Aluminum bronze is the definitive material choice for butterfly valve bushings, providing a critical low-friction, corrosion-resistant interface that prevents stem seizure in the world’s most demanding industrial environments. In high-pressure piping systems, the integrity of a stem bushing determines whether a valve operates smoothly or becomes a costly point of failure. By integrating an aluminium bronze butterfly valve into your infrastructure, you utilize an alloy specifically engineered to withstand mechanical stress while maintaining its physical properties in corrosive media.

1. Why use aluminum bronze for valve bushings?

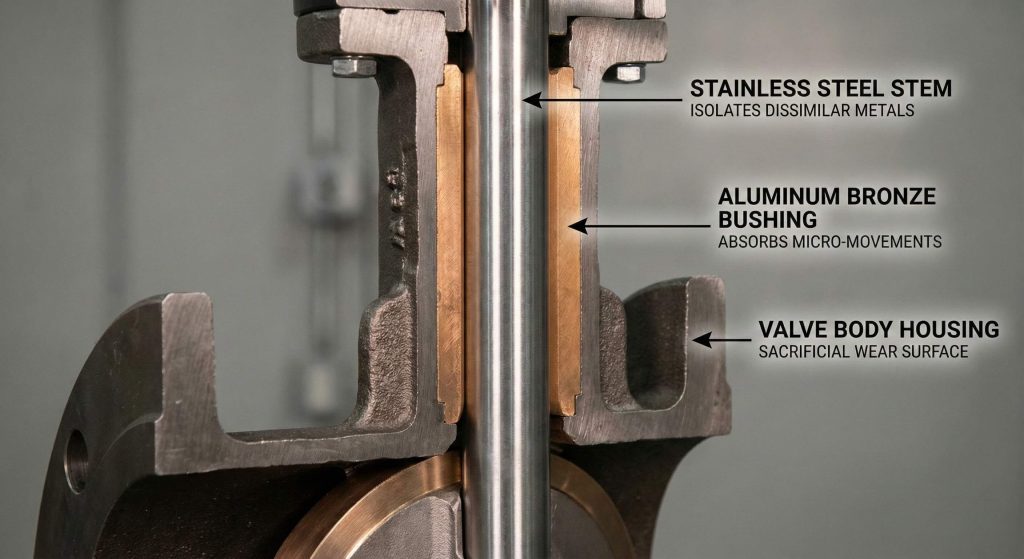

The selection of aluminum bronze for an aluminium bronze butterfly valve is driven by its ability to act as a sacrificial but highly durable bearing surface. These bushings prevent metal-to-metal galling between the valve stem and the body, ensuring that the pivoting disc can rotate freely even after long periods of inactivity. Without this specialized material, the oxidation of ferrous components would eventually lead to mechanical bonding, rendering the valve inoperable.

The Protective Nature of Bronze

Aluminum bronze alloys form a microscopic, self-healing oxide layer that serves as a permanent barrier against the environment. This characteristic is particularly valuable for stem bushings, which are often difficult to lubricate once the valve is installed. By providing a naturally lubricious surface, the material protects the harder stainless steel stem from wear and localized pitting.

Key Takeaway: Aluminum bronze bushings provide the essential low-friction, corrosion-resistant interface required to prevent mechanical seizure in harsh industrial environments.

| Feature | Aluminum Bronze (C95400) | Standard Carbon Steel |

|---|---|---|

| Corrosion Rating | Excellent (Seawater) | Poor (Oxidizes) |

| Friction Coeff. | Low | High |

| Self-Lubricating | Partial (Oxide layer) | No |

| Wear Life | High | Low |

The choice of material directly correlates to the mean time between failure in high-cycle industrial environments.

