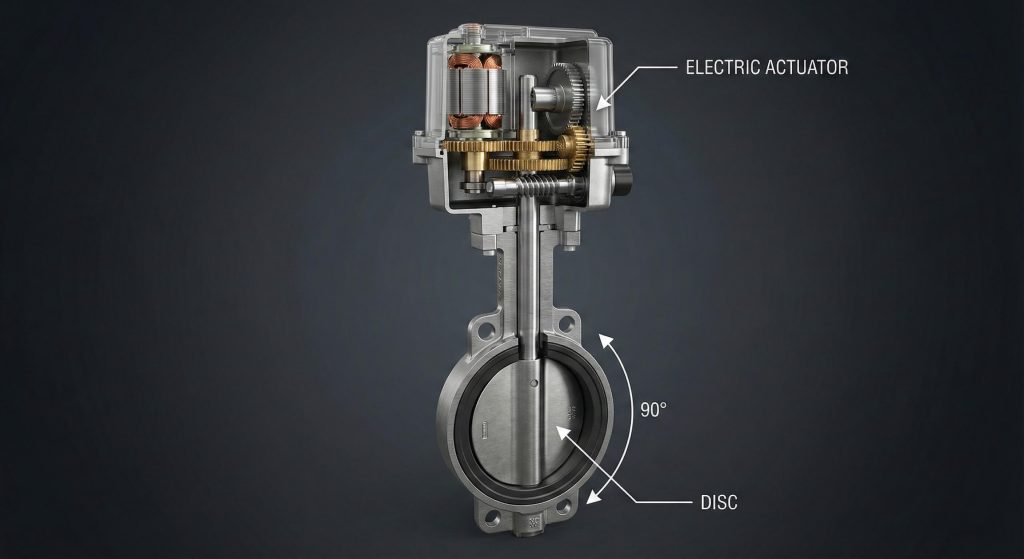

An electric butterfly valve works by utilizing an electric actuator to drive a stem, which rotates a disc 90 degrees to regulate or obstruct fluid flow. Imagine a massive container ship facing a sudden ballast system failure in high seas, threatening the vessel’s stability. A manual valve jam during such a crisis can lead to disastrous instability or extremely costly operational delays. The marine electric butterfly valve solves this by providing reliable, remote-controlled automation specifically engineered for harsh offshore environments.

What is a marine electric butterfly valve?

A marine electric butterfly valve is an automated flow control device that combines a quarter-turn valve body with an electric motor-driven actuator. This specific marine electric butterfly valve is designed to handle the corrosive nature of seawater while providing precise positioning.

What defines this valve type?

This equipment is characterized by its compact, lightweight design which is essential for limited space on ships. It utilizes an electric motor to rotate a circular disc within the pipe, allowing for quick isolation or throttling of liquid media.

Why is the actuator important?

But here is the kicker: the actuator allows for integration into the ship’s centralized control system. This means engineers can monitor and adjust flow rates from the bridge without manual intervention in the engine room.

Key Takeaway: A marine electric butterfly valve provides automated, space-saving flow control that is vital for modern vessel management and safety.

| Feature | Description |

|---|---|

| Primary Function | Automated flow isolation and regulation |

| Actuation | Electric motor (24V, 110V, or 220V) |

| Design Style | Quarter-turn concentric or eccentric |

Analysis: This combination of electric power and compact design makes the valve ideal for tight marine quarters where pneumatic lines are impractical.

How does a marine electric butterfly valve function?

The functional principle of a marine electric butterfly valve involves converting electrical energy into mechanical torque through a series of gears. When the motor receives a signal, it turns the valve stem, which in turn moves the disc into an open or closed position.

How does the disc rotate?

The core of the operation lies in the 90-degree rotation of the internal disc. As the marine electric butterfly valve disc aligns with the flow, the valve is fully open. Rotating it perpendicular to the flow creates a bubble-tight seal.

What ensures precise movement?

