The development history of butterfly valves centers on the transition from heavy gate valves to efficient, quarter-turn flow control solutions introduced in the 1930s. Early industrial operators struggled with massive gate valves that required significant torque and excessive installation space for large-diameter pipelines. These inefficiencies agitated project costs and slowed down response times during critical system shutdowns. To address these pains, the butterfly valve inventor introduced a compact disc-based mechanism that revolutionized high-volume fluid management.

Who was the original butterfly valve inventor during the 1930s?

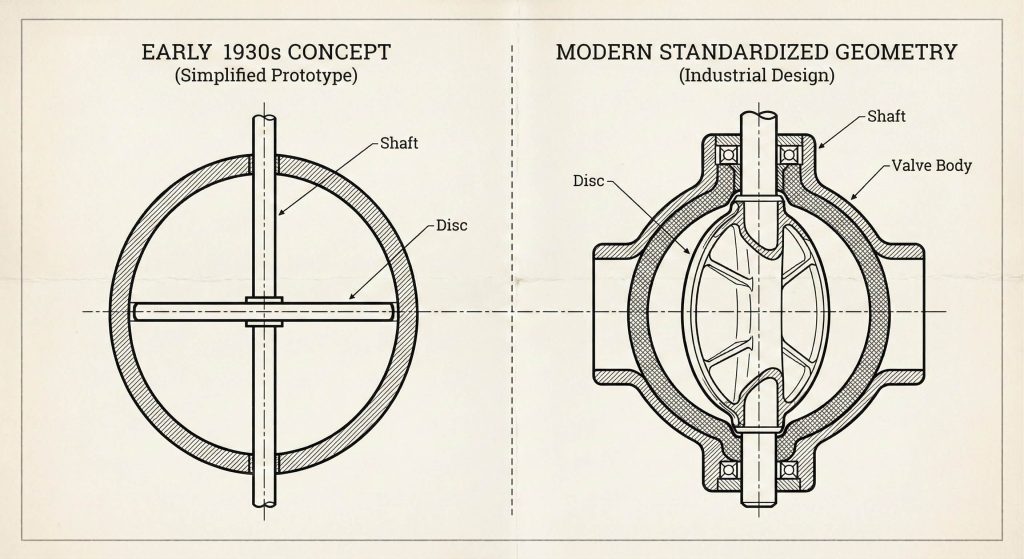

The butterfly valve inventor emerged in the United States during the early 1930s to solve specific weight and space constraints in piping. While various dampers existed previously, the 1930s marked the birth of the standardized industrial butterfly valve as we recognize it today. This innovation allowed for much faster operation compared to the multi-turn gate valves dominant at the time.

The Rise of the American Patent

- Early designs utilized a simple metal disc attached to a central rod.

- Manufacturing focused on low-pressure water systems and air ducts.

- The 1930s provided the foundational geometry for later sealing improvements.

It all started here.

Key Takeaway: The butterfly valve was a 1930s American invention designed to replace cumbersome gate valves in large-scale infrastructure.

| Feature | Early 1930s Design |

|---|---|

| Origin | United States |

| Main Advantage | Reduced weight and space |

| Primary Use | Low-pressure water and air |

The historical record confirms that the 1930s served as the critical decade for the commercialization of disc-based flow control.

How did the butterfly valve inventor solve early sealing issues?

