In large-scale industrial piping, relying on manual labor to control high-pressure flow is a recipe for disaster. When a system requires immediate shut-off or precise throttling, a human operator with a handwheel simply cannot react fast enough to prevent catastrophic pressure surges or media overflow. These delays don’t just waste time; they lead to blown seals, equipment damage, and massive financial losses due to operational downtime. If your process requires consistent, repeatable, and safe fluid control, the manual approach is no longer viable. The solution lies in integrating a specialized butterfly valve operator with high-precision automation.

Why choose an automated butterfly valve operator?

You choose an automated butterfly valve operator to eliminate the risks of manual delays and ensure high-precision flow control across your entire piping network. This transition from manual to automated control is the most effective way to safeguard your infrastructure and personnel.

Is automation safer for your critical lines?

Managing high-pressure lines manually is often a recipe for disaster in volatile industrial settings. Here’s the deal: automated systems react to pressure surges in milliseconds, preventing catastrophic failures before they escalate.

- Faster response times for emergency isolation.

- Remote operation capabilities from a central station.

- Significant reduction in human-related operational errors.

Can you achieve precision throttling?

Precision is non-negotiable when your process relies on specific flow rates for temperature or chemical balance. But wait, there’s more: these operators allow for minute adjustments that manual handles simply cannot replicate accurately over time.

- 0-90 degree modulating control for specific flow rates.

- Real-time feedback loops for automated monitoring.

- Consistent repeatability across thousands of cycles.

Key Takeaway: Automation provides the speed and digital accuracy required to protect infrastructure and optimize complex fluid dynamics more effectively than manual labor.

| Feature | Manual Operation | Automated Operator |

|---|---|---|

| Reaction Time | Seconds/Minutes | Milliseconds |

| Accuracy | Low/Approximate | High/Precise |

| Safety Level | Variable | Consistent/High |

Integrating automation is not just an upgrade; it is a fundamental shift toward operational excellence and long-term safety.

How does a modern butterfly valve operator work?

A modern butterfly valve operator works by converting electrical, pneumatic, or hydraulic energy into mechanical torque to rotate a disc 90 degrees. This mechanical movement is what allows you to start, stop, or regulate the flow of media with the push of a button.

How is energy converted to torque?

The core function of the unit is to translate a control signal into physical movement. Here’s the kicker: the internal mechanism ensures that the torque applied is sufficient to overcome the friction of the seat.

- Direct coupling to the valve stem for power.

- Transmission of force to the internal disc.

- Precision movement within a 90-degree arc.

What are the integrated components?

Every automated assembly relies on a synergy of high-quality components to function reliably under pressure. The bottom line is that the quality of each part determines the overall lifespan of your system.

- The actuator serves as the primary power source.

- Mounting kits ensure perfect alignment between the valve and drive.

- Limit switches provide status updates to the control room.

Key Takeaway: The operator functions as the “brain” and “muscle” of the valve, ensuring that electrical or fluid energy is perfectly translated into rotational motion.

| Component | Primary Material | Critical Function |

|---|---|---|

| Actuator Housing | Aluminum/Stainless | Environmental Protection |

| Drive Stem | SS304/SS316 | Torque Transmission |

| Limit Switch | Synthetic/Alloy | Position Feedback |

Understanding these mechanical principles allows you to troubleshoot issues faster and maintain a higher standard of system uptime.

