Introduction

Mismatched valve dimensions can instantly halt an entire production line. It happens more often than you think. Engineers frequently order components assuming a universal fit, only to discover the new butterfly valve leaves a critical gap or refuses to squeeze between the existing flanges. That silence on the factory floor? That is the sound of lost revenue and mounting frustration. Here is the deal. Understanding butterfly valve face to face standards ensures seamless integration every single time. As a global manufacturer, RUITO solves these fitment headaches daily with precision-engineered flow control solutions.

Why Do Butterfly Valve Face to Face Dimensions Impact Performance?

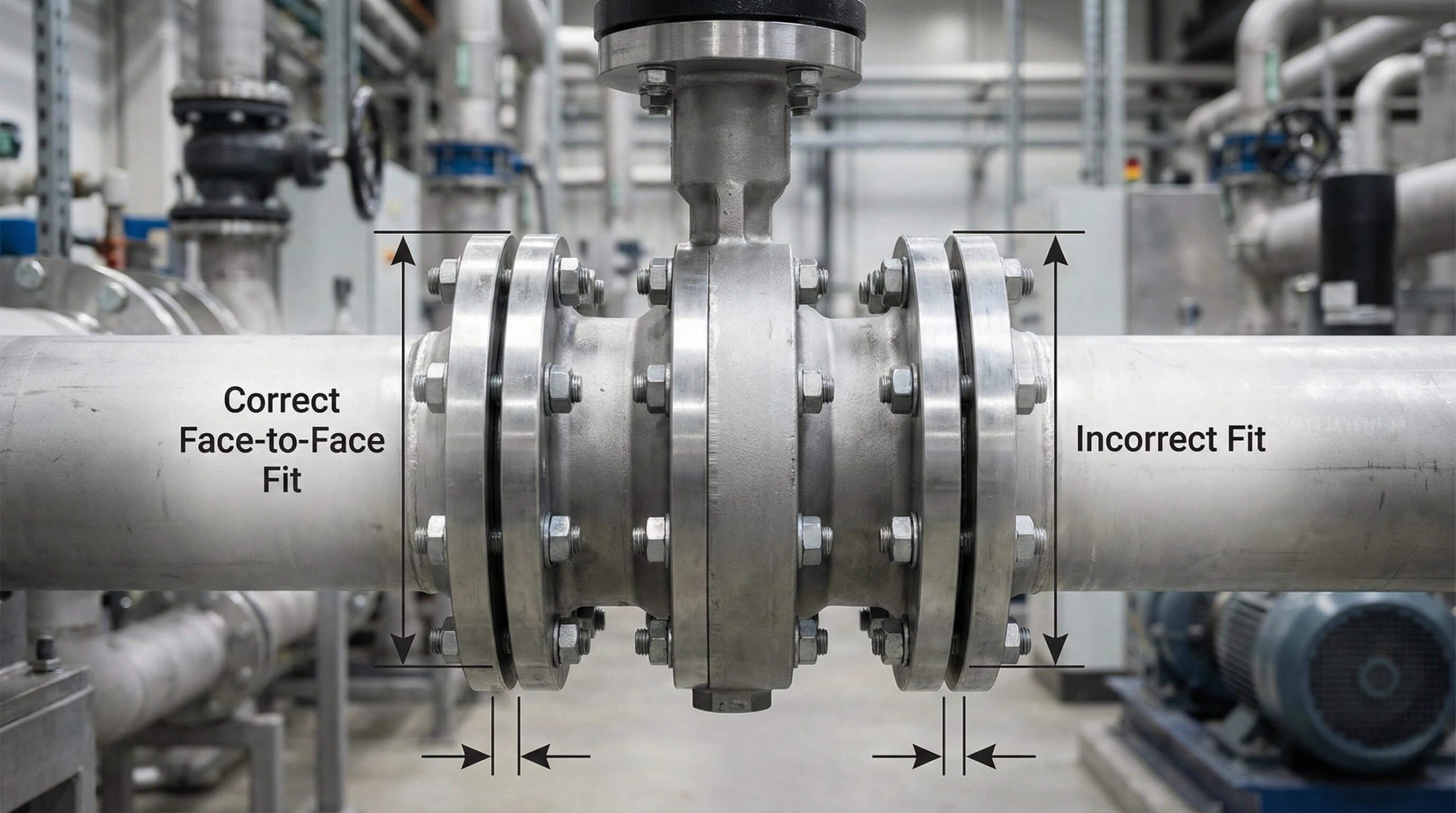

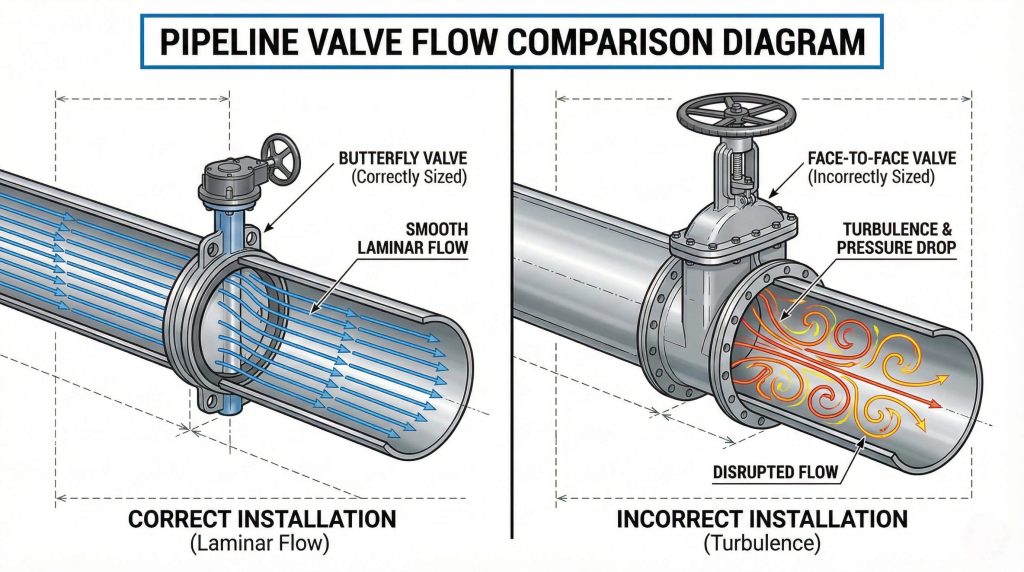

Correct butterfly valve face to face dimensions dictate the overall integrity of your piping system. But here’s the kicker… An incorrect length disrupts flow dynamics even if you manage to tighten the bolts successfully. Turbulence increases immediately downstream when gaps exist or alignment falters, leading to premature wear.

You might be wondering why a few millimeters matter so much. Extra space creates cavities where debris accumulates, risking seal failure, while compressed installations stress the valve body and warp the seat. Proper sizing guarantees laminar flow maintenance and prevents cavitation. Bottom line? Precision protects pumps and adjacent equipment from hydraulic shock.

Key Aspects of Dimensional Impact

- Flow Efficiency: Accurate spacing prevents turbulence eddies.

- Seal Longevity: Proper compression extends the liner life.

- Pressure Management: Correct fit maintains rated pressure handling.

Key Takeaway

Dimensional accuracy preserves hydraulic efficiency and equipment safety.

| Impact Factor | Consequence of Mismatch |

|---|---|

| Turbulence | Increased erosion of downstream pipe walls. |

| Mechanical Stress | Body deformation or potential flange cracking. |

| Leakage | Gasket failure due to uneven compression forces. |

Analysis: Ignoring precise dimensions inevitably accelerates component wear and drives system-wide inefficiency.

How Do Wafer vs Lug Butterfly Valve Face to Face Dimensions Differ?

