Introduction

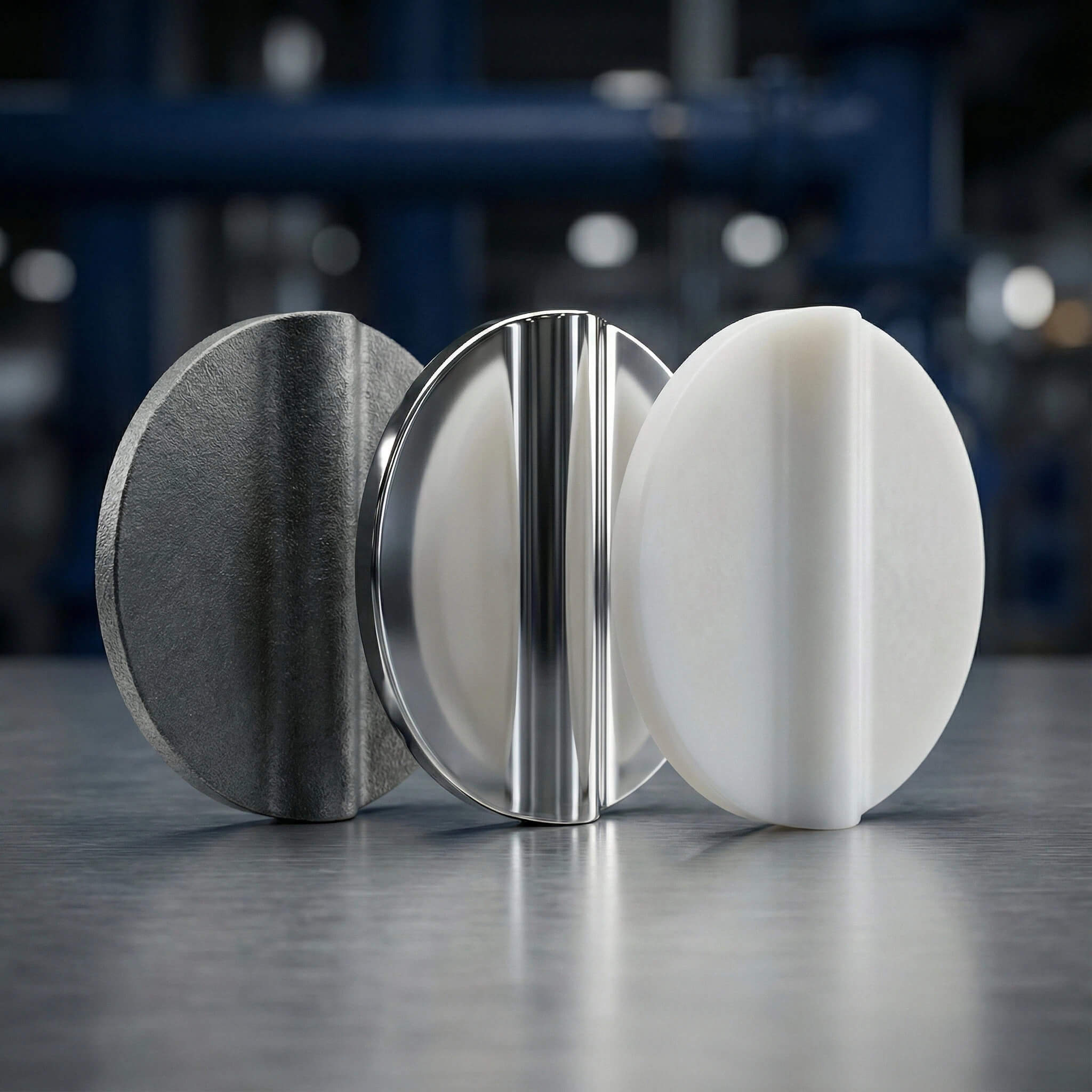

In critical fluid control systems, the butterfly valve disc serves as the primary point of failure, constantly besieged by high-velocity flow, chemical attacks, and extreme pressure differentials. A single material miscalculation here often triggers catastrophic system shutdowns, safety hazards, and spiraling maintenance costs that far exceed the initial price of the valve. Unfortunately, many engineers default to standard ductile iron or generic stainless steel without rigorously analyzing the specific media interaction or thermal cycling involved. This oversight frequently leads to “hidden” degradation mechanisms—such as chloride stress corrosion cracking or galvanic corrosion—which compromise seal integrity and cause leakage long before scheduled maintenance windows. This comprehensive guide delivers an expert analysis of butterfly valve disc materials, from standard ferrous metals to exotic alloys and lined options. By examining mechanical properties, chemical compatibility, and real-world failure scenarios, we enable you to make data-driven decisions that maximize durability and optimize your total cost of ownership.

The Critical Role of Butterfly Valve Disc Materials in System Integrity

The disc acts as the heart of the valve, enduring the highest mechanical stress while modulating flow. Understanding its interaction with both the valve seat and the process media is the absolute foundation of reliable system design.

How do fluid dynamics affect disc stress?

You must consider that as fluid velocity increases, the drag force on the disc rises exponentially, necessitating materials with higher yield strengths to prevent deformation. The geometry of the disc—whether concentric, double-offset, or triple-offset—directly influences how the material handles stress under high-velocity flow conditions.

- Key Dynamic Stress Factors:

- Flow Velocity: High speeds can cause flutter in weaker materials, leading to fatigue failure.

- Pressure Drop: Significant differentials across the disc require materials with high flexural modulus.

- Cavitation Potential: Sudden pressure drops can cause micro-jets that pit softer materials like standard aluminum.

