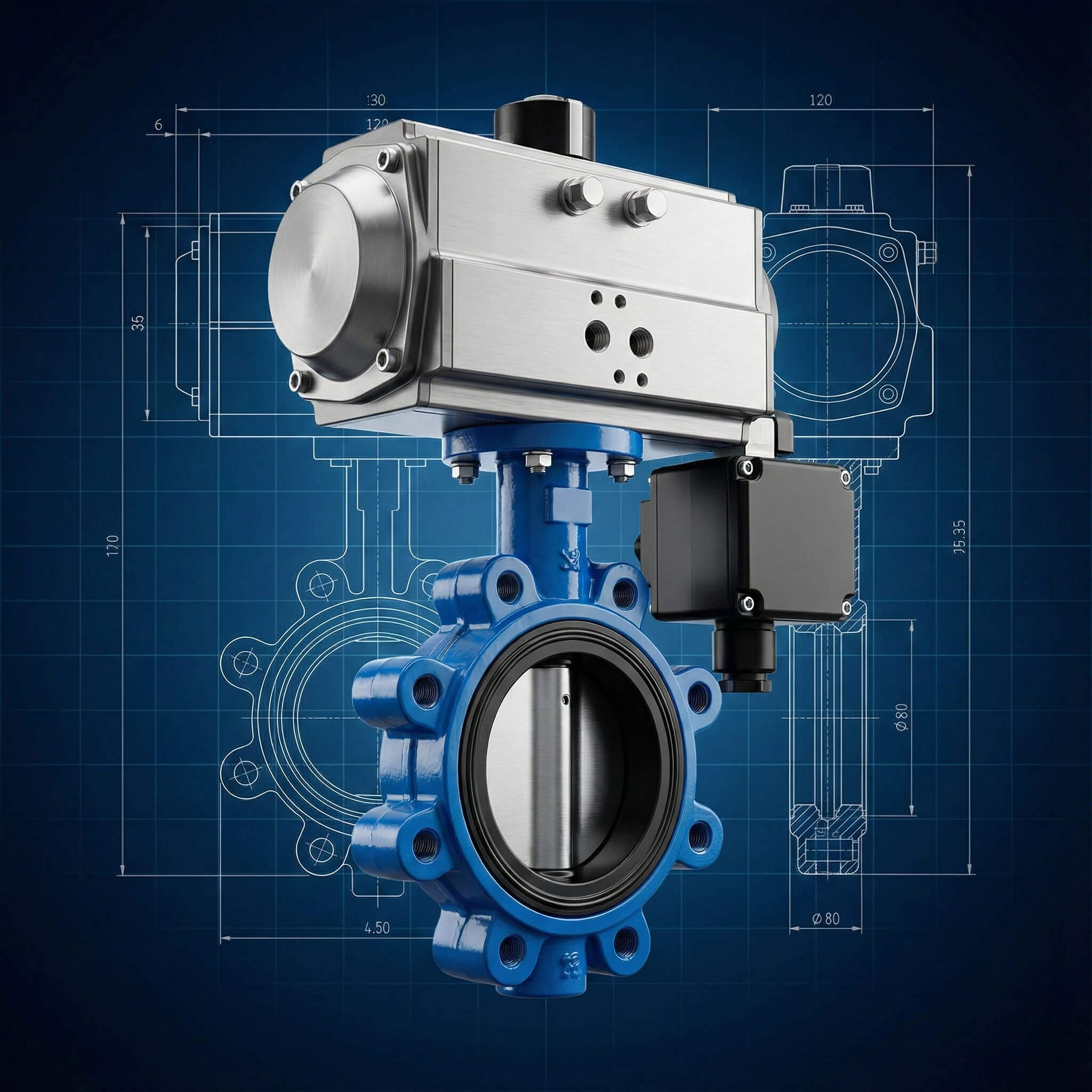

Are you tired of unexpected system downtime caused by unreliable valve automation? In industrial processing and water treatment, a failing actuator can cost you thousands in maintenance and lost production time. RUITO presents the Pneumatic Actuator Operated Butterfly Valve with Solenoid Valve, a precision-engineered solution designed to deliver the stability and DIN-standard compliance your projects demand.