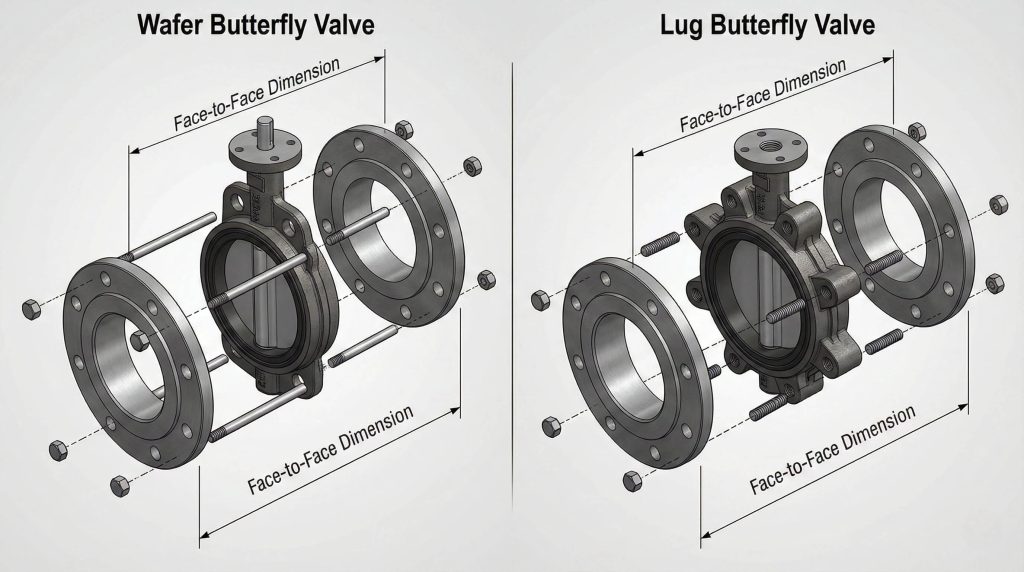

Wafer styles often share butterfly valve face to face specs with lug types, but the execution varies significantly. Here is the deal. Wafer valves sandwich between flanges, relying on compressive force, while robust butterfly valve solutions like lug types feature threaded inserts for direct bolting.

Why does this matter? Lug bodies might require wider clearance for bolt insertion depending on the thread depth. While API 609 Category A standardizes both, practical installation space differs. You must account for bolt length and stud clearance when swapping types. Don’t forget this. Lug valves allow downstream piping removal, demanding robust face-to-face structural integrity.

Differences in Application

- Wafer: Lighter, compressed installation between flanges.

- Lug: Heavy-duty, enables end-of-line isolation.

- Clearance: Lug bolts need specific thread engagement depth.

Key Takeaway

Lug valves offer isolation utility despite sharing similar lengths with wafer types.

| Feature | Wafer Type | Lug Type |

|---|---|---|

| Installation | Compressed between flanges | Bolted directly to flanges |

| Weight | Lighter | Heavier |

| End-of-Line | Not recommended | Suitable |

Analysis: Lug valves justify their higher cost through maintenance flexibility, even when they share the same dimensional footprint as wafer types.

Do Offset Designs Change Butterfly Valve Face to Face Specs?

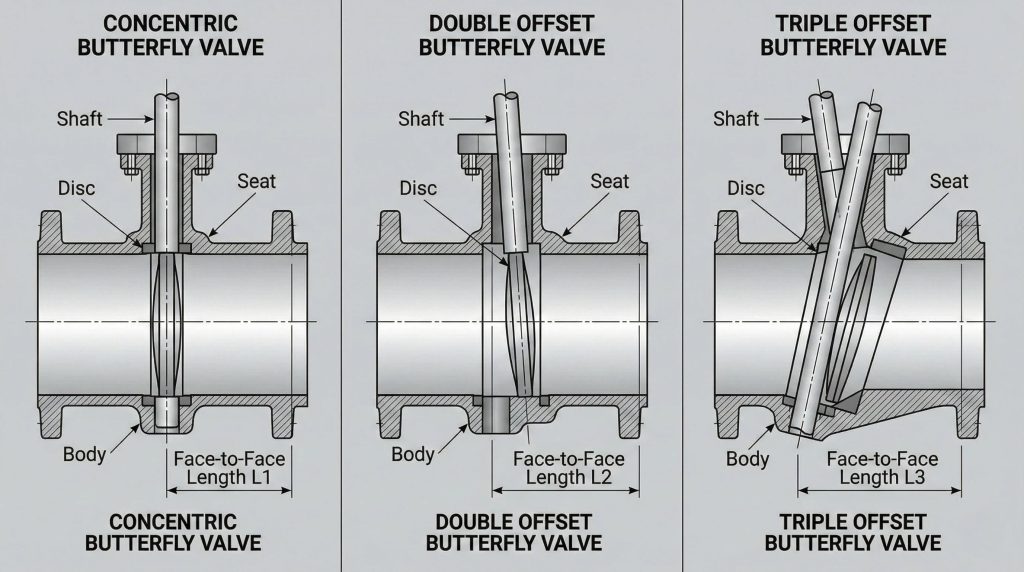

High-performance designs drastically alter butterfly valve face to face requirements compared to standard models. What’s the real story? Concentric (zero offset) valves remain compact, while double and triple offset variants require robust bodies to house complex seating mechanisms.

