Correct selection depends on matching chemical compatibility with specific thermal and pressure limits. Imagine a high-pressure line bursting because a rubber seal dissolved under intense chemical stress. Such accidents halt production while driving maintenance costs into astronomical ranges instantly. This butterfly valve seat material selection guide (ruitoflow.com/butterfly-valve/) provides the technical clarity you need to ensure operational safety. Utilizing data-driven insights ensures your piping system achieves maximum longevity across every cycle.

What is a butterfly valve seat material selection guide?

A butterfly valve seat material selection guide is a technical map for navigating elastomer compatibility and thermal stability. This document categorizes polymers based on physical limits like shore hardness and tensile strength. Every engineer utilizes these charts to prevent seal degradation within harsh industrial environments. Precise documentation serves as your primary shield against common engineering oversights.

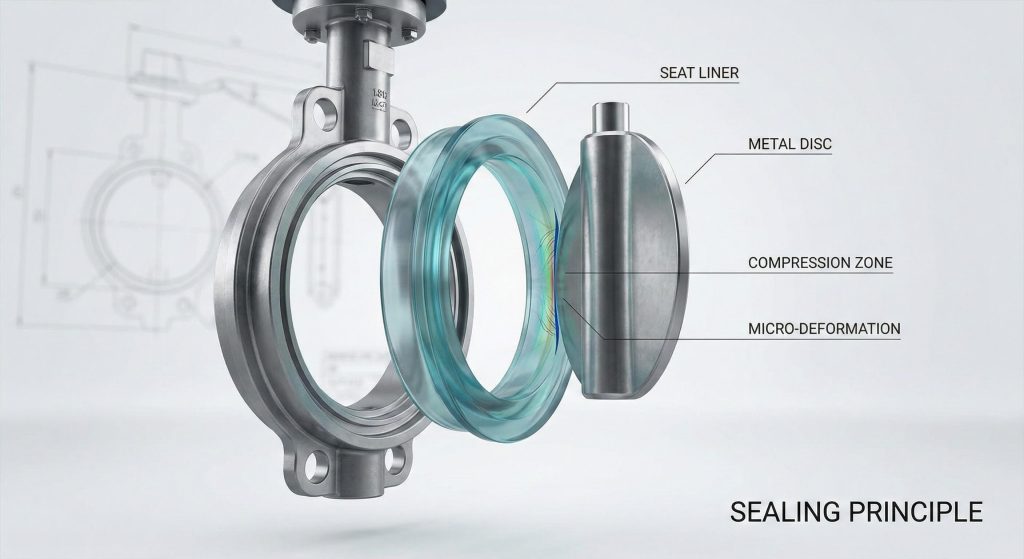

How do seat functions work?

Here is the deal. These components provide a stationary surface where your rotating disc creates a bubble-tight seal. Each liner must absorb the mechanical impact of closing while resisting constant flow erosion. High-quality designs incorporate reinforced backings to maintain shape under vacuum conditions.

- Absorb mechanical impact during closing.

- Provide a stationary sealing surface.

- Resist erosion from high-velocity media.

- Maintain shape under vacuum.

What is the role of the elastomer?

Think about this. Elastomers act as the flexible heart of resilient seated valves by providing the necessary compression. These polymers deform slightly under pressure to fill microscopic gaps between your metal surfaces. Modern compounds offer superior memory compared to older versions.

- Fill microscopic gaps through deformation.

- Provide necessary sealing compression.

- Return to original form after cycles.

- Prevent permanent compression set.

| Component | Material Type | Primary Function |

|---|---|---|

| Seat Liner | Elastomer | Primary Sealing |

| Reinforcement | Phenolic/Metal | Structural Support |

| Disc Edge | Stainless Steel | Sealing Interface |

Why use a butterfly valve seat material selection guide?

You use a butterfly valve seat material selection guide to predict maintenance intervals and mitigate the risk of premature component destruction. Skipping this analysis often results in elastomers becoming brittle or swelling within weeks of installation. This tool allows you to protect downstream equipment from sudden pressure drops. Consistent application of these principles protects your facility infrastructure.

Can we prevent system failure?

Wait, there’s more. Mismatched polymers quickly lose their structural integrity when you expose them to incompatible solvents. A failing seal allows media to bypass the disc, which compromises your process control. Detecting these leaks early prevents expensive environmental contamination or safety hazards.