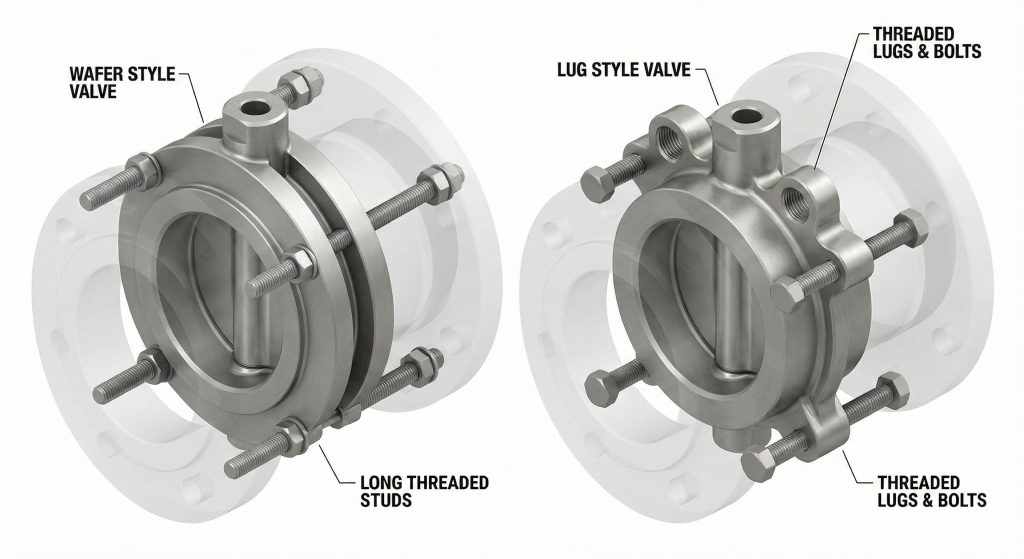

Which body style suits your butterfly valve operator?

The body style that suits your butterfly valve operator depends on whether you require a lightweight, cost-effective wafer design or a more robust lug configuration. Each style affects how the valve is physically supported between your pipe flanges and how the torque is distributed.

Wafer or lug design for your setup?

Choosing between these two styles is often a matter of maintenance requirements and piping flexibility. Here’s the deal: wafer types are simpler to install, but lug types offer superior flexibility for downstream maintenance.

- Wafer bodies are lighter and more economical for basic lines.

- Lug bodies allow for end-of-line service without depressurization.

- Flanged bodies provide maximum stability for very large diameters.

Why consider concentric vs. eccentric offsets?

The internal design of the disc determines how much torque your operator needs to exert to create a seal. But wait, there’s more: eccentric designs significantly reduce seat wear by minimizing contact during the opening cycle.

- Concentric designs are ideal for low-pressure water systems.

- Double offset valves handle higher pressures with less friction.

- Triple offset designs provide a bubble-tight metal seal for extreme heat.

Key Takeaway: Matching the body style and offset to your application ensures that the operator doesn’t suffer from excessive wear or premature motor failure.

| Style | Best Application | Torque Requirement |

|---|---|---|

| Wafer | Water/HVAC Systems | Standard |

| Lug | Process Piping | Standard |

| Triple Offset | Chemical/High-Temp | High |

Selecting the correct body configuration is a strategic decision that impacts both the initial installation cost and long-term maintenance labor.

When is an electric butterfly valve operator best?

An electric butterfly valve operator is best for facilities where compressed air is unavailable and where precise, repeatable positioning is required for modulating flow. These units operate similarly to an automated gate valve by using a motor to drive a gearbox.

What are the motorized advantages?

Electric units excel in clean environments where you need to integrate the valve directly into a digital control system. Here’s the kicker: they only consume power during movement, making them highly energy-efficient for isolation services.

- Easy integration with PLC and SCADA protocols.

- Extremely quiet operation compared to pneumatic units.

- Built-in thermal protection to prevent motor burnout.

Are there performance limitations?

While electric units offer great precision, they may not be the best fit for every high-speed scenario. The bottom line is that their cycle times are generally slower than fluid-driven alternatives.

- Slower cycle times (typically 10-60 seconds).

- Potential for overheating if used in high-cycle duty.

- Higher cost for explosion-proof certifications in hazardous zones.

Key Takeaway: Electric operators are the superior choice for high-precision, low-cycle applications that require advanced digital communication and energy efficiency.

| Feature | AC Motor | DC Motor |

|---|---|---|

| Voltage | 110V/220V/380V | 12V/24V |

| Best For | Industrial Infrastructure | Mobile/Remote Sites |

| Modulation | Highly Accurate | Moderate |

By understanding the strengths of electric motors, you can design a system that maximizes digital control without the need for complex air lines.