Think about it. A triple offset valve essentially acts like a segment of a globe valve, needing more axial length to accommodate the angled seat and camming action. Replacing a simple rubber-lined valve with a high-performance metal-seated one usually requires piping modification. You need to know that API 609 Category B covers these larger, offset dimensions distinct from Category A.

Offset Variations

- Concentric: Slimmest profile with a centered shaft.

- Double Offset: Shaft displaced from center and seat line.

- Triple Offset: Conical sealing profile, widest body design.

Key Takeaway

Performance upgrades to offset valves necessitate physical space adjustments.

| Design | Typical Width | Application |

|---|---|---|

| Concentric | Narrow | HVAC, Water |

| Double Offset | Medium | High Pressure |

| Triple Offset | Wide | Steam, Critical Service |

Analysis: Engineers cannot swap concentric valves for offset high-performance types without verifying pipeline gap allowance first.

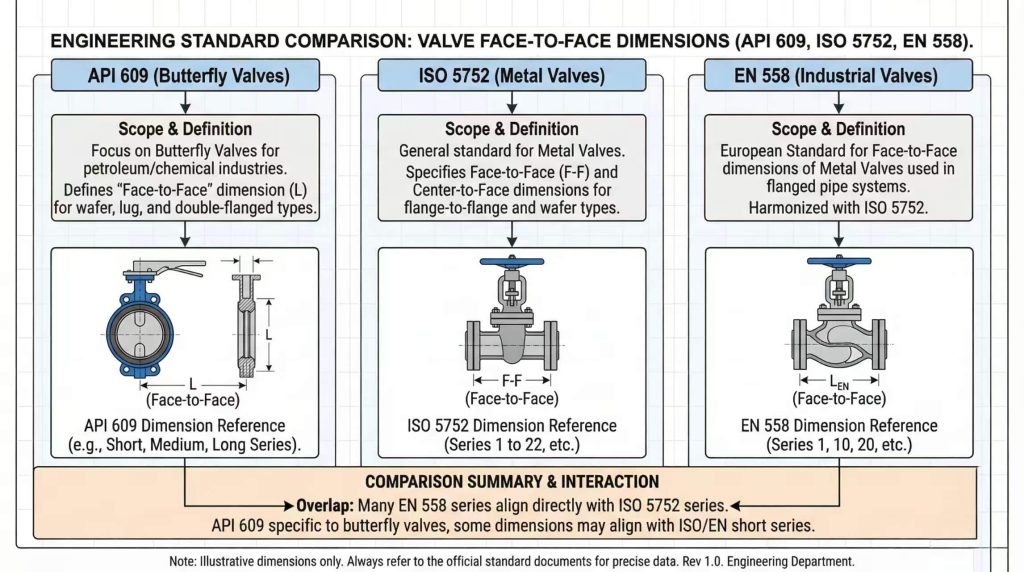

Which Standards Govern Butterfly Valve Face to Face Dimensions?

Global projects rely on specific butterfly valve face to face standards to ensure compatibility. Ready for the good part? Standardization ensures a valve bought in Germany fits a pipe in Singapore, provided you adhere to rigorous manufacturing standards like API 609 or ISO 5752.

It gets complicated. ASME B16.10 also dictates dimensions, often overlapping with API but occasionally diverging. You must verify which standard your piping design follows. A “short pattern” ISO valve might not replace an API “wide pattern” unit without spool pieces. Look closely at the “Series” designation in EN 558 (e.g., Series 20 vs Series 13).

Major Standards

- API 609: Category A (Wafer/Lug) & B (Offset).

- ISO 5752: International metric series.

