The structural features of a center line double flange butterfly valve focus on a concentric design where the stem and disc are perfectly aligned with the valve body’s center. Industrial facilities often struggle with inconsistent flow control and frequent seal degradation in high-vibration environments. These issues agitate production schedules and lead to expensive emergency repairs that disrupt your bottom line. By implementing the double flanged center line butterfly valve, you solve these challenges with a rigid, stable architecture that provides bubble-tight shut-off for long-term operational success.

Why choose a double flanged center line butterfly valve?

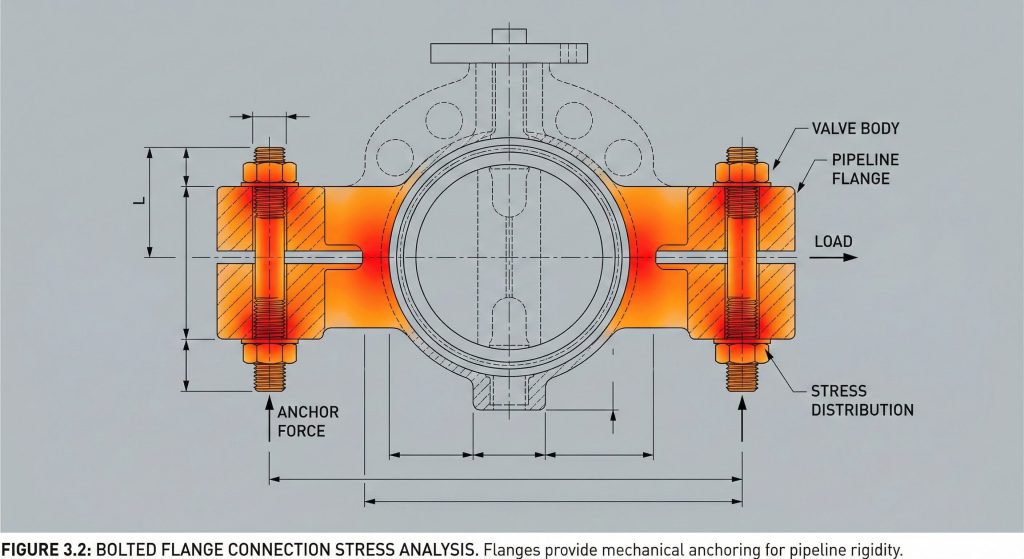

You choose this design when your piping system demands maximum structural rigidity and the ability to isolate sections for maintenance. The double flanged center line butterfly valve features integrated flanges on both sides of the body, allowing for secure bolting directly to the pipe. This configuration prevents the valve from shifting or leaking under thermal expansion, unlike lighter wafer-style alternatives.

What are the stability benefits?

You will find that the flanged ends act as a mechanical anchor, distributing the weight of the valve and fluid evenly across the pipe supports. This is crucial for large-diameter lines where gravity and flow surges can cause significant stress on the connection points.

Think about it:

When your system experiences sudden pressure spikes, the bolted flange connection ensures the valve doesn’t move a millimeter. You maintain a perfectly centered disc for reliable flow modulation.

| Feature | Engineering Benefit | Maintenance Impact |

|---|---|---|

| Integral Flanges | High Structural Rigidity | Simplifies Bolt Alignment |

| Bolted Connection | Superior Seal Stability | Reduced Gasket Failure |

| Concentric Stem | Balanced Torque Load | Extended Service Life |

The mechanical synergy between the flanged body and the central stem design creates a platform for precise and repeatable flow control.

Key Takeaway: You should prioritize the double flanged design for critical infrastructure because it offers the highest level of mechanical stability and safety for high-pressure industrial applications.

How to operate a double flanged center line butterfly valve?

You operate this valve by rotating the central disc exactly 90 degrees to transition between the fully open and fully closed states. The double flanged center line butterfly valve utilizes a simple quarter-turn mechanism that can be actuated manually or with automated systems. This direct mechanical movement ensures that the disc edge makes uniform contact with the seat throughout the entire sealing circumference.