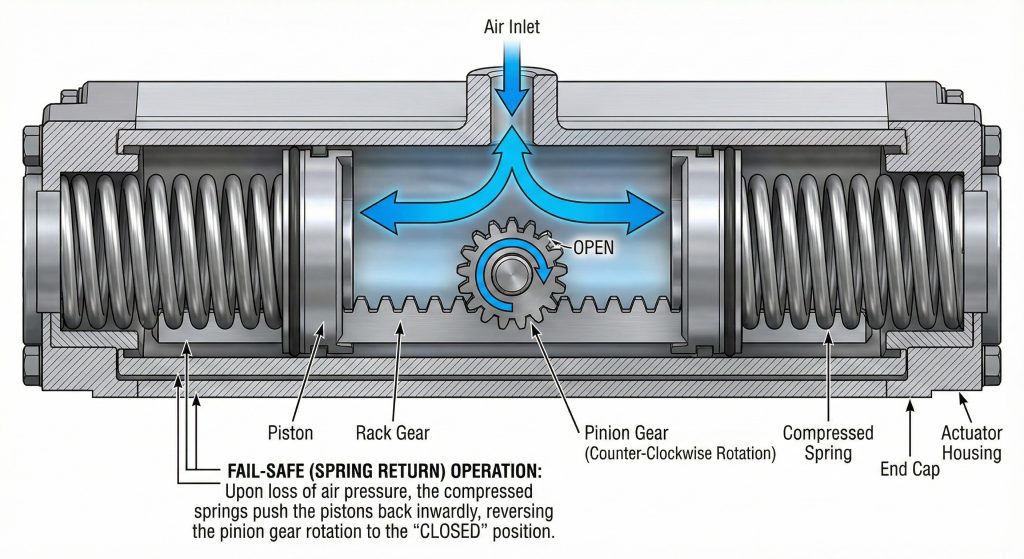

Why select a pneumatic butterfly valve operator?

You should select a pneumatic butterfly valve operator when your application demands rapid cycle speeds, a fail-safe configuration, and high-frequency operation in harsh environments. These air-driven units are the most common choice for industrial plants due to their simplicity and durability.

Is speed a priority for your system?

If your process requires a valve to close in under one second to prevent overflow, pneumatic power is your best friend. Here’s the deal: compressed air provides an almost instantaneous response that electric motors simply cannot match.

- Rapid opening and closing for emergency shutdowns.

- High cycle life extending into the millions.

- Inherently explosion-proof for hazardous gas environments.

How do you integrate with air headers?

To make a pneumatic system work, you need a reliable supply of dry, filtered compressed air. But wait, there’s more: the addition of accessories like solenoid valves and limit switches makes them just as “smart” as electric versions.

- Solenoids control the directional flow of air.

- Positioners allow for precise air-based modulation.

- Spring-return actuators provide a mechanical fail-safe option.

Key Takeaway: Pneumatic operators offer the best balance of speed, cost, and reliability for the majority of heavy-duty industrial fluid control tasks.

| Actuator Type | Speed | Fail-Safe Capability |

|---|---|---|

| Double Acting | Very Fast | No (Stays put) |

| Spring Return | Very Fast | Yes (Opens/Closes) |

| Positioner Equipped | Moderate | Optional |

Pneumatic systems remain the industry standard because they provide high-speed reliability at a lower price point than most other automation technologies.

Is a hydraulic butterfly valve operator right for you?

A hydraulic butterfly valve operator is right for you if you are managing massive pipelines where the torque requirements exceed the capabilities of pneumatic or electric units. Just as you might see a check valve managing surge in a dam, these operators manage the heaviest flow loads.

Do you need raw power for heavy-duty use?

Hydraulic systems use incompressible fluid to generate immense force in a very compact package. Here’s the kicker: this allows you to move discs in DN2000+ pipes that would otherwise require massive, bulky equipment.

- Highest torque-to-weight ratio of any operator.