- EN 558: European norm referencing ISO series.

Key Takeaway

Standards dictate interchangeability across borders and industries.

| Standard | Region/Industry | Key Series |

|---|---|---|

| API 609 | USA / Oil & Gas | Cat A & B |

| EN 558 | Europe / Water | Series 20, 13 |

| ASME B16.10 | USA / General | Class 125-2500 |

Analysis: Mismatching regional standards guarantees installation failure even if nominal pipe sizes appear identical.

What Is the Standard Butterfly Valve Face to Face Measurement?

Defining a single “standard” butterfly valve face to face measurement is misleading. Here is the truth. Dimensions vary by standard, pressure class, and size; for example, a 4-inch (DN100) valve under API 609 specifies 52mm for wafer types, while other standards might differ.

You must check the manufacturer’s data sheet rather than assuming a universal fit. Nominal Diameter (DN) drives the base length, but as diameter increases, face-to-face length grows non-linearly. Keep in mind that resilient seated valves often use the liner itself as the flange gasket, affecting the effective installed length.

Measurement Variables

- Nominal Size (DN): Primary driver of dimension.

- Pressure Rating: Higher pressure equals thicker body.

- Liner Type: Rubber extenders add effective width.

Key Takeaway

Always verify specific dimensions against DN size and pressure class.

| DN (mm) | NPS (inch) | Approx Length (mm) API 609 |

|---|---|---|

| 50 | 2 | 43 |

| 100 | 4 | 52 |

| 200 | 8 | 64 |

Analysis: Assuming a universal length for a given pipe size without checking the standard causes costly procurement errors.

What Are Class 150 Butterfly Valve Face to Face Sizes?

Class 150 represents the most common butterfly valve face to face pressure rating in industrial systems. This is where it gets interesting… These dimensions balance weight and strength, maintaining a compact profile often termed “narrow” or “short” pattern for general utility.

You generally find sizes like 2 inches at 43mm width, while larger 24-inch valves might extend to 154mm. Be careful. If you upgrade to Class 300, these lengths increase significantly to handle the higher stress. Mixing pressure classes in a single line guarantees fitment issues.

Class 150 Characteristics

- Compactness: Ideal for space-constrained skids.

- Weight: Significantly lighter than Class 300.

- Availability: The most readily stocked specification.

Key Takeaway

Class 150 offers the most compact industrial footprint.

| Valve Size | Class 150 Width | Class 300 Width |

|---|---|---|

| 6″ | ~56mm | ~59mm |

| 12″ | ~78mm | ~83mm |

| 24″ | ~154mm | ~165mm |

Analysis: Class 150 dimensions prioritize spatial efficiency without compromising standard industrial pressure containment.

How Does Installation Affect Butterfly Valve Face to Face Fit?

Installation procedures drastically alter the effective butterfly valve face to face gap. Here is a secret. Flange spreading tools are mandatory; you cannot simply slide a valve in because friction will damage the liner.

You need to open the flanges sufficiently (roughly 3/16 inch extra) to clear the sealing faces. Watch out. Gaskets are rarely needed for rubber-lined valves because the seat acts as the seal. Adding unnecessary gaskets increases the installed length, preventing bolts from engaging or crushing the valve body.

Installation Nuances

- Flange Spreading: Prevents liner tearing during insertion.

- Disc Position: Keep partially open (10%) to protect the edge.

- Gaskets: Avoid doubling up on resilient seats.

Key Takeaway

Proper spreading prevents seal damage during insertion.

| Step | Action | Reason |

|---|---|---|

| 1 | Spread Flanges | Avoid friction damage |

| 2 | Align Valve | Ensure bolt passage |

| 3 | Relax Spreader | Compress built-in seal |

Analysis: Physical installation technique is as critical as the manufactured dimension for a leak-free seal.