1. What Defines A Solenoid Operated Butterfly Valve?

The Core Mechanism Explained

Here is the deal: This device combines a resilient butterfly valve with a pneumatic actuator and an electric solenoid for precise automated control. It converts electrical signals into mechanical pneumatic energy to regulate flow without manual intervention.

- Pneumatic Actuator (Rack and Pinion).

- Solenoid Valve (NAMUR Interface).

- Butterfly Valve Body (Wafer or Lug).

Why Automation is Essential

You might be wondering why you should upgrade from manual operation. Automation ensures consistent flow regulation and safety in hazardous environments where human access is risky or inefficient.

- Remote operation capability.

- Reduced labor costs.

- Enhanced personnel safety.

Technical Specifications Overview

Let’s look closer at the parameters that define RUITO’s manufacturing capabilities. We adhere to strict ISO and DIN standards to ensure every unit fits your existing piping systems perfectly.

- Pressure: PN10/PN16 (150 PSI).

- Size: DN50-DN600.

- Voltage: 24VDC, 110VAC, 220VAC.

Key Takeaway: Understanding the specs ensures seamless integration into your German engineering projects.

| Parameter | Specification |

|---|---|

| Actuator Type | Double Acting / Single Acting |

| Control Signal | 4-20mA / 1-5V / On-Off |

| Air Supply | 3-8 Bar Compressed Air |

2. How Does The Solenoid Operated Butterfly Valve Work?

The Air Control Principle

It gets better when you understand the efficiency of pneumatic power. The solenoid valve directs compressed air into the actuator chambers, driving the pistons to rotate the valve stem 90 degrees.

- Solenoid receives electrical signal.

- Internal spool shifts air direction.

- Actuator pistons drive the pinion gear.

Signal Processing Logic

Think about this: Your control system’s accuracy depends on how the valve interprets signals. Whether you use a PLC or a simple switch, the solenoid bridges the gap between digital commands and physical movement.

- 24VDC (Standard safety).

- 220VAC (Standard mains).

- Namur Standard Mounting.

Fail-Safe Protection Modes

Don’t forget this crucial safety feature for your critical infrastructure. We offer single-acting actuators that automatically return the valve to a safe position if power or air supply fails.

- Spring Return Close (Normally Closed).

- Spring Return Open (Normally Open).

- Air Tank Backup.

Key Takeaway: Fail-safe modes protect your system integrity during unexpected power outages.

| Mode | Function | Application |

|---|---|---|

| Double Acting | Air to Open / Air to Close | General Control |

| Single Acting (NC) | Spring to Close | Safety Shut-off |

| Single Acting (NO) | Spring to Open | Cooling Systems |

3. Why Buy RUITO Solenoid Operated Butterfly Valve?

Factory Direct Reliability

Here is the truth: Unlike trading companies, RUITO is a 20-year manufacturer, meaning you get direct quality control and lower costs. You gain transparency in production and eliminate middleman markups.

- 96 dedicated employees.

- ISO 9001 certified facility.

- Full traceability of raw materials.

Rigorous Quality Testing

Why does it matter? Because a single leak can jeopardize your project’s success. Every solenoid operated butterfly valve undergoes 100% pressure testing before it leaves our factory floor.

- Hydrostatic shell test (1.5x pressure).

- Air seat seal test.

- Solenoid cycle testing.

Compliance with Global Standards

You need to know that our valves meet the strict requirements of European markets. We design our products to integrate seamlessly with DIN, EN, and ASME standard systems.

- CE Marking.

- WRAS (Water Approval).

- ISO Quality Management.

Key Takeaway: Our factory-direct model ensures you receive certified, high-performance valves without the markup.

| Feature | RUITO Standard | Competitor Avg |

|---|---|---|

| Testing | 100% of Units | Random Sampling |

| Warranty | 12 Months | 6-12 Months |

| Emergency Ship | 72 Hours | 1-2 Weeks |

4. Which Materials Fit A Solenoid Operated Butterfly Valve?

Body Material Selection

Consider this fact: The longevity of your valve depends entirely on choosing the right body material for your environment. We offer robust options ranging from cost-effective iron to durable stainless steel.

- Cast Iron (GG25).

- Ductile Iron (GGG40).

- Stainless Steel (CF8/CF8M).