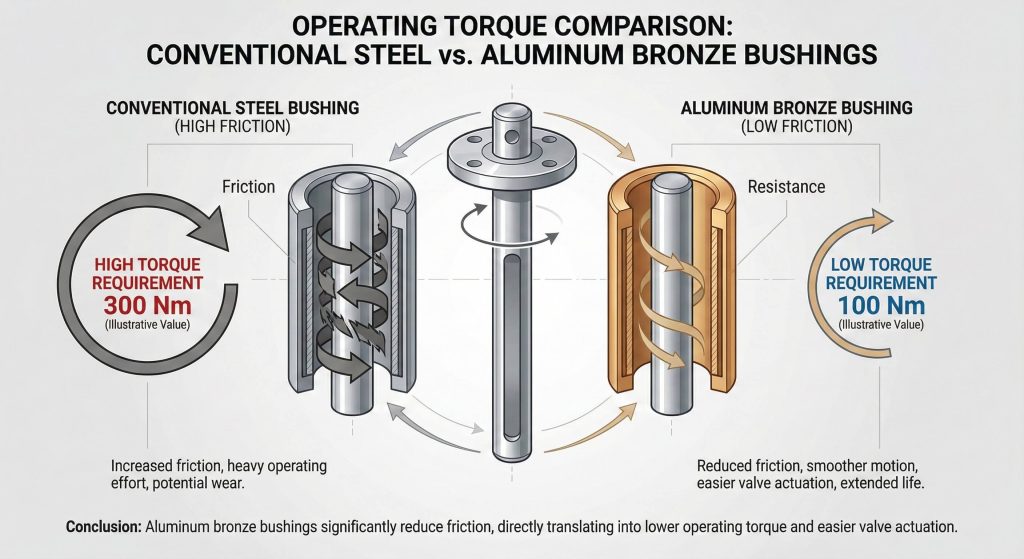

2. How does this material reduce operating torque?

Lowering the coefficient of friction at the stem interface is the most effective way to reduce the total operating torque of a valve. Because aluminum bronze is significantly more “slippery” than stainless or carbon steel, it allows the stem to rotate with minimal resistance. This reduction in force directly impacts the lifecycle of the entire valve assembly, as it reduces the mechanical strain on the stem and the internal seals.

Impact on Actuator Sizing

When the breakaway torque is lowered through the use of high-performance bushings, engineers can specify smaller, more energy-efficient actuators. This leads to significant capital savings and a smaller footprint for automated systems. Furthermore, smooth operation prevents the “stiction” effect, which can cause erratic movement and pressure surges in sensitive fluid control loops.

Key Takeaway: Lowering stem friction through specialized bronze bushings allows for the use of smaller, more cost-efficient actuators and ensures smoother valve modulation.

| Torque Parameter | With Al-Bronze Bushing | Without Specialized Bushing |

|---|---|---|

| Breakaway Torque | 15-20% Lower | Base Reference |

| Running Torque | 10-15% Lower | Base Reference |

| Component Wear | Minimal | Significant |

Actuation efficiency is significantly improved when the breakaway torque is minimized through specialized bushing alloys.