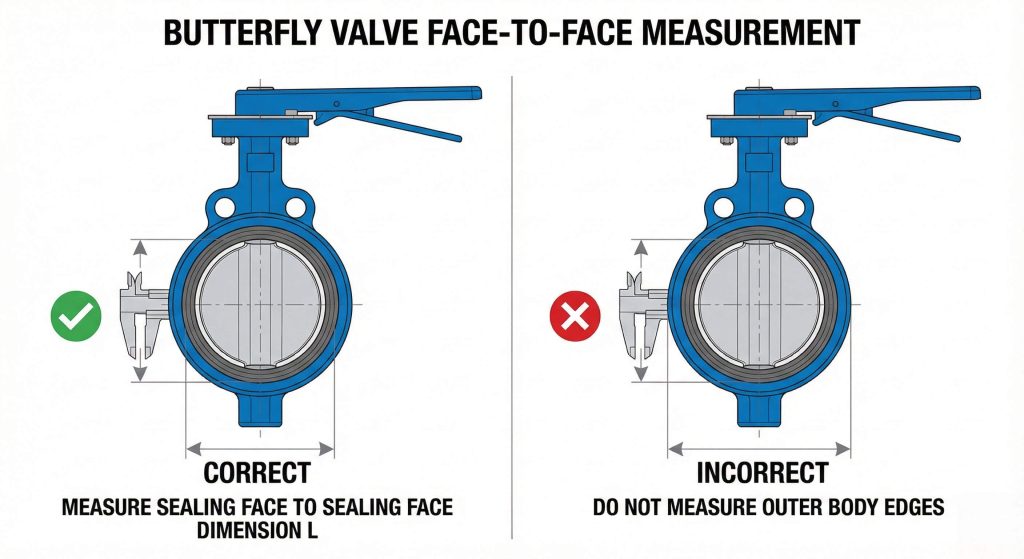

How to Accurately Measure Butterfly Valve Face to Face Length?

Measuring existing butterfly valve face to face length requires specific technique. Let’s face it. Measuring installed valves is tricky, and you must measure from inlet face to outlet face.

Use calipers for uninstalled units to get precise readings. For installed units, measure the gap between mating flanges. Do not ignore the liner; on resilient seated valves, the uncompressed liner extends slightly beyond the metal body. Manufacturers state the “installed” dimension, which assumes compression.

Measurement Steps

- Uninstalled: Body edge to body edge (plus liner allowance).

- Installed: Flange face to flange face.

- Tools: Calipers for precision, tape for rough estimates.

Key Takeaway

Measure the sealing surface, not just the metal body.

| Condition | Measure Point A | Measure Point B |

|---|---|---|

| Loose Valve | Liner Face | Liner Face |

| In-Line | Upstream Flange | Downstream Flange |

| Drawing | Datum Line | Datum Line |

Analysis: Failing to account for liner compression leads to measurements that appear larger than standard specifications.

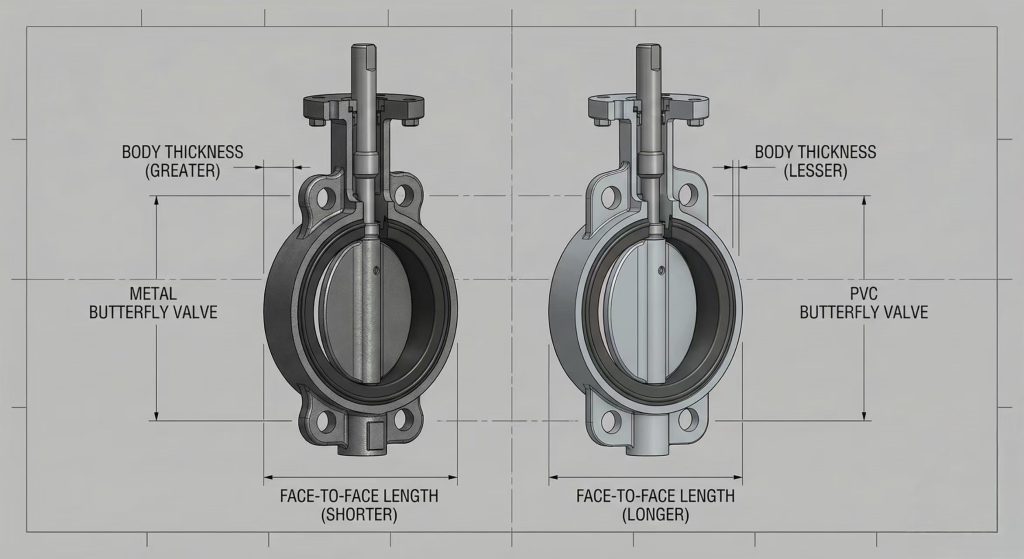

Does Material Choice Alter Butterfly Valve Face to Face Size?

