The triple eccentric butterfly valve works by utilizing three distinct offsets that allow the disc to rotate into the seat with a cam-action, eliminating friction until the final moment of closure. In high-pressure industrial environments, a single valve failure can halt an entire production line, leading to massive financial losses and safety risks. Many engineers struggle with standard valves that leak under thermal stress or wear out quickly due to constant friction. The butterfly valve triple eccentric is the precision-engineered answer to these challenges, guaranteeing zero-leakage while extending the operational lifecycle of your infrastructure.

What is a butterfly valve triple eccentric design?

A butterfly valve triple eccentric design is a high-performance quarter-turn valve that utilizes three distinct offsets to achieve a friction-free, metal-to-metal seal. You will notice that this specific geometry allows the disc to move away from the seat immediately upon opening. This avoids the wear and tear commonly associated with traditional rubber-seated valves. It is an ideal solution for critical infrastructure.

What defines this high-performance valve?

Think about it. Most valves rely on soft seats that degrade, but the triple eccentric version is built for durability. It uses three offsets to position the disc for a “cam-action” closure.

- Quarter-turn operation for rapid opening and closing.

- Metal-to-metal contact for fire-safe performance.

- Compact footprint compared to heavy gate valves.

- Bidirectional sealing capabilities in many designs.

How does it differ from standard valves?

Here is the deal: standard butterfly valves often rub against the seat throughout the entire stroke. This high-performance design ensures the disc only touches the seat at the final point of closure.

- Reduced wear on the sealing surfaces.

- Lower torque requirements for actuation.

- Higher pressure ratings reaching up to PN40 or higher.

- Extended service life in abrasive media.

Key Takeaway: The triple eccentric design moves away from interference-based sealing to a geometry-based seal, making it ideal for severe service.

| Feature | Standard Butterfly Valve | Triple Eccentric Valve |

|---|---|---|

| Sealing Type | Friction-based (Elastomer) | Friction-free (Metal) |

| Wear Level | High during rotation | Negligible until closure |

| Leakage Class | Often Class IV or V | Zero Leakage (Class VI) |

The transition from soft materials to metal-to-metal contact represents a fundamental shift in sealing reliability for harsh environments.

How does the butterfly valve triple eccentric mechanism work?

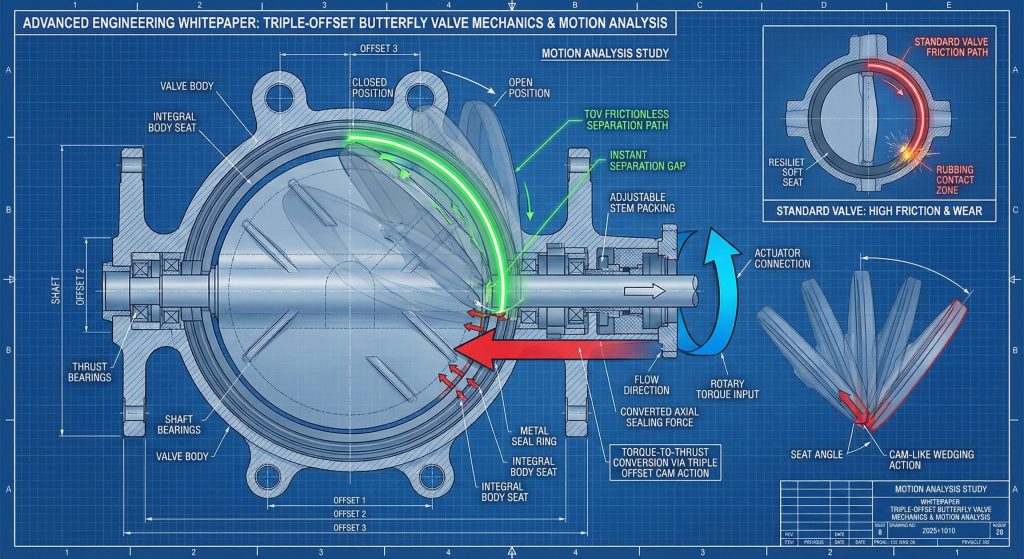

The butterfly valve triple eccentric mechanism works by translating rotational movement into an axial wedging force that seats the disc firmly against the seal ring. You can see how the disc travels in an uninterrupted path until the very last degree of rotation. This ensures that the sealing components do not experience friction-induced degradation. It effectively turns a rotary motion into a high-pressure seal.

What happens during the opening stroke?

Look: as soon as the valve begins to open, the disc lifts away from the seat. This is because the triple offsets create a path where the disc does not “drag” across the seal.

