Achieving precise fluid control in high-stakes industrial pipelines is often compromised by the inherent non-linearity of standard quarter-turn valves. Engineers frequently face system instability where a valve operates sluggishly at one end of its travel and overly aggressively at the other, leading to poor process control. 30 seconds of unstable flow can ruin a batch, leading to costly unscheduled downtime and wasted raw materials. By mastering the specific flow characteristics of a butterfly valve, including the nuances of disc geometry and installed gain, operators can achieve the throttling precision of a globe valve at a fraction of the cost and weight. Explore our butterfly valve series to see how advanced geometry can solve these control challenges.

What Defines the Fundamental Flow Characteristics of a Butterfly Valve?

The flow characteristics of a butterfly valve describe the non-linear relationship between the disc’s degree of opening and the rate of fluid passing through the pipeline. Unlike linear valves, a standard butterfly valve typically exhibits an equal percentage characteristic, meaning flow capacity increases exponentially as the disc rotates open.

Understanding Inherent Curves

Here is the deal: The inherent curve is derived in a lab with constant pressure drop, but it rarely matches real-world performance. In its first 20 degrees of opening, a butterfly valve allows very little flow, creating a “dead band” that is ineffective for control. As the disc moves past 30 degrees, the flow area expands rapidly, creating a steep curve that offers high capacity but sensitivity.

- Linear: Flow increases consistently with travel (rare in standard butterfly valves).

- Equal Percentage: Flow changes exponentially (common in butterfly valves).

- Quick Opening: Max flow is reached at low travel angles.