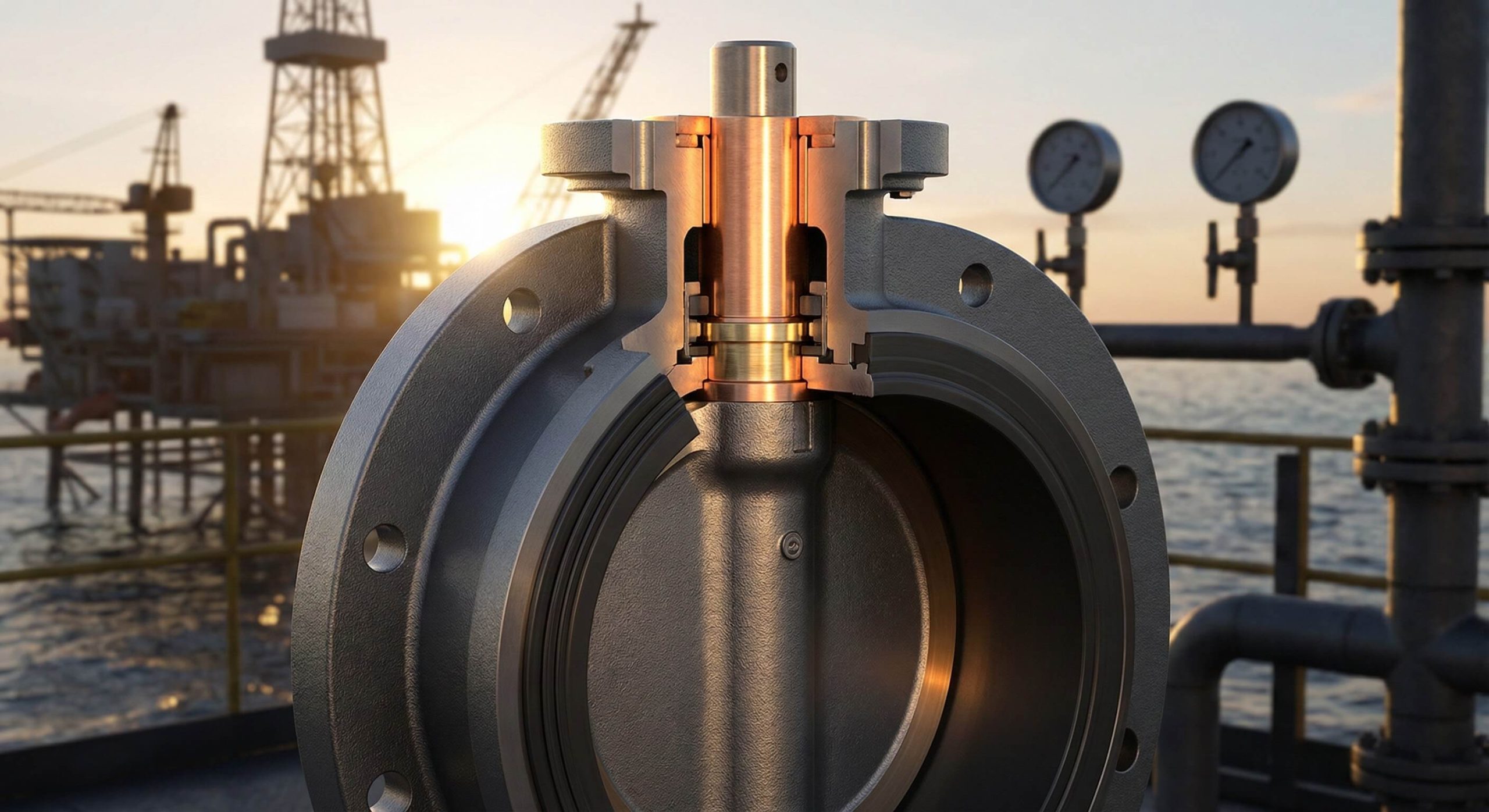

3. Where is it used in subsea oil applications?

In the offshore sector, an aluminium bronze butterfly valve is frequently utilized for seawater injection, firewater systems, and crude oil transport. Subsea environments are exceptionally aggressive, where high salinity and pressure work together to degrade standard metals. Aluminum bronze is one of the few materials that can survive years of immersion without experiencing significant loss of material or structural integrity.

Marine Environment Durability

The addition of aluminum and nickel to the copper base creates an alloy that is nearly immune to the pitting and crevice corrosion that plagues stainless steels in stagnant seawater. For subsea hardware, where maintenance is often impossible or cost-prohibitive, these bushings provide the long-term reliability necessary to prevent catastrophic leaks or system shutdowns.

Key Takeaway: High-strength bronze alloys are indispensable for deep-sea and offshore hardware where corrosive saltwater makes traditional ferrous materials unviable.

| Industry Segment | Application Type | Typical Valve Size |

|---|---|---|

| Subsea Oil | Isolation & Control | 8″ to 24″ |

| Desalination | Brine Management | 12″ to 48″ |

| Power Gen | Cooling Water | 20″ to 60″ |

In subsea hardware, the ability to resist pitting and crevice corrosion determines the total lifecycle of the flow control system.

4. Which alloy grade is best for industrial valves?

The most common choice for heavy-duty valve bushings is C95400 cast aluminum bronze, known for its exceptional tensile strength and hardness. For specialized marine or subsea applications, engineers often pivot to C95800, which includes nickel to further enhance its resistance to seawater corrosion. Selecting the correct grade is a matter of balancing mechanical load requirements with the chemical nature of the media being controlled.

Selecting the Correct Specification

While C95400 is the versatile workhorse of the industry, higher-strength variants like C63000 (Nickel Aluminum Bronze) are used for extreme pressure applications. These alloys maintain their mechanical properties across a wide temperature range, ensuring that the bushings do not deform even when the piping system undergoes thermal expansion or pressure surges.