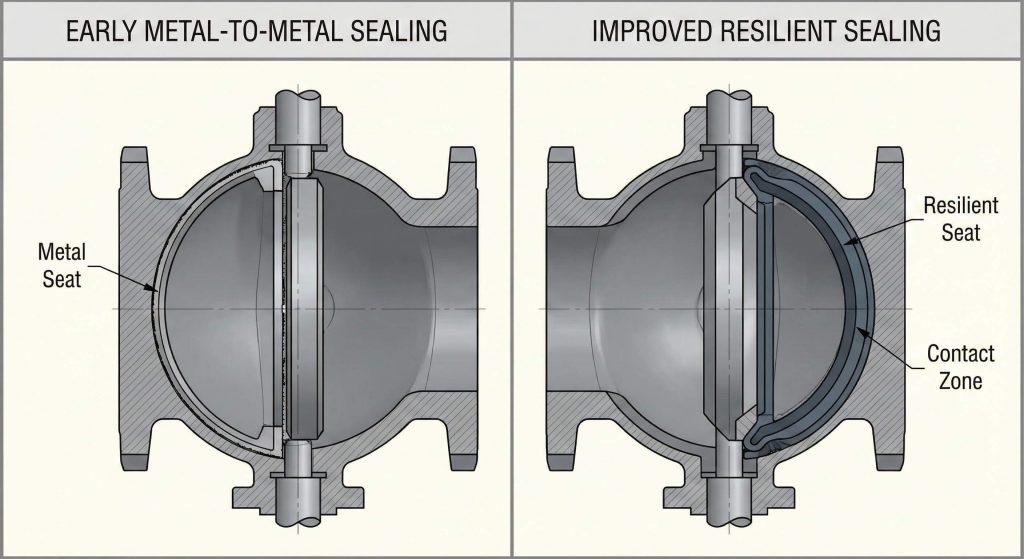

Early iterations struggled with “bubble-tight” shutoff because metal-to-metal contact was difficult to machine perfectly. The butterfly valve inventor recognized that a flexible interface was required to ensure a complete seal against fluid pressure. This led to the integration of soft seats made from early synthetic rubbers and polymers.

Breakthroughs in Resilience

- Introduction of replaceable rubber liners in the 1950s.

- Development of interference fits between the disc and the seat.

- Utilization of vulcanized bonding to prevent liner displacement.

Think about this.

Key Takeaway: Sealing issues were overcome by transitioning from rigid metal seats to resilient, flexible materials like rubber and PTFE.

| Era | Sealing Solution |

|---|---|

| 1930s | Metal-to-metal (High leakage) |

| 1950s | Resilient rubber seats |

| 1970s | Double and triple offset metal seals |

The shift toward resilient materials transformed the butterfly valve from a simple damper into a reliable isolation tool.

Why did the butterfly valve inventor choose the quarter-turn design?

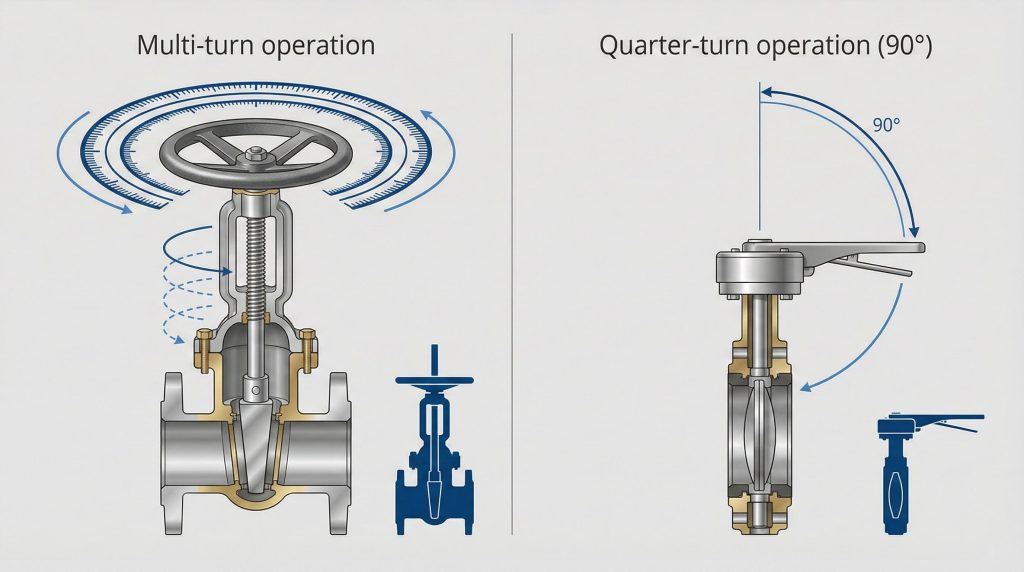

Efficiency was the primary driver for the butterfly valve inventor when selecting the 90-degree rotation mechanism. Traditional valves required dozens of turns to open or close, which was physically demanding and slow during emergencies. The quarter-turn design enabled rapid actuation with minimal effort from the operator.

