Managing industrial fluid systems often involves navigating the complexities of pressure drops and seat leakage. When a valve fails to provide a bubble-tight seal, the resulting operational downtime and maintenance costs can quickly spiral out of control. Here is the deal: selecting the wrong flow control component is not just an inconvenience; it is a direct threat to system integrity and plant safety. By utilizing a professional butterfly valve selection guide, you can accurately match mechanical specifications to environmental demands, ensuring long-term reliability and efficient performance across your critical pipelines.

1. Why is a butterfly valve selection guide essential?

A butterfly valve selection guide is essential because it prevents catastrophic system mismatches by aligning technical specifications with specific fluid characteristics. Think about it: choosing a valve based solely on pipe size ignores critical factors like torque requirements and chemical compatibility. Without a structured framework, you risk installing a component that erodes prematurely or fails under high-pressure surges.

Core Selection Factors

Selecting the right valve configuration for end-of-line service or maintenance isolation requires an interrogative approach to your system’s operational limits. This guide helps you evaluate the trade-offs between initial cost and lifecycle maintenance. By following these industry standards, you protect your infrastructure from the “jetting” effects of oversized valves and the high torque of undersized actuators.

Key Takeaway

| Factor | Impact on Selection | System Risk |

|---|---|---|

| Media Type | Dictates seat and disc material | Corrosion/Leakage |

| Pressure Class | Determines offset design | Structural Failure |

| Flow Rate (Cv) | Influences valve sizing | Cavitation/Erosion |

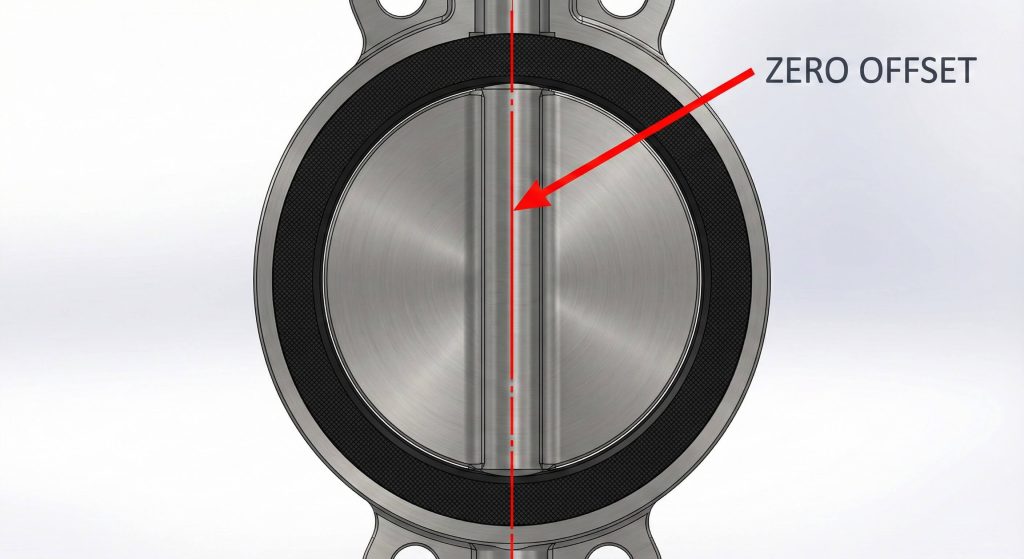

2. How do concentric butterfly valves fit your butterfly valve selection guide?

Concentric butterfly valves fit into your selection guide as the primary choice for low-pressure, non-corrosive water and air applications. What is the real story? These valves feature a centered stem and a resilient seat that provides a bubble-tight seal at an economical price point. Because the disc is always in contact with the seat, they are ideal for systems where the temperature remains relatively stable.

Standard Concentric Applications

You will typically find these in configurations for end-of-line service or maintenance isolation. While they are highly effective for simple fluids, they struggle with high-velocity gas or abrasive slurries. Understanding the limitations of the rubber seat is the first step in ensuring your system remains leak-free for years.