Key Takeaway: While C95400 is the standard for general industrial use, specialized marine projects benefit from the enhanced nickel content of C95800 for superior saltwater resistance.

| Alloy Grade | Tensile Strength (PSI) | Yield Strength (PSI) | Best Use Case |

|---|---|---|---|

| C95400 | 75,000 | 30,000 | General Industrial |

| C95800 | 85,000 | 35,000 | Marine/Subsea |

| C63000 | 110,000 | 68,000 | Extreme Load |

Engineering specifications must match the specific chemical exposure of the media to ensure long-term metallurgical stability.

5. How does it prevent catastrophic stem seizure?

The primary role of the aluminium bronze butterfly valve bushing is to eliminate the risk of the stem bonding to the valve body. This phenomenon, known as “seizure,” often occurs when rust forms in the stem journal, effectively welding the components together. Because aluminum bronze is non-ferrous, it cannot produce the iron oxide (rust) required for this type of bonding.

Eliminating Mechanical Bonding

Furthermore, the material prevents “cold welding” or galling, which can occur when two similar hard metals rub together under pressure. The softer, lubricious nature of the bronze ensures that even if lubrication fails, the stem can still rotate without tearing the surface of the bushing. This fail-safe characteristic is vital for safety-critical valves that must operate during emergencies.

Key Takeaway: Non-ferrous bushings effectively eliminate the risk of stem seizure and cold welding, ensuring the valve remains operational throughout its design life.

| Seizure Risk | Bronze Bushing | Steel-on-Steel |

|---|---|---|

| Oxidation Bond | None | High Risk |

| Surface Galling | Low | Moderate |

| Cold Welding | Negligible | Possible |

Preventing mechanical seizure is critical for emergency shutdown valves (ESV) that must operate reliably after long periods of inactivity.

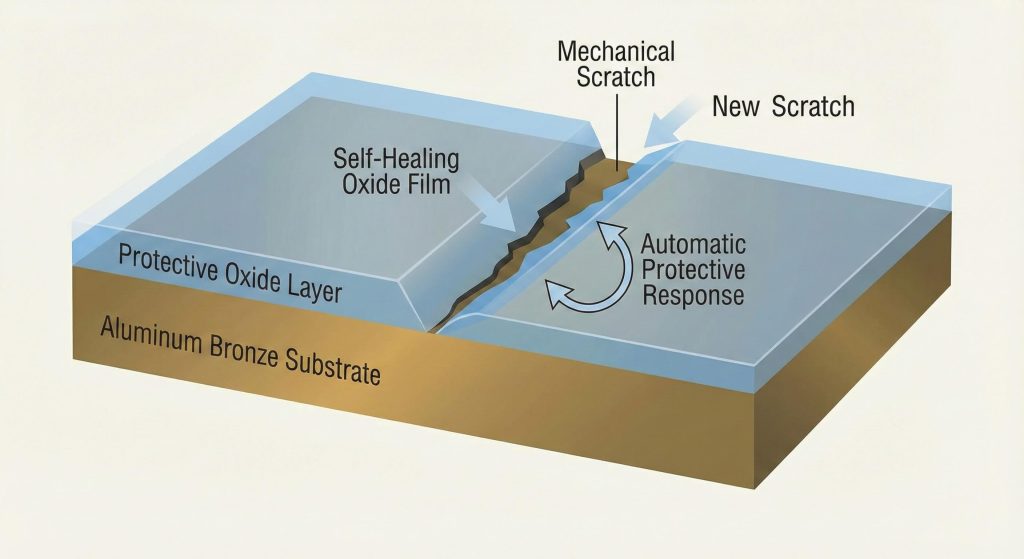

6. Why is the oxide layer considered self-healing?

Aluminum bronze is unique because of its ability to repair its own protective surface. When the metal is exposed to oxygen—whether in the air or dissolved in water—it immediately forms a tough, adherent layer of aluminum oxide. If the bushing surface is scratched by a particle in the fluid stream, the exposed metal reacts with the environment to reform the barrier almost instantly.