But what if the fluid contains particulates? Turbulence accelerates material degradation through a synergistic effect known as erosion-corrosion, particularly in throttling applications where local velocities are highest. Hardened materials or specialized coatings become essential here to prevent the rapid scouring of the disc edge.

Why is sealing compatibility non-negotiable?

Crucially, the relationship between the rigidity of the disc material and the elasticity of the seat (EPDM, NBR, PTFE, or Metal) is vital for ensuring zero-leakage shutoff. If the disc material is too soft, it may deform under the seating torque, while a surface that is too rough will quickly abrade the soft seat liner.

Key Takeaway:

Selecting the right disc material is not just about chemical resistance; it is about ensuring the component has the mechanical integrity to withstand dynamic hydraulic forces without compromising the seal. By prioritizing the strength-to-weight ratio and surface hardness, you ensure the valve remains operable and leak-free through thousands of cycles.

Standard Ferrous Materials: Types of Ductile Iron and Carbon Steel

For general industrial applications where cost-efficiency is paramount, ferrous materials remain the industry standard. However, their limitations must be strictly observed to prevent premature oxidation and system contamination.

When is Ductile Iron the right choice?

Ductile Iron (DI) is the workhorse of the industry, offering high mechanical strength and excellent impact resistance at a low price point. It is typically the best choice for municipal water systems, HVAC loops, and inert gas lines where the media is non-corrosive and temperatures are moderate.

- Ductile Iron Specifications:

- Strength: Comparable to carbon steel but with better vibration damping.

- Cost-Efficiency: Lowest initial cost for large diameter valves.

- Surface Treatment: Almost always requires Nickel plating or Epoxy coating to prevent rust.

How do WCB and LCC Carbon Steel grades differ?

If your application involves higher pressures or extreme temperatures, you might need to upgrade to Carbon Steel. WCB (Wrought Carbon B) is the standard for high-temperature oil and gas applications, while LCC (Low-Temperature Carbon Steel) provides superior toughness in sub-zero environments where iron would become brittle.

What are the protective requirements for ferrous discs?