Key Takeaway

| Feature | Concentric Specification | Limitation |

|---|---|---|

| Seat Design | Resilient / Elastomer | Temperature Sensitive |

| Stem Offset | Zero Offset (Centered) | Constant Friction |

| Typical Pressure | PN10 – PN16 | Lower Pressure Only |

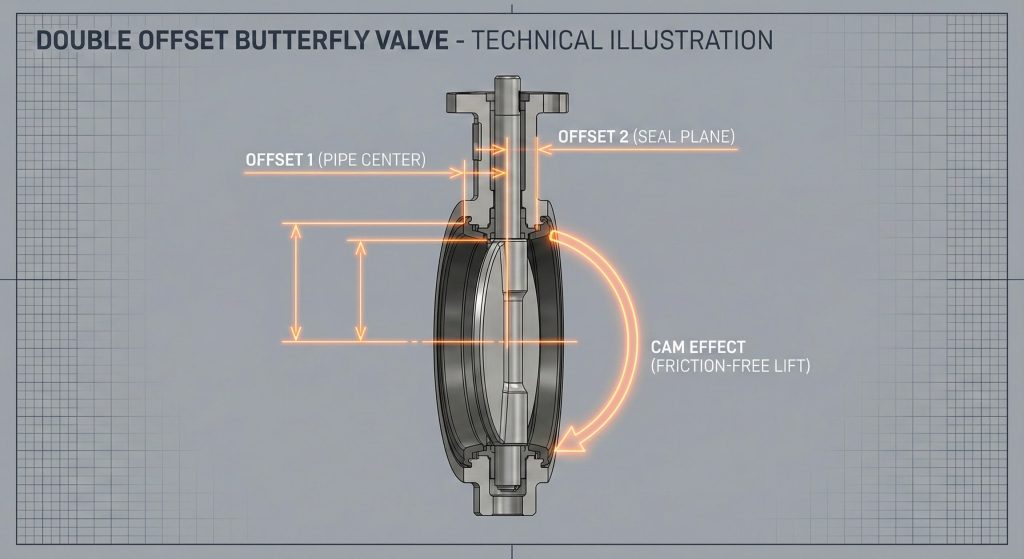

3. Why choose double offset valves in your butterfly valve selection guide?

You should choose double offset valves in your butterfly valve selection guide when your system requires a high-performance seal for higher pressures or volatile chemicals. You might be wondering: how does it differ from a standard design? The stem is positioned behind the disc and slightly to one side, creating a camming action that lifts the disc off the seat almost immediately upon opening.

High-Performance Advantages

This “High Performance” design allows you to use more durable materials like reinforced PTFE or fire-safe metal seats. By reducing the contact time between the disc and the seat, you effectively double the operational life of the valve compared to concentric types. This makes them a staple for chemical processing and industrial steam loops where reliability is non-negotiable.

Key Takeaway

| Benefit | Double Offset Advantage | Best Used For |

|---|---|---|

| Friction | Minimal contact during cycle | High-cycle operation |

| Materials | PTFE / Metal / Fire-Safe | Hazardous Chemicals |

| Rating | PN25 – PN40 | High-Pressure Loops |

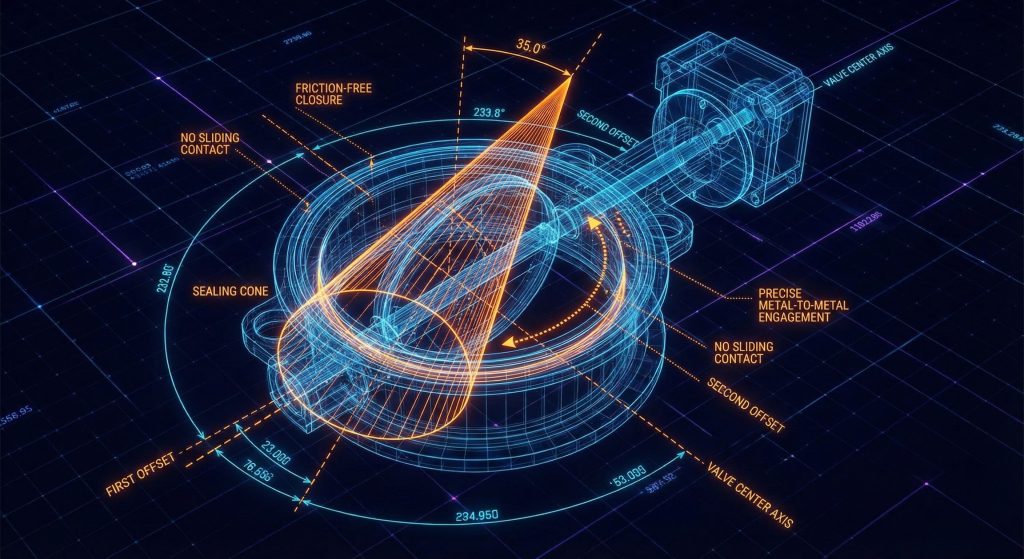

4. When does a triple offset butterfly valve selection guide matter?

A triple offset selection guide matters specifically when your application involves extreme temperatures, high pressure, or the need for zero-leakage metal-to-metal sealing. Wait, there’s more: the third offset is a unique cone-shaped geometry of the sealing components that eliminates all rubbing between the seat and disc. This allows for a frictionless closure that even the most demanding oil and gas systems require.

