The problem is your industrial pumping system runs at full throttle, yet energy bills skyrocket and output remains weak. The hidden enemy is often the ignored pressure drop across butterfly valve installations that restrict flow. By mastering Flow Coefficient (Cv) with RUITO’s expertise, you can eliminate waste and balance flow rates efficiently.

1. Basics of pressure drop across butterfly valve

Do you know what restricts your flow?

Here’s the deal: Even fully open butterfly valves create resistance. Unlike full-bore ball valves, the disc remains in the flow path at all times.

- The disc acts as a physical obstacle.

- Fluid must navigate around the structure.

- Velocity changes create inevitable friction.

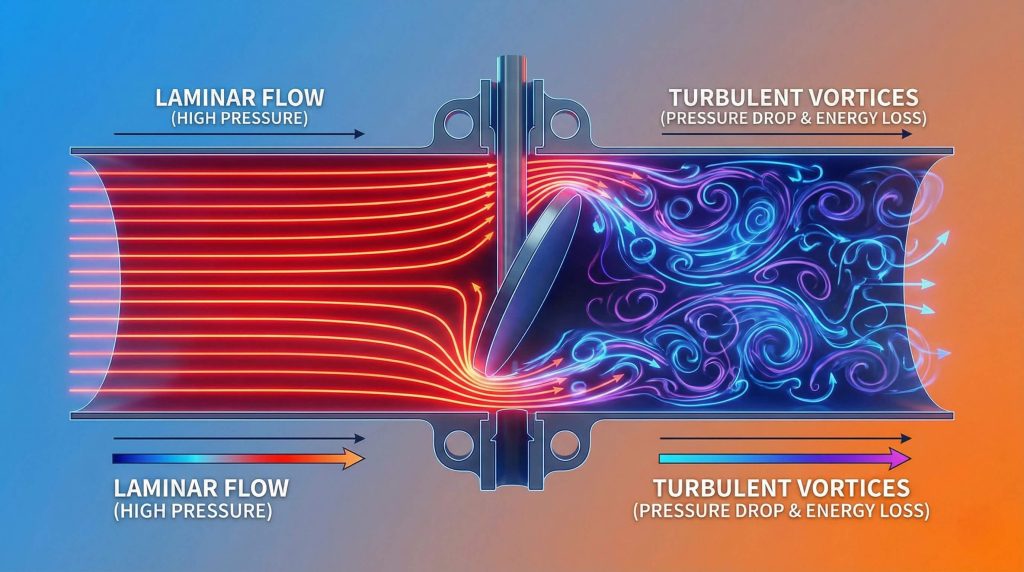

How does turbulence impact you?

You might be wondering: Why does flow get chaotic? Partial openings create downstream swirls that disrupt smooth fluid movement.

- Vortices form behind the disc.

- Energy is lost as heat and vibration.

- Laminar flow becomes turbulent.

Why measuring loss matters to you?

Bottom line: Unmeasured loss equals system failure and wasted budget. You need baseline data to prevent pump overload.

- Monitoring prevents cavitation risks.

- Data aids in predictive maintenance.

- Efficiency drops without accurate measurement.

| Feature | Impact on Flow | Impact on Pressure |

|---|---|---|

| Disc Thickness | High obstruction | High Drop |

| Surface Finish | Low friction | Low Drop |

| Liner Type | Variable friction | Moderate Drop |

The physical geometry of the disc is the primary contributor to initial resistance in any butterfly valve setup.

Key Takeaway: Understanding the physical obstruction is the first step to efficiency. Recognizing the disc as a permanent restriction helps you plan pump head requirements and avoid under-powering your system.

