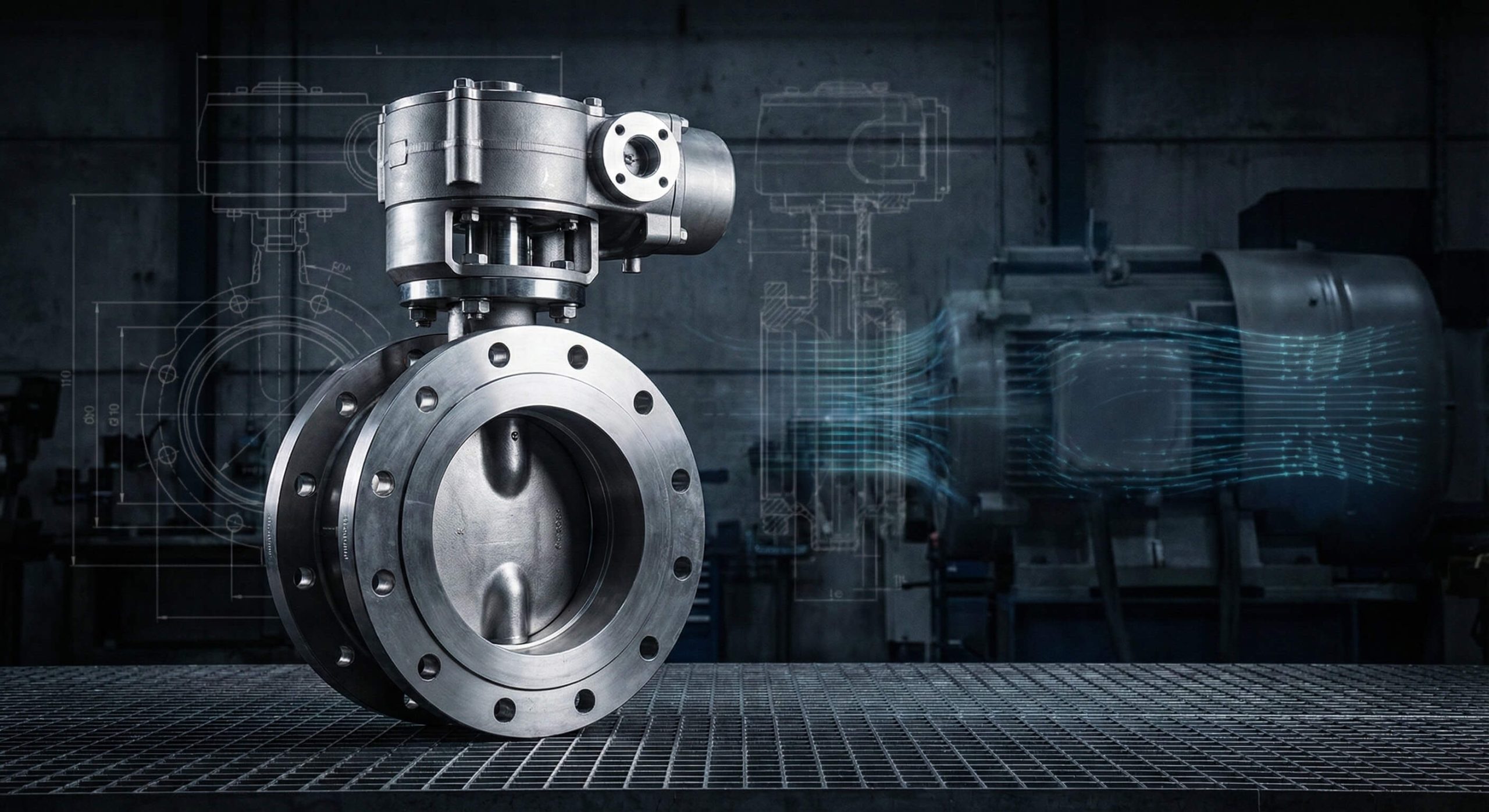

An overview of butterfly valves provides a comprehensive examination of the mechanical structure, design variants, and industrial benefits of these essential quarter-turn flow control devices. You may frequently encounter the logistical burden of installing heavy, oversized valves that consume excessive space and inflate project budgets. These bulky components create significant maintenance strain and installation complexity in modern piping systems. Implementing a streamlined design of butterfly valve offers you a lightweight, efficient solution that maximizes performance while minimizing your system’s physical footprint.