Since neither ductile iron nor carbon steel possesses inherent corrosion resistance, you must rely on secondary protection mechanisms. Applying a fusion-bonded epoxy (FBE) or nylon coating is mandatory when handling anything other than hydrocarbons to prevent immediate oxidation.

Summary Comparison of Ferrous Materials

| Material Grade | Temp Range | Corrosion Resistance | Relative Cost | Primary Limitation |

|---|---|---|---|---|

| Ductile Iron (DI) | -20°C to 80°C | Low (Needs Coating) | $ | Poor acid resistance; rusts easily. |

| Carbon Steel (WCB) | -29°C to 425°C | Low (Needs Coating) | $$ | Poor resistance to corrosive media. |

| Carbon Steel (LCC) | -46°C to 345°C | Low (Needs Coating) | $$ | Specialized for low-temp toughness. |

Expert Analysis: While ferrous materials are cost-effective, reliance on coatings creates a single point of failure; if the coating is scratched by debris, the underlying metal will corrode rapidly, causing the coating to delaminate and the seat to tear.

Key Takeaway:

Leveraging ferrous materials like Ductile Iron or Carbon Steel offers significant cost savings for non-corrosive utility lines. However, you must ensure that the operating environment stays strictly within the temperature and chemical limits of the protective coatings used, or risk rapid failure.

Stainless Steel Properties and Duplex Variants for Corrosive Environments

When media becomes aggressive or hygiene is critical, stainless steel becomes the baseline requirement. This section breaks down the nuances between grades to prevent over-specification or under-performance.

304 vs. 316 Stainless Steel: Which grade suits your needs?

The distinction between 304 and 316 stainless steel often determines the lifespan of the valve in wet environments. While 304 (CF8) is adequate for fresh water and air, 316 (CF8M) contains molybdenum, which provides essential resistance to pitting in chloride-rich environments like brackish water or industrial effluents.

- Stainless Steel Grade Breakdown:

- 304 (CF8): Excellent for oxidizing acids and general sanitation; poor in salt.

- 316 (CF8M): The industry standard for chemical processing and wastewater.

- 316L: Low carbon version to prevent carbide precipitation during welding or high-heat use.

Why choose Duplex or Super Duplex for extreme stress?

But what if 316 is not enough? In desalination and hot brine applications, standard austenitic stainless steels often fail due to Stress Corrosion Cracking (SCC), whereas Duplex (e.g., 2205) and Super Duplex steels offer a microstructure that doubles yield strength and effectively blocks SCC propagation.

How do hygienic applications impact material choice?

In food, beverage, and pharmaceutical sectors, the material must prevent bacterial harbor rather than just resisting corrosion. You should specify polished 316L stainless steel discs which allow for effective Clean-in-Place (CIP) protocols and ensure no microscopic crevices exist for pathogen growth.

Stainless Steel Family Performance Matrix

| Material | Pitting Resistance (PREN) | Yield Strength (MPa) | Typical Application |

|---|---|---|---|

| 304 SS | ~18 | 205 | Freshwater, Food, Air |

| 316 SS | ~24 | 205 | Chemicals, Wastewater |

| Duplex (2205) | ~35 | 450 | Desalination, Offshore |

| Super Duplex | >40 | 550 | Hot Brine, Acid Leaching |

Expert Analysis: The jump from 316SS to Duplex increases cost by roughly 30-50%, but in high-chloride environments (>1000ppm) above 60°C, it is effectively the only way to prevent catastrophic cracking failure.

Key Takeaway:

Stainless steel is the versatile champion of the valve world, but “stainless” is not a monolith. By precisely matching the grade—304 for utilities, 316 for general chemicals, and Duplex for high-stress chlorides—you ensure system longevity without wasting budget on unnecessary alloy content.

Non-Ferrous and Exotic Alloys: Aluminum Bronze, Titanium, and Nickel

For extreme environments involving seawater, strong acids, or high-velocity slurries, standard steels are insufficient. Exotic alloys provide targeted resistance properties that ferrous metals simply cannot match.