- Extremely smooth movement without the “bounce” of air.

- Perfect for submerged or heavy-duty infrastructure projects.

Is the complexity worth the investment?

The raw power of hydraulics comes with a set of infrastructure requirements that you must be prepared to maintain. The bottom line is that you need a dedicated power unit to make these valves operational.

- Requires a Hydraulic Power Unit (HPU) and piping.

- Potential risk of oil leaks in sensitive environments.

- Significantly higher initial capital expenditure.

Key Takeaway: Hydraulic operators are niche solutions reserved for applications where extreme torque and smooth control are mandatory for system safety.

| Specification | Pneumatic | Hydraulic |

|---|---|---|

| Max Torque | Moderate/High | Extreme |

| Control Fluid | Compressed Air | Hydraulic Oil |

| Footprint | Large for High Torque | Compact |

For large-scale municipal water or oil transport projects, the power of hydraulics is often the only viable way to maintain control under pressure.

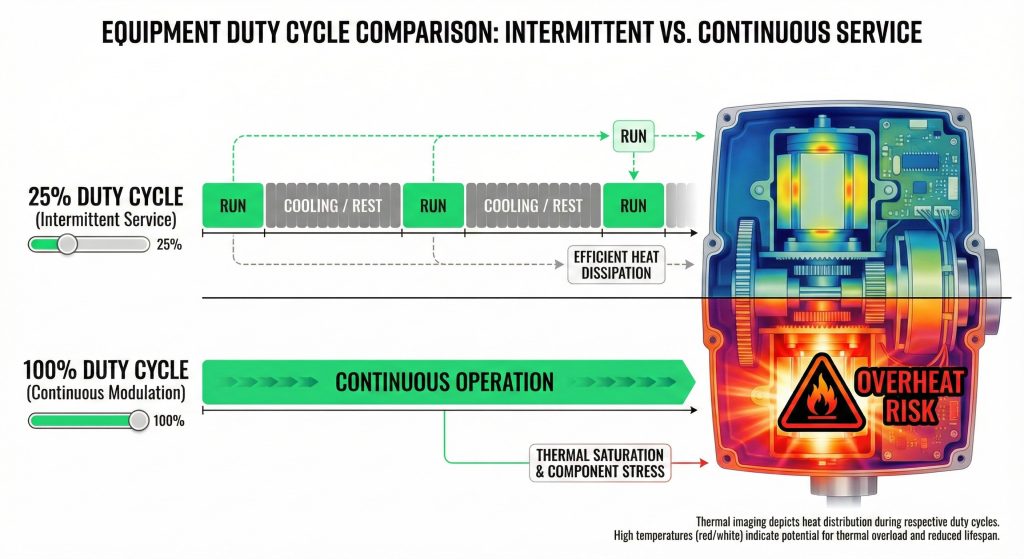

Does your butterfly valve operator meet duty cycles?

Your butterfly valve operator must meet the specific duty cycle of your process to ensure the motor or seals do not fail under the stress of constant movement. Ignoring this specification is one of the most common causes of premature failure in automated systems.

What are duty cycle ratings?

The duty cycle is essentially the ratio of a valve’s “on” time versus its “off” time during a standard hour of operation. Here’s the deal: a motor designed for 25% duty will quickly burn out if it is asked to modulate flow 100% of the time.

- 25% Duty: Ideal for simple on/off isolation tasks.

- 75% Duty: Required for light modulating or mixing.

- 100% Duty: Essential for critical control loops and constant adjustment.

How does temperature affect operation?

Ambient and media temperatures play a massive role in how hard your operator has to work. But wait, there’s more: extreme cold can thicken lubricants and increase the torque required to move the disc.

- High heat can degrade electronic insulation in electric motors.

- Sub-zero temps require trace heating for pneumatic air lines.

- Thermal expansion of the seat can increase friction significantly.