What defines the basic design of butterfly valve?

The fundamental design of butterfly valve is characterized by a circular disc that rotates on a central axis to regulate or obstruct fluid flow. This mechanism operates as a quarter-turn valve, meaning a 90-degree rotation moves the device from fully closed to fully open. You will find that this simplicity allows for rapid operation and a much thinner profile than traditional gate valves.

Wait, there’s more to the assembly than just the rotating disc.

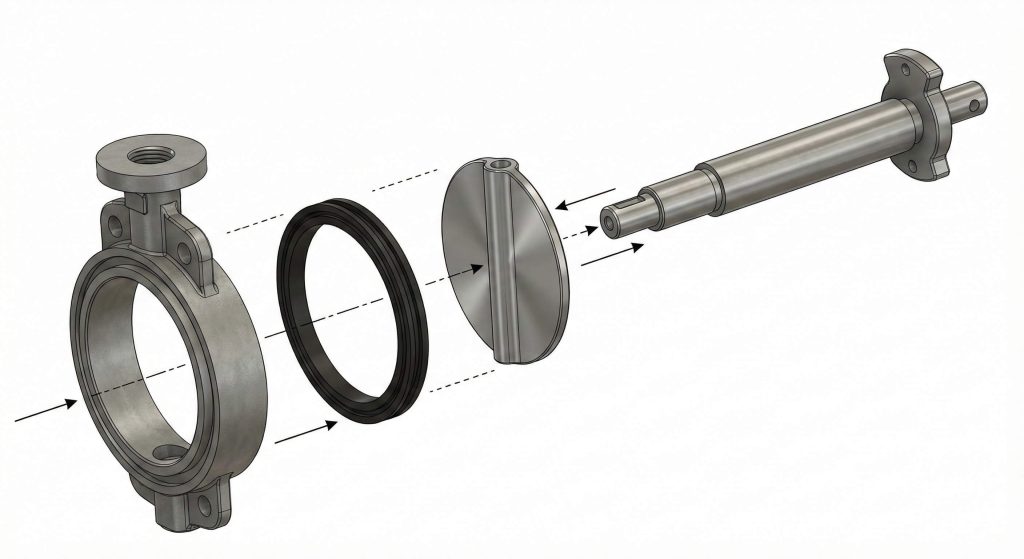

What are the primary internal components?

The internal structure consists of the valve body, a rotating disc, the stem, and a resilient or metal seat. These four elements work in unison to provide a seal and control the passage of media through your piping. Each component must be selected based on the specific pressure and temperature requirements of your application.

- Valve Body: The outer shell that houses the internal parts and connects to the pipe.

- Rotating Disc: The flow-controlling element that sits in the center of the pipe.

- Valve Stem: The shaft that connects the actuator or handle to the disc.

- Sealing Seat: The lining or ring that provides a leak-proof closure when the disc is shut.

Key Takeaway: Understanding the basic component interaction is essential for selecting a valve that provides long-term reliability in high-cycle environments.

| Component | Function | Material Example |

|---|---|---|

| Body | Pressure containment | Ductile Iron |

| Disc | Flow regulation | Stainless Steel |

| Seat | Leakage prevention | EPDM / PTFE |

The integration of these parts ensures that the valve remains functional even under significant mechanical stress.

Why is the concentric design of butterfly valve popular?

The concentric design of butterfly valve is widely utilized because it provides a cost-effective and reliable seal for low-pressure utility services. In this configuration, the stem passes directly through the centerline of the disc and the seat. You will see this design most often in water treatment, HVAC, and general industrial water systems.

Think about this for a moment.

How does the resilient seat function?

The resilient seat in a concentric valve creates a bubble-tight seal by utilizing interference between the disc edge and the soft liner. As you close the valve, the disc compresses the elastomer seat to prevent any fluid from passing. This design is particularly effective for fluids that do not contain abrasive solids.