- Immediate detachment preventing seal deformation.

- Smooth rotation without the “stuck” feeling.

- Minimal torque needed to break the seal.

- Protection against seat erosion during high-flow starts.

How does the cam effect ensure sealing?

The best part? The valve acts like a cam, wedging the disc into the seat only at the final degree of rotation. This ensures a uniform compression around the entire circumference.

- Elastic deformation for a tight fit.

- Uniform pressure across the metal seal face.

- Self-cleaning action as the disc wipes the seat.

- Tight shut-off that improves with higher line pressure.

Key Takeaway: The cam-action mechanism transforms rotational energy into axial sealing force, ensuring zero leakage without mechanical wear.

| Component | Action during Closing | Impact on Performance |

|---|---|---|

| Valve Disc | Rotates and wedges | Creates high-integrity seal |

| Valve Seat | Remains stationary | Resists erosion and high heat |

| Stem | Transfers torque | Ensures precise disc positioning |

Mechanical wedging ensures that the seal remains tight even when system pressures fluctuate significantly during operation.

What are the three offsets in a butterfly valve triple eccentric?

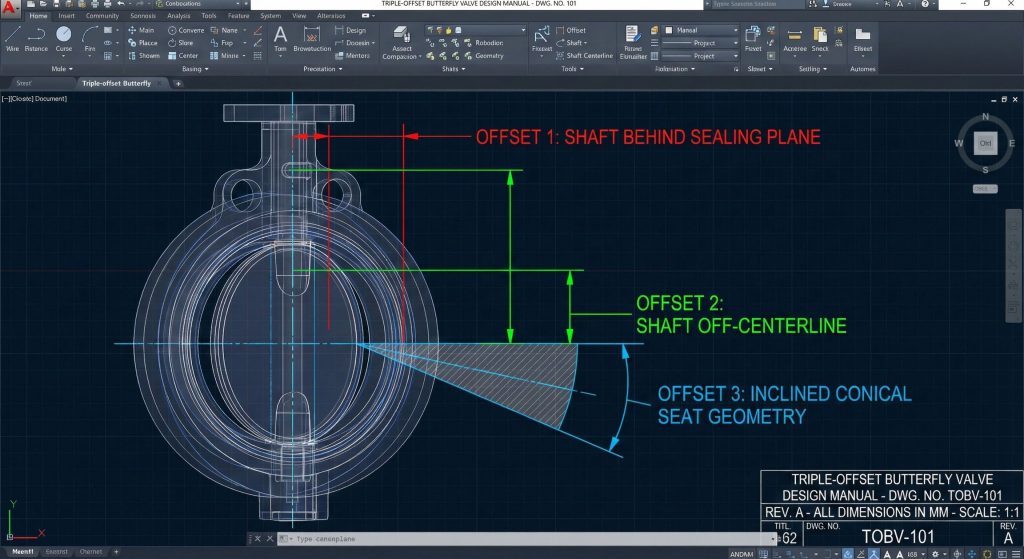

The three offsets in a butterfly valve triple eccentric refer to the shaft’s position behind the seal, its position off-center of the pipe, and the conical geometry of the seating surface. You must understand that these three geometric variables work together to eliminate rubbing. Without these offsets, the valve would behave like a standard concentric model. Each offset serves a specific mechanical purpose.

What is the first and second offset?

You might wonder what “triple” actually refers to. The first offset places the shaft behind the sealing surface, while the second moves the shaft away from the centerline of the bore.

- First Offset: Shaft located behind the seal plane.

- Second Offset: Shaft eccentric to the pipe centerline.

- Result: Provides a continuous sealing path.

- Benefit: Allows the disc to swing clear of the seat quickly.

What is the critical third conical offset?

This is the “magic” ingredient. The third offset is the geometry of the seating surface, which is machined into an asymmetrical conical shape.

- Inclined cone axis relative to the bore.

- Elimination of friction throughout the 90-degree stroke.

- Right-angle compression at the point of contact.

- Optimized flow characteristics when fully open.

Key Takeaway: The combination of three offsets allows the disc to “drop” into the seat like a plug, removing the rubbing action entirely.

| Offset Number | Technical Description | Primary Purpose |

|---|---|---|

| Offset 1 | Shaft behind seal face | Enables 360° sealing |

| Offset 2 | Shaft off-center of pipe | Provides cam-like rotation |

| Offset 3 | Conical seat geometry | Eliminates friction |

The synergy of these three offsets allows the valve to operate with lower torque while achieving a higher level of sealing integrity.

