You’re designing a new piping system, but space is already tight, and every ounce of weight adds to structural support costs. Traditional flanged valves are bulky, heavy, and complicate an already crowded layout. This leads to design compromises, higher installation expenses, and maintenance headaches down the line when a simple valve replacement requires significant effort. What if there was a valve that offered the same reliable performance but was designed specifically for compact, lightweight, and efficient systems?

1. What Defines a Ball Valve Wafer Type?

The ball valve wafer type is a quarter-turn valve characterized by its slim, flangeless body designed to be “sandwiched” between two pipe flanges. This unique construction is its defining feature, making it a master of efficiency in both space and weight. It provides the reliable shutoff of a standard ball valve in a much more compact package.

How does its compact design save you space?

Its genius lies in its flangeless body, which has a significantly shorter face-to-face dimension than traditional flanged valves. This allows you to fit reliable flow control into incredibly tight spaces where other valves simply won’t work. This design is perfect for skid-mounted systems, manifold assemblies, and complex piping runs.

- Reduces overall system footprint and length.

- Allows for closer placement of parallel pipes.

- Simplifies designs in constrained areas like equipment rooms.

What are its core components?

Like other ball valves, its operation hinges on a few critical parts working in harmony to control flow. The main components include the body, a rotating ball with a bore, two seats to create a seal, and a stem to connect the ball to an actuator or handle. Here’s the deal: its minimalist design uses fewer materials without compromising on these essential functions.

Understanding its unique mounting style

This valve is mounted by being clamped between two existing pipe flanges using long bolts or studs that extend from one flange to the other. The valve body has alignment holes, but not threaded bolt holes, which ensures it is centered correctly as the flanges are tightened. This method secures the valve and creates a seal with the gaskets on either side.

| Feature | Description | Implication |

|---|---|---|

| Mounting | Clamped between two pipe flanges | Relies on tension from long bolts |

| Alignment | Through-holes guide the bolts | Proper centering is crucial for sealing |

| Sealing | Gaskets on both faces | Gasket material must match process media |

This mounting style is the primary reason for the valve’s compact and lightweight nature.

Key Takeaway: The wafer type’s unique mounting design directly translates to lower material costs and a lighter, more compact system, saving you money on both the valve and the supporting infrastructure.

2. Key Benefits of a Ball Valve Wafer Type

When evaluating your options, the core advantages of a ball valve wafer type center on efficiency in cost, space, and installation time. Its design inherently reduces material usage, which drives down its initial purchase price and weight. This makes it a highly economical and practical choice for a wide range of applications.

Is it really lighter and more cost-effective?

Yes, absolutely, because it eliminates the bulky, heavy flanges that are integral to traditional valves. Less metal means a lower manufacturing cost and reduced weight, which can lead to significant savings on shipping, handling, and structural support requirements for your piping. But that’s not all.

How does it speed up installation and removal?

Installation is faster because there’s no need to align and bolt two separate sets of flanges to the valve itself. Instead, you simply slip the valve between the pipe flanges and tighten the long through-bolts, which also simplifies alignment. This streamlined process reduces labor time and gets your system online faster.

- Fewer bolts to manage compared to two separate flanged connections.

- Self-centering design aids in rapid, accurate alignment.

- Easier to handle and position due to lower weight.

Achieving optimal flow with less pressure drop

Many wafer ball valves feature a full-bore design, meaning the hole in the ball is the same diameter as the connecting pipe. This creates an unobstructed flow path when the valve is fully open, minimizing pressure drop and turbulence. This helps maintain the efficiency of your entire system.

| Benefit | How It’s Achieved | Reader Advantage |

|---|---|---|

| Cost-Effective | Flangeless body requires less material | Lower initial purchase price and shipping costs |

| Lightweight | Elimination of integrated flanges | Easier handling, reduced structural load |

| Fast Installation | Sandwiched design with through-bolts | Reduced labor time and faster system commissioning |

These benefits collectively contribute to a lower Total Cost of Ownership (TCO).

Key Takeaway: Choosing a wafer type ball valve optimizes your project budget and timeline by providing a solution that is cheaper to buy, lighter to handle, and faster to install.