You might be wondering how it stops at the right spot. Internal limit switches or encoders track the disc’s position to prevent over-rotation and ensure accuracy within thousandths of a degree.

Key Takeaway: The valve functions by translating electrical signals into precise mechanical rotation to manage fluid passage effectively.

| Component | Role in Function |

|---|---|

| Motor | Provides the driving force |

| Gearbox | Multiplies torque and slows rotation |

| Limit Switch | Stops the motor at 0° or 90° |

Analysis: Precise electrical control ensures the valve maintains the requested flow rate without the drift common in manual systems.

Why choose a marine electric butterfly valve for ships?

A marine electric butterfly valve is often the preferred choice because it eliminates the need for bulky air compressors required by pneumatic systems. On a ship, saving weight and simplifying infrastructure directly contributes to fuel efficiency and reduced maintenance costs.

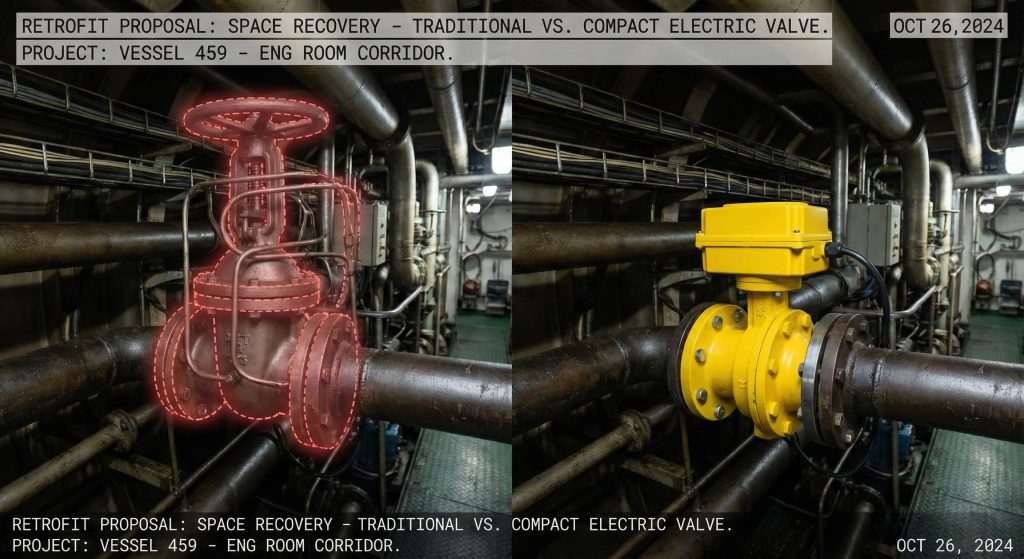

Does it save installation space?

Yes, it does. Because the marine electric butterfly valve is significantly lighter than gate or globe valves, it reduces the structural load on piping systems. This allows for more flexible engine room layouts and easier retrofitting.

Is it more reliable than manual valves?

Think about this: manual valves are prone to human error and physical strain in emergency scenarios. Electric automation ensures that every command is executed with consistent torque and timing, regardless of environmental conditions.

Key Takeaway: Choosing electric actuation reduces vessel weight and infrastructure complexity while enhancing operational safety and consistency.

| Benefit | Impact on Marine Operations |

|---|---|

| No Air Required | Reduces reliance on secondary ship systems |

| Low Weight | Eases installation and pipe stress |

| Remote Control | Enables bridge-side emergency response |

Analysis: The move toward electric systems reflects the maritime industry’s shift toward fully automated and digitized “smart ships.”