Sealing for Zero Leakage

Bottom line is: The seat material dictates the valve’s ability to handle temperature and chemicals. We use high-grade elastomers to ensure a bubble-tight seal even after thousands of cycles.

- EPDM (Water/Steam).

- NBR (Oil/Gas).

- VITON (High Temperature).

Corrosive Environment Solutions

Here is the kicker: For aggressive media, standard metals often fail prematurely. RUITO provides PTFE-lined options and specialized coatings to resist chemical attack and extend service life.

- PTFE/PFA Lining.

- Epoxy Coating.

- SS316L Disc.

Key Takeaway: Selecting the correct material combination prevents premature failure and reduces TCO.

| Material | Best Application | Temp Range |

|---|---|---|

| Ductile Iron / EPDM | Water Treatment | -10°C to 120°C |

| SS316 / Viton | Chemical Process | -10°C to 180°C |

| PTFE Lined | Corrosive Acids | -20°C to 200°C |

5. Where To Apply The Solenoid Operated Butterfly Valve?

Water Treatment Efficiency

Picture this scenario: Your municipal water plant requires reliable flow modulation for filtration systems. Our valves provide the durability needed for high-frequency backwash cycles.

- Filtration units.

- Sludge handling.

- Desalination plants.

HVAC and Building Automation

What’s the real story? Efficient climate control relies on the precise regulation of chilled and hot water lines. Solenoid operated valves integrate easily with building management systems for optimal energy use.

- Cooling towers.

- Heat exchangers.

- District heating.

Industrial Process Control

Ready for the best part? Our valves are robust enough to handle the rigorous demands of manufacturing and chemical processing. They ensure process stability in cement, paper, and petrochemical industries.

- Chemical dosing.

- Food & Beverage (Sanitary).

- Pneumatic conveying.

Key Takeaway: From waterworks to factories, these valves are versatile workhorses for fluid control.

| Industry | Common Media | Key Requirement |

|---|---|---|

| Municipal | Potable Water | WRAS Approval |

| HVAC | Glycol/Water | Fast Actuation |

| Chemical | Acids/Alkalis | Corrosion Resistance |

6. How To Install A Solenoid Operated Butterfly Valve?

Pre-Installation Checklist

First things first: Before mounting, verify that the pipeline flanges are clean and aligned to prevent stress on the valve body. Ensure you have the correct solenoid voltage and air pressure available.

- Flange alignment.

- Clean sealing surfaces.

- Correct air supply (4-6 Bar).

Wiring and Connections

Be careful here: Incorrect wiring can burn out the solenoid coil instantly. Follow the provided wiring diagram strictly, ensuring the ground connection is secure for safety.

- Verify voltage matches coil.

- Connect air tubes to Namur ports.

- Test manual override first.

Pneumatic System Setup

Make no mistake: Clean, dry air is vital for the long-term health of the actuator. Install a filter regulator lubricator (FRL) unit upstream to prevent moisture and debris damage.

- Air Filter.

- Pressure Regulator.

- Lubricator (if required).

Key Takeaway: Proper installation prevents 90% of early operational failures.

| Step | Action | Precaution |

|---|---|---|

| 1. Inspect | Check alignment | Do not force bolts |

| 2. Connect | Attach air/power | Verify Voltage |

| 3. Test | Cycle valve | Keep hands clear |

7. Maintaining Your Solenoid Operated Butterfly Valve?

Routine Inspection Schedule

Here is the plan: Schedule a visual inspection every month to check for air leaks or loose bolts. A proactive approach prevents minor issues from becoming major system shutdowns.

- Listen for air leaks.

- Check visual position indicator.

- Inspect flange bolts.

Troubleshooting Common Issues

What if this happens? If the valve fails to open, check the air supply pressure and solenoid coil continuity first. Most issues are external to the valve, such as clogged silencers or low voltage.

- Valve stuck (Check air pressure).

- Solenoid buzzing (Check voltage).

- Leakage (Check seat).

Spare Parts Management

Save your money: Keep a small stock of critical spares to minimize downtime during maintenance. RUITO provides full spare kits for seals and solenoid coils.

- Solenoid Coils.

- EPDM/NBR Seats.

- Actuator Seal Kits.