- EPDM Seats: Ideal for water and steam applications at moderate temperatures.

- Buna-N Seats: Best suited for oil and gas applications where petroleum resistance is required.

- Viton Seats: Used for high-temperature chemical services where other elastomers might fail.

Key Takeaway: Concentric valves offer the best value for general utility applications where bubble-tight shutoff is required at lower pressure ratings.

| Feature | Concentric Design | Benefit |

|---|---|---|

| Stem Position | Centered | Balanced torque |

| Seat Type | Resilient Liner | Low cost |

| Shutoff | Bubble-tight | Zero leakage |

The simplicity of the center-line alignment makes these valves easy to manufacture and maintain across large-scale projects.

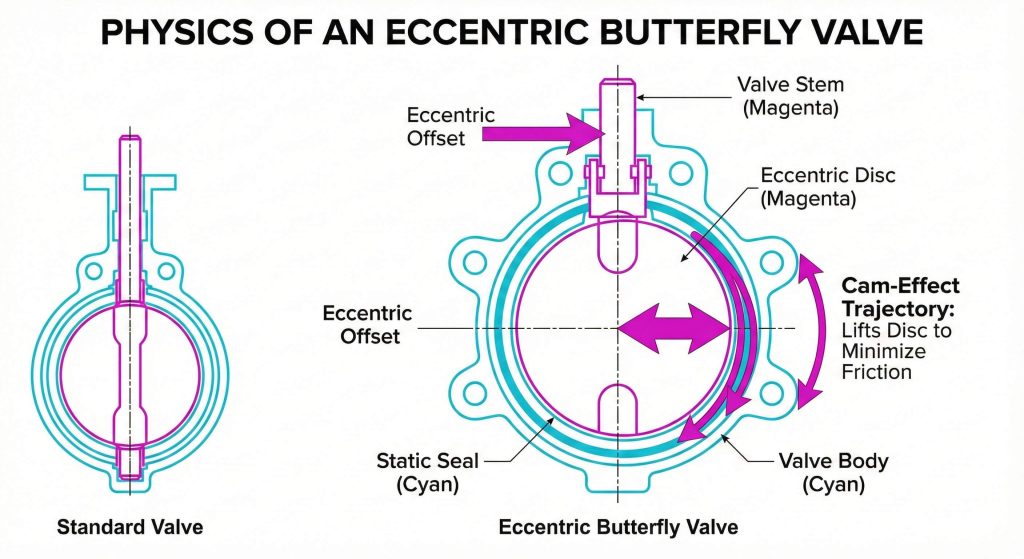

How does the offset design of butterfly valve work?

An offset design of butterfly valve works by moving the stem away from the centerline of the disc to reduce friction during operation. This modification allows the disc to “cam” into the seat rather than rubbing against it for the entire 90-degree rotation. You can utilize this design to extend the life of your seals in high-frequency applications.

It gets even better.

Why is friction reduction important?

Reducing friction between the disc and the seat lowers the torque required for operation and prevents premature wear of the sealing surfaces. In a standard concentric valve, the disc rubs the seat throughout its travel, which can lead to degradation. By employing an offset, you ensure the disc only contacts the seat at the final point of closure.

- Lower Torque: Allows for the use of smaller, less expensive actuators.

- Extended Life: Seats remain intact for more cycles compared to concentric versions.

- Higher Pressure: The offset geometry supports higher ASME class ratings.

Key Takeaway: Moving to an offset configuration is a strategic choice for process lines that require frequent cycling and higher durability.

| Offset Type | Position | Primary Result |

|---|---|---|

| First Offset | Stem behind disc | Continuous seal ring |

| Second Offset | Stem off-center | Camming action |

This mechanical shift transforms the valve from a utility component into a high-performance process tool.

What is the double eccentric design of butterfly valve?

The double eccentric design of butterfly valve features two distinct offsets that allow the disc to lift off the seat immediately upon opening. This design is frequently called a “high-performance” butterfly valve because it handles higher pressures and temperatures than resilient-seated types. You will benefit from its ability to use reinforced PTFE or metal seats for harsh media.