Material strength heavily influences butterfly valve face to face design decisions. It turns out that plastic (PVC/CPVC) valves often have different dimensions than metal ones to maintain structural rigidity. Metal valves (Cast Iron, Stainless Steel) generally adhere strictly to API/ISO standards.

You will notice that lined valves (PTFE/PFA) keep standard metal dimensions but add liner thickness. However, replacing a metal valve with a plastic one usually requires piping modifications due to differing flange thickness and face-to-face specs found in plastic piping standards like ASTM F1970.

Material Factors

- Metal: Follows API 609/ISO 5752 strictly.

- Plastic: May follow different industry norms (ASTM).

- Lined: Metal body dimensions plus liner variance.

Key Takeaway

Plastic and metal dimensions are rarely identical.

| Material | Standard Adherence | Dimensional Stability |

|---|---|---|

| Cast Iron | High (ISO/API) | Rigid |

| Stainless | High (ISO/API) | Rigid |

| PVC | Variable | Bulkier |

Analysis: Material properties dictate structural thickness, often deviating from metal standards in thermoplastic valves.

How to Select the Correct Butterfly Valve Face to Face Size?

Selecting the right butterfly valve face to face dimension prevents project disasters. Here is the plan. Start with the pipe Nominal Diameter (DN), then confirm the Pressure Class (150 vs 300).

Check your constraints. Are you replacing traditional gate valves? You will likely need a spool piece because butterfly valves are much shorter. Always consult the manufacturer’s drawing. RUITO provides detailed dimensional drawings to ensure our valves fit your specific layout before manufacturing begins.

Selection Checklist

- Confirm Pipe DN: Match valve size.

- Verify Standard: API vs ISO vs JIS.

- Check Replacement: Spool piece needed?

Key Takeaway

Cross-reference DN, Pressure, and Standard before ordering.

| Input | Action | Result |

|---|---|---|

| Pipe Size | Measure ID/OD | Valve Size (DN) |

| Flange Type | Check Rating | Pressure Class |

| Gap | Measure Gap | Face-to-Face Spec |

Analysis: Proper selection requires a holistic view of the piping system, not just the valve component itself.

Conclusion

Incorrect dimensions derail projects. We have seen it happen. A mismatch of a few millimeters forces expensive shutdowns and frantic refabrication. Here is the bottom line. By understanding face-to-face standards—from API 609 to ISO 5752—and measuring correctly, you ensure operational continuity.

At RUITO, we engineer certainty. Our valves undergo rigorous dimensional checks to guarantee they fit your system perfectly the first time. Do not leave fitment to chance.

Contact us today for technical drawings and consultation. Let’s build a leak-free future together.

FAQ

Can I replace a wafer type valve with a lug type without changing dimensions?

Yes, usually. Both wafer and lug types typically follow the same API 609 Category A face-to-face standards. However, you must verify that your bolt lengths are appropriate, as lug valves require shorter bolts threading directly into the body.

What is the best standard for high-pressure butterfly valve dimensions?

API 609 Category B is superior. It specifically covers offset, high-performance valves designed for higher pressure classes (Class 150, 300, 600). These dimensions are robust enough to handle the stress of critical heavy-industry applications.

Can I measure face-to-face dimensions without removing the valve?

It is difficult but possible. You can measure the distance between the mating flange faces while the valve is installed. Note that this “installed” length includes the compressed seal, so you must compare it with manufacturer data sheets for the “installed” vs “uninstalled” dimension.

What is the main difference between API 609 and EN 558 dimensions?

They serve different regions. API 609 is the US standard common in oil and gas, while EN 558 is the European standard. Crucially, while some series overlap, others differ significantly, so never assume they are interchangeable without checking the specific series number.

Do plastic butterfly valves have the same dimensions as metal ones?

Rarely. Plastic valves often require thicker bodies to achieve similar pressure ratings, resulting in different face-to-face lengths. Always check the specific standard (like ASTM F1970) for plastic valves rather than applying metal valve standards.