Critical Triple Offset Scenarios

In these scenarios, a standard resilient seat would melt or degrade, and a double offset might still experience minor friction wear over time. Triple offset valves provide the safety of a high-performance unit with the durability of a gate valve. They offer a compact, lightweight solution for large-diameter pipelines where space and weight are at a premium.

Key Takeaway

| Condition | Triple Offset Performance | Competitive Edge |

|---|---|---|

| Temperature | Up to 600°C+ and Cryogenic | Survives extreme heat |

| Sealing | Metal-to-Metal Zero Leakage | Replaces gate valves |

| Durability | No seat-disc rubbing | Lowest maintenance cost |

5. Which seat materials belong in your butterfly valve selection guide?

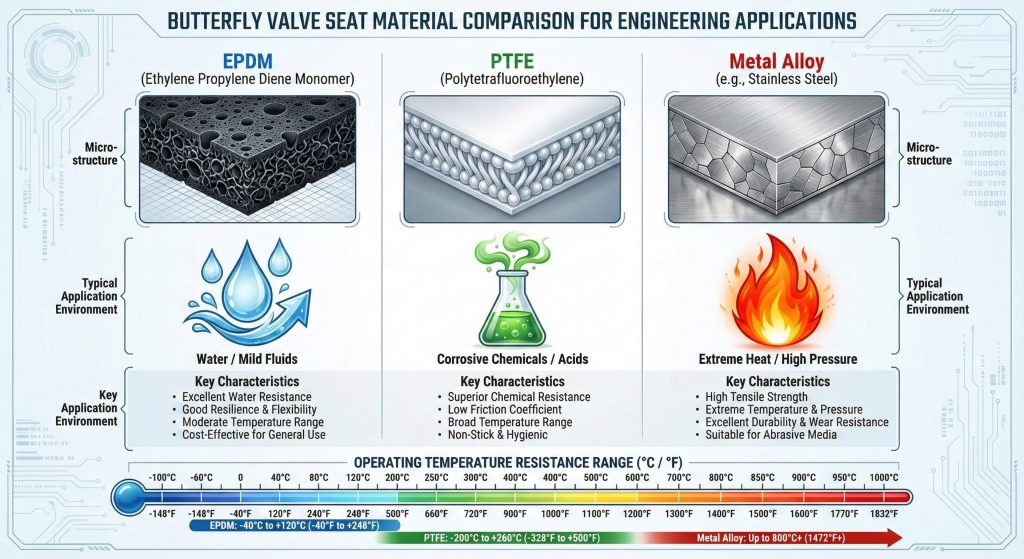

The seat materials that belong in your butterfly valve selection guide include EPDM, NBR, PTFE, and specialized metal alloys, depending on your media’s chemistry. Here is the deal: the seat is the primary “wetted” part, and a mismatch here leads to swelling, hardening, or total seal failure. You must evaluate the PH levels, abrasive content, and thermal range of your fluid before finalizing this component.

Essential Material Properties

Integrating these materials correctly ensures your system doesn’t require auxiliary parts to compensate for a leaking isolation unit. For example, using EPDM in an oily environment will cause the seat to expand and jam the disc, potentially burning out your actuator. Always match the elastomer or alloy to the specific safety data sheet (SDS) of the media flowing through your pipes.

Key Takeaway

| Material | Temp Range | Ideal Media |

|---|---|---|

| EPDM | -20°C to 120°C | Potable Water, HVAC |

| PTFE | -20°C to 200°C | Acids, Corrosive Chemicals |

| Metal | -250°C to 600°C | Steam, Slurry, Oil & Gas |

6. How to choose materials for a butterfly valve selection guide?

Material selection is your frontline defense against corrosion and mechanical wear in aggressive industrial environments. You must evaluate the chemical compatibility of wetted components like the disc and seat to prevent premature failure. For instance, while ductile iron is a cost-effective choice for municipal water, you should opt for stainless steel or duplex alloys when handling seawater or corrosive chemicals.

Material Durability and Coatings

Protective coatings also play a vital role in extending the operational life of your hardware. You can specify fusion-bonded epoxy or specialized nylon coatings to protect the valve body from external environmental factors. These layers provide an essential barrier that reduces maintenance frequency and protects your capital investment from oxidation.