How does the 90-degree sweep work?

You can achieve a full shut-off by turning the stem until the disc is perpendicular to the flow path. This movement compresses the elastic seat material to create a tight seal that prevents any fluid bypass.

Here is the kicker:

A 90-degree turn is the fastest way to stop flow in an emergency. You don’t have to wait for a long-travel gate to lower into the stream.

| Position | Flow State | Sealing Force |

|---|---|---|

| 0° (Open) | Maximum Capacity | Minimal Stem Stress |

| 45° (Mid) | Throttling | Moderate Turbulence |

| 90° (Closed) | Zero Flow | Maximum Seat Compression |

The efficiency of the quarter-turn operation reduces the wear on the internal components by minimizing the time the seal is exposed to high-velocity flow.

Key Takeaway: You benefit from a simple, high-speed actuation method that provides immediate flow control and reduces the energy required to operate large valves.

What defines the double flanged center line butterfly valve?

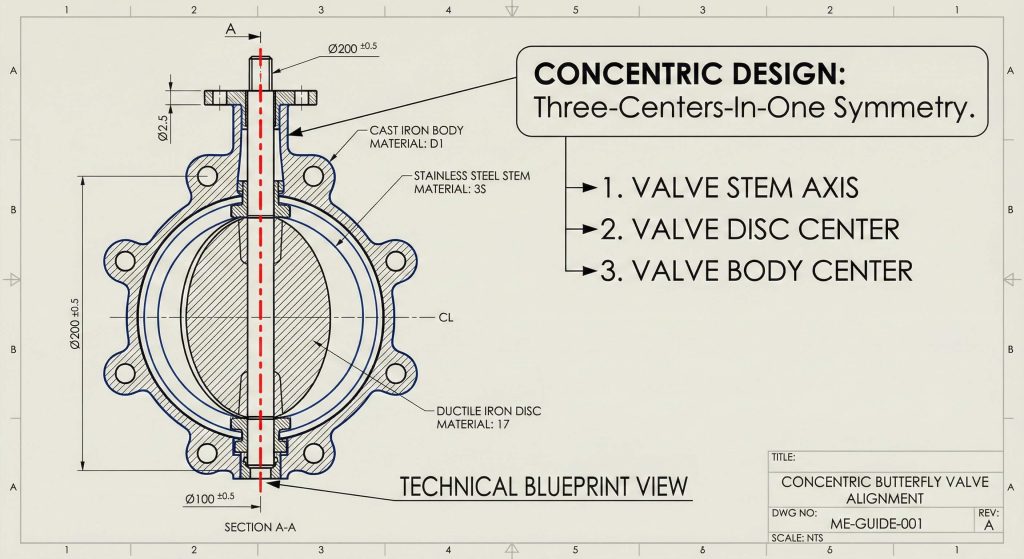

The defining characteristic is the alignment of the stem, the disc, and the valve body along a single geometric center line. A double flanged center line butterfly valve is built on a concentric principle, meaning there are no offsets to complicate the mechanical rotation. This symmetrical construction makes the valve bi-directional and reduces the complexity of manufacturing, which lowers your procurement costs.

Where are the centers located?

You can identify this valve by checking if the stem passes directly through the middle of the disc. Unlike high-performance eccentric valves, the center line design maintains a constant contact point with the seat during rotation.

Think about this:

Symmetry isn’t just about looks; it’s about performance. By keeping everything centered, you ensure the valve works perfectly no matter which way the water is flowing.

| Component | Alignment Detail | Practical Advantage |

|---|---|---|

| Stem Axis | Body Center | Simplified Actuation |

| Disc Surface | Flow Axis | Even Pressure Distribution |

| Seat Path | Geometric Center | Bi-Directional Sealing |

The geometric simplicity of the three-center alignment is the primary reason for the valve’s reliability in general utility service.