- Prevent environmental contamination.

- Maintain precise process control.

- Avoid total system shutdowns.

- Protect expensive downstream hardware.

How does media influence selection?

Now for the secret. Fluid chemistry dictates which molecular bonds will survive within your specific piping network. High acidity levels demand fluoropolymers while oily mixtures require you to use nitrile-based compounds. Thick slurries require abrasion-resistant liners to prevent thinning of the seal wall.

- Acidity levels determine polymer survival.

- Viscosity affects seat wall thinning.

- pH levels impact chemical resistance.

- Temperature changes fluid-seat interactions.

| Media Condition | Risk Factor | Recommended Action |

|---|---|---|

| High Acidity | Chemical Attack | Specify Fluoropolymers |

| Abrasive Grit | Mechanical Wear | Use High-Durometer Rubber |

| Oily Residue | Material Swelling | Select Nitrile Compounds |

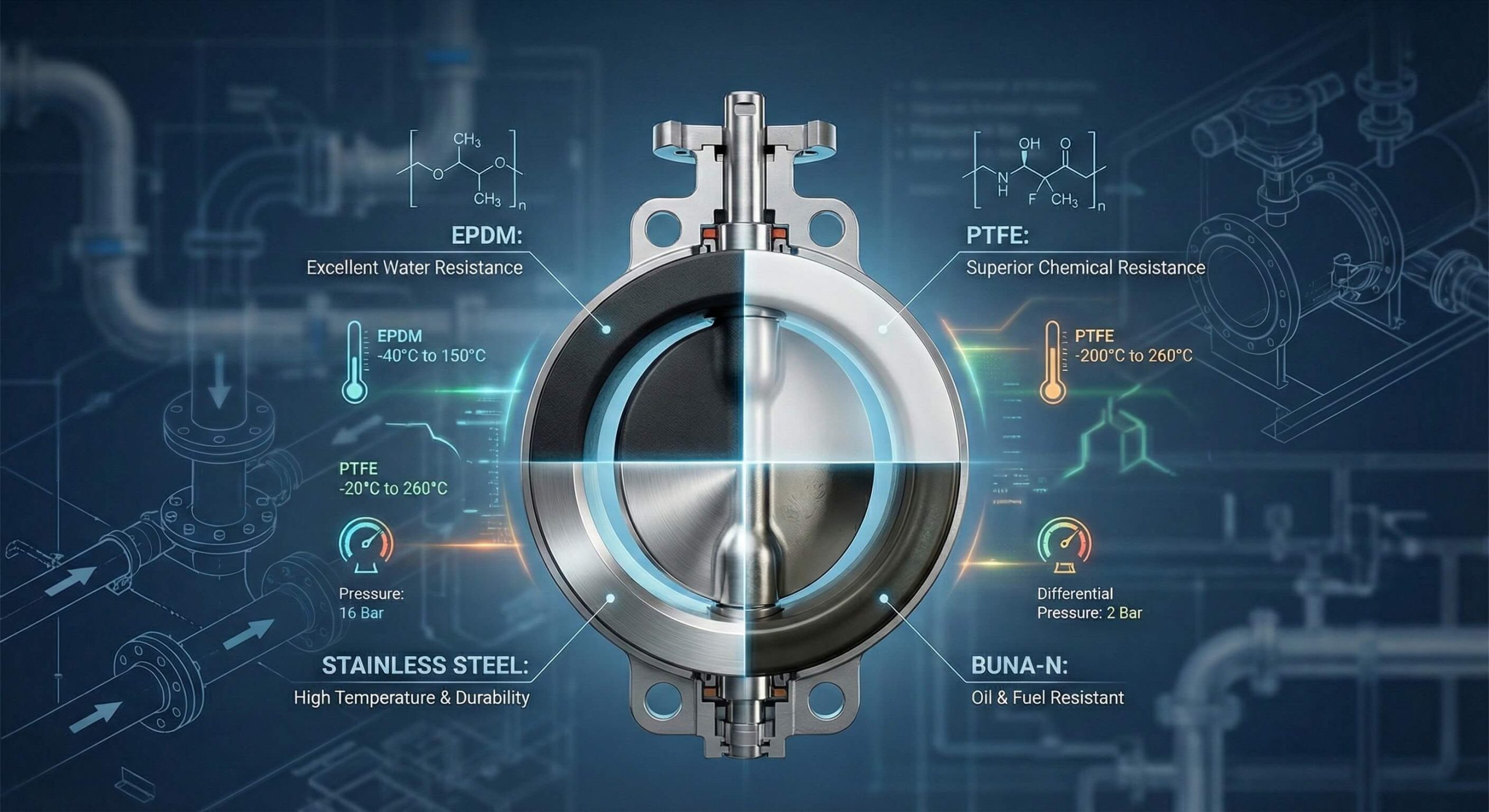

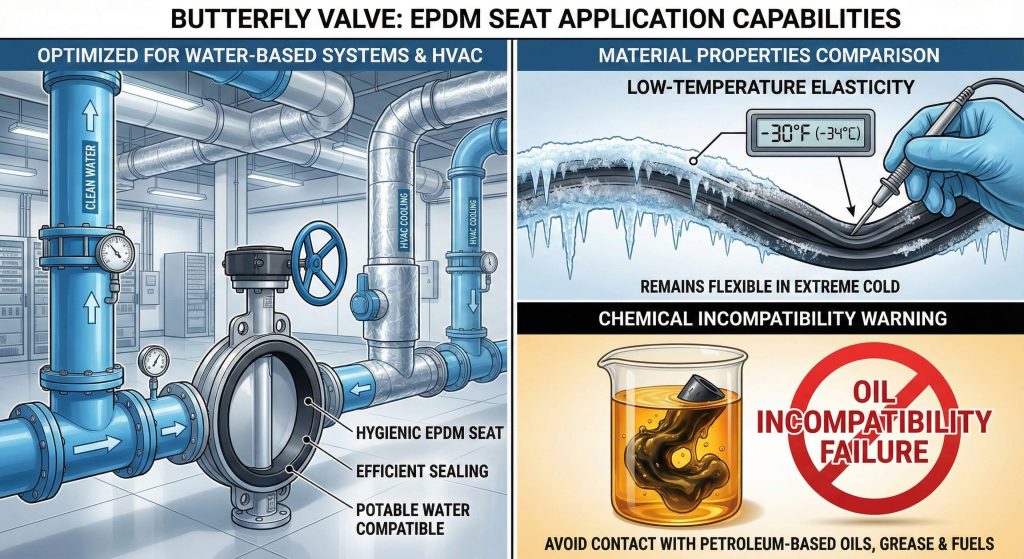

Is EPDM best in a butterfly valve seat material selection guide?

EPDM is often considered best for water systems due to its exceptional resistance to ozone and weather conditions. You will find this synthetic rubber in most HVAC systems and municipal water projects worldwide. It functions perfectly within steam environments up to specific temperature thresholds. However, it fails miserably when touching petroleum products or mineral oils in your lines.

What are the temperature limits?

Let’s dive in. Most standard configurations operate safely between minus thirty and two hundred twenty-five degrees Fahrenheit. Specialized high-heat versions can reach nearly three hundred degrees for short durations. Cold weather performance stays stable without the material turning brittle or cracking.

- Cold weather stability down to -30°F.

- Standard heat resistance up to 225°F.

- High-heat version limits at 300°F.

- Stable performance in outdoor climates.

What is the chemical resistance profile?

Here is the kicker. It handles phosphate esters and many diluted acids without losing its mechanical grip or sealing ability. Many industrial cleaning solutions also prove compatible with this resilient and versatile polymer. It remains the top choice for alkaline liquids or hot water circulation loops.

- Resistant to phosphate esters.

- Compatible with diluted acids.

- Safe for alkaline liquid solutions.