Why choose a butterfly valve triple eccentric for sealing?

You should choose a butterfly valve triple eccentric for sealing because it provides a bi-directional, zero-leakage shut-off that can withstand extreme pressures and temperatures. You will find that the metal-to-metal interface is far more resilient than elastomer alternatives. It is specifically designed to handle the “severe service” applications where other valves fail. This makes it a cost-effective choice for long-term reliability.

Why is metal-to-metal sealing superior?

In extreme environments, rubber or PTFE simply won’t last. A metal-to-metal seal can withstand fire, high-velocity steam, and corrosive chemicals without melting or tearing.

- High temperature resistance up to 538°C.

- Corrosion resistance using SS316L or exotic alloys.

- Fire-safe by inherent design.

- High pressure stability in steam systems.

How does friction-free design save costs?

It’s simple: less friction means smaller actuators. Because you don’t have to overcome the “breakout torque” of a rubbing seal, you can save significantly on automation costs.

- Smaller actuators reduce the total weight.

- Lower maintenance due to fewer seal replacements.

- Reduced downtime in critical process loops.

- Energy efficiency in automated systems.

Key Takeaway: Choosing this valve type reduces both CAPEX through smaller actuators and OPEX through increased durability.

| Cost Factor | Soft-Seated Valve | Triple Offset Valve |

|---|---|---|

| Actuator Size | Larger (high friction) | Compact (low torque) |

| Seal Replacement | Frequent (wear) | Rare (friction-free) |

| Safety Compliance | Needs extra testing | Inherently fire-safe |

Utilizing a friction-free design minimizes the mechanical strain on the entire valve assembly, leading to a much longer operational life.

Where is the butterfly valve triple eccentric used?

The butterfly valve triple eccentric is primarily used in the oil and gas, power generation, and chemical processing industries where high-pressure steam or hazardous fluids are present. You will also see them in water treatment plants where large-scale isolation is required. They are versatile enough to handle both cryogenic temperatures and superheated steam. Their compact design makes them perfect for space-constrained environments.

Is it suitable for oil and gas sectors?

Absolutely. In the upstream and downstream oil industry, preventing leaks is a matter of life and death, and these valves are the gold standard for isolation.

- Refining processes involving high-heat cracking.

- Offshore platforms where space is limited.

- LNG transport requiring cryogenic performance.

- Pipeline isolation for hazardous hydrocarbons.

Does it work for water treatment plants?

Surprisingly, yes. While often used for “severe service,” large-scale municipal water systems use them for their longevity and ease of maintenance in massive sizes.

- Large diameter mains for isolation.

- Pump stations requiring reliable shut-off.

- Desalination plants handling aggressive brine.

- Wastewater treatment with abrasive particulates.

Key Takeaway: While traditionally a “heavy industry” valve, its benefits are being adopted across all fluid control sectors for long-term safety.

| Industry | Specific Application | Reason for Choice |

|---|---|---|

| Power Gen | Steam isolation | High temp/pressure |

| Chemical | Acid/Alkali handling | Alloy material options |

| Municipal | Water distribution | Long-term reliability |

The adaptability of this valve across diverse industries proves its robustness as a universal solution for high-integrity flow control.

How to maintain a butterfly valve triple eccentric?

To maintain a butterfly valve triple eccentric, you must periodically inspect the stem packing and ensure the actuator’s travel limits are correctly calibrated to maintain the wedging force. You should note that these valves are virtually maintenance-free due to their lack of friction. However, regular cycling is recommended to prevent debris build-up in the seat area. This ensures that the “zero-leakage” status is maintained over years of service.

What are the routine inspection steps?

Believe it or not, maintenance is relatively straightforward because there are no soft seats to perish over time. Periodic checks are still vital for safety.

- Visual inspection of the stem packing.

- Cycling the valve for smooth operation.

- Checking torque against factory specs.

- Cleaning the seat if the media is scaling.

How to troubleshoot common sealing issues?

If you notice a leak, don’t panic. Most issues in these valves are related to incorrect actuator limits or debris trapped in the conical seat.

- Adjust limit switches for full closure.

- Flush the line to remove particulates.

- Verify packing tightness at the stem.

- Inspect for cavitation if used for throttling.

Key Takeaway: Most “leaks” in triple offset valves are actually mechanical calibration issues rather than actual seal failures.

| Issue | Potential Cause | Recommended Solution |

|---|---|---|

| Passing Leakage | Actuator not fully closed | Re-calibrate limits |

| Stiff Operation | Packing too tight | Adjust packing nuts |

| Seat Damage | Abrasive debris | Flush and inspect |

Proactive calibration of the actuator ensures that the geometric wedging remains effective throughout the valve’s entire lifespan.