3. Installing a Ball Valve Wafer Type

Properly installing a ball valve wafer type is critical to ensuring a leak-free seal and reliable long-term performance. While the process is faster than with flanged valves, attention to detail is essential to avoid common pitfalls. The key is ensuring perfect alignment and even pressure on the gaskets.

What tools and steps are required?

You’ll need a torque wrench, flange spreaders, appropriate gaskets, and the correct size of bolts and nuts for your flange class. The basic process is straightforward and efficient if you follow the correct sequence.

- Spread the pipe flanges apart just enough to insert the valve and gaskets.

- Insert the valve and gaskets, ensuring the valve is centered.

- Insert and hand-tighten the bolts in a star or criss-cross pattern.

- Use a torque wrench to tighten the bolts to the specified value.

How do you ensure proper alignment?

Proper alignment is the most critical step for preventing leaks and ensuring smooth valve operation. The valve should be perfectly concentric with the pipe flanges before you begin tightening the bolts. Think about it this way: an off-center valve will cause uneven gasket compression, creating a potential leak path and stressing the valve body.

Common mistakes to avoid during setup

The most frequent errors are over-torquing the bolts, which can damage the valve body or crush the gasket, and using the wrong type of gasket for the process media. Another common mistake is failing to tighten the bolts in an even, star-like pattern, which leads to uneven flange loading. Following manufacturer specifications is non-negotiable.

| Mistake | Consequence | Prevention |

|---|---|---|

| Over-Torquing | Damaged valve body, crushed gasket | Use a calibrated torque wrench and follow specs |

| Misalignment | Uneven seal, potential for leaks | Use alignment tools, visually confirm centering |

| Wrong Gasket | Chemical degradation, seal failure | Verify gasket material compatibility with media |

Avoiding these simple mistakes is the key to a successful, leak-free installation.

Key Takeaway: A methodical and precise installation process ensures you fully capitalize on the valve’s performance, preventing costly leaks and premature failures.

4. Where to Use a Ball Valve Wafer Type

The versatility of a ball valve wafer type makes it an excellent choice for a broad spectrum of industries and applications where space and weight are primary considerations. Its simple yet effective design is suitable for controlling a wide range of fluids. However, understanding its limitations is just as important as knowing its strengths.

Ideal industries and applications for this valve

You will find these valves performing reliably in systems that demand efficiency and a compact footprint. They are particularly well-suited for general-purpose on/off applications in moderately demanding environments. Here’s where it shines:

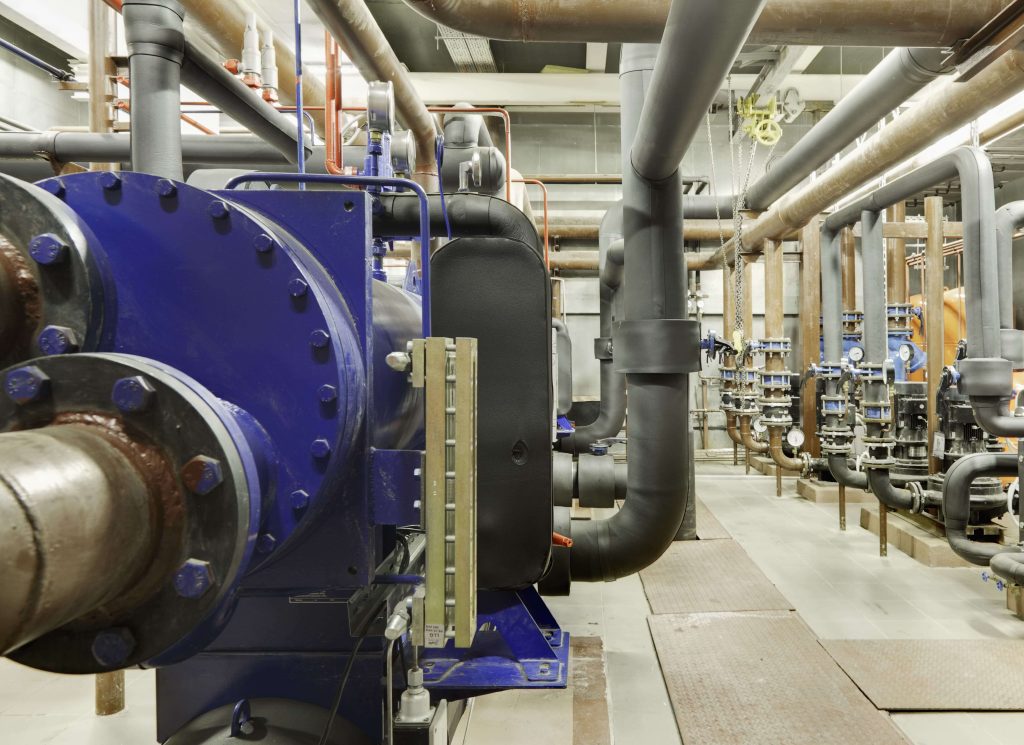

- HVAC: Used in chilled water lines and heating systems.

- Water/Wastewater Treatment: Ideal for flow control in treatment plants.

- Chemical Processing: Suitable for less aggressive chemicals where space is a premium.

- Food & Beverage: Used in utility lines like water or air.

But wait, there’s more. They are also a favorite for original equipment manufacturers (OEMs) building modular skids.

Can you use it for gas, liquid, or slurry?

Yes, the ball valve wafer type is highly adaptable and can handle clean liquids, gases, and even some light slurries. The key is to ensure the materials of the body, ball, and especially the seats are compatible with the process media. For slurries, a full-bore design is recommended to prevent clogging.

When is it NOT the right choice?

This valve is not a universal solution. It should generally be avoided for end-of-line service, as there is no flange on the downstream side to contain the process media safely when the piping is disconnected. It’s also less suitable for applications with very high pressures, extreme temperatures, or severe vibration, where a robust flanged valve might be a safer choice.

| Application Type | Suitability | Rationale |

|---|---|---|

| General On/Off | Excellent | Provides reliable shutoff in a compact design |

| Throttling/Control | Poor | Standard ball valves are not designed for precise flow modulation |

| End-of-Line | Not Recommended | Lacks a downstream flange for safe disconnection |

| High Vibration | Caution | Through-bolt design may be less rigid than flanged connections |

Matching the valve type to the application ensures safety and reliability.

Key Takeaway: By using the wafer ball valve in its ideal applications, you get a cost-effective and reliable component; using it incorrectly introduces unnecessary risk.

5. Ball Valve Wafer Type vs. Flanged Valves

The decision between installing a ball valve wafer type and a traditional flanged valve often comes down to specific system requirements for space, weight, and maintenance. While both provide quarter-turn shutoff, their design differences lead to significant trade-offs. The wafer type excels in compactness, whereas the flanged valve offers greater structural robustness.

Comparing weight, size, and system footprint

There is no contest here; the wafer type is the clear winner in terms of size and weight. By eliminating the heavy, cast-in flanges, a wafer valve can be up to 50% lighter and have a much shorter face-to-face dimension than its flanged counterpart. Let’s dig deeper.

- System Footprint: The wafer valve’s slim profile allows for more compact piping layouts.

- Structural Load: Reduced weight means you may need less substantial pipe supports.

- Handling: Lighter valves are easier and safer for personnel to install and handle.

What are the cost differences over time?

Initially, the wafer ball valve is almost always less expensive due to its lower material content. However, the Total Cost of Ownership (TCO) can be more nuanced. While installation is cheaper, maintenance can be more complex since the entire section of pipe must be isolated and depressurized to service the valve.

How does maintenance effort compare?

A flanged valve can be removed from a line while the other side remains under pressure (with proper safety procedures), making it better for certain maintenance scenarios. To remove a wafer valve, you must completely remove the through-bolts, which requires fully depressurizing the entire isolated pipe section. This can lead to longer system downtime during servicing.

| Parameter | Ball Valve Wafer Type | Flanged Ball Valve |

|---|---|---|

| Size & Weight | Very Low | High |

| Initial Cost | Low | High |

| Installation Speed | Fast | Slower |

| Maintenance Removal | Requires full line depressurization | Can be removed from one side |

The wafer type prioritizes installation efficiency, while the flanged type offers maintenance flexibility.