The Quarter-Turn Dynamic

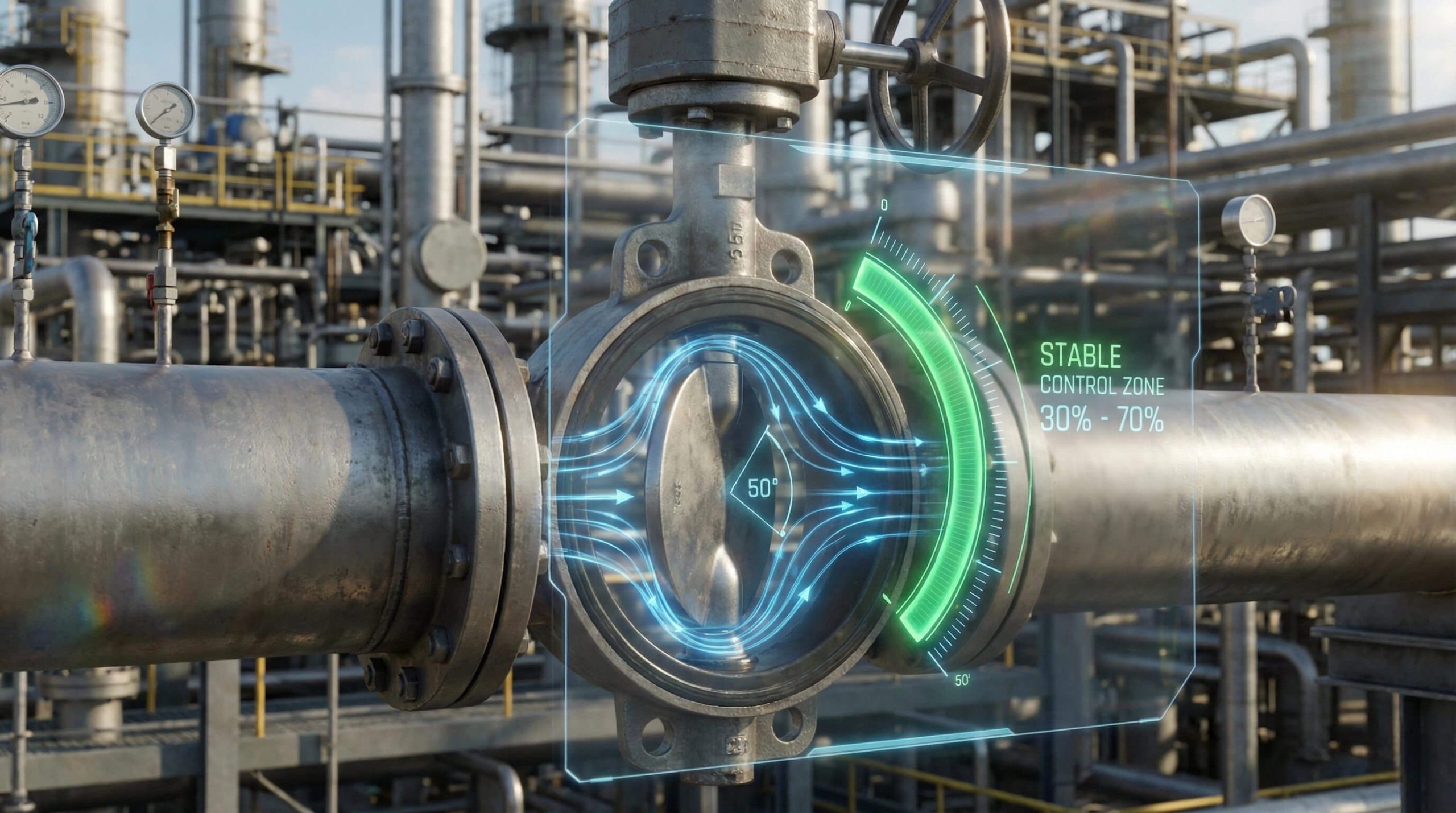

The geometry of a rotating disc creates a changing obstruction profile that alters fluid velocity dramatically. You might be wondering why this matters for your control loop. As the disc rotates, it acts like an airfoil, generating dynamic torque that interacts with the flow velocity. This dynamic behavior means the valve’s ability to control flow diminishes significantly after about 60 to 70 degrees of opening.

Key Takeaway: Standard butterfly valves behave with an equal percentage characteristic, offering precise control in the 30°–60° range but becoming overly sensitive or ineffective outside this band.

| Characteristic Type | Typical Opening Range | Control Sensitivity |

|---|---|---|

| Linear | 10% – 90% | Constant |

| Equal Percentage | 30% – 70% | Increasing |

| Quick Opening | 0% – 30% | Extreme |

Analysis: The table illustrates that while linear valves offer consistent control, the flow characteristics of a butterfly valve concentrate their effectiveness in the mid-range of travel.

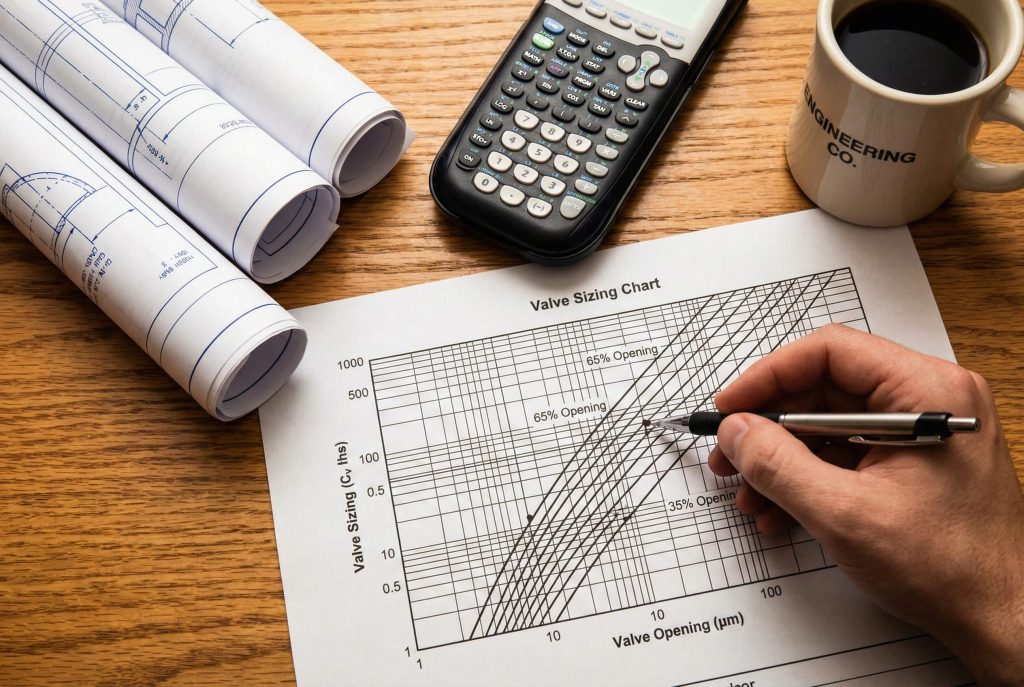

How Do Cv Values Quantify the Flow Characteristics of a Butterfly Valve?

