costs. For professional assistance with high-quality fluid control solutions, please contact us today.

Frequently Asked Questions

Q1: Can I use a water-tested valve for gas service?

Yes, but you must ensure the valve passed a high-pressure pneumatic test, as gas molecules escape through smaller gaps than liquid.

Q2: What’s the best way to verify a test report’s accuracy?

You should look for a signature from a certified third-party inspector or verify the calibration dates of the testing equipment used.

Q3: How do I know if my valve needs fire-safe testing?

If your pipeline carries flammable media like oil or natural gas, you must use fire-safe certified valves to prevent disaster.

Q4: Can I perform these tests on-site after installation?

Site hydrostatic testing is common for the whole pipeline, but individual valve performance should be confirmed at the factory first.

Q5: How do I know if a valve is API 598 compliant?

Check the permanent nameplate on the valve body for the API 598 stamp and request the specific test certificate from the manufacturer.