Why is Aluminum Bronze the marine standard?

Aluminum Bronze (AlBr) is virtually mandatory for seawater applications because it forms a self-healing alumina layer that resists both corrosion and bio-fouling. Unlike stainless steel, it is inherently resistant to crevice corrosion in stagnant seawater, making it the superior choice for ballast and cooling water systems.

- Advantages of Aluminum Bronze:

- Anti-Fouling: Copper content naturally repels algae and barnacle growth.

- Non-Sparking: Safe for use in explosive atmospheres on oil rigs.

- Seawater Durability: Outlasts coated iron by years in saline conditions.

When are Nickel Alloys like Hastelloy and Inconel required?

When you are handling hot sulfuric or hydrochloric acids, iron and standard stainless steel will dissolve in days. Nickel alloys like Hastelloy C-276 or Inconel 625 provide unparalleled resistance to reducing acids and maintain structural integrity at temperatures exceeding 600°C, crucial for power generation and chemical synthesis.

Can Titanium Alloys solve weight and corrosion issues?

Titanium offers an exceptional strength-to-weight ratio and is immune to corrosion in oxidizing chloride environments, such as hypochlorite bleach plants. While expensive, its low density significantly reduces the torque required to actuate large valves, potentially lowering the cost of the actuator itself.

Key Takeaway:

Exotic alloys like Aluminum Bronze and Hastelloy are engineered for environments where failure is not an option. While the upfront cost is higher, their ability to withstand specific chemical attacks (seawater, acids) where other metals dissolve makes them the most economical choice over the system’s lifecycle.

Lined and Non-Metallic Options: Comparison of PTFE and Thermoplastics

In applications where chemical purity is absolute or the media is too aggressive for any metal, lined and plastic discs offer a distinct solution. These materials prioritize chemical inertness over raw mechanical strength.

How do PTFE lined discs ensure chemical purity?

PTFE (Teflon) linings provide a continuous, non-porous barrier that protects the metal core from virtually all acids, alkalis, and solvents. This is critical not only for preventing corrosion but also for maintaining the purity of the media, such as in semiconductor manufacturing or ultrapure water systems.

- Benefits of PTFE/PFA Linings:

- Universal Resistance: Inert to almost all industrial chemicals.

- Low Friction: Drastically reduces operating torque requirements.

- Non-Stick: Prevents buildup of glues, slurries, or food pastes.

Are solid thermoplastics viable for industrial pressure?

Solid thermoplastic discs (UPVC, PP, PVDF) offer a lightweight, cost-effective alternative for lower pressure chemical lines. While they provide excellent corrosion resistance without the need for a metal core, you must be aware that their structural limit is generally capped at 150 psi (10 bar), making them unsuitable for high-pressure transmission.

What are the temperature limits for non-metallic discs?

The primary vulnerability of non-metallic options is thermal instability; PTFE and plastics are prone to “cold flow” or creep at elevated temperatures. You must carefully evaluate the pressure-temperature rating, as a PTFE lined disc that works at 20°C may fail catastrophically at 150°C under the same pressure load.

Key Takeaway:

Lined and non-metallic discs are the ultimate problem solvers for ultra-corrosive or high-purity applications. By using these materials, you eliminate the risk of metallic contamination and corrosion, provided you strictly adhere to their pressure and temperature limitations to prevent physical deformation.

Key Engineering Factors Driving Material Selection Strategy

Selecting the right material is a multi-variable equation that requires balancing chemical needs with physical realities. This section outlines the hierarchy of decision-making criteria you should follow.

How critical is chemical compatibility in selection?

The non-negotiable first step is cross-referencing your specific media concentration and temperature against corrosion charts. You must consider not just the primary fluid, but also cleaning agents (CIP fluids) and potential impurities that could trigger unexpected reactions like galvanic corrosion.

- Selection Hierarchy:

- Chemical Compatibility: Can it survive the fluid?