Advantages of 90-Degree Rotation

- Faster response times during system emergencies.

- Lower torque requirements for manual operation.

- Simplified mechanical linkage for automated actuators.

Here’s the kicker.

Key Takeaway: The quarter-turn design provides the fastest possible manual operation and simplifies the integration of automated control systems.

| Mechanism | Speed of Operation | Torque Level |

|---|---|---|

| Multi-turn Gate | Slow | High |

| Quarter-turn Butterfly | Fast | Moderate to Low |

The choice of a 90-degree swing remains the defining characteristic that gives butterfly valves a competitive edge in modern plants.

What materials did the butterfly valve inventor use for durability?

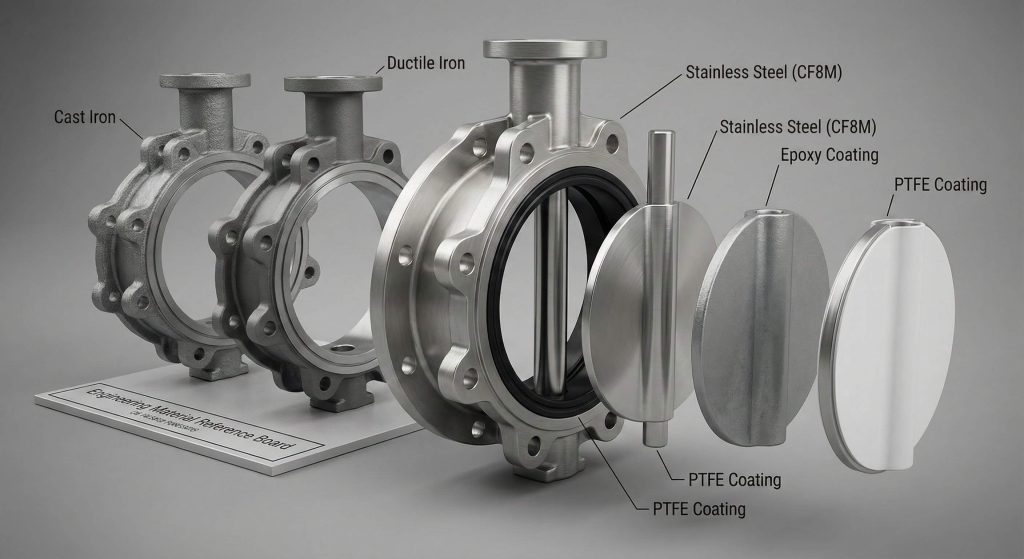

Initially, the butterfly valve inventor relied on cast iron and simple steels which were prone to corrosion in water applications. As chemical and oil industries expanded, the demand for more robust materials led to the use of ductile iron and stainless steel. These materials ensured that the internal disc could withstand high velocities without eroding.

The Evolution of Metallurgy

- Adoption of ductile iron for higher tensile strength.

- Use of CF8M stainless steel for corrosive environments.

- Implementation of specialized coatings like epoxy and PTFE.

But wait, there’s more.

Key Takeaway: Material science moved from simple cast iron to high-grade alloys to meet the demands of corrosive and high-pressure media.

| Material Type | Typical Application |

|---|---|

| Cast Iron | Basic water systems |

| Ductile Iron | Municipal infrastructure |

| Stainless Steel | Chemical processing |

The selection of high-durability alloys has extended the operational life of butterfly valves across all heavy industries.

How has the butterfly valve inventor influenced modern automation?