Key Takeaway: Always verify that your operator’s duty cycle and temperature rating match your actual process conditions to avoid unexpected downtime.

| Process Type | Cycle Frequency | Recommended Duty |

|---|---|---|

| Emergency Shutoff | Rare | 25% (On/Off) |

| Batch Processing | Hourly | 50% – 75% |

| Continuous Control | Constant | 100% (Continuous) |

Choosing an operator with a higher duty cycle than required provides a safety margin that can extend the life of your equipment by years.

Will your media damage the butterfly valve operator?

The chemical composition and physical state of your media will damage the butterfly valve operator if the materials and seals are not specifically chosen for compatibility. Even a robust ball valve can fail if its automation is compromised by the environment it resides in.

Is corrosion protection necessary?

In chemical plants or coastal facilities, the air itself can be as corrosive as the fluid inside the pipes. Here’s the kicker: standard aluminum housings can vanish in a matter of months if they aren’t properly coated.

- Epoxy coatings protect against saltwater and acid mist.

- Stainless steel housings are required for sanitary food processing.

- Vapor seals prevent corrosive media from migrating up the stem.

Can slurry handle your valve assembly?

When you are dealing with abrasive media like slurry or cement, the torque requirements change as material builds up. The bottom line is that you must size your operator to handle the “worst-case” friction scenario.

- Scaling and buildup increase the force needed for closure.

- Abrasive particles can score the stem and damage seals.

- Safety factors of 30% or more are standard for dirty media.

Key Takeaway: Environmental and media compatibility are the primary drivers for selecting the material and torque safety factor of your operator.

| Media | Risk Factor | Protection Strategy |

|---|---|---|

| Hydrocarbons | Fire/Explosion | Explosion-Proof (ATEX) |

| Acidic Vapors | External Corrosion | Epoxy/Stainless Housing |

| Slurry | Seat Friction | High Torque Safety Factor |

By analyzing your media before purchasing, you can select an operator that will withstand the specific challenges of your industrial environment.

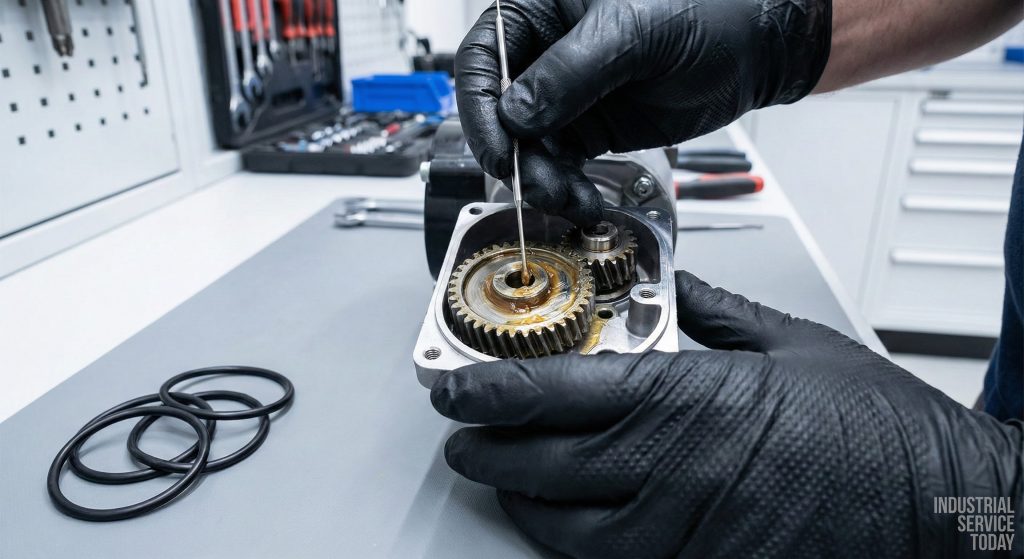

How do you maintain a butterfly valve operator?

You maintain a butterfly valve operator by implementing a schedule of visual inspections, functional testing, and preventative seal replacement to ensure long-term reliability. A proactive approach is much cheaper than an emergency shutdown caused by a seized valve.

What are the inspection protocols?

