In a closed ball valve, thermal expansion or process cycling can trap pressurized fluid within the valve’s body cavity. This trapped pressure can lead to dangerous over-pressurization, causing seal failure, valve damage, or even catastrophic system failure, posing a significant safety risk to personnel and equipment. Understanding the purpose of a vented ball valve is the first step toward preventing these risks, and this guide explains how they work, where to use them, and why they are essential for your system’s safety and integrity.

The Purpose of a Ball Valve Vent

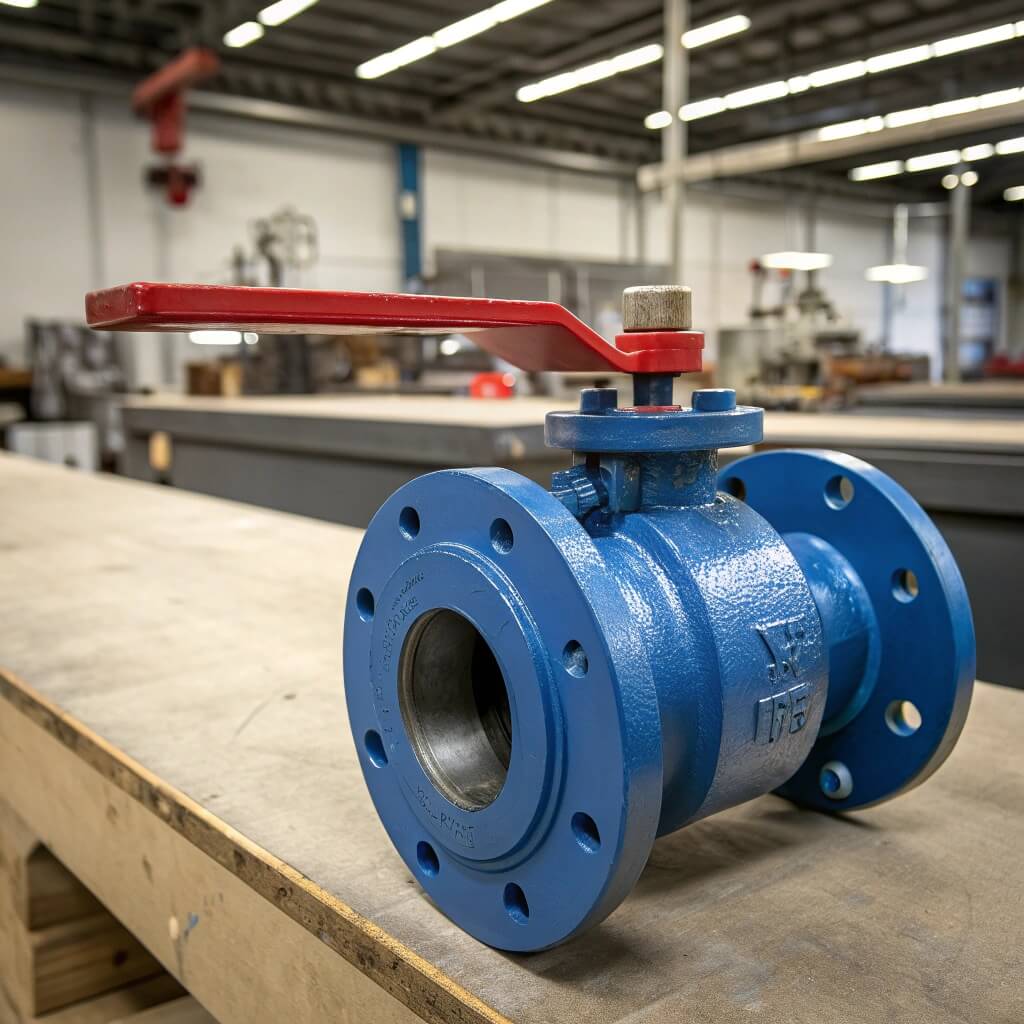

A vented ball valve is a safety device designed to prevent the buildup of dangerous pressure within the valve body cavity. This specialized valve features a small, drilled hole in the ball that allows trapped fluid to be safely released when the valve is closed. Its primary purpose is to mitigate risks associated with thermal expansion or flashing of liquids, ensuring operational integrity and personnel safety.

What is pressure trapping in valves?

Pressure trapping occurs when a ball valve closes, isolating a fixed volume of fluid in the cavity between the ball and the valve body. If this trapped liquid’s temperature increases, it expands, causing a rapid and extreme spike in internal pressure. This phenomenon is particularly common in systems handling volatile liquids or those subject to temperature fluctuations.

How a vent hole prevents overpressure

You might be wondering: how does a simple hole solve such a big problem? The vent hole creates a relief path for the expanding fluid, equalizing the pressure between the valve cavity and the upstream side of the pipeline. When the valve is in the closed position, the vent hole aligns with the upstream port, allowing excess pressure to bleed off safely. This prevents the cavity pressure from exceeding the system’s design limits.

- Pressure Equalization: The vent connects the high-pressure cavity to the lower-pressure upstream side.

- Safety Release: It acts as a passive, built-in relief mechanism.

- Seal Protection: It prevents overpressure from damaging or extruding the valve seats.

Key components of a vented valve

A vented ball valve is structurally similar to a standard ball valve but includes one critical modification: the vent hole. This hole is precisely drilled through the side of the ball, perpendicular to the main flow path. Its size and placement are engineered based on the valve’s size and service conditions to ensure effective pressure relief without compromising structural integrity.