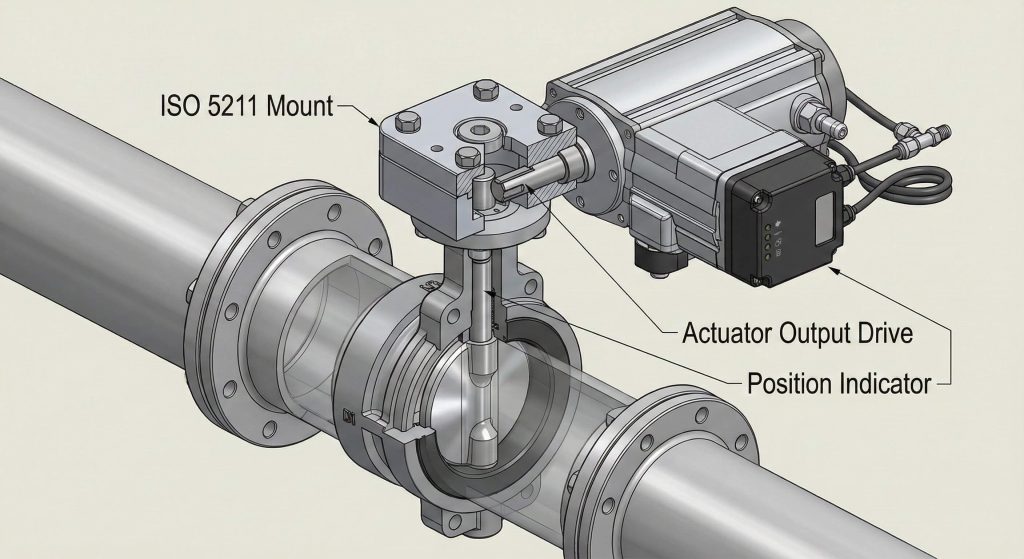

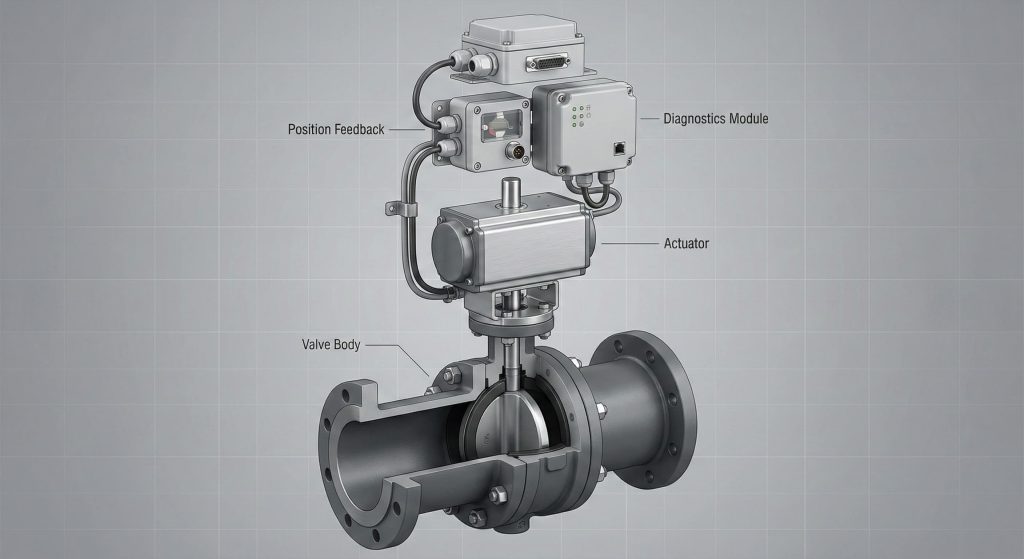

Modern automation is a direct descendant of the butterfly valve inventor vision for a compact, low-torque flow controller. Because the disc only rotates 90 degrees, it is the ideal candidate for pneumatic and electric actuators. This compatibility has allowed butterfly valves to become the backbone of smart factories and remote monitoring systems.

Actuation and Digital Integration

- Standardized mounting pads (ISO 5211) for universal actuator fit.

- Integration of positioners for precise throttling control.

- Use of “smart” actuators with diagnostic capabilities.

Believe it or not.