- Temperature Limits: Will it creep or become brittle?

- Mechanical Strength: Can it handle the pressure drop?

- Abrasion Resistance: Will particulates wear it away?

What role does abrasion resistance play in slurries?

If your media contains solids, chemical resistance alone is insufficient; soft materials like PTFE or standard stainless steel will erode rapidly. In these cases, you need to prioritize hardness, opting for materials like Aluminum Bronze or coated Ductile Iron, or even specialized ceramic-lined valves for extreme abrasive slurries.

How do temperature extremes dictate material limits?

Temperature dictates the mechanical behavior of the disc; low temperatures risk embrittlement (requiring LCC Steel or 316 SS), while high temperatures risk creep and strength loss (requiring Carbon Steel or Inconel). You must ensure the material maintains its yield strength at the maximum design temperature, not just the operating average.

Key Takeaway:

A successful material selection strategy requires a holistic view of the process conditions. By systematically evaluating chemical, thermal, and mechanical stressors, you can filter out unsuitable materials and identify the candidate that offers the necessary safety margin for your specific operation.

Comparative Cost-Benefit Analysis and Performance Trade-offs

A side-by-side evaluation is essential to assist procurement and engineering teams in balancing budget constraints with performance requirements. This analysis reveals where spending more upfront yields massive long-term savings.

How does initial cost compare to total lifespan value?

While a Ductile Iron disc is cheap, its lifespan in corrosive water might be only 2 years compared to 10+ years for a Duplex Stainless disc. When you factor in the cost of downtime, labor for replacement, and the risk of leakage, the “expensive” alloy often emerges as the significantly cheaper option over a 5-year period.

What are the performance trade-offs between materials?

Every material choice involves a compromise; for instance, Titanium offers perfect corrosion resistance but is poor against abrasion, while hardened steels resist abrasion but corrode easily. You must identify the primary failure mode of your system—be it corrosion, erosion, or fatigue—and select the material that is strongest against that specific threat.

- Common Performance Trade-offs:

- Titanium: Exceptional chemical resistance vs. Poor abrasion resistance.

- Hardened Carbon Steel: High abrasion resistance vs. Low corrosion resistance.

- PTFE Lining: Superior chemical inertness vs. Lower pressure capability.

Master Comparison Matrix

| Material | Corrosion Resistance | Mech. Strength | Abrasion Resistance | Relative Cost | Primary Application |

|---|---|---|---|---|---|

| Ductile Iron | Low (Needs Coating) | High | Good | $ | Water, HVAC, Gas |

| 316 Stainless | High (Good in Chlorides) | High | Moderate | $$$ | Chemical, Food, Industrial |

| Aluminum Bronze | Excellent (Seawater) | High | Excellent | $$ | Marine, Desalination |

| Duplex SS | Very High (Resists SCC) | Very High | Good | $$$$ | Offshore, Oil & Gas |

| PTFE Lined | Superior (Universal) | Low (Lining dependent) | Low | $$$ | Aggressive Acids, Ultrapure |

| Titanium | Exceptional | High | Moderate | $$$$$ | Bleach, Aerospace |

Expert Analysis: The most common error in valve specification is over-specifying for benign applications (wasting budget) or under-specifying for intermittent corrosive conditions (risking safety). Always match the material properties strictly to the worst-case process conditions.

Key Takeaway:

Cost-benefit analysis proves that the lowest bid is rarely the best value for critical valves. By investing in the correct material for your specific degradation risks, you effectively purchase insurance against unplanned downtime and frequent replacements.

Industry-Specific Applications and Failure Prevention Case Studies

Theory is useful, but real-world examples demonstrate the tangible consequences of material selection. These case studies highlight common pitfalls and the solutions that corrected them.

Case Study: How Aluminum Bronze saved a marine system?

A commercial vessel initially utilized 316 Stainless Steel valves for its seawater ballast system, but experienced rapid pitting and seal failure within 6 months due to crevice corrosion in stagnant water.