Key Takeaway

| Component | Standard Choice | Extreme Choice |

|---|---|---|

| Valve Body | Ductile Iron | Carbon Steel / SS |

| Valve Disc | SS304 | Aluminum Bronze |

| External Coating | Standard Paint | Fusion-Bonded Epoxy |

7. What specs matter for a butterfly valve selection guide?

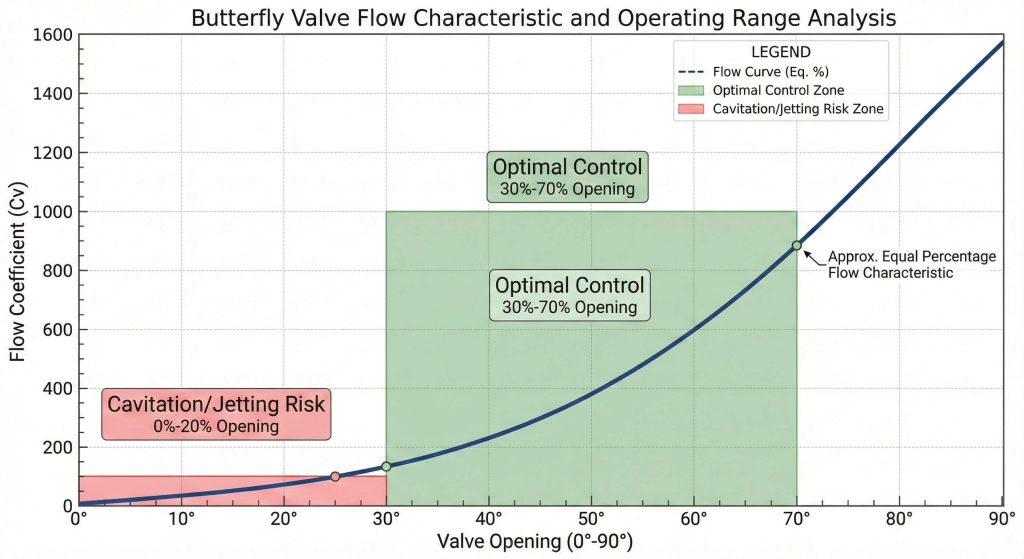

Accurate sizing is about much more than simply matching the pipe diameter of your existing system. According to a professional butterfly valve selection guide, you must calculate the Flow Coefficient (Cv) to ensure the valve operates within its optimal range. If you install an oversized valve, the disc may operate too close to the seat, leading to high-velocity “jetting” that causes rapid erosion.

Sizing and Efficiency Specs

You should also pay close attention to the pressure drop across the valve during peak flow conditions. Excessive pressure loss can force your pumps to work harder, increasing energy costs and the risk of cavitation. By following a structured technical guide, you can balance flow requirements with energy efficiency to optimize your facility’s performance.

Key Takeaway

| Specification | Technical Importance | Impact |

|---|---|---|

| Flow Coefficient (Cv) | Measures flow capacity | Sizing accuracy |

| Pressure Drop | Measures energy loss | Pump efficiency |

| Torque Rating | Determines actuator size | Operational reliability |

8. Where are valves used in a butterfly valve selection guide?

Butterfly valves are the workhorses of large-scale infrastructure, offering a compact footprint for high-volume flow control. In water treatment facilities, you rely on these valves to manage massive flow rates with minimal space requirements. Their lightweight design makes them ideal for elevated piping systems where the weight of heavy gate valves would require expensive structural support.

Infrastructure and Automation

You will also find these components integrated into power generation cooling loops and HVAC systems for high-cycle isolation. Because they can cycle quickly, they are perfect for emergency shut-off scenarios and automated flow regulation. Whether you are managing municipal utilities or industrial manufacturing, these valves provide the versatility needed for diverse project scopes.