Key Takeaway: The valve’s quarter-turn nature makes it the most efficient design for electric and pneumatic automation in modern industry.

| Automation Type | Primary Benefit |

|---|---|

| Pneumatic | Fast and fail-safe |

| Electric | Precise control and feedback |

| Manual | Reliability without power |

The original design’s mechanical simplicity is exactly what makes it so resilient in the era of digital automation.

Can the butterfly valve inventor vision handle high-pressure systems?

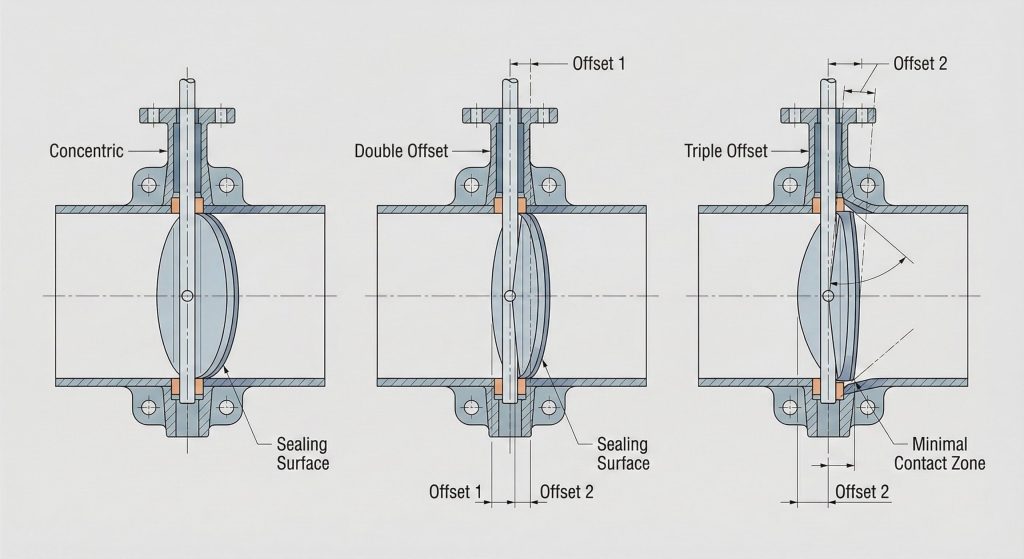

For decades, the butterfly valve inventor vision was restricted to low-pressure applications due to seat limitations. However, the development of high-performance butterfly valves with eccentric offsets changed this narrative entirely. By moving the stem away from the center of the disc, engineers created valves capable of handling Class 600 pressures and beyond.

Overcoming High-Pressure Barriers

- Use of double and triple offset geometry to reduce friction.

- Transition to metal-seated designs for extreme sealing.

- Reinforced bodies to prevent deformation under heavy loads.

Now for the best part.

Key Takeaway: High-performance butterfly valves use eccentric offsets to manage high pressures that would destroy standard concentric designs.

| Valve Class | Max Pressure Capability | Sealing Style |

|---|---|---|

| Concentric | Low to Medium | Rubber/Soft |

| Double Offset | High | High-performance soft |

| Triple Offset | Very High | Metal-to-metal |

Innovation in geometry has allowed butterfly valves to compete directly with globe and ball valves in high-pressure sectors.

Where did the butterfly valve inventor first apply this technology?

The butterfly valve inventor first found success in the massive water works and cooling systems of the early 20th century. These environments required the movement of large volumes of water where total isolation was secondary to flow regulation. As the technology matured, it moved from municipal water into the power generation and HVAC industries.

Early Adoption Sectors

- Municipal water treatment and distribution networks.

- Hydroelectric power plant cooling circuits.

- Shipbuilding and maritime ballast systems.

Sounds simple, right?

Key Takeaway: Water management was the initial testing ground, providing the data needed to refine the valve for more aggressive industrial uses.

| Sector | Why Butterfly Valves? |

|---|---|

| Municipal | Handling massive pipe diameters |

| Power Plants | Efficient cooling water control |

| Shipbuilding | Lightweight and corrosion resistant |

The success in early water applications proved the durability of the disc design before it entered the oil and gas market.