- FDA-grade versions for food processing.

| Property | EPDM Specification | Application Benefit |

|---|---|---|

| Weathering | Outstanding | Great for Outdoors |

| Abrasion | Excellent | Handles Particulates |

| Oil Resistance | Poor | Not for Fuel Lines |

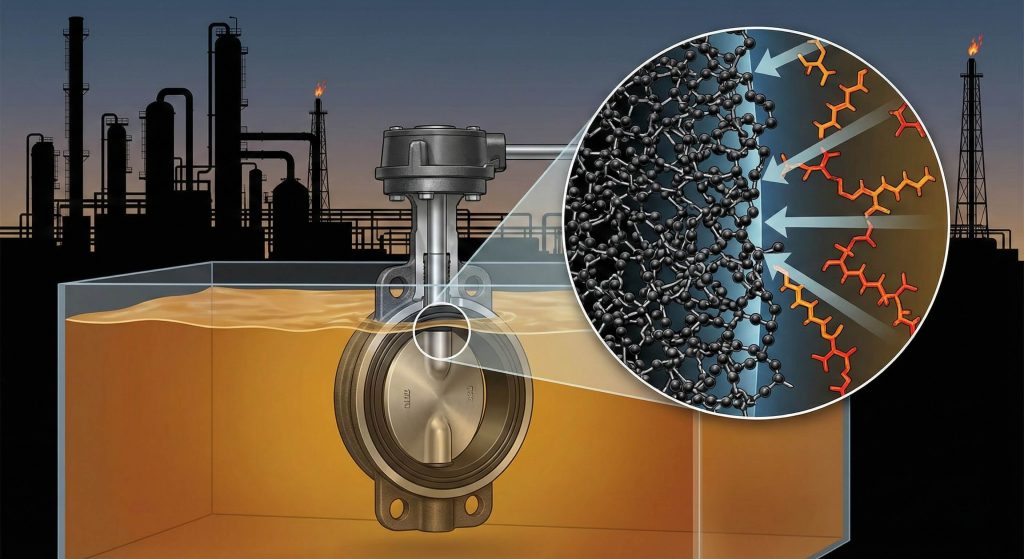

How does Buna-N fit a butterfly valve seat material selection guide?

Buna-N fits perfectly in oil-rich environments where you need a butterfly valve seat material selection guide to specify fuel-resistant hardware. Also known as Nitrile, this copolymer excels where other rubbers fail during constant hydrocarbon contact. Its high tensile strength allows your system to withstand heavy industrial wear and tear. It provides a cost-effective solution for standard petroleum-based applications across many sectors.

Is it suitable for oil-based media?

Think about this. Its molecular structure resists penetration by hydrocarbons and fatty acids effectively during operation. It stays stable for you even when submerged in gasoline or diesel fuel for years. This characteristic prevents the seal from expanding and jamming your valve disc.

- Resists penetration by hydrocarbons.

- Stable in gasoline and diesel.

- Prevents seal expansion in fuels.

- Reliable for crude oil transport.

How does it outperform other elastomers?

Believe it or not. It provides better compression set resistance than many soft alternatives in your heavy-duty industrial cycles. This means your seat returns to its shape even after the valve stays closed for months. Nitrile seats often cost less than specialized fluorocarbons or exotic plastics.

- Superior compression set resistance.

- Lower cost than fluorocarbons.

- High mechanical toughness in cycles.

- Industry standard for refineries.

| Metric | Nitrile Value | Operational Impact |

|---|---|---|

| Oil Resistance | Excellent | No Swelling in Fuels |

| Tensile Strength | High | Resists Mechanical Tearing |

| Temp Range | 0°F to 180°F | Standard Industrial Stability |

When is PTFE used in a butterfly valve seat material selection guide?