Key Takeaway: You should choose the center line configuration for its straightforward design, which provides reliable performance and easier maintenance than complex offset valves.

Is the double flanged center line butterfly valve durable?

Durability is achieved through the use of high-strength body materials and resilient elastic seats that resist chemical and mechanical wear. The double flanged center line butterfly valve features a robust housing that protects the internal liner from external environment damage. You must ensure that the seat material, such as EPDM or NBR, is compatible with your media to prevent premature hardening or swelling.

How does interference sealing last?

You rely on the interference fit where the disc is slightly larger than the seat’s inner diameter. This constant squeezing ensures a tight seal, though it does require a durable elastomer to withstand the friction of thousands of cycles.

In fact:

Modern vulcanized seats are bonded directly to the valve body. This prevents the liner from “bunching up” when you open the valve under high pressure.

| Material | Application | Temperature Limit |

|---|---|---|

| EPDM | Water & Air | Up to 120°C |

| NBR | Oils & Fats | Up to 80°C |

| PTFE | Aggressive Chemicals | Up to 150°C |

The longevity of the seal depends entirely on your ability to operate the valve within its specified thermal and chemical limits.

Key Takeaway: You can extend the life of your valve significantly by matching the elastomer seat to your specific fluid type and maintaining proper operating temperatures.

Where to apply a double flanged center line butterfly valve?

You should apply this valve in industries such as water treatment, petroleum, and chemical processing where reliable isolation is required. The double flanged center line butterfly valve is the standard choice for large municipal water works and cooling water systems. Its ability to provide a secure, flanged connection makes it ideal for fire protection lines that must remain operational under extreme conditions.

Is it right for hydropower?

You can use these valves for penstock isolation and turbine cooling where high flow volumes are common. The double flange provides the necessary strength to handle the vibrations and water hammer often found in power generation facilities.

Here is the deal:

When you pair this with a high-quality gate valve for primary isolation, you create a redundant and safe flow control system. This dual-layer approach is the gold standard for critical infrastructure.

| Industry | Typical Use Case | Preferred Media |

|---|---|---|

| Water Treatment | Pump Station Isolation | Potable Water |

| Hydropower | Turbine Cooling | Raw River Water |

| HVAC Systems | Condenser Water | Glycol Mixes |

The versatile application range of this valve makes it a foundational component for any large-scale fluid management project.

Key Takeaway: You should utilize the flanged center line design for any application where pipe stability and long-term sealing are more important than minimizing the valve’s footprint.

Does a double flanged center line butterfly valve seal both ways?

Yes, the symmetrical design allows the valve to handle pressure and provide a tight seal regardless of flow direction. Because the double flanged center line butterfly valve is perfectly concentric, the sealing force remains consistent whether the pressure is coming from the upstream or downstream side. This bi-directional capability gives you more flexibility when designing complex piping manifolds where flow may reverse during pump shutdowns.

How is the seal maintained?

You benefit from the interference seal where the disc edge is compressed into the resilient liner. The fluid pressure actually helps push the disc into the seat, reinforcing the seal and preventing any seepage.

Believe it or not:

You can install this valve backward by mistake, and it will still work perfectly. That is the beauty of a truly symmetrical, bi-directional design.

| Pressure Source | Seal Performance | Integrity Level |

|---|---|---|

| Upstream | Interference + Pressure | Bubble-Tight |

| Downstream | Interference + Pressure | Bubble-Tight |

| Static Load | Mechanical Compression | Zero Leakage |

The ability to maintain a seal from both sides simplifies your installation process and protects your system against unexpected back-pressure.

Key Takeaway: You can install these valves with total confidence in their bi-directional performance, ensuring a safe shut-off regardless of your system’s flow dynamics.

Are there limits to a double flanged center line butterfly valve?