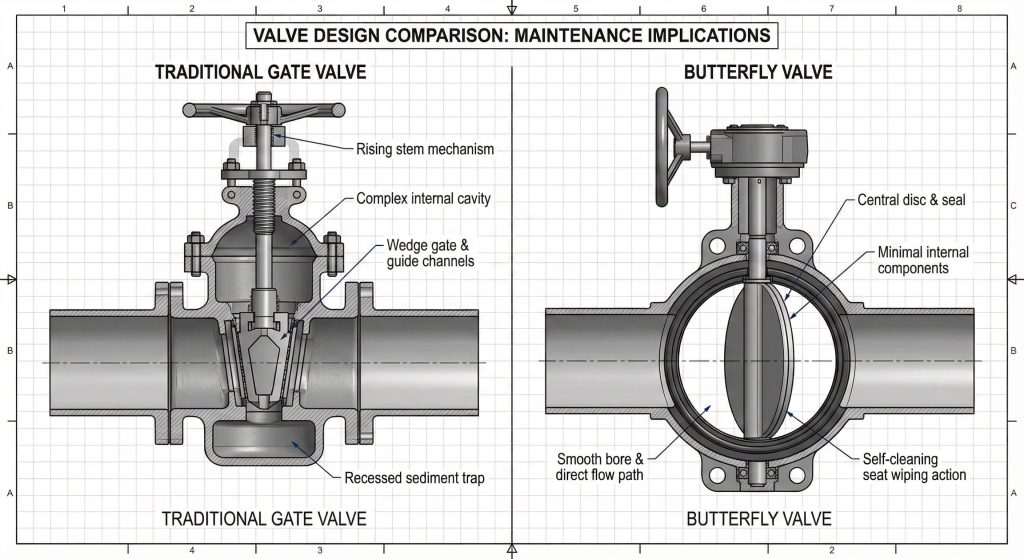

How does the butterfly valve inventor design reduce maintenance?

Maintenance reduction was a core goal for the butterfly valve inventor when compared to complex globe or gate valves. With fewer moving parts and no internal cavities for debris to collect, the butterfly valve is naturally resistant to clogging. Most modern designs allow for seat replacement without removing the entire valve body from the line.

Maintenance Advantages

- “Self-cleaning” disc action that wipes the seat during operation.

- Simplified internal structure with only a few critical components.

- Reduced downtime through easy-to-replace resilient liners.

You might be wondering.

Key Takeaway: A simpler design with fewer internal parts translates directly into lower long-term maintenance costs and higher uptime.

| Maintenance Task | Butterfly Valve | Gate Valve |

|---|---|---|

| Seat Replacement | Fast/On-site | Difficult/Slow |

| Cleaning | Automatic | Requires teardown |

| Weight | Low (Easier to pull) | High (Requires crane) |

The streamlined profile of the butterfly valve ensures that it remains the most cost-effective choice for long-term facility management.