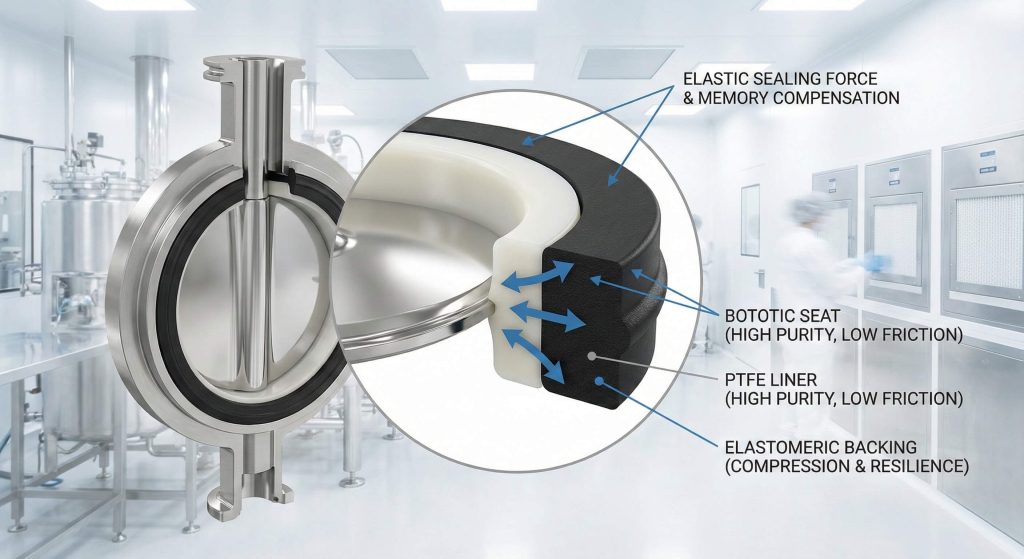

PTFE is used in applications requiring extreme chemical purity and near-universal resistance to aggressive solvents. This thermoplastic liner offers a low-friction surface that reduces the torque required to move the disc. You can use smaller actuators to operate large valves efficiently, saving on overall costs. Many pharmaceutical plants insist on this material to prevent fluid contamination.

Why is chemical resistance superior?

Here is the deal. Its carbon-fluorine bonds are among the strongest in organic chemistry, resisting almost all aggressive media. This material survives your contact with nitric and sulfuric acids without showing signs of wear. It stays inert even when exposed to high-purity chemicals in semiconductor manufacturing.

- Strong carbon-fluorine molecular bonds.

- Universal resistance to aggressive acids.

- Inert in semiconductor manufacturing.

- No absorption of process moisture.

What are the pressure limitations?

You might be wondering. This plastic tends to “creep” or deform slowly under your extremely high mechanical loads over time. It lacks the natural “spring-back” found in traditional rubber elastomers used in resilient designs. Many manufacturers use an elastomer cushion behind the liner to provide the necessary sealing force.

- Susceptible to mechanical cold flow.

- Requires an elastomer backing cushion.

- Lacks natural material memory.

- Optimized through hybrid designs.

| Feature | PTFE Specification | Benefit |

|---|---|---|

| Friction Coeff | Extremely Low | Lower Actuator Torque |

| Max Temp | Up to 400°F | Steam & Hot Acid Safety |

| Purity | High | Pharmaceutical Compliant |

Does Viton lead a butterfly valve seat material selection guide?

Viton leads the butterfly valve seat material selection guide for high-temperature chemical service involving aggressive mineral acids. This premium fluorocarbon elastomer handles heat that would melt or char your standard rubber compounds. You can maintain seal flexibility even after prolonged exposure to three hundred degrees Fahrenheit. It effectively combines the chemical resistance of PTFE with the physical elasticity of Nitrile.

How to select for high heat?

What’s the catch? Fluorocarbon materials remain stable for you when thermal energy breaks down other polymer chains easily. They resist hardening or cracking in environments where your temperatures fluctuate rapidly. This stability prevents seal failure during unexpected process spikes in your industrial furnaces.

- Resists thermal chain breakdown.

- Prevents seal hardening in heat.

- Maintains flexibility at 300°F+.

- Offers a wide thermal safety margin.

Is it compatible with aggressive acids?

Now for the good part. It performs well with most mineral acids and concentrated hydrocarbons you find in modern refineries. However, you should not use it for hot water or steam as it may degrade. Viton excels in vacuum service where low outgassing properties are vital for your success.

- Excellent with concentrated hydrocarbons.

- Superior performance in vacuum service.

- Resists modern lubricating oil additives.

- Stable with most mineral acids.

| Condition | Viton Performance | Limitation |

|---|---|---|

| High Heat | Excellent | Stiffens below -15°F |

| Aggressive Oil | Outstanding | Not for Steam Use |

| Chemical Vapor | High Resistance | Swells in Ketones |

Can metals join a butterfly valve seat material selection guide?

Metals join the selection guide for extreme conditions where soft elastomers lose their structural integrity entirely. When your temperatures exceed four hundred degrees Fahrenheit, precision-machined metal surfaces are necessary to block flow. These valves handle abrasive slurries that would shred a polymer or rubber butterfly liner. While they may not offer zero-leakage, they survive in molten metal or high-pressure steam.

Why are metal seats necessary?