Understanding Surface Passivation

Unlike the porous rust that forms on iron, the aluminum oxide layer is impermeable and tightly bonded to the underlying metal. This prevents further oxidation from reaching the core of the component. This self-healing nature makes the material highly resistant to “erosion-corrosion,” where the flow of fluid continuously strips away the protective layers of lesser metals.

Key Takeaway: The natural formation of a self-healing aluminum oxide layer provides a permanent defense against the aggressive nature of seawater and abrasive media.

| Layer Property | Al-Bronze Oxide | Iron Oxide (Rust) |

|---|---|---|

| Adhesion | Very High | Low/Flaky |

| Permeability | Impermeable | Highly Permeable |

| Self-Healing | Yes | No |

This microscopic self-repair mechanism is the primary reason for the material’s longevity in abrasive fluid streams.

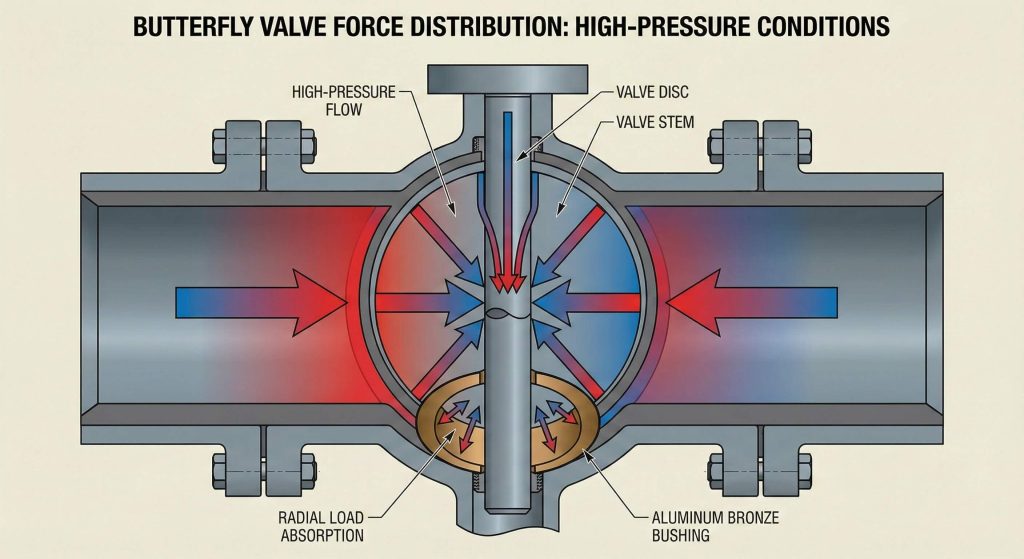

7. Can it withstand high-pressure flow conditions?

An aluminium bronze butterfly valve is designed to meet rigorous ANSI and API standards for high-pressure service. The bushings must support the radial thrust exerted on the stem when the valve is in the closed position under full pressure. Aluminum bronze alloys possess the compressive strength required to handle these loads without “pancaking” or losing their circular profile.

Load Bearing Under Pressure

Maintaining dimensional stability is critical because any deformation of the bushing would lead to stem misalignment. Misalignment causes uneven wear on the primary seals, eventually resulting in external leakage. The high hardness of C95400 and similar alloys ensures that the stem remains perfectly centered, preserving the integrity of the entire sealing system.

Key Takeaway: The structural integrity of aluminum bronze allows it to support extreme radial loads, preventing stem misalignment and subsequent seal failure.

| Valve Rating | Max Pressure (PSI) | Recommended Bushing |

|---|---|---|

| Class 150 | 285 | C95400 |

| Class 300 | 740 | C95800 |

| Class 600 | 1480 | C63000 |

Maintaining dimensional tolerances under peak load is essential for preserving the secondary seals of the valve assembly.

8. What makes these bushings safe for hazardous media?

Safety is a paramount concern in oil, gas, and chemical processing facilities. Aluminum bronze is inherently non-sparking, making it an essential material for equipment operating in explosive atmospheres. If a valve component were to fail or strike another part during a high-pressure event, the use of bronze ensures that no frictional sparks are generated that could ignite flammable vapors.