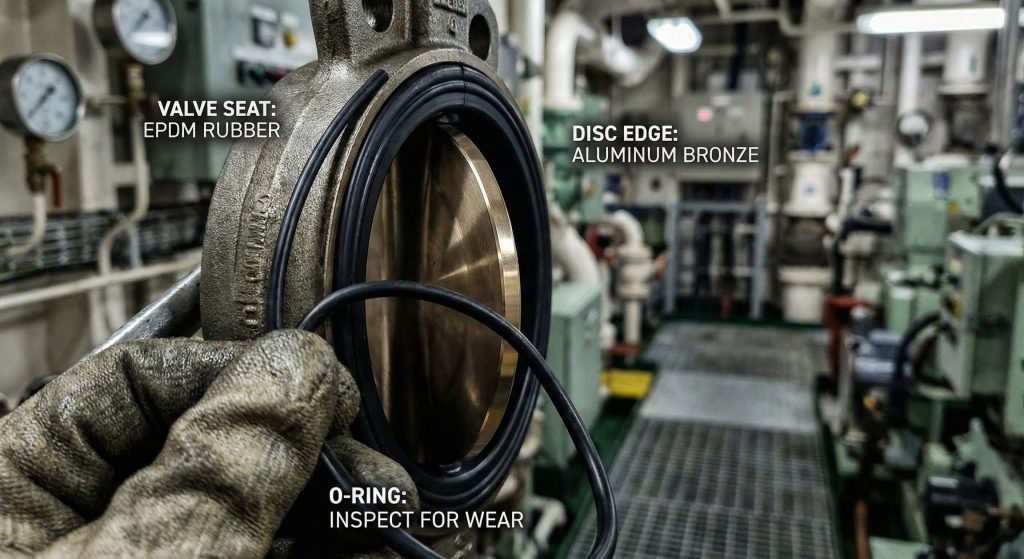

Which components make a marine electric butterfly valve?

A marine electric butterfly valve consists of several high-performance parts, including the actuator housing, the valve body, the disc, the seat, and the stem. For offshore use, these components must be made from corrosion-resistant materials like aluminum bronze or stainless steel.

What materials are used for the body?

The body is typically constructed from ductile iron or stainless steel to withstand high pressures. To ensure longevity, the marine electric butterfly valve often features an EPDM or PTFE seat that resists saltwater degradation.

What is inside the actuator?

The actuator houses the electric motor, a worm gear train, and the control circuit board. This gear train is crucial because it provides the necessary torque to overcome the “break-away” friction of the disc against the seat.

Key Takeaway: Each component is selected for its ability to resist corrosion and provide the high torque necessary for saltwater environments.

| Component | Standard Marine Material |

|---|---|

| Disc | Aluminum Bronze or SS316 |

| Seat | EPDM or NBR |

| Housing | IP67/IP68 Rated Aluminum |

Analysis: Using high-grade materials like bronze for the disc prevents the biofouling and pitting common in marine seawater systems.

How to control a marine electric butterfly valve?