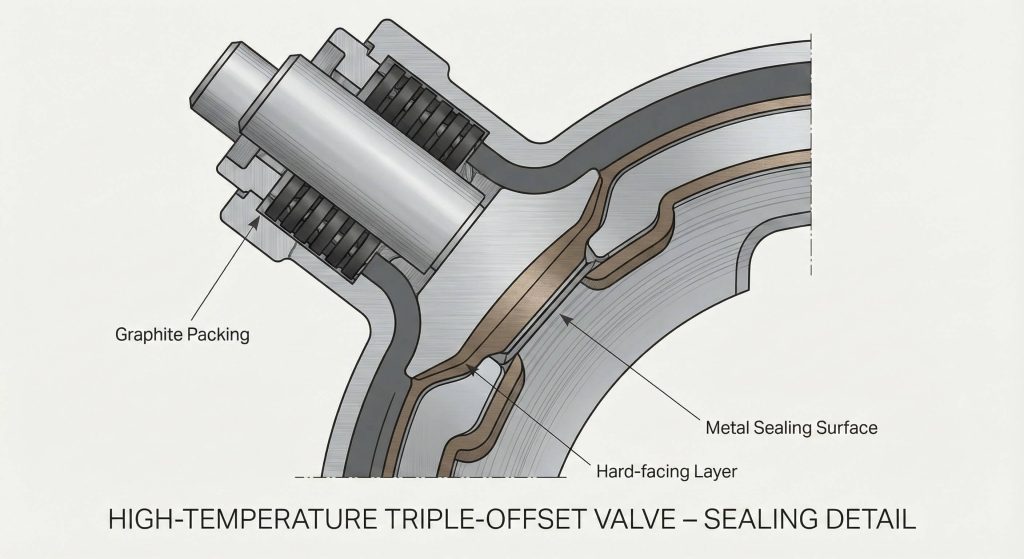

Is the butterfly valve inventor concept suitable for extreme heat?

Modern extensions of the butterfly valve inventor concept have successfully conquered high-temperature environments using triple-offset technology. Standard rubber-seated valves fail at high temperatures, but metal-seated butterfly valves can operate in excess of 500°C. This makes them indispensable for steam services and refinery applications where thermal expansion is a constant threat.

Thermal Resistance Features

- Stellite-faced metal seats for wear and heat resistance.

- Triple-offset geometry that eliminates seat friction during travel.

- High-temperature graphite packing to prevent external leakage.

It gets even better.

Key Takeaway: Through advanced metallurgy and triple-offset geometry, butterfly valves now thrive in environments previously reserved for globe valves.

| Temperature Range | Seat Material | Common Use |

|---|---|---|

| < 120°C | EPDM/NBR | Water/Air |

| < 200°C | PTFE/Viton | Chemicals/Low Steam |

| > 400°C | Metal (SS316/Stellite) | High-pressure Steam/Refinery |

Engineering advancements have effectively removed the thermal “ceiling” that once limited this valve’s industrial utility.

What is the legacy of the butterfly valve inventor in 2024?

In 2024, the legacy of the butterfly valve inventor is seen in the global standard of pipeline engineering. Almost all gate valves above DN300 mm have been replaced by butterfly valves due to their logistical and operational superiority. Today’s valves are smarter, lighter, and more durable than any of the prototypes developed nearly a century ago.

The 2024 Landscape

- Global dominance in large-diameter fluid transport.

- Integration of IoT sensors for real-time valve health monitoring.

- Continued shift toward triple-offset designs for critical safety applications.

The bottom line?

Key Takeaway: The butterfly valve has evolved from a simple low-pressure damper into a high-tech, precision-engineered flow control solution for the 21st century.

| Metric | 1930s Standard | 2024 Standard |

|---|---|---|

| Precision | Basic Throttling | ±1% Accuracy |

| Actuation | Manual Handwheel | Smart Digital Actuator |

| Materials | Cast Iron | Super Duplex/Inconel |

The butterfly valve’s development history is a testament to how a single design concept can be refined to meet the world’s most demanding engineering challenges.

Conclusion

The journey from the 1930s to the current era has proven that the butterfly valve is the most versatile tool in the industrial arsenal. Its ability to scale from small HVAC ducts to massive water treatment plants remains unmatched. If you are looking to upgrade your facility with high-performance flow control, contact us today for expert guidance.

FAQ

- Can I use a butterfly valve for high-pressure gas?

Yes, high-performance triple-offset butterfly valves with metal seats are specifically designed to handle high-pressure gas and steam safely. - What’s the best seat material for corrosive chemicals?

PTFE (Teflon) or specialized fluoroelastomers like Viton are generally the best choices for resisting chemical degradation. - How do I know if a triple-offset valve is necessary?

You typically need a triple-offset valve if your application involves high temperatures (above 200°C), high pressure, or requires zero-leakage metal sealing. - Can I automate an old manual butterfly valve?

Most modern butterfly valves have standard mounting pads that allow for the easy addition of pneumatic or electric actuators later. - What’s the best way to prevent cavitation in butterfly valves?

The best way is to ensure proper sizing and use modern anti-cavitation trim or comb-tooth disc designs to break up high-velocity flow streams.