Regular check-ups allow you to catch small issues like a loose mounting bolt before they lead to a complete system failure. Here’s the deal: a quick 5-minute walk-through every month can save you thousands in future repair costs.

- Visual checks for stem leaks or housing cracks.

- Listening for air leaks in pneumatic tubing.

- Confirming that all mounting hardware is tight and aligned.

When should you replace seals and lube?

Internal components like O-rings and gear grease have a finite lifespan, especially in high-cycle or high-heat environments. But wait, there’s more: replacing these parts before they fail is the key to maintaining 99.5% operational uptime.

- Replace pneumatic seal kits every 1-2 million cycles.

- Re-lubricate electric gearboxes as per the manufacturer’s hours.

- Re-calibrate positioners annually to ensure accuracy.

Key Takeaway: A structured maintenance plan transforms your valve operator from a wear item into a long-term asset with a 20+ year lifespan.

| Maintenance Task | Typical Interval | Goal |

|---|---|---|

| Operational Test | Monthly | Verify Movement |

| Seal Inspection | Annually | Prevent Leaks |

| Full Overhaul | 5 Years | Restore Factory Performance |

Consistent maintenance is the only way to guarantee that your automated system will perform exactly as expected during an emergency.

What is the ROI of a butterfly valve operator?

The ROI of a butterfly valve operator is found in the drastic reduction of manual labor costs, the elimination of human error, and the extension of your system’s overall lifespan. While the upfront cost is higher than a manual handle, the long-term savings are undeniable.

How much can you save on labor?

In a large plant, having technicians walk to every valve to make manual adjustments is a massive waste of human resources. Here’s the kicker: one person in a control room can manage hundreds of automated valves simultaneously.

- Reduction in personnel required for routine adjustments.

- Faster transition between process batches.

- Elimination of travel time to remote or hazardous areas.

Can you enhance your total system life?

Automated operators provide a level of torque control that prevents the seat damage caused by over-tightening manual handles. The bottom line is that precision movement protects your valve and the surrounding equipment from hydraulic shock.

- Gentle closing prevents water hammer in the pipes.

- Consistent torque application extends seat life.

- Integrated diagnostics warn you of failures before they happen.

Key Takeaway: The investment in automation pays for itself through increased productivity, lower maintenance costs, and the prevention of catastrophic system damage.

| Cost Factor | Manual (Long Term) | Actuated (Long Term) |

|---|---|---|

| Initial Price | Low | Moderate/High |

| Labor Expense | High | Low |

| Equipment Life | Moderate | High |

Investing in high-quality automation today ensures that your facility remains competitive and safe for decades to come.

Conclusion

Selecting the right actuated butterfly valve operator is the cornerstone of a reliable, modern piping system. Whether you prioritize the lightning speed of pneumatic units, the digital precision of electric motors, or the raw power of hydraulic systems, understanding your duty cycle and media compatibility is paramount. By choosing precision-engineered components, you ensure 99.5% quality reliability and protect your facility from costly downtime.

If you are ready to optimize your fluid control infrastructure with ISO-certified solutions, contact us today for a free technical consultation. Our engineering team provides custom solutions and 24-hour technical responses to help you build a safer, more efficient piping network.

Frequently Asked Questions

Can I retrofit an actuator to a manual butterfly valve?

Yes, most modern valves include an ISO 5211 mounting pad that allows you to swap a manual lever for an automated operator without removing the valve from the pipe.

What’s the best way to determine the required torque for my operator?

The best way is to consult the manufacturer’s torque charts and add a 20-30% safety factor based on your specific media and pressure.

How do I know if I need a spring-return pneumatic operator?

You need a spring-return operator if your system requires the valve to automatically move to a safe “open” or “closed” position during a loss of power or air.

Can I use an electric operator in an outdoor environment?

Yes, as long as the unit is rated IP67 or IP68, it is fully protected against moisture and dust for long-term outdoor service.

What’s the best material for a valve operator in a coastal area?

The best choice is a housing with high-grade epoxy coating or a complete SS316 stainless steel enclosure to resist salt air corrosion.