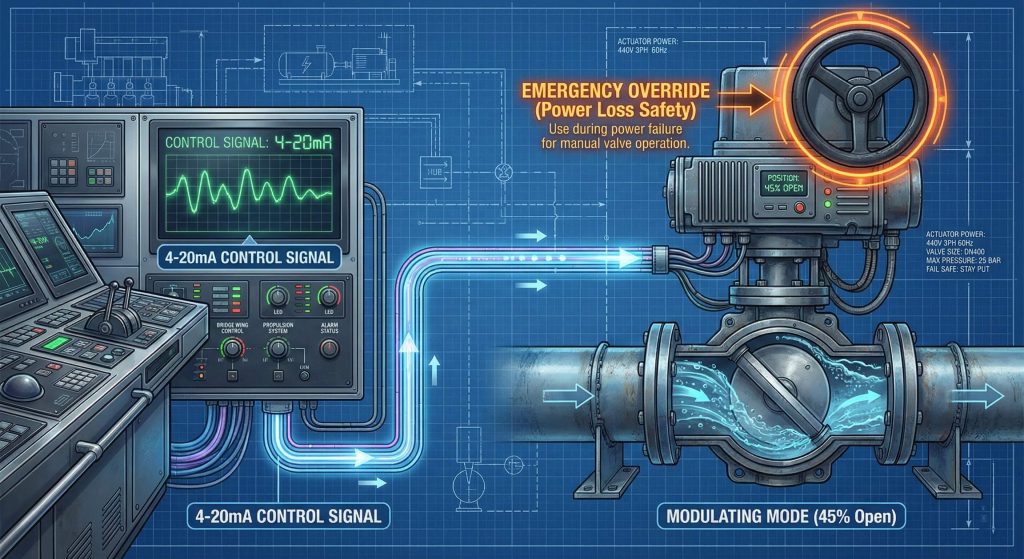

Controlling a marine electric butterfly valve involves sending electrical pulses or analog signals to the actuator’s internal controller. Operators can choose between simple on/off commands or complex modulating control for precise flow throttling.

Can it be integrated into SCADA?

Absolutely. Modern marine electric butterfly valve units support 4-20mA signals or Modbus protocols, allowing them to talk directly to the ship’s PLC or SCADA system. This integration enables real-time monitoring of valve status and health.

What happens during power failure?

You might be wondering about safety during a blackout. Many actuators include a manual override handwheel or a fail-safe battery backup to ensure the valve can still be closed manually.

Key Takeaway: Control flexibility allows these valves to serve both as simple isolation tools and as sophisticated components of an automated ship system.

| Control Type | Description |

|---|---|

| On/Off | Basic open or closed state |

| Modulating | Throttling from 0% to 100% |

| Manual Override | Mechanical handwheel for emergencies |

Analysis: Advanced control options like 4-20mA feedback allow for precise pressure regulation in cooling and ballast loops.

Where is a marine electric butterfly valve installed?

A marine electric butterfly valve is ideally suited for installation in the vessel’s ballast water treatment systems, bilge systems, and engine cooling loops. Its versatility allows it to function in any piping section where space is at a premium and automation is required.

Is it used in ballast systems?

Ballast management is the primary application for the marine electric butterfly valve. These valves must cycle frequently to adjust the ship’s trim and draft during loading and unloading at port.

Can it handle engine cooling?

But here is the kicker: it is also essential for regulating the flow of raw seawater to heat exchangers. This ensures the engine stays at the optimal temperature regardless of the outside water temperature.

Key Takeaway: From ballast to engine cooling, these valves are the workhorses of fluid management across various shipboard systems.

| Application | Fluid Type |

|---|---|

| Ballast System | Seawater |

| Fire Main | Water/Foam |

| Fuel Transfer | Marine Diesel/Heavy Oil |

Analysis: The wide range of applications proves the valve’s adaptability to both corrosive seawater and viscous fuel oils.

How to maintain a marine electric butterfly valve?

Maintaining a marine electric butterfly valve requires periodic inspection of the actuator’s electrical seals and the valve’s internal seating surface. Seawater is notoriously harsh, so checking for salt buildup or seal aging is critical for long-term reliability.

How often should it be cycled?

It is recommended to cycle the marine electric butterfly valve at least once a month if it is not in regular use. This prevents the disc from “seizing” in the seat due to marine growth or mineral deposits.

What should be checked in the actuator?

Check the IP rating seals and cable entries for any signs of moisture ingress. If water enters the actuator housing, it can short-circuit the control board and lead to a total system failure.

Key Takeaway: Routine cycling and moisture checks are the simplest ways to extend the life of your automated marine valves.

| Maintenance Task | Frequency |

|---|---|

| Visual Inspection | Monthly |

| Manual Cycling | Quarterly |

| Seal Replacement | Every 2-3 Years |

Analysis: Preventative maintenance costs a fraction of the price of an emergency dry-dock repair caused by a seized valve.

What sizes fit a marine electric butterfly valve?

The size of a marine electric butterfly valve typically ranges from DN40 for small branch lines to over DN1200 for major ballast mains. Selecting the correct size is vital to avoid cavitation and excessive pressure drops within the ship’s piping.

Are large sizes common?

Large-diameter marine electric butterfly valve units are standard for main seawater intakes. These larger valves require high-torque actuators to ensure they can close against high-velocity flows during an emergency.

