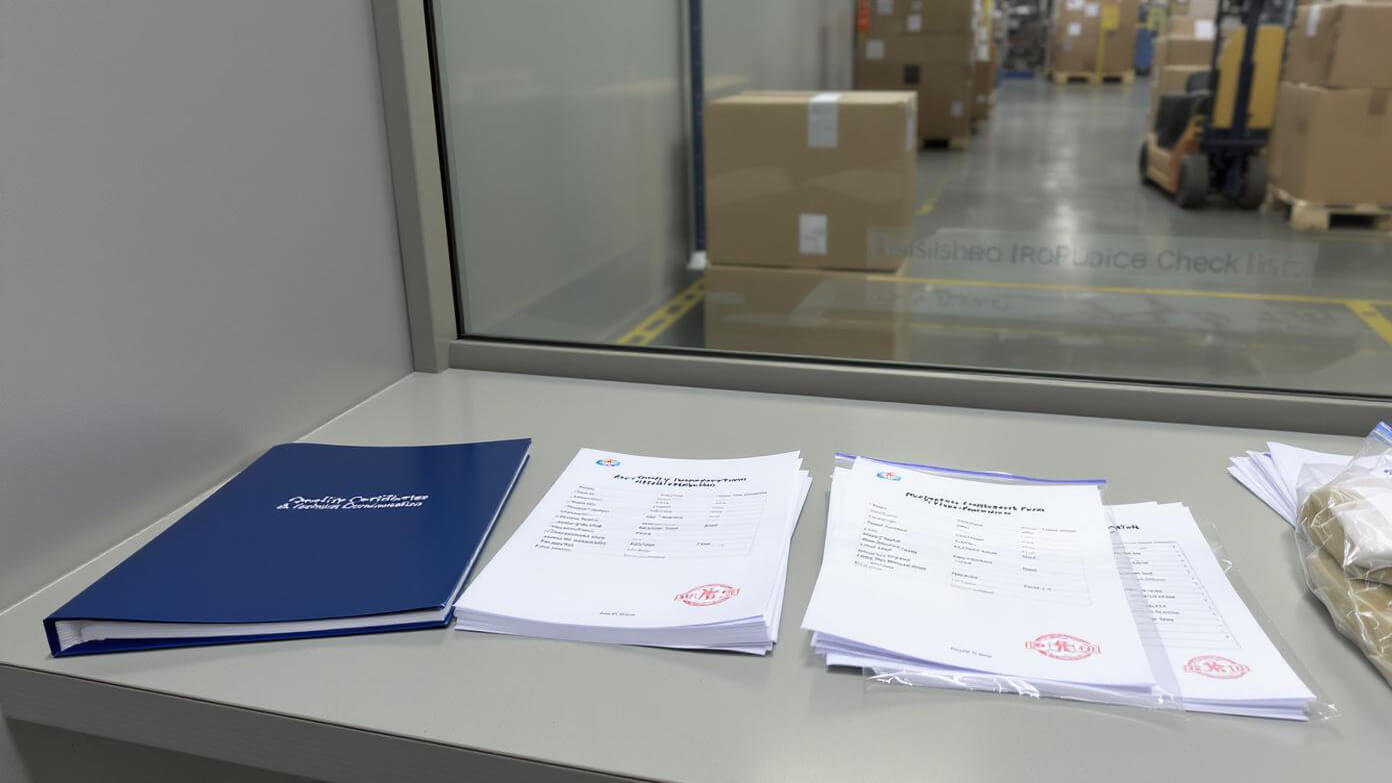

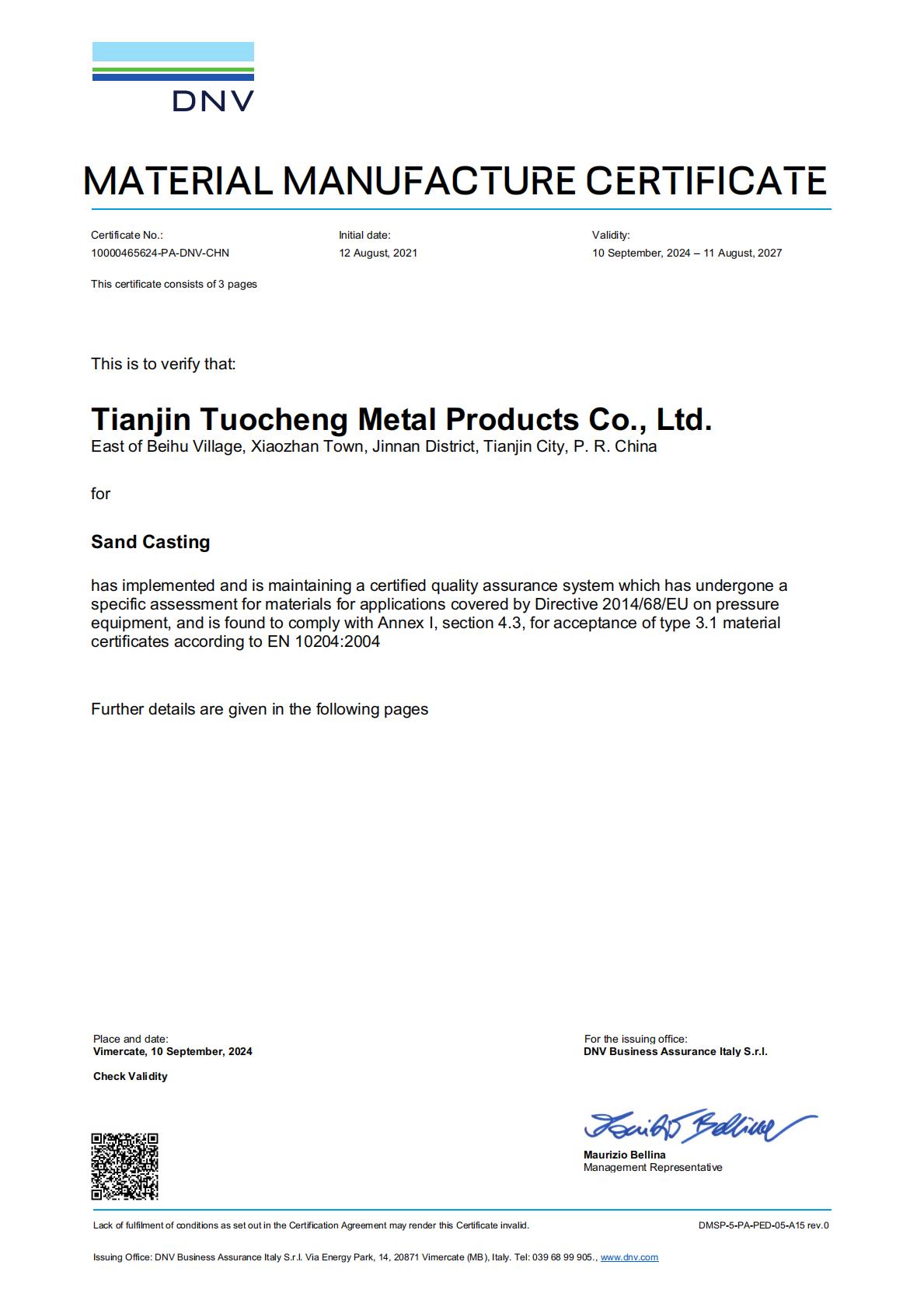

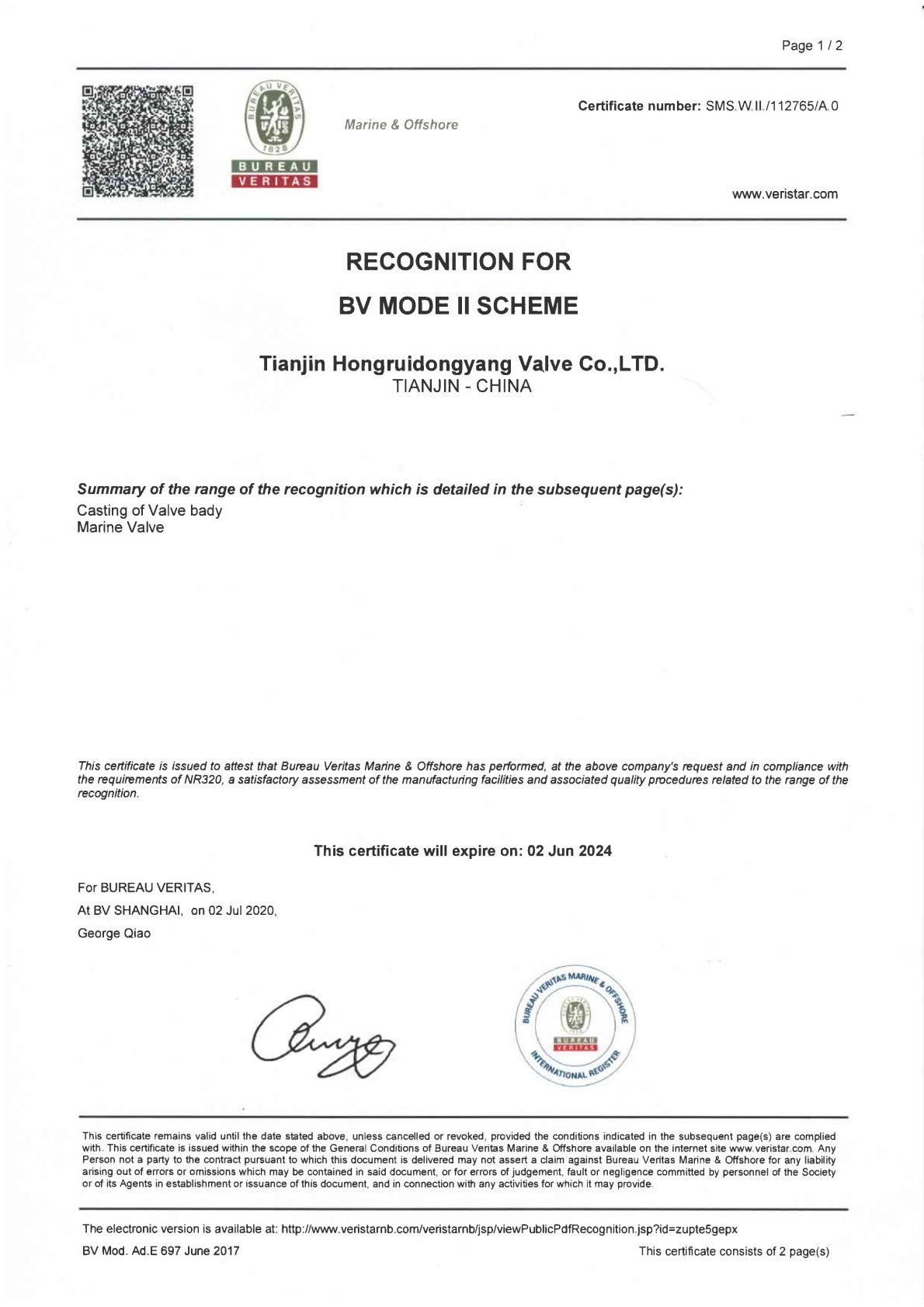

Material Verification Systems

Incoming material inspection covers chemical composition and mechanical properties against ASTM/EN/DIN; batch records are linked to serialised production orders to ensure consistent conformity for plug‑valve manufacturing.