Cv values quantify the flow characteristics of a butterfly valve by measuring the volume of water in gallons per minute that passes through at a 1 PSI pressure drop. This metric provides a standardized baseline for engineers to compare the capacity of different valve sizes and geometries at specific opening angles.

The Math of Flow Capacity

What’s the real story? A single Cv number at 90° open is useless for control sizing. To predict performance, you need the Cv data at every 10-degree increment to map the slope of the flow curve. If the Cv doubles between 20° and 30°, your control loop gain doubles, potentially causing instability if the controller isn’t tuned for it.

- Cv 100%: Maximum capacity at full open.

- Cv min: Minimum controllable flow (usually at 20°).

- Rangeability: The ratio of max to min controllable Cv.

Angle vs. Capacity Pitfalls

Sizing a valve based solely on line size often results in a valve with a maximum Cv far higher than the process requires. This is where it gets interesting: An oversized valve will force the disc to operate near the seat (below 20°) to restrict flow. Operating in this “cracked open” position leads to high velocity, wire drawing, and cavitation damage to the seat.

Key Takeaway: Always map the required process Cv against the valve’s Cv curve to ensure the operating point falls between 30° and 70° open.

| Opening Angle | % of Max Cv | Flow Regime |

|---|---|---|

| 10° | 1-2% | Leakage / Tight Shutoff |

| 30° | 15-20% | Control Entry Point |

| 60° | 60-70% | Linear Control limit |

| 90° | 100% | Max Capacity |

Analysis: The data shows that the flow characteristics of a butterfly valve result in the majority of capacity gain occurring in the latter half of the stroke, necessitating careful sizing for low-flow control.

Why Are Inherent vs. Installed Flow Characteristics of a Butterfly Valve Different?

Inherent flow characteristics of a butterfly valve represent lab performance, whereas installed characteristics account for the pressure fluctuations caused by the surrounding piping system. In a real pipeline, friction from pumps, elbows, and long runs alters the pressure drop available to the valve as flow changes.

Lab Data Reality Check

But here’s the kicker: A valve with an equal percentage inherent curve can appear linear once installed. As the valve opens and flow increases, the system pressure drop rises due to pipe friction, leaving less pressure drop across the valve. This natural “flattening” effect actually helps butterfly valves perform better in control loops than their inherent curves suggest.

System Gain Factors

The ratio of valve pressure drop to total system pressure drop, known as valve authority, dictates the final curve shape. It turns out that if you ignore system gain, your valve will likely be oversized. For complex loops where pressure equilibrium is critical, integrating system balancing and flow regulation ensures the valve retains authority over the flow.

- High Authority: Valve controls the flow (Good).

- Low Authority: System friction controls the flow (Bad).

- Distortion: How much the installed curve deviates from the inherent curve.

Key Takeaway: High pipe friction losses can transform a non-linear butterfly valve into a linear control device in the installed state.

| Factor | Effect on Curve | Result |

|---|---|---|

| Pipe Friction | Flattens Curve | Linearization |

| Pump Head | Steeps Curve | Higher Gain |

| Elbows/Fittings | Turbulence | Noise/Instability |

Analysis: Understanding that the installed flow characteristics of a butterfly valve differ from the datasheet is crucial for predicting actual process gain and stability.

How Does Disc Geometry Influence the Flow Characteristics of a Butterfly Valve?

The physical shape of the disc directly modifies the flow characteristics of a butterfly valve by altering how fluid separates and accelerates around the obstruction. Manufacturers utilize advanced hydrodynamic profiling to reduce the turbulence and dynamic torque that plague standard flat discs.

Obstruction Factors

Ready for the good part? A standard flat disc acts like a wall to the fluid, creating a large wake and significant drag. This results in a high pressure drop and a steep, unpredictable flow curve at intermediate angles.