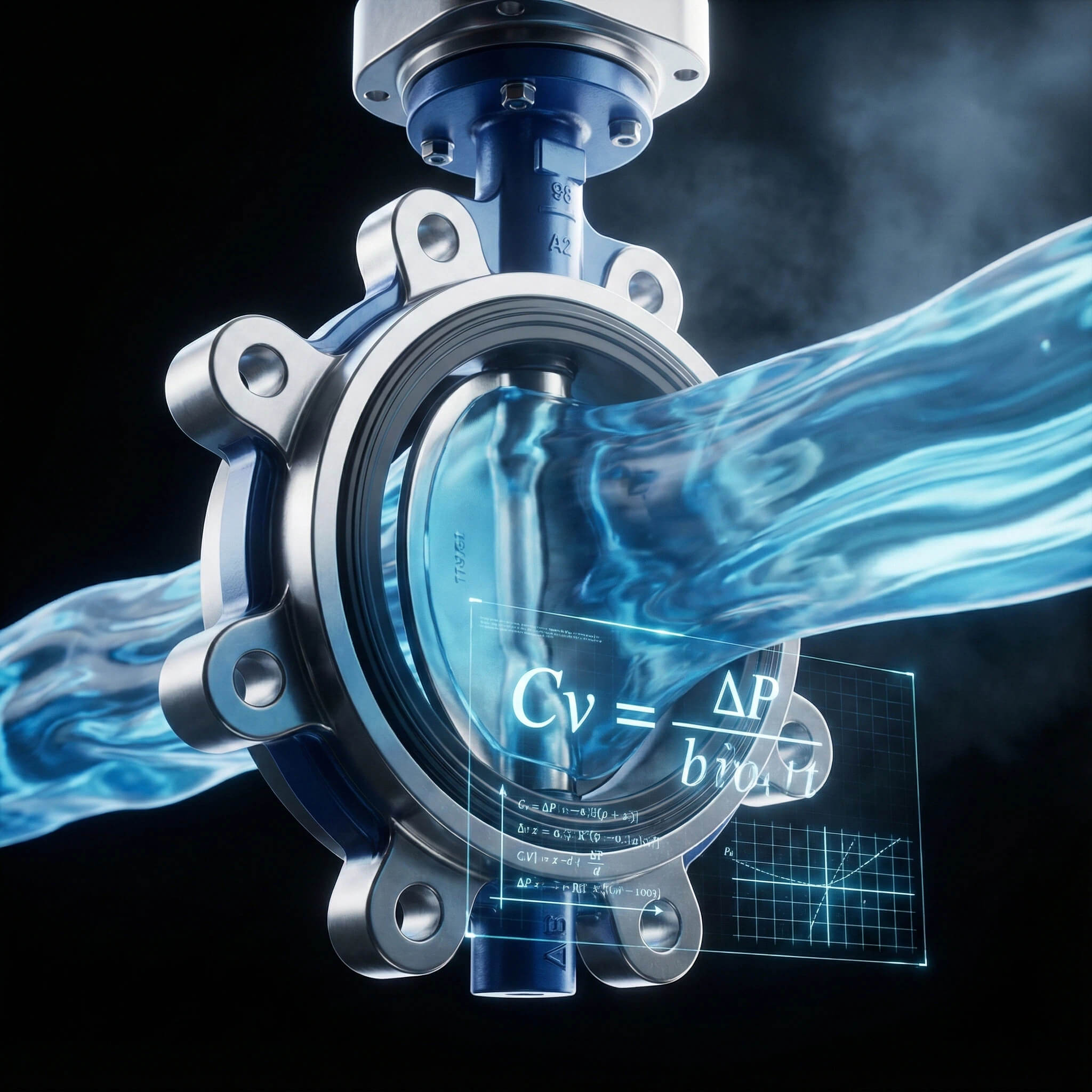

2. Calc pressure drop across butterfly valve

Do you have the right formula?

Let’s look at the math: Don’t guess; calculate using the industry standard. Use the formula $\Delta P = SG \times (Q / Cv)^2$ for liquids.

- $\Delta P$ is pressure drop.

- $Q$ is flow rate.

- $Cv$ is the valve’s flow coefficient.

Are your inputs accurate?

Here is the catch: Bad data ruins calculations. Verify your Flow Rate (Q) in GPM and ensure you use the Manufacturer’s published Cv.

- Check specific gravity (SG).

- Verify units (GPM vs LPM).

- Consult RUITO datasheets.

What do the numbers tell you?

It turns out: High results mean you are wasting energy. Compare calculated drop against pump head limits immediately.

- High drop means high energy cost.

- Re-evaluate if drop > 20%.

- Optimize sizing if needed.

| Variable | Definition | Standard Unit |

|---|---|---|

| $\Delta P$ | Pressure Drop | PSI |

| Q | Flow Rate | GPM |

| Cv | Flow Coefficient | GPM/1psi |

The inverse square relationship means even small errors in Cv estimation lead to exponential errors in predicted pressure loss.

Key Takeaway: Precision in Cv data is non-negotiable for accurate planning. Accurate calculations prevent the installation of undersized valves that act as bottlenecks.

3. Cv role in pressure drop across butterfly valve

What is the Cv relationship?

Basically: A high Cv value means effortless flow. It measures the gallons passing through with only a 1 PSI drop.

- Higher Cv equals lower resistance.

- Ideal for isolation valves.

- Reduces pump workload.

How does sizing change Cv?

Think about this: Bigger isn’t always better for control. Line-size valves offer maximum Cv for on/off, but reduced ports improve throttling.

- Oversizing reduces control.

- Undersizing chokes flow.

- Match Cv to process needs.

Can you optimize the coefficient?

Here’s the secret: Select streamlined discs to boost Cv naturally. Offset shafts improve the flow path without changing pipe size.

- Thin profiles cut drag.

- Offset shafts clear the seal.