The primary limitations involve high-temperature steam and extremely abrasive slurries that can damage the elastic seat. A double flanged center line butterfly valve relies on rubber or PTFE, which will fail if exposed to temperatures beyond 150°C. Additionally, if your fluid contains sharp metal shavings or heavy sand, the “scratching” effect during rotation will eventually lead to a loss of sealing integrity.

Why avoid abrasive media?

You will find that solids trapped between the disc and the seat act like sandpaper. Every time you open or close the valve, these particles gouge the elastomer, creating small leak paths that grow over time.

But there’s more:

If you have a high-solids application, you might need a ball valve with hardened metal seats instead. Knowing the limits of your equipment is the first step toward preventing a disaster.

| Constraint | Limit Value | Failure Mode |

|---|---|---|

| Temperature | Max 120-150°C | Seat Melting/Charring |

| Media Solids | < 2% concentration | Rapid Abrasive Wear |

| Pressure | PN10 – PN25 | Seat Deformation |

The structural limits of the center line design are strictly tied to the physical properties of the elastomer liner and the friction of the disc.

Key Takeaway: You must avoid using center line butterfly valves for high-pressure steam or heavy sludge to prevent the rapid degradation of the sealing surface.

How to install a double flanged center line butterfly valve?

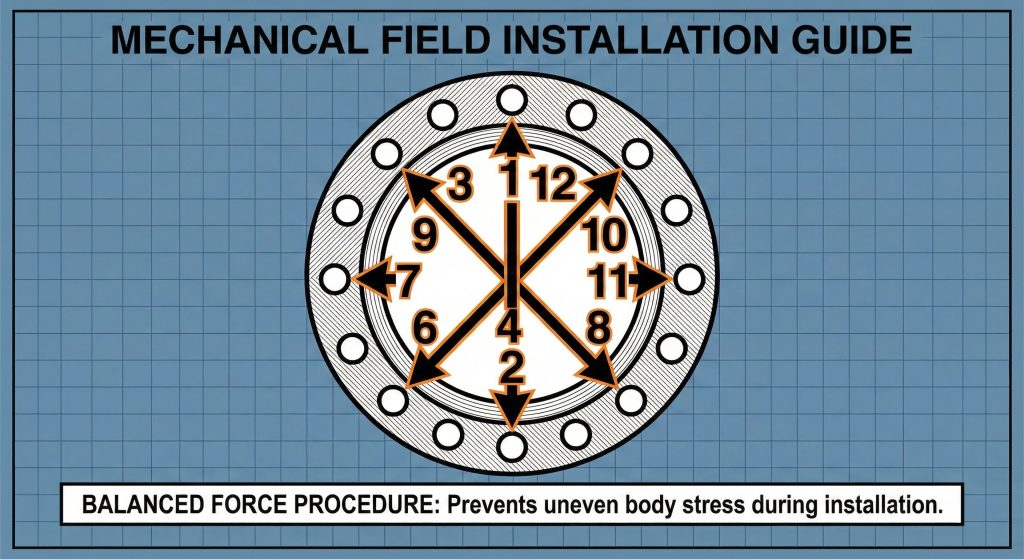

You must prioritize flange alignment and clean sealing surfaces to ensure a leak-free installation. The double flanged center line butterfly valve requires you to use studs or bolts that pass through the pipe flanges and the valve’s integrated flanges. It is essential that you tighten these bolts in a star pattern to apply even pressure across the face of the valve and prevent the body from warping during service.

What is the best bolting practice?

You should start by hand-tightening all bolts to ensure the valve is centered between the pipe ends. Then, use a torque wrench to tighten the bolts in small increments, moving back and forth across the center of the valve.