- Flat Disc: High turbulence, high dynamic torque.

- Lens Disc: Smoother flow, lower drag.

- Undercut Disc: Better low-flow control.

Profiled Disc Benefits

Hydrodynamic or “airfoil” shaped discs allow fluid to streamline over the surface, maintaining attachment and reducing the wake. You might not know that this smoothing effect reduces the dynamic torque spike, allowing for smaller actuators and more stable throttling. By thinning the disc profile, manufacturers also increase the maximum Cv, reducing energy loss in the fully open position.

Key Takeaway: Profiled discs smooth out the flow characteristics of a butterfly valve, extending the controllable range and reducing actuator strain.

| Disc Type | Flow Efficiency | Control Range |

|---|---|---|

| Flat Concentric | Low | 30° – 60° |

| Lens/Airfoil | Medium | 25° – 65° |

| High Performance | High | 15° – 70° |

Analysis: Selecting a profiled disc significantly improves the linearity of the flow characteristics of a butterfly valve, justifying the extra investment for control applications.

What Is the Impact of Eccentric Design on the Flow Characteristics of a Butterfly Valve?

Eccentric designs, such as double and triple offset valves, modify the flow characteristics of a butterfly valve by changing how the disc interacts with the seat and the flow stream. The offset shaft creates a camming action that lifts the disc off the seat instantly, eliminating friction and changing the initial flow profile.

Offset Advantages

This is huge: In a concentric valve, the disc rubs the seat for the first 10 degrees, creating friction that ruins control precision (“stick-slip”). Double offset valves eliminate this contact immediately, allowing for smooth, repeatable movement right from the “crack open” position.

- Single Offset: Reduces top-seat wear.

- Double Offset: Eliminates seat friction during travel.

- Triple Offset: Frictionless stroke with metal sealing.

Modulation Range Extension

Because there is no friction to overcome during the stroke, the actuator can position the disc with extreme accuracy. Believe it or not, this mechanical advantage allows high-performance butterfly valves to throttle effectively down to 10% or 15% open, providing a much wider turndown ratio than rubber-lined concentric types.

Key Takeaway: Eccentric designs linearize the mechanical movement, allowing the flow characteristics of a butterfly valve to be utilized for high-precision modulation.

| Design | Friction Level | Modulating Start Point |

|---|---|---|

| Concentric | High | ~25° |

| Double Offset | Low | ~15° |

| Triple Offset | Zero | ~10° |

Analysis: The data confirms that eccentric geometry is essential for maximizing the usable flow characteristics of a butterfly valve in precision applications.

How Do the Flow Characteristics of a Butterfly Valve Compare to Globe Valves?

While the flow characteristics of a butterfly valve are generally equal percentage, globe valves are prized for their inherent linearity and high pressure recovery. Comparing these two helps engineers decide when to trade the precision of a globe valve for the efficiency and capacity of a butterfly valve.

Linearity Battles

Let’s be honest: If you need absolute linear control over a wide pressure range, a globe valve is the gold standard. Its plug-and-seat design allows for a 1:1 relationship between lift and flow. However, for large lines (above 6 inches), globe valves become prohibitively heavy and expensive. Precise throttling globe valve solutions are best for smaller, high-pressure lines where accuracy is paramount.

Cost vs. Precision

Butterfly valves offer a high-capacity alternative that is lighter and cheaper. Here is the trade-off: You sacrifice some inherent linearity, but you gain massive flow capacity ($C_v$) and a smaller footprint. With modern characterized positioners, the output of a butterfly valve can be digitally modified to mimic a globe valve, bridging the performance gap.

- Globe: Linear, heavy, expensive.

- Butterfly: Equal %, light, efficient.

- Hybrid: Segmented ball or plug valves.

Key Takeaway: Digital positioners allow the flow characteristics of a butterfly valve to approximate globe valve performance in large-bore applications.

| Feature | Butterfly Valve | Globe Valve |

|---|---|---|

| Inherent Curve | Equal Percentage | Linear |

| Pressure Recovery | High (Low Loss) | Low (High Loss) |

| Turndown Ratio | 20:1 | 50:1 |

Analysis: While globe valves lead in linearity, the flow characteristics of a butterfly valve provide a more economical solution for high-flow bulk regulation.