- Flow area increases.

| Valve Size (DN) | Typical Cv (Open) | Resistance Level |

|---|---|---|

| DN50 (2″) | 115 | Moderate |

| DN100 (4″) | 580 | Low |

| DN200 (8″) | 3,400 | Minimal |

Larger valves provide exponentially better flow coefficients, drastically reducing the energy required to move fluid.

Key Takeaway: Maximize Cv to minimize operational costs in isolation lines. Selecting the right coefficient ensures your system runs smoothly without unnecessary head loss.

4. Disc shape & pressure drop across butterfly valve

Is your disc creating drag?

Be honest: Is your valve design archaic? Thick, flat discs act like walls in the pipe, killing efficiency.

- Old designs block flow.

- Turbulence increases drop.

- Efficiency suffers greatly.

Why choose offset designs?

It gets better: Triple offsets clear the path almost entirely. They move the disc out of the seal zone immediately.

- Friction wear disappears.

- Flow path opens wider.

- Sealing integrity improves.

Does material thickness matter?

You should know: Strength requires thickness, but engineering matters. High-pressure discs are thicker, so you must balance rating with flow needs.

- High pressure = thick disc.

- Check pressure ratings.

- Verify flow area.

| Design Type | Flow Obstruction | Pressure Drop |

|---|---|---|

| Concentric | High (Thick Disc) | Moderate-High |

| Double Offset | Medium | Moderate |

| Triple Offset | Low (Streamlined) | Lowest |

Triple offset valves offer the superior aerodynamic profile required for high-efficiency systems where pressure conservation is critical.

Key Takeaway: Upgrade to eccentric designs to reduce inherent mechanical resistance. Modern disc geometries from RUITO minimize obstruction while maintaining high pressure ratings.

5. Sizing for pressure drop across butterfly valve

Are you oversizing your valves?

Wait a minute: Too big is dangerous for control. You lose authority near the closed position, causing the valve to “hunt.”

- Unstable pressure waves form.

- Wear accelerates on seals.

- Control becomes erratic.

Are you choking the system?

Here’s the kicker: Undersizing creates massive bottlenecks. You force the pump to work against the valve, causing erosion.

- Velocity exceeds limits.

- Noise levels rise.

- Erosion damages metal.

How to find the sweet spot?

Try this: Aim for specific drop ratios. Control valves need to absorb 25-50% of system drop, while isolation needs <5%.

- Calculate system drop.

- Assign drop to valve.

- Select based on Cv.

| Application | Ideal $\Delta P$ Ratio | Sizing Strategy |

|---|---|---|

| Isolation | < 5% | Line Size |

| Modulation | 25% – 50% | Less than Line Size |

| Bypass | 10% – 20% | Calculated Cv |

Correct sizing is a trade-off between control authority and energy efficiency; one size does not fit all applications.

Key Takeaway: Size for the function (control vs. isolation), not just the pipe diameter. Proper sizing ensures stable operation and prevents the costly damage of cavitation.

6. Cavitation by pressure drop across butterfly valve

What causes the popping noise?

It’s scary: That gravel-like sound is metal eroding. High pressure drop creates vapor bubbles that implode downstream.

- Bubbles form at low pressure.

- Implosion releases energy.

- Sound indicates damage.

How does it damage valves?

Here is the truth: It pits metal and destroys seats. Micro-jets from implosions destroy disc edges and lead to failure.

- Surface pitting occurs.

- Seats are torn.

- Leakage starts soon.

Can you stop the damage?

The good news: Yes, by managing $\Delta P$. Keep the drop below the recovery factor ($F_L$) or use staged reduction.

- Check recovery factors.

- Reduce drop across valve.

- Consider anti-cavitation trims.

| Damage Stage | Audible Sign | $\Delta P$ Severity |

|---|---|---|

| Incipient | Hissing | Moderate |

| Constant | Gravel noise | High |

| Choked | Screaming/Vibration | Critical |

Cavitation is a direct symptom of excessive pressure drop that exceeds the fluid’s physical limits, indicating immediate resizing needs.

Key Takeaway: If you hear gravel, your pressure drop is destroying your investment. Immediate action to resize or reconfigure the valve is necessary to save the piping system.

7. Installation & pressure drop across butterfly valve

Is your piping too tight?

Listen up: Elbows and bends create chaos. Turbulence entering a valve kills its effective Cv rating.

- Avoid close elbows.

- Smooth flow is vital.

- Cv ratings assume laminar flow.

Do you follow the 6D rule?

Rule of thumb: Distance saves energy. Install valves 6 diameters upstream and 4 downstream from disturbances.

- 6D upstream clearance.

- 4D downstream clearance.

- Stabilize the velocity profile.

Are gaskets restricting flow?

Small detail, big problem: Check gasket alignment. Misaligned gaskets intrude into the pipe bore, creating artificial restrictions.

- Center gaskets perfectly.