But wait, there’s more to the geometry.

How does the second offset improve performance?

The second offset involves shifting the stem to one side of the valve’s vertical centerline. This creates a camming motion that further reduces the time the disc is in contact with the seat. You will find that this geometry prevents “seat scrubbing,” which is the primary cause of seal failure in traditional valves.

- Reinforced PTFE: Provides chemical resistance and higher temperature thresholds.

- Fire-Safe Designs: Often utilize a secondary metal seat for emergency protection.

- High Cycle Life: Designed to perform reliably over thousands of operations.

Key Takeaway: Double eccentric valves are the industry standard for process applications requiring a balance of performance and space efficiency.

| Component | Material Option | Advantage |

|---|---|---|

| Seat | R-PTFE | Chemical resistance |

| Stem | 17-4 PH SS | High strength |

| Disc | 316 SS | Corrosion resistance |

The dual-offset geometry effectively bridges the gap between basic utility valves and heavy-duty triple offset versions.

Where is the triple offset design of butterfly valve used?

The triple offset design of butterfly valve is used in critical, high-pressure, and high-temperature environments where zero leakage is mandatory. This design adds a third offset—an inclined conical sealing axis—that eliminates all rubbing between the disc and seat. You will typically find these valves in oil refineries, power plants, and chemical processing facilities.

Here is the key insight.

Why is the third offset revolutionary?

The third offset changes the sealing mechanism from interference-based to torque-based, allowing for a metal-to-metal seal that remains tight even in extreme conditions. Because the disc only makes contact at the very last degree of closure, there is virtually no wear on the sealing surfaces. You can rely on this design for steam service and volatile hydrocarbons.

- Zero Leakage: Meets the most stringent international standards for shutoff integrity.

- High Temperature: Capable of operating in environments exceeding 1,000°F.

- All-Metal Construction: Inherently fire-safe due to the absence of soft elastomer parts.

Key Takeaway: For your most dangerous or demanding process lines, the triple offset design provides the ultimate safety and sealing performance.

| Comparison | Double Offset | Triple Offset |

|---|---|---|

| Sealing | Interference | Torque-Seated |

| Seat Material | Soft / Metal | Metal Laminate |

| Application | General Process | Critical / High Temp |

This specialized geometry allows a quarter-turn valve to compete with the sealing capabilities of much larger globe or gate valves.

How do disc shapes affect the design of butterfly valve?

Disc shapes in the design of butterfly valve directly influence the flow coefficient and the amount of turbulence generated in your system. A thicker disc provides higher structural integrity for high-pressure lines but increases the pressure drop across the valve. You must select a disc profile that balances your flow requirements with the mechanical demands of the media.

Keep this in mind for your system efficiency.

How does disc geometry impact flow?

The geometry of the disc edge determines how smoothly the fluid transitions around the valve when it is in the partially open position. High-performance discs are often contoured to reduce turbulence and cavitation, which can damage your downstream equipment. You will find that streamlined discs offer a higher Cv (flow coefficient) for the same pipe diameter.

- Polished Discs: Reduce friction and prevent material buildup in food or pharmaceutical lines.

- Reinforced Discs: Essential for high-differential pressure applications to prevent bending.

- Lined Discs: Covered in PTFE or PFA to handle aggressive acids and corrosive fluids.

Key Takeaway: Optimizing the disc shape is critical for maintaining system pressure and preventing long-term mechanical erosion.

| Disc Type | Best Use Case | Benefit |

|---|---|---|

| Streamlined | High-flow systems | Lower pressure drop |

| Heavy-Duty | High-pressure lines | Structural stability |

| Encapsulated | Corrosive media | Chemical protection |

The interaction between the disc and the fluid is the primary factor in determining your system’s overall hydraulic efficiency.

Does the body type impact the design of butterfly valve?

The body type in the design of butterfly valve determines how the unit is installed and whether it can support “dead-end” service. You will primarily choose between wafer, lug, and flanged body styles based on your maintenance needs and safety protocols. Each style offers unique advantages in terms of weight, cost, and installation flexibility.