Can Actuation Strategy Optimise the Flow Characteristics of a Butterfly Valve?

Smart actuation strategies can digitally correct the inherent non-linear flow characteristics of a butterfly valve, creating a linear response from the control system’s perspective. By mapping the input signal to a custom position curve, engineers can eliminate the variable gain that causes instability.

Characterized Positioners

Think about this: A standard positioner moves the valve 50% for a 50% signal. A characterized positioner might move the valve 65% for a 50% signal to compensate for the “S” shaped flow curve. This digital mapping ensures that a 10% change in signal always results in a proportional change in flow, regardless of the valve’s position.

- Signal Mapping: Customizing input/output ratios.

- Cam Calibration: Mechanical correction in older units.

- Digital Feedback: Real-time diagnostics.

Addressing Stiffness

Actuators must be sized not just for closing torque, but for the “stiffness” required to hold a position against dynamic fluid forces. The bottom line is that a weak actuator will allow the disc to flutter, rendering any flow characteristic optimization useless. High-stiffness pneumatic or hydraulic actuators are essential for maintaining stable throttling.

Key Takeaway: Characterized positioners are the equalizer, digitally linearizing the flow characteristics of a butterfly valve for superior control loop performance.

| Actuator Feature | Benefit | Impact on Control |

|---|---|---|

| Digital Positioner | Curve Mapping | Linearization |

| High Torque | Holds Position | Stability |

| Fast Response | Quick Correction | Reduced Overshoot |

Analysis: Implementing smart actuation allows engineers to overcome the physical limitations of the flow characteristics of a butterfly valve.

What Role Does Pressure Drop Play in the Flow Characteristics of a Butterfly Valve?

Pressure drop determines the energy available to drive fluid through the valve, deeply influencing the flow characteristics of a butterfly valve and defining the onset of choked flow. Butterfly valves are high-recovery devices, meaning pressure drops at the constriction but recovers significantly downstream.

Recovery Factors

Why does this matter? High pressure recovery is great for efficiency but dangerous for cavitation. Because the pressure dips low at the vena contracta (narrowest point) and then recovers, there is a high risk that the fluid will flash into vapor and then collapse, causing damage.

- $F_L$ Factor: Measures pressure recovery capability.

- Choked Flow: Limit where flow no longer increases with pressure drop.

- Noise: Indication of turbulent energy loss.

Cavitation Risks

When the pressure drop exceeds the valve’s recovery limit, the flow curve flattens out, and the valve becomes choked. Here is a warning: Operating in this region destroys the valve and piping. Engineers must calculate the cavitation index ($sigma$) to ensure the valve operates within the safe zone of its flow characteristic curve.

Key Takeaway: High pressure recovery improves efficiency but limits the effective pressure drop range of the flow characteristics of a butterfly valve before cavitation occurs.

| Parameter | Butterfly Valve | Implication |

|---|---|---|

| Recovery Factor ($F_L$) | ~0.6 – 0.7 | High recovery |

| Cavitation Risk | Moderate/High | Requires checking |

| Energy Efficiency | High | Lower pumping costs |

Analysis: The high-recovery nature of the flow characteristics of a butterfly valve mandates careful pressure drop analysis to prevent destructive cavitation.

How Do the Flow Characteristics of a Butterfly Valve Affect Throttling Stability?

The steep slope of the flow characteristics of a butterfly valve at low opening angles creates a region of high gain that is notorious for causing control loop instability. This phenomenon, often called “hunting,” occurs when the valve overshoots its target due to excessive sensitivity.

The Hunting Phenomenon

Picture this: Your controller asks for a 2% flow increase. The valve opens 1 degree, but because of the high gain curve, flow jumps 10%. The controller panics and closes the valve. This cycle repeats, causing wear and process oscillation. This is why sizing the valve to operate away from the “cracked open” position is vital.

- High Gain: Small move = Big flow change.

- Low Gain: Big move = Small flow change.

- Stable Zone: Moderate, constant gain (30-70%).

Friction and Hysteresis

Instability is compounded by seal friction. Here is the problem: If the valve sticks, the controller ramps up the pressure until it “pops” free, causing an overshoot. For applications requiring pure isolation without throttling concerns, tight shut-off ball valves are often a better choice to avoid these dynamic stability issues.