- Check ID compatibility.

- Avoid artificial chokes.

| Component | Minimum Distance | Effect of Proximity |

|---|---|---|

| Elbow | 6x Pipe Dia | High Turbulence |

| Pump | 6x Pipe Dia | Pulsation/Wear |

| Check Valve | 4x Pipe Dia | Flow Interference |

Even a perfectly sized valve will fail to perform if installed in a turbulent zone, effectively derating its Cv.

Key Takeaway: Respect upstream/downstream spacing to preserve the valve’s rated flow capacity. Proper installation ensures the valve performs as engineered.

8. Energy costs & pressure drop across butterfly valve

How much are you wasting?

Reality check: Pressure drop is energy loss. Pumps burn kilowatts to overcome resistance every minute.

- Higher drop = higher amps.

- Energy bills increase.

- System efficiency plummets.

Can you lower TCO?

Here’s the kicker: Efficient valves pay back quickly. Lowering drop by just 2 PSI saves massive power annually.

- Lower operational costs.

- Reduce pump wear.

- Extend system life.

Is the upgrade worth it?

Do the math: Calculate ROI on high-Cv valves. Compare RUITO’s efficient designs to standard options.

- ROI often < 18 months.

- Savings compound yearly.

- Invest in efficiency.

| $\Delta P$ Reduction | Pump Energy Savings | Yearly Savings (Est) |

|---|---|---|

| 1 PSI | 2-3% | $1,500 |

| 5 PSI | 10-12% | $7,000+ |

| 10 PSI | 20%+ | $15,000+ |

The operational expenditure (OPEX) of fighting pressure drop often exceeds the capital expenditure (CAPEX) of the valve itself.

Key Takeaway: Buying a “cheap” valve with high pressure drop is an expensive decision. Investing in high-efficiency valves reduces your total cost of ownership significantly.

9. RUITO fixes pressure drop across butterfly valve

Why trust RUITO engineering?

We know fluids: With 20 years of mastery, we understand the physics. Our team optimizes disc geometry for real-world conditions.

- ISO 9001 certified precision.

- Expert flow analysis.

- OEM/ODM capabilities.

How do we improve flow?

Here’s our edge: Streamlined discs reduce drag. We use high-strength materials to reduce thickness while maintaining safety.

- Thinner, stronger discs.

- Smooth surface finishes.

- Maximum flow paths.

Ready to upgrade your system?

This is it: Stop bleeding energy. Custom solutions for high-flow, low-drop needs are ready for your project.

- Factory-direct pricing.

- Fast global shipping.

- Guaranteed performance.

| RUITO Feature | Benefit | Result |

|---|---|---|

| Streamlined Disc | Less Turbulence | Higher Cv |

| Precision Casting | Smooth Surface | Lower Friction |

| Custom Sizing | Perfect Fit | Optimized $\Delta P$ |

RUITO combines material science with hydraulic design to offer valves that minimize the energy penalty of flow control.

Key Takeaway: RUITO valves are engineered to maximize flow efficiency and minimize your pumping bill. Empower your system with valves designed for performance and longevity.

Conclusion

We have explored how the pressure drop across butterfly valve installations impacts your efficiency, safety, and bottom line. From the math of Cv to the dangers of cavitation, the message is clear: precision matters. Do not let invisible resistance drain your budget.

RUITO is your strategic partner in fluid control. We deliver optimized flow solutions backed by global standards and manufacturing excellence to empower efficient systems worldwide.

Ready to optimize your flow rate? Contact RUITO’s engineering team today for a free pressure drop analysis of your system.

FAQ

Q1: Can I use a butterfly valve for flow control without high pressure drop?

Yes, but with limits. For modulation, you need some pressure drop (about 25-50% of the system drop) to have control authority. For isolation, choose a line-size valve with a high Cv to ensure the drop is negligible.

Q2: What’s the best way to calculate the exact pressure drop I will face?

Use the manufacturer’s Cv curve. The general formula is useful, but because Cv changes at every degree of opening, you must request the specific Cv data sheet from the manufacturer (like RUITO) for the exact opening angle.

Q3: How do I know if my pressure drop is causing cavitation?

Listen and measure. The earliest sign is a gravel-like sound in the pipe. Technically, if downstream pressure falls near the vapor pressure of the liquid, you are in the danger zone and need to re-evaluate.

Q4: Can I reduce pressure drop by just installing a larger valve?

Not necessarily. Installing a valve larger than your pipe requires expanders and reducers. These fittings introduce their own turbulence and pressure loss, often negating the benefit of the larger valve’s high Cv.

Q5: What’s the best valve design to minimize pressure loss?

Triple Offset Butterfly Valves. These high-performance valves feature aerodynamic disc profiles and clear the flow path more effectively than concentric rubber-lined valves, offering the lowest resistance in critical applications.