Does size affect the actuator?

As the valve diameter increases, the torque requirement grows exponentially. Therefore, larger valves are paired with heavy-duty actuators featuring reinforced gearboxes to handle the increased physical load.

Key Takeaway: Proper sizing ensures efficient flow and guarantees that the actuator has sufficient power to operate the valve under load.

| Valve Size | Typical Application |

|---|---|

| DN40 – DN100 | Small cooling lines |

| DN150 – DN400 | Bilge and ballast branches |

| DN500+ | Main intake and ballast headers |

Analysis: A properly sized valve maintains system efficiency and prevents premature wear on the actuator motor.

Is a marine electric butterfly valve DNV certified?

Yes, a high-quality marine electric butterfly valve must carry certifications from bodies like DNV, ABS, or LR to be legally installed on commercial vessels. These certifications guarantee that the valve has been tested for vibration resistance and saltwater durability.

Why does DNV matter?

The DNV certification ensures that the marine electric butterfly valve can withstand the constant vibration and shock loads found in an engine room. Without these standards, a valve might fail prematurely due to mechanical fatigue.

Are they pressure tested?

Every certified valve undergoes rigorous hydrostatic and seat leakage testing at 1.5 times the working pressure. This ensures that the valve will not leak or burst even during extreme system pressure spikes.

Key Takeaway: Certification provides peace of mind that the valve meets the stringent safety and durability standards required for international shipping.

| Certification | Focus Area |

|---|---|

| DNV | Marine safety and reliability |

| CE | General equipment standards |

| API 598 | Valve leakage testing |

Analysis: Choosing certified valves is not just about quality; it is a regulatory requirement for marine insurance and safety compliance.

How to select a marine electric butterfly valve?

Selecting the right marine electric butterfly valve requires analyzing the fluid type, operating pressure, and environmental temperature. You must also consider the voltage available on your vessel to ensure the actuator is compatible with the power grid.

Should I focus on the seat?

The seat material is the most critical factor for a marine electric butterfly valve used in seawater. EPDM is generally preferred for its excellent resistance to aging and chemical degradation in aquatic environments.

What about torque safety?

But here is the kicker: always choose an actuator with a torque rating 20-30% higher than the valve’s breakaway torque. This “safety factor” ensures the valve will open even if there is slight scale buildup or increased friction.

Key Takeaway: Successful selection balances material compatibility, power requirements, and a sufficient torque safety margin for long-term use.

| Selection Factor | Priority |

|---|---|

| Material | High (Seawater resistance) |

| Torque Margin | High (Operational safety) |

| Voltage | Medium (System compatibility) |

Analysis: Investing time in the selection phase prevents costly mismatches that lead to operational downtime at sea.

Summary of Solutions

The modern marine electric butterfly valve solves the most pressing challenges of offshore fluid control. By replacing manual labor with precise automation, these valves eliminate human error and reduce the physical footprint of ship systems. They withstand the harshest corrosive environments while providing the data feedback necessary for digital vessel management.

Our mission at Ruito is to provide the maritime industry with high-reliability, DNV-certified flow solutions that enhance safety and efficiency. We are dedicated to engineering excellence that keeps your fleet moving without interruption. To learn more about our precision-engineered products or to request a quote for your next project, contact us today.

Frequently Asked Questions

Can I use this in seawater?

Yes. These valves are specifically designed with aluminum bronze discs and EPDM seats to resist the corrosive effects of saltwater.

What’s the best seat material?

Generally, EPDM is the best choice for marine applications due to its durability and resistance to seawater degradation.

Can I manually override it?

Yes. Most marine actuators come equipped with a manual handwheel or a hex-drive override for use during power failures.

What’s the best voltage for ships?

Ships typically utilize 24V DC for small control lines or 220V AC for larger, more powerful actuation needs.

Can I install it vertically?

Yes. While horizontal installation is often preferred to reduce sediment buildup, these valves can be installed in any orientation.