Wait, there’s more. High-pressure steam lines and molten processes require you to use the strength of steel alloys. These environments cause synthetic polymers to vaporize or melt instantly upon contact with the flow. Metal seats resist the “sandblasting” effect of high-velocity particulates in your flow stream.

- Essential for molten metal processes.

- Resists abrasive slurry “sandblasting.”

- Necessary for high-pressure steam.

- Survives where polymers vaporize.

What are triple-offset advantages?

This is where it gets interesting. Triple-offset geometry allows your disc to wedge into the seat without rubbing or friction. This reduces wear and extends the life of your metal sealing surfaces significantly. Unlike traditional designs, these valves provide a more compact solution for your large pipes.

- Eliminates rubbing during actuation.

- Laminated design for better sealing.

- Extends life of sealing surfaces.

- Handles temperatures up to 1200°F.

| Seat Type | Temp Limit | Wear Resistance |

|---|---|---|

| Soft Resilient | 400°F | Moderate |

| Metal-to-Metal | 1200°F | High |

| Laminated Metal | 1000°F | Excellent |

How to apply a butterfly valve seat material selection guide?

Applying a butterfly valve seat material selection guide requires balancing pressure, temperature, and chemical variables simultaneously. You must consider the maximum pressure and the highest expected temperature of your specific system. Use a compatibility chart to cross-reference your fluid against various polymers before purchasing hardware. A systematic approach prevents expensive mistakes during your initial installation phase.

What are P-T ratings?

You might be wondering. You use P-T charts to see how the strength of your seat drops as heat increases. A material might handle one hundred PSI at room temperature but fail for you when hot. Always check the specific curve for the exact model you plan to install.

- Use specialized P-T rating charts.

- Account for heat-induced strength loss.

- Follow international ASME or ISO data.

- Verify specific manufacturer curves.

How to maintain seat performance?

Now for the good part. Regular inspection for signs of pitting or swelling remains your best way to prevent failure. If a seat feels brittle during your manual check, it requires immediate replacement by your team. Proper care doubles the operational lifespan of any flow control component you use.

- Inspect regularly for swelling or pitting.

- Replace brittle seats immediately.

- Lubricate disc edges to reduce friction.

- Ensure pipes are clean before install.

| Step | Action | Objective |

|---|---|---|

| 1 | Fluid Identification | Chemical Matching |

| 2 | Thermal Check | Material Stability |

| 3 | Pressure Mapping | Mechanical Integrity |

What fails in a butterfly valve seat material selection guide?

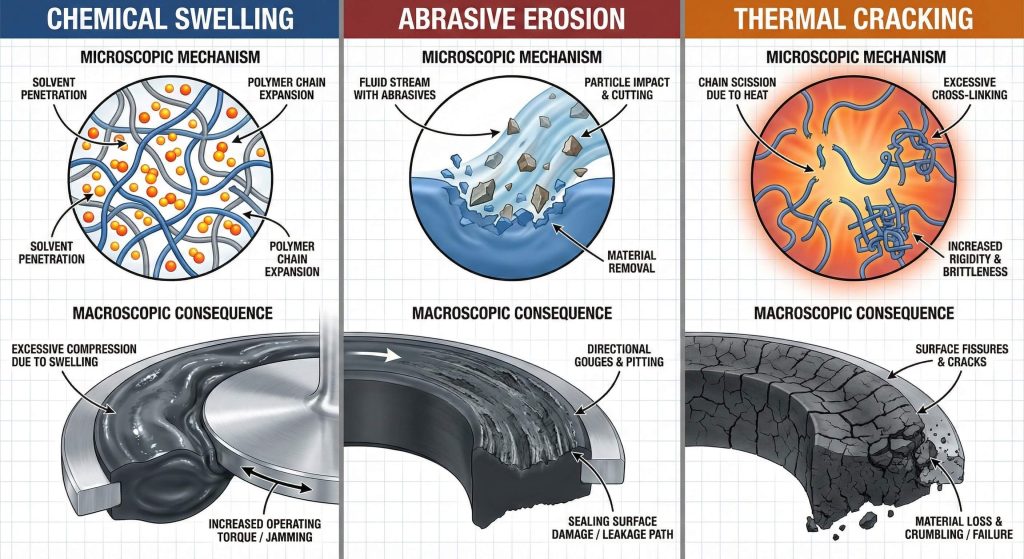

Failure modes in the guide include chemical attack, swelling, and mechanical erosion that compromise your system. Understanding these patterns allows you to pick a better material for your next maintenance cycle. Mechanical wear happens when abrasive particles gouge your elastomer surface over time. Thermal degradation leads to hardening, which makes your seal crack under pressure.