Wait, there’s a vital safety distinction here.

What is the difference between wafer and lug?

Wafer bodies are designed to be sandwiched between two pipe flanges, while lug bodies feature threaded inserts that allow for independent bolting to each flange. If you need to remove downstream piping for maintenance while keeping the upstream side under pressure, you must use a lug body. You will find that wafer valves are lighter and less expensive but do not support this maintenance flexibility.

- Wafer Style: Lightest and most compact; ideal for systems with limited space.

- Lug Style: Allows for dead-end service and downstream maintenance.

- Double Flanged: Used for very large diameter valves to ensure maximum stability.

Key Takeaway: Always verify your maintenance requirements before selecting a body type, as choosing a wafer valve for dead-end service is a major safety risk.

| Body Style | Dead-End Service | Installation Weight |

|---|---|---|

| Wafer | No | Low |

| Lug | Yes | Medium |

| Flanged | Yes | High |

Selecting the correct body style ensures your piping system remains adaptable for future repairs or modifications.

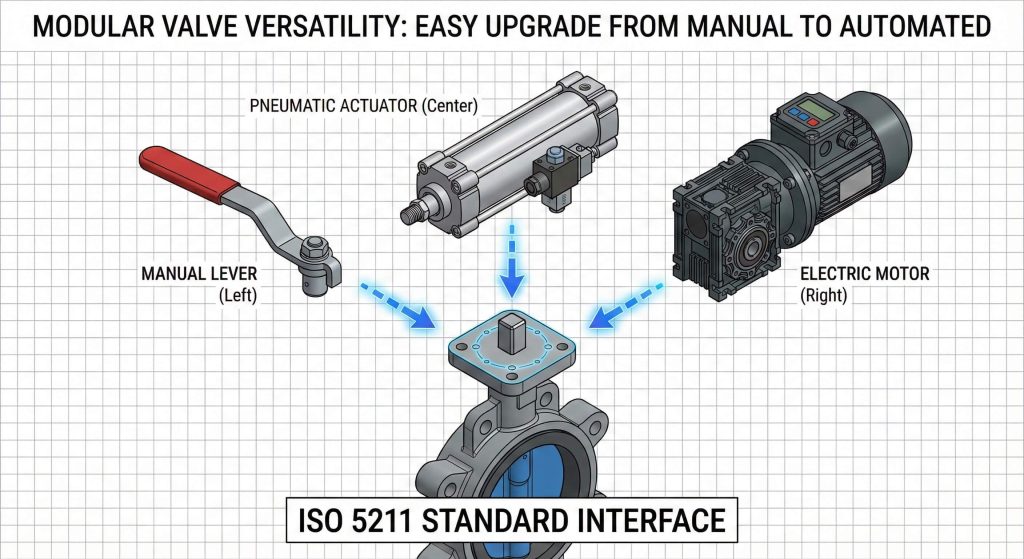

Can actuators automate the design of butterfly valve?

Actuators can easily automate the design of butterfly valve to provide remote control and precise flow modulation. Because butterfly valves are quarter-turn devices, they are highly compatible with pneumatic, electric, and hydraulic actuators. You will find that automation increases your operational efficiency by allowing for synchronized control from a central station.

There is more to consider regarding torque.

Which actuator type should you choose?

Your choice of actuator depends on the available power source and the speed of operation required by your process. Pneumatic actuators are favored for their fast response and “fail-safe” capabilities, while electric actuators offer high precision for modulating flow. You should always ensure the actuator’s torque output exceeds the valve’s “breakaway” torque requirements.

- Pneumatic: Fast, reliable, and ideal for hazardous areas.

- Electric: Best for remote locations where compressed air is unavailable.

- Manual Gear: A cost-effective solution for valves that are rarely operated.

Key Takeaway: Standardizing your actuator mounting pads to ISO 5211 ensures you can easily upgrade or replace automation components in the future.

| Actuator Type | Speed | Precision |

|---|---|---|

| Pneumatic | High | Moderate |

| Electric | Moderate | High |

| Manual | Low | Low |

Automation transforms a simple manual component into a sophisticated node within your facility’s control network.