Does butterfly valve triple eccentric handle high heat?

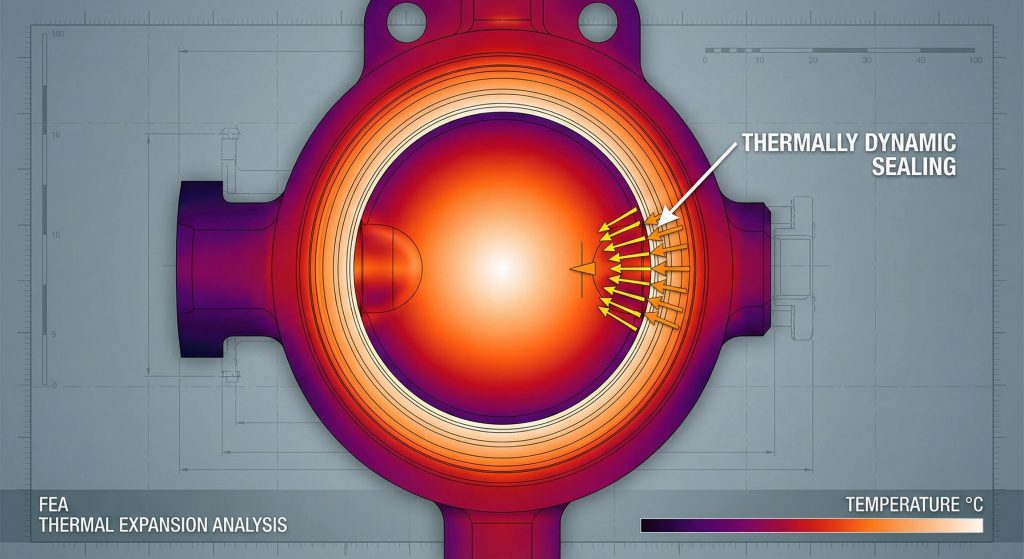

The butterfly valve triple eccentric handles high heat exceptionally well by using metal-to-metal sealing and torque-seated designs that compensate for thermal expansion. You can rely on these valves in applications reaching over 500°C where standard elastomers would simply melt. The conical sealing geometry ensures that as parts expand, the seal actually tightens. This makes them the primary choice for superheated steam and refining processes.

What materials withstand extreme temperatures?

The beauty is in the alloys. From carbon steel to Inconel, the material can be matched to the thermal profile of the media.

- Stellite® hard-facing for wear resistance.

- Laminated seal rings for flexibility.

- High-temp alloys like Duplex or Monel.

- Cast steel bodies for expansion management.

How does thermal expansion affect sealing?

The best part? Because the seal is conical and torque-seated, the valve can compensate for thermal expansion without losing its tight shut-off.

- Torque-seating allows deeper disc movement.

- Uniform expansion due to symmetrical design.

- Resilience against thermal shock.

- Zero-leakage remains consistent at peak heat.

Key Takeaway: Unlike gate valves that can “heat bind,” the triple offset design remains easy to operate even at maximum temperatures.

| Temp Range | Material Recommendation | Common Application |

|---|---|---|

| Cryogenic | Stainless Steel | LNG Transport |

| Medium Heat | Carbon Steel / WCB | District Heating |

| High Heat | Alloy Steel / WC6 / WC9 | Superheated Steam |

The ability to maintain a leak-proof seal during rapid temperature changes makes this valve indispensable for modern power plants.

Can butterfly valve triple eccentric replace gate valves?

A butterfly valve triple eccentric can replace gate valves in almost any high-pressure isolation application, offering a much lighter and more compact alternative. You will save significant space in your piping layout by switching to this quarter-turn solution. It provides the same bi-directional shut-off as a gate valve but with faster operation. Additionally, the maintenance requirements are significantly lower.

Is the weight advantage significant?

Yes, it is massive. A 12-inch triple offset valve can weigh up to 70% less than a comparable gate valve, simplifying structural supports.

- Lower shipping costs due to reduced mass.

- Easier installation requiring fewer tools.

- Smaller footprint for tight galleries.

- Simpler piping supports for the system.

Does it provide better flow control?

While primarily an isolation valve, the triple offset design is superior for basic throttling or flow regulation. It offers more control than a standard gate valve.

- Linear flow for the first 60 degrees.

- Less turbulence than a partially open gate.

- Faster response via 90-degree turn.

- Stable control with precision actuators.