What indicates material swelling?

It gets better. Swelling occurs when fluid molecules penetrate your polymer matrix and push the molecular chains apart. This increases the volume of your seat and makes the valve extremely hard to operate. If your seat looks larger than its original size, you have a chemical mismatch.

- Signals a direct chemical mismatch.

- Increases seat volume and torque.

- Can cause actuator burn-out.

- Jams the valve disc permanently.

How does media cause erosion?

Let’s dive in. High-velocity grit acts like a cutting tool against your soft plastic or rubber surfaces. This erosion creates paths for fluid to leak through even when your valve is closed. Choosing a seat with higher shore hardness prevents this type of damage.

- Grit acts as a mechanical cutting tool.

- Erosion creates permanent leak paths.

- Requires seats with high shore hardness.

- Polyurethane is ideal for mining slurries.

| Failure Mode | Visual Sign | Likely Cause |

|---|---|---|

| Swelling | Distortion / Jamming | Chemical Incompatibility |

| Pitting | Surface Holes | Abrasive Wear |

| Cracking | Brittle Texture | Thermal Exhaustion |

Who needs this butterfly valve seat material selection guide?

Every procurement manager and plant operator needs this butterfly valve seat material selection guide to avoid buying the wrong parts. You rely on this data to maintain safety standards and reach your production quotas. Design engineers use these guides to build systems that last you for decades rather than months. Sharing this knowledge across departments improves the overall technical literacy of your workforce.

Can we standardize across valve types?

Wait, there’s more. While the geometry differs, the material science remains identical for all your industrial seals. A polymer that fails you in a butterfly valve will also fail in a globe or gate design. Understanding these limits helps you standardize your inventory across the entire plant.

- Material science is identical across types.

- Standardize inventory to reduce costs.

- Simplifies maintenance training procedures.

- Reduces warehouse spare part counts.

How to achieve long-term ROI?

Here is the kicker. Choosing the right seat reduces your total cost of ownership by extending the time between repairs. Even if a premium material costs you more initially, it saves thousands in avoided downtime. Investing in high-quality seats represents a smart financial decision for your business.

- Extends time between expensive repairs.

- Prevents costly production downtime.

- Lowers total cost of ownership (TCO).

- Safeguards your facility infrastructure.

| Stakeholder | Primary Benefit | Strategic Value |

|---|---|---|

| Plant Manager | Reduced Downtime | Operational Continuity |

| Procurement | Lower Lifecycle Cost | Budget Optimization |

| Engineer | System Reliability | Risk Mitigation |

Conclusion

Correct seat selection defines the success of your industrial flow control system. This manual summarized how EPDM, Nitrile, PTFE, and Viton serve your distinct operational needs. We emphasized the necessity of matching chemical properties with polymer characteristics to prevent failure. Why does this matter? Avoiding downtime and maintaining safety should be your primary objectives. To optimize your hardware life and ensure absolute sealing integrity, contact us today for a technical consultation.

Frequently Asked Questions

Q1: Can I use EPDM for petroleum lines?

No, you should never use EPDM with petroleum because it will swell and degrade rapidly when it touches mineral oils or hydrocarbons.

Q2: Can I find a universal seat for all acids?

PTFE is the closest to a universal seat for acids, as its carbon-fluorine bonds offer near-total resistance to aggressive chemical solvents.

Q3: Can I determine if my valve seat is failing?

Yes, you can identify failure by monitoring for internal leakage, an increase in operating torque, or visible material cracking during inspection.

Q4: Can I utilize Viton for high-pressure steam?

No, Viton is generally not recommended for steam applications because it can suffer from hydrolysis; EPDM is typically the superior choice for steam.

Q5: Can I select soft seats for heat above 400°F?

No, soft elastomers lose their structural integrity above 400°F, so you must transition to metal-to-metal or laminated metal seats for these extreme temperatures.