Key Takeaway: Avoid the high-gain region (0-20°) to ensure the flow characteristics of a butterfly valve provide stable, non-oscillating control.

| Region | Gain Level | Stability Risk |

|---|---|---|

| 0° – 20° | Very High | Severe Hunting |

| 30° – 70° | Moderate | Stable Control |

| 80° – 90° | Very Low | Sluggish Response |

Analysis: Operating within the moderate gain region of the flow characteristics of a butterfly valve is the single most effective strategy for preventing control loop instability.

How To Select the Right Flow Characteristics of a Butterfly Valve for Your System?

Selecting the correct flow characteristics of a butterfly valve requires a calculated approach that prioritizes process data over pipeline diameter. Engineers must ignore line size and focus on matching the valve’s Cv curve to the specific minimum, normal, and maximum flow requirements of the system.

Sizing Rules

Follow this rule: Size the valve so that your maximum design flow occurs at approximately 60-70% open. This reserves the upper range for surge capacity and keeps the normal flow in the stable control zone. Never size a control valve to be 100% open at normal flow, as you lose all control authority.

- Max Flow: @ 60-70% Open.

- Min Flow: @ >20% Open.

- Safety Factor: 1.3x on Torque.

Safety Factors

Dynamic torque peaks around 70 degrees. Don’t forget: You must ensure your actuator has enough torque to drive through this peak fluid resistance. Undersizing the actuator based on seating torque alone will result in a valve that stalls mid-stroke during high-flow conditions.

Key Takeaway: Proper selection aligns the system’s flow requirements with the stable 30-70% range of the flow characteristics of a butterfly valve.

| Step | Action | Goal |

|---|---|---|

| 1 | Calculate Cv | Determine load |

| 2 | Check 60% Open | Ensure headroom |

| 3 | Check 20% Open | Avoid high gain |

Analysis: Strict adherence to sizing rules ensures the selected flow characteristics of a butterfly valve deliver reliable performance and longevity.

Conclusion

The flow characteristics of a butterfly valve are inherently non-linear, presenting both challenges and opportunities for industrial control. While the equal percentage curve offers high capacity, it requires careful sizing to avoid the instability of the high-gain regions. By utilizing profiled discs, eccentric designs, and characterized positioners, engineers can harness the efficiency of butterfly valves for precise throttling applications.

Final Thought: Do not let line size dictate your valve choice. Prioritize the installed gain and control range to build a system that is both cost-effective and operationally stable.

Call to Action: For critical applications involving complex flow dynamics or high-pressure requirements, contact us today at RUITO. Our engineering team can verify your sizing calculations and provide precision valve solutions that solve your specific control challenges.

FAQ

Q1: What is the ideal opening range for a butterfly valve used in throttling?

The ideal control range is generally between 30% and 70% of the disc travel. Below 30%, the high gain causes instability and “hunting,” while above 70%, the valve creates very little additional pressure drop, losing its ability to effectively control the flow rate.

Q2: Can a butterfly valve have a linear flow characteristic?

Inherently, no. Standard discs produce an equal percentage characteristic. However, high-performance discs (like V-port designs) or characterized digital positioners can modify the output to approximate a linear response, allowing for better integration into linear control loops.

Q3: How does dynamic torque affect butterfly valve flow control?

Dynamic torque is the force of the fluid pushing against the disc, which changes as the valve opens. It typically peaks around 70-75° open. If the actuator isn’t sized to handle this specific peak load, the valve may stall or slam shut, disrupting flow control.

Q4: What is the difference between inherent and installed flow characteristics?

Inherent characteristics are measured in a lab with a constant pressure drop and represent the valve’s theoretical performance. Installed characteristics account for the real-world friction of pipes and fittings, which alters the pressure drop as flow changes, often making an equal percentage valve appear more linear in operation.

Q5: Why do butterfly valves have high gain at low travel?

At low opening angles (0-20°), the disc just barely unseats, creating a thin, crescent-shaped opening. A very small degree of rotation significantly increases the area of this opening relative to its initial size, allowing a disproportionately large amount of fluid to pass.