- The Fix: Replacing the discs with Aluminum Bronze (C95800) provided the necessary resistance to chloride attack and bio-fouling.

- Result: The new valves extended the service interval to over 5 years, eliminating dry-dock repairs related to valve failure.

Case Study: Solving sticky buildup with PTFE coatings?

A food flavor producer faced chronic issues with sticky powder buildup on standard stainless steel discs, causing the valves to jam and requiring frequent manual cleaning.

- The Fix: They switched to Stainless Steel discs with a PFA/PTFE coating.

- Result: The non-stick properties allowed the powder to slide off the disc, ensuring unobstructed flow and allowing for automated self-cleaning during cycles.

Case Study: Why did Titanium fail in acidic vapor?

In a chemical plant, Titanium valves were installed to handle an acidic vapor stream, chosen for their chemical resistance, yet they failed within a month.

- The Failure: The stream contained fine abrasive particulates traveling at high velocity; while chemically resistant, the Titanium was too soft to resist the erosion.

- Result: The plant had to switch to Ceramic-lined valves to handle the abrasion, proving that chemical compatibility does not equal erosion resistance.

Key Takeaway:

These case studies illustrate that material success is application-specific. Whether it’s utilizing Aluminum Bronze for the ocean or PTFE for sticky foods, analyzing the specific interaction between the media and the material is the only way to prevent costly failures.

Conclusion

The selection of butterfly valve disc material is a critical engineering decision that dictates the safety, efficiency, and profitability of fluid systems. While standard Ductile Iron serves well for general utility, the specific demands of chemical, marine, and high-pressure environments require a nuanced approach involving Stainless Steel, Aluminum Bronze, or Exotic Alloys.

By prioritizing fluid compatibility, understanding thermal limits, and analyzing the total cost of ownership rather than just initial price, operators can prevent costly downtime and ensure long-term reliability.

Ready to optimize your valve specifications? Contact our engineering team today for a material compatibility audit tailored to your specific process conditions.

Empowering reliable fluid control worldwide through materials science and engineering excellence.

Frequently Asked Questions (FAQs)

- Can I use 304 Stainless Steel for seawater applications?

No, you should generally avoid 304 Stainless Steel for seawater. While it has moderate corrosion resistance, it is highly susceptible to pitting and crevice corrosion in chloride-rich environments; 316 Stainless Steel is the minimum standard, but Aluminum Bronze or Duplex Stainless Steel are far superior choices for long-term reliability. - What is the best material for handling abrasive slurries?

The best choice depends on the chemical nature, but generally, hardened materials like Coated Ductile Iron or Aluminum Bronze are preferred over standard stainless steel. For extreme abrasion, specialized ceramic linings or Stellite-coated discs are necessary to prevent the rapid erosion of the sealing edge that occurs with softer metals. - How do I know if I need a PTFE-lined disc or a solid metal disc?

You should choose a PTFE-lined disc if you are handling highly aggressive acids, alkalis, or ultra-pure media that would corrode or be contaminated by metal. However, if your application involves high pressure (above 10 bar) or abrasive particles, a solid metal disc (like Duplex or Hastelloy) is required to maintain structural integrity. - Can Aluminum Bronze discs be used in HVAC systems instead of Ductile Iron?

Yes, and they are often the smarter choice. While Ductile Iron is cheaper, Aluminum Bronze offers significantly better corrosion resistance against the varying water chemistry and glycol mixes found in HVAC loops, preventing the rust formation that often causes iron valves to seize after periods of inactivity. - Why is Duplex Stainless Steel preferred over 316SS in desalination plants?

Duplex Stainless Steel is preferred because it has a dual-phase microstructure that provides double the yield strength of 316SS and superior resistance to Chloride Stress Corrosion Cracking (CSCC). In the hot, high-chloride environment of desalination, standard 316SS is prone to sudden cracking failure, making Duplex the safer and more durable option.