Introduction

You are managing a complex industrial piping system where inconsistent flow control is driving up energy costs and causing operational headaches. Leaks, inefficient throttling, and bulky equipment are not just annoyances; they are draining your budget and compromising safety standards daily. Enter the butterfly valve—a compact, quarter-turn solution designed to revolutionize how you define butterfly valve efficiency and reliability in modern infrastructure.

How to Define Butterfly Valve Basics

What Is This Device?

A butterfly valve is a quarter-turn rotational valve specifically engineered to stop, regulate, or start fluid flow with precision. The “butterfly” concept refers to the metal disc mounted on a rod, which acts as the primary closure element.

- Regulates flow

- Isolates fluids

- Quarter-turn operation

But here is the interesting part…

Why Is It Called That?

The name stems from the visual similarity to a butterfly, as the disc creates a “wing-like” motion when it pivots 90 degrees on the stem. Unlike ball valves, you will notice that the disc is always present in the flow path, which influences pressure dynamics.

- Disc resembles wings

- Stem acts as the body

- Rotates 90 degrees

Key Takeaway: Basic Definition

You should grasp that this valve offers a lightweight, low-cost alternative to bulky gate valves. It provides a balance of quick operation and space-saving design for your piping needs.

| Feature | Description |

|---|---|

| Motion | Rotary (Quarter-turn) |

| Disc Position | Always in flow path |

| Primary Use | Isolation and Regulation |

Analysis: This table highlights that while the mechanism is simple, the constant presence of the disc is a defining characteristic you must consider for pressure drop.

Define Butterfly Valve Origins & History

When Was It Invented?

The technology traces its roots back to the 1930s in the USA, evolving from James Watt’s early steam engine prototypes. It quickly replaced ball valves in the petroleum industry because it offered a more cost-effective and easier-to-install solution.

- 1930s US Invention

- 1950s Japan introduction

- Post-WWII synthetic rubber boom

Now, let’s look at how it evolved…

How Has It Evolved?

The industry shifted from simple low-pressure designs to high-performance models utilizing synthetic rubbers and robust metal seats. Since the 1970s, the technology expanded into China and global markets, driving mass adoption across diverse sectors.

- Material science advances

- High-pressure adaptation

- Global adoption

Key Takeaway: Historical Context

You can see that modern butterfly valves are the result of decades of material engineering. They have evolved from simple dampers to critical high-pressure safety devices.

| Era | Key Development |

|---|---|

| 18th Century | Steam engine prototypes |

| 1930s | Invention in USA |

| Post-WWII | Synthetic seal introduction |

Analysis: The historical trajectory demonstrates that material advancements in sealing technologies were the primary driver for the valve’s widespread industrial adoption.

Define Butterfly Valve Core Components

What Parts Make It Work?

Four main parts define the system: the body fits between flanges, while the stem connects the actuator to the disc. The disc acts as the closure element, and the seat ensures a tight seal against the valve body.

- Body (Wafer/Lug)

- Disc (The closure element)

- Stem (Transmission rod)

You might be wondering about the seal…

How Do Actuators Fit In?

The actuator is the mechanism that drives the stem, ranging from simple manual levers to complex electric or pneumatic systems. Automation is key for your facility if you require precise remote flow control and monitoring.

- Manual levers

- Gearboxes

- Pneumatic/Electric

Key Takeaway: Component Function

Understanding these components ensures you can identify wear points like the seat or packing. Proper knowledge of the stem and disc connection prevents operational failures.

| Component | Function |

|---|---|

| Disc | Stops/Starts flow |

| Seat | Prevents leakage |

| Stem | Transmits torque |

Analysis: The synergy between the seat and the disc is the most critical factor for preventing leakage, making component quality essential for your system’s integrity.