Key Takeaway

| Industry | Typical Application | Preferred Type |

|---|---|---|

| Water Treatment | Bulk flow isolation | Concentric Wafer |

| Power Generation | Cooling water loops | High Performance Lug |

| HVAC | Chilled water control | Resilient Seated |

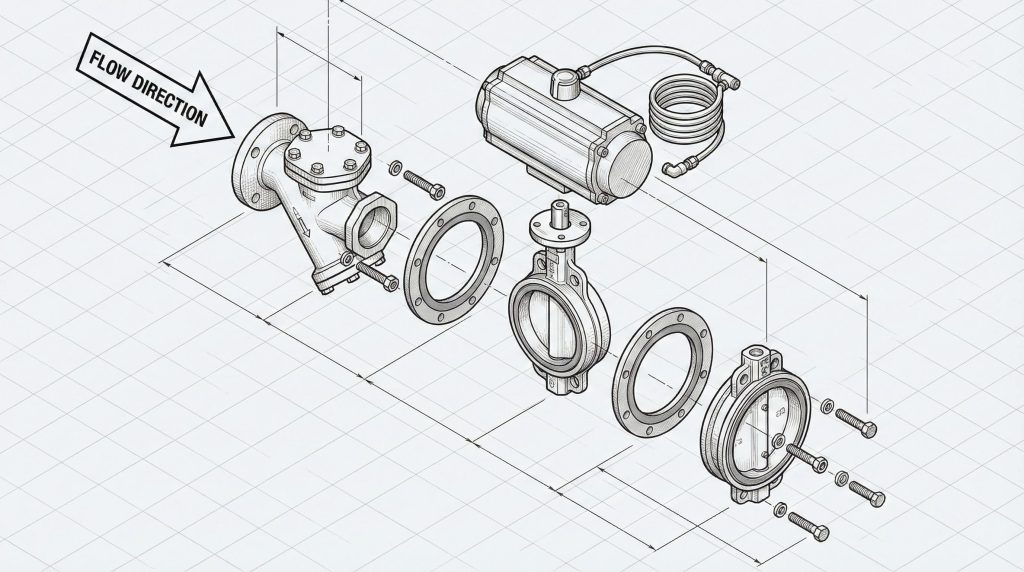

A complete fluid control system requires a holistic approach that goes beyond a single isolation unit. When you consult a butterfly valve selection guide, you should also consider the placement of check valves to prevent backflow surges. Integrating strainers and filters upstream of your valves will protect the seats from debris that could cause scoring or leakages.

Auxiliary Protection and Control

For systems requiring high-precision modulation, you might integrate high-performance ball valves for smaller auxiliary lines. This combination allows you to handle bulk flow with butterfly units while maintaining fine-tuned control over critical bypass loops. Coordinating these components ensures your entire pipeline operates with maximum reliability and safety.

Key Takeaway

| Component | Function in System | Protection Goal |

|---|---|---|

| Check Valve | Backflow prevention | Prevents water hammer |

| Strainer | Debris filtration | Protects valve seats |

| Actuator | Remote operation | Automates flow control |

10. How do I finalize a butterfly valve selection guide?

Finalizing your choice involves a rigorous verification of quality certifications and manufacturing standards. You should ensure your supplier provides comprehensive technical dossiers, including material test reports and pressure testing certificates. Verifying compliance with API 609 or ISO 9001 standards gives you the confidence that the valves will perform under real-world industrial stress.

Compliance and Support Verification

You must also evaluate the long-term support and maintenance services offered by the manufacturer. Having access to remote technical consultation and a reliable supply of spare parts reduces the risk of extended downtime. A well-finalized selection process guarantees that your fluid systems remain optimized for both performance and cost-efficiency.

Key Takeaway

| Verification Step | Required Document | Benefit |

|---|---|---|

| Standard Compliance | API 609 / ISO 9001 | Certified quality |

| Material Integrity | MTC (Material Test Report) | Chemical safety |

| Performance Check | Pressure Test Report | Leakage prevention |

Conclusion

Selecting the ideal flow control solution is a critical decision that impacts the safety and efficiency of your entire operation. Our vision is to provide precision-engineered fluid control solutions that empower industrial safety and efficiency worldwide. By following a structured approach to materials, sizing, and applications, you protect your infrastructure from costly failures. If you need personalized engineering support for your next project, contact us today to receive a free technical consultation.

Frequently Asked Questions

Q1: Can I use a butterfly valve for high-pressure steam?

Standard concentric valves are not suitable, but triple offset butterfly valves with metal seats are specifically engineered to handle high-temperature and high-pressure steam.

Q2: What is the best way to prevent seat leakage?

You must match the seat material (EPDM, NBR, or PTFE) to the chemical properties of your media and ensure your actuator provides enough torque for a full seal.

Q3: Can I install a butterfly valve in a vertical pipeline?

Yes, you can install them vertically, though it is often recommended to keep the stem horizontal to prevent sediment from settling in the bottom bearing.

Q4: What material is best for seawater applications?

For marine environments, you should prioritize aluminum bronze discs and duplex stainless steel stems to resist chloride-induced pitting and galvanic corrosion.

Q5: Are butterfly valves suitable for throttling?

They are excellent for throttling, but you should generally operate them between 30 and 70 degrees open to avoid cavitation and premature seat wear.