Here is the kicker:

If you tighten one side too fast, you will tilt the valve and cause a leak on the opposite side. Patience during installation saves you from having to do the job twice.

| Installation Step | Critical Action | Success Metric |

|---|---|---|

| Alignment Check | Verify Pipe Parallelism | < 1mm Deviation |

| Bolt Torquing | Star Pattern Method | Uniform Nut Tension |

| Final Inspection | Low-Pressure Leak Test | Zero Visible Seepage |

The integrity of your valve’s seal is as much about the quality of the installation as it is about the quality of the valve itself.

Key Takeaway: You must use a systematic, incremental torquing procedure to ensure the valve body remains perfectly aligned and the flanges provide a uniform seal.

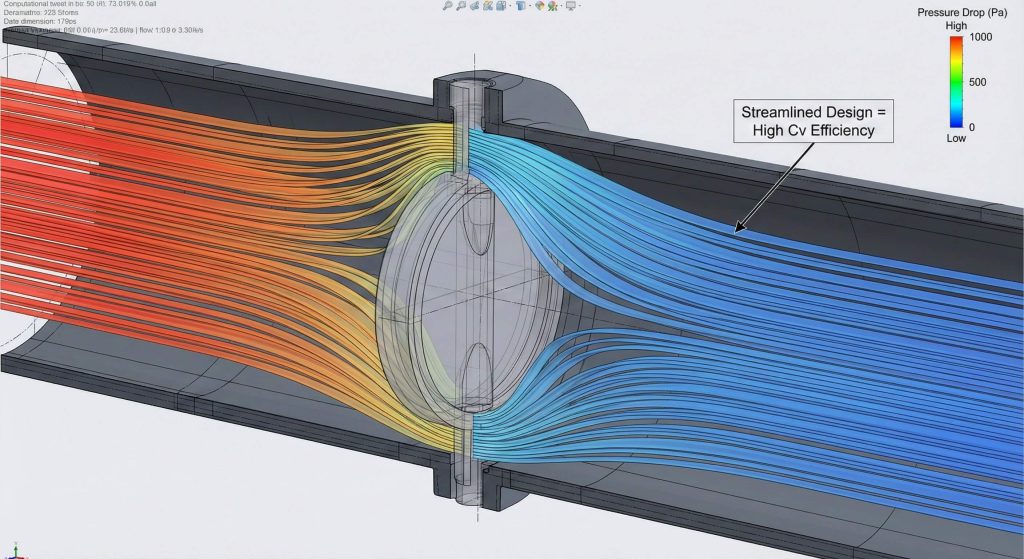

Why is a double flanged center line butterfly valve efficient?

Efficiency is derived from the high flow coefficient (Cv) and the lightweight construction compared to gate or globe valves. The double flanged center line butterfly valve offers a streamlined flow path that minimizes turbulence and pressure drop. This means your pumps don’t have to work as hard, which reduces your facility’s energy consumption and lowers the total cost of ownership over the valve’s life.

Does it save energy?

You benefit from the thin disc design that presents very little resistance when fully open. In large systems, the cumulative energy savings from using high-efficiency butterfly valves can reach thousands of dollars annually.

Think about it:

Every millibar of pressure you save by using a streamlined valve stays in your pocket as reduced utility costs. It is the most cost-effective upgrade you can make to your plant.

| Parameter | Butterfly Valve | Gate Valve |

|---|---|---|

| Flow Coefficient | High | Very High |

| Component Weight | Low | High |

| Installation Time | Fast | Slow |

The combination of low pressure loss and manageable weight makes this valve the most efficient choice for modern industrial piping.

Key Takeaway: You can significantly lower your operational expenses by utilizing the high-efficiency design of the center line butterfly valve to minimize system pressure drops.