How to Define Butterfly Valve Operation

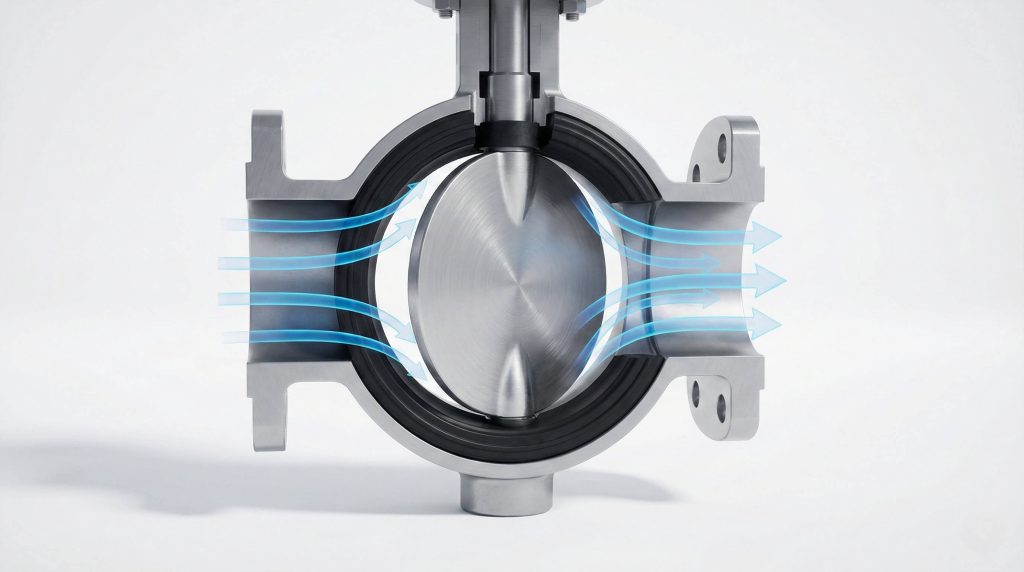

How Does It Control Flow?

The valve operates on a quarter-turn principle, meaning a simple 90-degree rotation moves it from fully open to fully closed. When open, the disc aligns parallel to the flow; when closed, it sits perpendicular to block the line.

- 0° = Closed

- 90° = Open

- Intermediate = Throttling

But consider this restriction…

Can It Regulate Flow?

Yes, you can use it for throttling, but it is generally limited to low differential pressures to avoid damage. Be warned that extensive use for flow modulation can lead to cavitation risks and rapid seat wear.

- Limited throttling range

- Risk of cavitation

- Non-linear flow characteristic

Key Takeaway: Operational Logic

You gain the benefit of rapid actuation compared to multi-turn valves. However, you must be cautious about pressure drops since the disc remains in the flow path.

| State | Disc Orientation | Flow Status |

|---|---|---|

| Open | Parallel to pipe | Maximum |

| Closed | Perpendicular | Blocked |

| Throttling | Angled (e.g., 45°) | Partial |

Analysis: Operational efficiency relies heavily on accurate actuator calibration, as even slight misalignments in the disc angle can significantly alter flow rates.

Define Butterfly Valve Types & Designs

What Is a Concentric Design?

This zero-offset design features a centered stem and disc, which is the standard for basic applications. The soft seat provides the seal, making it a cost-effective choice for low-pressure environments.

- Centered stem

- Soft seat (Rubber/EPDM)

- Low pressure use

For tougher environments, look at this…

What Are Eccentric Valves?

Eccentric valves include double and triple offset designs that displace the stem to reduce friction and wear. These offsets allow for metal seats, enabling the valve to handle high-pressure and high-temperature applications reliably.

- Double Offset (High performance)

- Triple Offset (Bubble-tight)

- Metal-to-metal sealing

Key Takeaway: Choosing Designs

You need to match the offset type to your pressure requirements. Use concentric for water, but upgrade to triple offset for steam or chemicals to ensure safety.

| Type | Sealing | Best Application |

|---|---|---|

| Concentric | Soft | Water/HVAC |

| Double Offset | High-Perf | Oil & Gas |

| Triple Offset | Metal | Extreme Temp/Pressure |

Analysis: While concentric valves offer the lowest upfront cost, eccentric designs provide superior longevity and sealing performance in harsh industrial environments.

Define Butterfly Valve Industrial Uses

Where Are They Common?

You will frequently see these in major sectors like Water Treatment, Oil & Gas, and Power Generation. They are critical in large-diameter piping systems where minimizing weight and space is a priority.

- Water Distribution

- Wastewater Treatment

- Petroleum Refining

Even in cleaner sectors…

Are They Used in Food?

Yes, they are widely used in Food & Beverage and Pharmaceuticals due to their cleanability. Hygienic designs with specific FDA-approved seat materials are required to meet strict sanitary standards.

- Dairy processing

- Brewing

- Pharmaceutical flows

Key Takeaway: Versatility

You will find these valves in almost every sector handling fluids. Their compact footprint makes them the top choice for tight spaces in HVAC and marine systems.

| Industry | Typical Usage |

|---|---|

| HVAC | Chilled/Hot Water |

| Chemical | Corrosive Fluids |

| Marine | Ballast Systems |

Analysis: The ubiquity of this valve across diverse sectors proves its adaptability, provided you select the correct body and seat materials for the specific medium.

Define Butterfly Valve Pros and Cons

Why Should You Choose Them?

The main benefits include their lightweight structure, compact footprint, and cost-effectiveness compared to other valve types. They act fast and require significantly less structural support than heavy gate valves.

- Space-saving

- Low cost

- Fast actuation

However, there is a catch…

What Are the Downsides?

Disadvantages include the pressure drop caused by the disc always being in the flow and the inability to use “pigs” for cleaning lines. You must also be aware of their susceptibility to cavitation during throttling.

- Disc obstructs flow

- Not piggable

- Throttling limits

Key Takeaway: Cost vs. Performance

You save money and space with butterfly valves, but you compromise slightly on flow capacity. They are ideal unless you need a full-bore opening for cleaning tools.

| Pros | Cons |

|---|---|

| Compact & Light | Pressure Drop |

| Low Maintenance | Cleanability Issues |

| Quick 90° Turn | Cavitation Risk |

Analysis: The trade-off between cost-efficiency and hydraulic performance makes these valves excellent for general service but less suitable for pipelines requiring regular pigging operations.