Key Takeaway: The choice depends on your priorities: select the wafer type to optimize initial cost and space, or choose a flanged valve when ease of maintenance and maximum robustness are more critical.

6. Maintaining Your Ball Valve Wafer Type

To ensure the long-term reliability and safety of your ball valve wafer type, a consistent maintenance schedule is essential. Although these valves are known for their durability, proactive inspections and servicing can prevent unexpected failures. Proper maintenance is straightforward and dramatically extends the valve’s operational life.

How often should you inspect it?

Inspection frequency depends entirely on the service conditions. For critical applications or those with corrosive media, quarterly inspections are wise. For general-purpose utility services like air or water, an annual check-up during planned shutdowns is often sufficient.

What are the signs of wear or failure?

Keep an eye out for tell-tale signs that your valve needs attention, as catching them early can prevent a major incident. The most common indicators point to seal degradation or internal wear. But wait, there’s more: a stiff handle can also signal internal problems.

- Leaks: Any visible leakage from the stem or between the valve and flanges.

- Difficult Operation: Increased torque required to turn the handle.

- Incomplete Shutoff: The valve passes media even when in the fully closed position.

Key steps for simple, effective servicing

Servicing typically involves replacing the soft components like the seats and seals, which are the most common wear items. After safely isolating and depressurizing the line, you remove the valve and disassemble it to replace these parts. Always re-torque the flange bolts to the correct specification upon reinstallation.

| Maintenance Task | Frequency | Purpose |

|---|---|---|

| Visual Inspection | Quarterly to Annually | Check for external leaks and physical damage |

| Operational Check | During Inspections | Cycle the valve to ensure smooth operation |

| Seal Replacement | As needed / during shutdowns | Renew the primary wear components for a reliable seal |

A proactive maintenance plan is far cheaper than dealing with an emergency failure.

Key Takeaway: Regular maintenance transforms your wafer ball valve from a simple component into a long-term, reliable asset, ensuring system integrity and preventing costly downtime.

Conclusion

You no longer have to compromise your system design with bulky, expensive valves that create more problems than they solve. The ball valve wafer type directly addresses the challenges of limited space, system weight, and installation costs, providing a lean and effective solution without sacrificing performance. At Ruito, we provide expertly engineered wafer ball valves that meet stringent API, ISO, and CE certifications, ensuring you get the reliability your operations demand. We don’t just sell valves; we engineer operational certainty.

Ready to optimize your system? Request a complimentary consultation with a Ruito application engineer to find the perfect valve for your needs.

Frequently Asked Questions (FAQ)

1. Can I use a ball valve wafer type for end-of-line service?

No, it is strongly discouraged. Wafer valves rely on the compression between two pipe flanges to maintain their seal and position. Using one at the end of a line without a downstream flange creates a significant safety hazard, as there is nothing to secure the valve or contain the process media if you remove the downstream piping.

2. What’s the best orientation to install a wafer ball valve?

For most applications, the orientation doesn’t matter, and it can be installed vertically or horizontally. However, if the media contains solids or slurry, installing the valve with the stem pointing horizontally is often preferred. This prevents solids from settling in the lower part of the body when the valve is closed, which could hinder sealing and operation.

3. How do I know if my gaskets are compatible?

This is critical: you must verify that the gasket material is chemically compatible with your process media, temperature, and pressure. Consult a chemical compatibility chart or the gasket manufacturer’s specifications. Using an incompatible gasket will lead to rapid degradation, leaks, and potential system failure.

4. Can I automate a ball valve wafer type easily?

Yes, absolutely. Wafer ball valves are very easy to automate. They feature a standard ISO 5211 mounting pad on top, which allows for the direct mounting of electric or pneumatic actuators. This makes them an excellent choice for automated systems where remote control is required.

5. How do I know if this valve can handle my process media?

You must check the materials of construction against your process requirements. Pay close attention to the body material (e.g., stainless steel, carbon steel), the ball and stem material, and especially the seat material (e.g., PTFE, RPTFE, PEEK). Each has different chemical and temperature limitations, and selecting the right combination is key to ensuring long-term, safe operation.