Safety in Explosive Atmospheres

Beyond its non-sparking properties, the material’s excellent thermal conductivity helps dissipate heat away from the stem interface. This prevents localized “hot spots” that could compromise the integrity of soft seals or packing materials. In the event of a facility fire, these bushings maintain their structural stability much longer than plastic or composite alternatives, providing critical time for emergency systems to function.

Key Takeaway: The non-sparking and thermally conductive properties of aluminum bronze make it a vital safety feature for any facility handling explosive or flammable media.

| Safety Feature | Aluminum Bronze | Standard Steel |

|---|---|---|

| Sparking Risk | Non-Sparking | Spark Hazard |

| Magnetic | No | Yes |

| Thermal Conductivity | High | Moderate |

Material safety compliance reduces the risk of ignition during maintenance or accidental mechanical impact.

9. How should you maintain these bushings proactively?

While an aluminium bronze butterfly valve requires far less maintenance than traditional designs, a proactive strategy is still necessary to reach the full design life. This involves periodic monitoring of the operating torque. An unexpected increase in torque is often the first sign that a bushing has reached its wear limit or that debris has entered the stem journal.

Monitoring Wear and Performance

Maintenance teams should also check for “stem play” or radial movement, which indicates that the bushing ID has enlarged due to wear. Replacing these bushings is a relatively simple procedure that can be performed during a standard turnaround, preventing the much more expensive damage that occurs if a stem begins to wear directly against the valve body.

Key Takeaway: Regular monitoring of torque and stem play allows for the proactive replacement of bushings, protecting the more expensive valve stem and body components.

| Task | Frequency | Objective |

|---|---|---|

| Visual Check | Quarterly | External Leaks |

| Torque Test | Annually | Monitor Friction |

| Full Overhaul | 5-10 Years | Bushing Replacement |

A data-driven maintenance strategy shifts the operational model from reactive repair to planned optimization.

10. Where can you source high-quality components?

The performance of any industrial valve is only as good as its individual components. Sourcing aluminum bronze bushings requires a partner who understands the tight metallurgical tolerances of C95400 and C95800. Quality manufacturers provide the necessary material certifications to prove that the alloy chemistry meets the specific needs of the application, ensuring that the self-healing and load-bearing properties are present.

Partnering for Technical Excellence

When sourcing replacement parts or new valve assemblies, it is essential to verify that the components are machined with the precision required for high-pressure sealing. Professional suppliers offer both the raw materials and finished machined components, ensuring that every bushing provides the exact fit and finish necessary to minimize friction and maximize the life of your fluid control system.

Key Takeaway: Partnering with a specialized manufacturer ensures you receive the exact alloy chemistry and precision machining required for long-lasting valve performance.

| Service Item | Manufacturer | General Distributor |

|---|---|---|

| Material Certs | Included | Often Extra |

| Custom Sizes | Yes | No (Standard Only) |

| Technical Support | High | Low |

Strategic procurement of certified components minimizes the risk of introducing substandard materials into critical infrastructure.

Conclusion

The integration of aluminum bronze stem bushings represents a significant step forward in the reliability and safety of industrial fluid control. By choosing materials that naturally resist corrosion and minimize friction, you are investing in the long-term health of your piping infrastructure. If you are ready to upgrade your systems with high-performance hardware, feel free to contact us today for a technical consultation and detailed material specifications.

Frequently Asked Questions

Q1: Can I use aluminum bronze bushings with a stainless steel stem?

Yes, this is the industry-standard pairing. The bronze provides a softer bearing surface that protects the harder stainless steel stem from galling while offering a low-friction interface.

Q2: What’s the best way to determine which alloy grade I need?

The best way is to evaluate your media chemistry; C95400 is excellent for general heavy industry, while C95800 or C63000 is preferred for saltwater and high-pressure subsea service.

Q3: How do I identify if my bushings are failing without opening the valve?

How you identify failure usually involves monitoring for a sudden rise in actuation torque or observing leakage through the stem packing, which indicates misalignment.

Q4: Which alloy should I choose for a high-temperature steam system?

Aluminum bronze maintains its structural integrity and oxidation resistance up to 500°F (260°C), making it suitable for many saturated steam applications.

Q5: Can I replace these bushings without replacing the entire valve?

Yes, these bushings are designed as replaceable components, allowing maintenance teams to restore the valve’s performance without the cost of a full body replacement.