How to Define Butterfly Valve Selection

How Do Pressure Ratings Matter?

Pressure handling capability is dictated by the design, distinguishing between concentric and eccentric models. You must specify high-performance double or triple offset valves for high-pressure systems to prevent blowout.

- Low Pressure: Concentric

- High Pressure: Triple Offset

- Vacuum ratings

Next, consider the media…

How to Pick Materials?

You must match the valve materials to your fluid properties to prevent failure. Corrosive chemicals require stainless steel or PTFE, while standard water systems perform well with cast iron and EPDM.

- Body: Cast Iron vs. Steel

- Seat: EPDM vs. PTFE/Metal

- Disc: Stainless vs. Bronze

Key Takeaway: Selection Criteria

You must evaluate the media, pressure, and temperature before buying. A mismatch here leads to rapid seat degradation and valve failure.

| Factor | Consideration |

|---|---|

| Media | Corrosion/Abrasion |

| Temperature | Seat Material Limit |

| Operation | Manual vs. Automated |

Analysis: Successful valve selection is less about the valve itself and more about accurately mapping the valve’s specifications to the chemical and physical properties of the process fluid.

Define Butterfly Valve Install & Care

How Should You Install It?

Inspect flanges and align piping carefully before you begin the installation process. Crucially, keep the disc slightly open (10°–20°) to prevent seat damage when you tighten the bolts.

- Clean flange faces

- Disc partially open

- Cross-pattern tightening

Once it is installed…

What Is the Maintenance Routine?

Establish a strict schedule: cycle the valve monthly if it is inactive to prevent sticking. Lubricate the stem regularly and inspect the packing gland for any signs of leaks.

- Monthly cycling

- Stem lubrication

- Visual leak checks

Key Takeaway: Longevity

Your valve will last longer if you ensure proper alignment during installation. Never force the valve into a gap; this distorts the seat and causes immediate leaks.

| Task | Frequency |

|---|---|

| Visual Inspection | Monthly |

| Cycle Valve | Monthly (if inactive) |

| Lubrication | Semi-Annually |

Analysis: Most butterfly valve failures are traced back to improper installation, specifically flange misalignment or closing the disc fully during the bolting process.

Define Butterfly Valve Troubleshooting

Why Is It Leaking?

Leaks often stem from worn seats, improper installation torque, or debris trapped between the disc and seat. You should also check for stem packing failure as a secondary cause of external leakage.

- Worn seat/gasket

- Debris obstruction

- Loose flange bolts

If it won’t move…

Why Is the Disc Stuck?

High torque or sticking issues usually result from a lack of lubrication or corrosion on the stem. Thermal expansion can also bind the disc if the temperature exceeds the valve’s design limits.

- Stem corrosion

- Actuator failure

- Thermal binding

Key Takeaway: Problem Solving

You can solve most issues by cleaning the sealing surfaces and checking bolt torque. If the handle forces are excessive, check the actuator before blaming the valve body.

| Symptom | Likely Cause | Solution |

|---|---|---|

| Leakage | Worn Seat | Replace Seat |

| Hard to Turn | Corroded Stem | Lubricate/Clean |

| Vibration | High Velocity | Adjust Flow |

Analysis: Systematic troubleshooting usually reveals that external factors, such as debris or improper actuator sizing, are more responsible for performance issues than inherent valve defects.

Conclusion

We have addressed the challenges of inefficient flow control and how butterfly valves offer a compact, cost-effective solution for isolation and regulation. By understanding the types, components, and maintenance needs, you are now equipped to make informed decisions that reduce downtime and operational costs. Embracing the right valve technology is the first step toward empowering efficient industrial futures with reliable, leak-free systems.

FAQ

- Can I Use Butterfly Valves in Corrosive Environments?

Yes, providing you select the correct materials. Research indicates that using stainless steel bodies with PTFE seats or high-performance triple offset valves ensures resistance to aggressive chemicals and acids. - What’s the Best Type for High-Pressure Systems?

The Triple Offset Butterfly Valve is the superior choice. Unlike concentric types, its metal-to-metal sealing and cam-action design allow it to withstand high pressures and temperatures without seat degradation. - How Do I Know If My Valve Needs Maintenance?

You will notice signs like seal leakage or increased operating torque. Regular inspections revealing wear on the seat or stiffness in the stem rotation are clear indicators that maintenance or lubrication is required immediately. - Can Butterfly Valves Be Used for Throttling?

Yes, but with limitations. While they can regulate flow, prolonged throttling can cause cavitation and wear; double or triple offset valves are better suited for this than standard concentric designs. - Why Is the Disc Position Important During Installation?

It is critical to keep the disc slightly open (about 10-20 degrees). Installing with the disc fully closed can cause the seat to distort when flanges are tightened, leading to immediate leakage or damage.