Key Takeaway: Replacing gate valves with triple offset butterfly valves reduces weight, improves control, and lowers the total cost of ownership.

| Feature | Gate Valve | Triple Offset Valve |

|---|---|---|

| Weight (DN300) | Very Heavy (~300kg) | Lightweight (~90kg) |

| Operation Time | Slow (Multiple turns) | Fast (90° rotation) |

| Throttling | Not recommended | Moderate capability |

Reducing the weight of your infrastructure while maintaining high-pressure integrity allows for more efficient and cost-effective plant designs.

How to select a butterfly valve triple eccentric?

To select a butterfly valve triple eccentric, you must consider the system’s pressure rating, temperature range, and the chemical compatibility of the media. You should also evaluate the required end connections to ensure a seamless fit into your existing piping. Selecting the right material, such as stainless steel or carbon steel, is vital for longevity. Always verify the leakage class requirements for your specific application.

What pressure ratings are available?

When selecting, you must ensure the valve matches your system’s pressure class. These valves cover everything from low-pressure water to high-pressure steam.

- ANSI Class 150 to 600 are standard.

- PN10 to PN100 for European standards.

- High-pressure variants for power plants.

- Vacuum service with special sealing.

Which end connections are most reliable?

The choice of connection depends on your maintenance strategy and pipe layout. Selection impacts the ease of future replacements and overall safety.

- Wafer type for maximum space savings.

- Lug type for “dead-end” service.

- Double-flange for large-diameter safety.

- Butt-weld for leak-proof steam systems.

Key Takeaway: Always match the body material and connection type to existing piping standards to ensure a seamless and safe installation.

| Connection Type | Pros | Cons |

|---|---|---|

| Wafer | Lightest and cheapest | No end-of-line use |

| Lug | Downstream pipe removal | Heavier than wafer |

| Double Flange | Most secure for pressure | Takes up more space |

The correct selection process balances technical performance with budgetary constraints to ensure the highest return on investment.

What makes butterfly valve triple eccentric flow control unique?

The butterfly valve triple eccentric flow control is unique because it combines the tight shut-off of a globe valve with the high flow capacity of a standard butterfly valve. You will notice that the conical seat design allows for a more predictable flow curve during the opening phase. This reduces the risk of cavitation and turbulence in the pipeline. It is a hybrid solution for both isolation and control.

Wait, there is more to the control!

Wait, there is more: the torque-seated nature of the valve allows for very precise positioning when using high-quality digital actuators. This is critical for automated process loops.

- Minimal “break-out” torque for smoother starts.

- Repeatable positioning for process consistency.

- High rangeability compared to gate valves.

- Reduced hunting in automated control systems.

The secret lies in the disc shape

The secret lies in the disc shape: the asymmetrical design and the triple offsets prevent the disc from “fluttering” in high-velocity flows. This results in a much quieter operation.

- Reduced vibration at high flow rates.

- Stable disc positioning throughout the stroke.

- Lower noise levels in steam applications.

- Minimal pressure drop when fully open.

Key Takeaway: The triple offset design offers a unique balance of high flow capacity and precision control that traditional valves cannot match.

| Control Metric | Gate Valve | Triple Offset Valve |

|---|---|---|

| Flow Coefficient (Cv) | High | Very High |

| Precision | Low | Moderate to High |

| Vibration Risk | High when throttled | Low |

Achieving both a high flow rate and reliable control in a single valve body significantly simplifies complex piping systems.

Conclusion

Selecting the right valve is critical for the efficiency and safety of your plant. The triple eccentric butterfly valve stands out as a robust, high-performance solution that overcomes the limitations of traditional designs. At Ruitoflow, we are dedicated to providing precision-engineered flow control solutions that empower industries to operate safely and efficiently. For expert guidance on integrating these valves into your system or to explore our full range of industrial solutions, please contact us.

FAQ

Can I use this valve for gas applications?

Yes, the zero-leakage design and metal-to-metal sealing make it exceptionally safe for both hazardous and inert gas transport.

What’s the best material for corrosive media?

For corrosive environments, stainless steel or high-nickel alloys like Monel or Duplex are generally the best choices to prevent pitting and erosion.

How does temperature affect the sealing?

The conical design actually uses thermal expansion to its advantage, as the disc wedges deeper into the seat as temperatures rise, maintaining the seal.

Why is it called triple offset?

It is called triple offset because the design incorporates three separate geometric shifts: the shaft position, the shaft alignment, and the conical seating angle.

Will it leak over time?

Due to the friction-free motion, these valves experience significantly less wear than other types, maintaining their Class VI zero-leakage status for much longer.