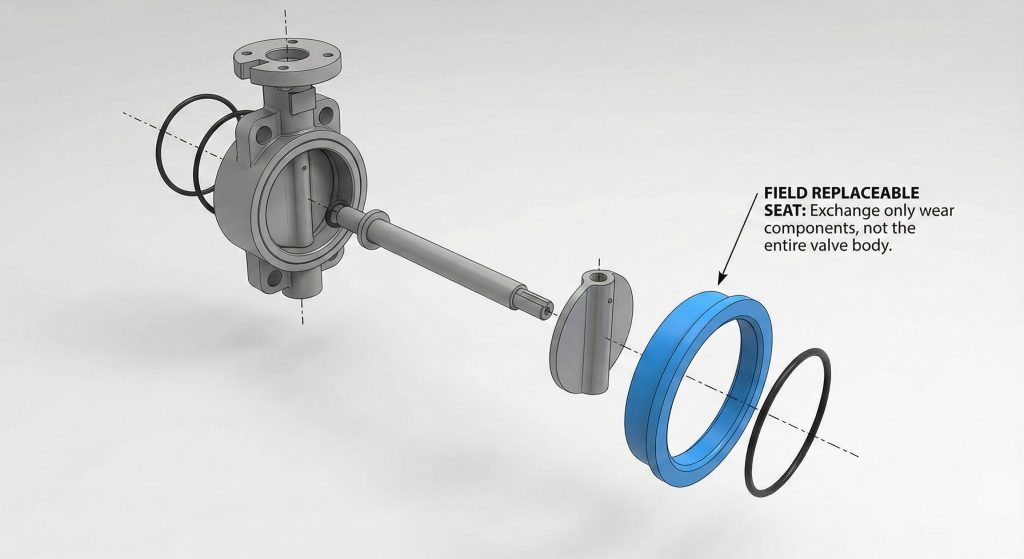

Can you repair a double flanged center line butterfly valve?

You can easily repair these valves by replacing the internal seat or the stem seals without having to replace the entire body. The modular nature of the double flanged center line butterfly valve allows you to perform field maintenance with basic tools. Regular inspection of the disc edges and seat compression is necessary to identify wear patterns before they result in a total seal failure.

Is seat replacement easy?

You can remove the old liner by pulling the stem through the top of the valve and then sliding the seat out of the body. Most manufacturers provide replacement kits that include a new seat and stem O-rings to restore the valve to its original performance.

Here is the kicker:

You don’t need a factory shop to fix these valves. With a little training, your on-site team can swap a seat in less than an hour.

| Maintenance Task | Timing | Objective |

|---|---|---|

| Stem Lubrication | Bi-Annually | Reduce Friction |

| Seat Inspection | Annually | Prevent Leakage |

| Seal Replacement | As Needed | Restore Integrity |

The ability to maintain and repair the valve on-site ensures that your downtime is kept to an absolute minimum during scheduled maintenance periods.

Key Takeaway: You should maintain a stock of replacement seats to ensure you can quickly restore your valves to peak performance without the cost of complete replacements.

Conclusion

The structural features of center line double flange butterfly valve provide the mechanical foundation for safe and efficient industrial flow control. By focusing on a concentric design and robust flanged connections, you ensure that your system remains reliable under the most demanding conditions. We are committed to delivering the highest quality valve technology for your facility’s future—contact us today to learn more about our innovative solutions.

Frequently Asked Questions

Can I use a double flanged center line butterfly valve for steam?

No, you should not use this valve for steam because the elastic seats (rubber or PTFE) will melt or degrade rapidly under high-temperature steam conditions.

What’s the best way to prevent seat wear in these valves?

The best way is to ensure that the media is filtered to remove abrasive particles and to operate the valve within its recommended temperature and pressure ranges.

Can I install this valve in any orientation?

Yes, you can install it in both horizontal and vertical piping, although for very large valves, installing the stem horizontally can help prevent debris from settling in the bottom bearing.

What’s the main difference between this and a wafer type?

The main difference is the double flange design provides much greater structural stability and allows you to disconnect downstream piping while the valve remains securely bolted to the upstream side.

How do I know if the seat is interfering too much with the disc?

You will notice an unusually high torque requirement to close the valve, which may indicate that the seat has swollen or that debris is trapped in the sealing area.