Key Takeaway: Regular maintenance extends valve life and secures your “Total Cost of Ownership.”

| Component | Maintenance Frequency | Action |

|---|---|---|

| Solenoid | Monthly | Check coil/wiring |

| Actuator | Quarterly | Check for leaks |

| Valve Seat | Annually | Inspect wear |

8. Solenoid Operated Butterfly Valve vs Electric?

Speed of Operation

Let’s compare facts: Pneumatic actuators are significantly faster than electric actuators. A pneumatic unit can close a large valve in roughly one second, whereas electric units may take 10-30 seconds.

- Pneumatic: Instant actuation.

- Electric: Geared motor delay.

- Adjustable speed (Pneumatic).

Cost Effectiveness

Money talks: For sizes above DN50, pneumatic assemblies are generally cheaper than electric alternatives. They also consume less energy, using air pressure rather than constant electricity for holding torque.

- Lower initial purchase price.

- Lower maintenance costs.

- Longer cycle life.

Reliability in Failure

Crucial point here: Pneumatic valves are inherently safer because they can use spring-return technology. Electric valves require expensive battery backups to achieve the same fail-safe capability.

- Pneumatic: Mechanical Spring Return.

- Electric: Battery/Capacitor required.

- Explosion-proof rating (Easier with Pneumatic).

Key Takeaway: Choose pneumatic for speed, safety, and cost efficiency in industrial automation.

| Feature | Pneumatic Solenoid | Electric Motorized |

|---|---|---|

| Actuation Speed | Fast (< 1 sec) | Slow (> 10 sec) |

| Fail-Safe | Simple Spring | Complex Battery |

| Duty Cycle | 100% Continuous | Often Limited |

9. Customizing A Solenoid Operated Butterfly Valve?

OEM and ODM Services

We’ve got you covered: RUITO offers extensive customization to match your brand or specific project requirements. We can modify valve colors, add your logo, and adjust technical parameters.

- Custom paint/colors.

- Laser etched logos.

- Special flange drilling.

Special Accessory Integration

Looking for more? Beyond the standard solenoid, we can integrate limit switches, positioners, and declutchable manual overrides. We deliver a fully assembled and tested package ready for installation.

- Limit Switch Box (APL-210).

- Electro-Pneumatic Positioner (4-20mA).

- Air Filter Regulator.

Fast Delivery Options

Need it fast? We understand that project deadlines are non-negotiable. Our factory maintains a stock of components to ensure we can assemble and ship custom orders in as little as 72 hours.

- Standard Stock: 3-5 Days.

- Emergency: 72 Hours.

- OEM Orders: 15-20 Days.

Key Takeaway: Our customization and speed allow you to meet unique project demands without delay.

| Service | Standard Lead Time | Rush Option |

|---|---|---|

| Stock Items | 5 Days | 24-48 Hours |

| Custom Logo | 10 Days | 5 Days |

| Special Material | 25 Days | 15 Days |

Conclusion

In summary, the solenoid operated butterfly valve is a cornerstone of modern industrial automation, providing the speed, reliability, and safety your projects require. RUITO stands as your trusted global partner, offering 20 years of manufacturing expertise, DIN-compliant quality, and rapid delivery that trading companies simply cannot match. Contact us today to secure your supply chain and experience the RUITO difference.

FAQ Section

Q1: Can I replace the solenoid coil without removing the valve?

Yes, the solenoid coil is designed for easy replacement. You can simply unclip or unscrew the coil from the stem and replace it while the valve remains in the line, provided the power is isolated.

Q2: What’s the best voltage for my solenoid valve?

24VDC is the industrial standard for safety and control integration. However, if you are replacing an existing unit, you must match the voltage of your current control system (110VAC or 220VAC) to avoid damage.

Q3: How do I know if I need a single or double acting actuator?

If your process requires the valve to close automatically during a power failure (fail-safe), you need a Single Acting (Spring Return) actuator. If the valve should stay in its last position upon failure, a Double Acting actuator is sufficient.

Q4: Can I install the valve in a vertical pipeline?

Yes, our pneumatic butterfly valves function perfectly in both vertical and horizontal pipelines. We recommend ensuring the actuator is supported if the valve size is very large to prevent stress on the pipe joints.

Q5: How fast can you ship custom orders?

We maintain a robust stock of components that allows us to assemble and ship standard custom orders (such as specific voltages or limit switches) in as little as 72 hours for emergency requirements.