How does wear impact the design of butterfly valve?

Wear patterns in the design of butterfly valve usually manifest as erosion on the disc edge or degradation of the sealing seat. Over time, high-velocity fluids or abrasive media will strip away material, leading to internal leakage and loss of control. You must monitor these wear indicators to prevent catastrophic failure in your process lines.

Think about the long-term costs.

How can you prevent premature wear?

Selecting the correct material for your media is the most effective way to prevent premature wear and extend the service life of your valves. For example, using a stainless steel disc in a salt water application prevents the galvanic corrosion that would quickly destroy a standard iron disc. You should also consider the “offset” designs discussed earlier to minimize mechanical friction.

- Hardened Discs: Resist erosion from slurries and abrasive particles.

- Lined Bodies: Protect the valve structure from corrosive chemical attack.

- Periodic Testing: Identifies small leaks before they become major system issues.

Key Takeaway: Proactive material selection and regular inspections are your best defenses against the high costs of unexpected valve replacement.

| Wear Type | Cause | Prevention |

|---|---|---|

| Erosion | High velocity | Hardened materials |

| Corrosion | Chemical attack | Proper Metallurgy |

| Friction | High cycling | Offset geometry |

Monitoring wear patterns allows you to schedule maintenance during planned shutdowns rather than reacting to emergencies.

How to perform maintenance on the design of butterfly valve?

Performing maintenance on the design of butterfly valve typically involves inspecting the seat for tears and checking the stem seals for leaks. Because these valves have fewer moving parts than globe or gate valves, your maintenance routines will be significantly shorter and less labor-intensive. You can often replace the seat or seals in the field without removing the entire valve from the line.

Wait, there’s a specific process to follow.

What are the steps for a successful overhaul?

A successful overhaul begins with isolating the valve and ensuring the line is fully depressurized before you begin work. You should then remove the actuator and inspect the stem for any signs of scoring or bending that could compromise the seal. You will find that keeping a stock of replacement seats and seal kits significantly reduces your downtime during scheduled maintenance.

- Visual Inspection: Check the disc edge for pitting or erosion.

- Seat Replacement: Ensure the new liner is properly seated and lubricated.

- Stem Seal Check: Verify that the packing or O-rings are preventing external leaks.

Key Takeaway: The simplicity of the butterfly design makes it one of the easiest valves to maintain, provided you follow standardized safety and service protocols.

| Maintenance Task | Frequency | Objective |

|---|---|---|

| Lubrication | 6 Months | Ensure smooth operation |

| Leak Test | Annually | Verify seal integrity |

| Seat Inspection | 2 Years | Prevent internal bypass |

Regular care ensures that your flow control infrastructure remains reliable and efficient for its entire intended service life.

Frequently Asked Questions

Q1: Can I use a butterfly valve for high-temperature steam?

Yes, but you must specify a triple offset design with a metal seat to handle the thermal expansion and high pressure. Concentric designs with soft seats will melt or deform quickly in steam service.

Q2: What’s the best way to prevent cavitation damage?

The best way to prevent cavitation is to ensure the valve is properly sized for your flow requirements and to avoid operating it in the “near-closed” position for long periods. Choosing a disc profile designed for throttling can also help.

Q3: Can I install a butterfly valve in any orientation?

Most butterfly valves can be installed horizontally or vertically, but for larger sizes, it is often recommended to install the stem horizontally to prevent debris from settling in the bottom stem bearing.

Q4: Why is the disc always in the flow path?

This is a fundamental part of the quarter-turn design where the disc rotates on its axis within the pipe. While this causes a small pressure drop, it allows for the compact and lightweight nature of the valve.

Q5: Is a lug valve safer than a wafer valve?

In terms of maintenance flexibility, the lug valve is safer because it allows for downstream piping removal while the valve remains closed under pressure, whereas a wafer valve requires the entire section to be depressurized.

Conclusion

Selecting the right flow control solution is essential for the safety and efficiency of your industrial operations. We are dedicated to providing precision-engineered hardware that meets the world’s most demanding technical standards. To optimize your system with high-performance components, contact us today for a professional consultation and custom quote.