Key Takeaway: A vented ball valve uses a strategically drilled hole in the ball to automatically relieve trapped pressure, preventing dangerous over-pressurization in the valve body cavity.

| Component | Standard Ball Valve | Vented Ball Valve |

|---|---|---|

| Ball | Solid, no perforations | Drilled with a vent hole |

| Function | Flow control (On/Off) | Flow control + Automatic pressure relief |

| Safety Feature | None for cavity pressure | Integrated vent for overpressure |

This comparison highlights that the addition of a simple vent hole transforms the valve from a basic control device into a critical safety component.

How a Ball Valve Vent Functions

The functionality of a vented ball valve is centered on its ability to automatically relieve pressure from the valve’s central cavity. This passive safety feature operates based on the valve’s position, ensuring that a relief path is available only when needed. Understanding this mechanism is crucial for correct installation and reliable system operation.

The venting process in the closed position

When you turn the handle to close a vented ball valve, the solid face of the ball blocks the flow, but the vent hole simultaneously aligns with the upstream side. This creates a direct path from the valve’s body cavity back to the upstream piping. As fluid trapped in the cavity expands, the resulting pressure is immediately and safely vented upstream, maintaining equilibrium.

Upstream vs. downstream venting

Here’s the deal: the vent must always face the correct direction to function. In an upstream vented valve, the vent hole releases pressure toward the source of the flow, which is the standard and safest configuration. Downstream venting, where pressure is released in the direction of flow, is less common and only used in specific bidirectional applications where pressure relief is needed on both sides.

- Upstream Venting (Standard): The vent hole is oriented to face the upstream side when the valve is closed. This is the most common and recommended configuration.

- Downstream Venting (Specialized): The vent is oriented to face the downstream side. This is used in applications where the pressure source may switch.

- Dual Vents: In rare cases, valves may have vents on both sides for complex bidirectional flow scenarios.

Does flow direction matter for the vent?

Yes, flow direction is absolutely critical for a vented ball valve to function correctly. The valve must be installed with the vent hole oriented toward the side of the system where pressure can be safely relieved, which is almost always the upstream or high-pressure side. Installing it backward renders the vent useless and can lead to the very over-pressurization event it was designed to prevent.

Key Takeaway: Proper function relies on installing the valve so the vent hole faces the upstream pipeline when the valve is closed, providing a safe path for pressure release.

| Orientation | Functionality | Application |

|---|---|---|

| Correct (Vent Upstream) | Safely relieves cavity pressure | Standard installation for process safety |

| Incorrect (Vent Downstream) | Traps pressure, disables safety feature | Installation error, creates a safety hazard |

The data confirms that valve orientation is not a suggestion but a mandatory requirement for achieving the intended safety function.

Risks Without a Ball D-Ball Valve Vent

Failing to use a vented ball valve in applications prone to thermal expansion exposes your system to severe and often hidden risks. These risks range from minor equipment damage to catastrophic failures that can halt production and endanger personnel. The initial cost saving of a non-vented valve is insignificant compared to the potential financial and safety consequences of a pressure-related incident.

The danger of thermal liquid expansion

When a liquid is trapped in the confined space of a valve cavity, even a small increase in temperature can cause a massive increase in pressure due to thermal expansion. For example, trapped water heating from 20°C to 50°C can generate pressures exceeding 3,000 PSI (200 bar), far beyond the design limits of most standard valves. This hydraulic pressure can exert enough force to deform internal components or burst the valve body.

Potential for catastrophic seal failure

But what does that mean for your system? When cavity pressure exceeds the line pressure, it can physically push the valve seats out of their housing and into the flow path, causing an immediate and total loss of sealing capability. This is known as seat extrusion and can lead to uncontrolled leakage, process contamination, and potentially hazardous spills. A damaged seat not only causes the valve to fail but can also lead to downstream equipment damage.

- Seat Extrusion: High cavity pressure forces soft seats out of position.

- Stem Seal Leakage: Excessive pressure can compromise the stem seals, leading to external leaks.

- Valve Body Rupture: In extreme cases, the valve body itself can fracture or burst.

Compliance and safety standard violations

Using a non-vented valve in an application where one is required can result in non-compliance with industry safety standards like ASME and API. Regulatory bodies and insurance providers mandate specific safety measures to prevent pressure-related accidents. A failure resulting from improper valve selection can lead to significant fines, legal liability, and a tarnished safety record.

Key Takeaway: The primary risks of omitting a vented valve are catastrophic seal failure and valve body rupture due to uncontrolled pressure from thermal liquid expansion.

| Risk Category | Consequence of Using Non-Vented Valve | Prevention with Vented Valve |

|---|---|---|

| Mechanical | Seat extrusion, stem leakage, body rupture | Pressure is equalized, protecting components |

| Operational | Unplanned downtime, process contamination | Ensures reliable valve operation and isolation |

| Regulatory | Non-compliance fines, legal liability | Adheres to industry safety standards (e.g., ASME) |

This analysis shows that the risks are multi-faceted, affecting mechanical integrity, operational uptime, and legal compliance.

Key Ball Valve Vent Applications

Vented ball valves are not necessary for every application, but they are absolutely critical in specific services where pressure trapping is a known risk. Identifying these scenarios is the first step for any engineer or procurement manager aiming to build a safe and reliable fluid system. These valves are specified where the process medium or operating conditions can lead to dangerous pressure buildup.

When is a ball valve vent required?

You need a vented ball valve in any application where a liquid can be trapped in the valve cavity and is subject to a temperature increase. This includes services handling cryogenic fluids (like LNG), liquids that can flash into gas, or any system exposed to ambient temperature swings. Any process involving thermal cycling or the transfer of fluids between temperature-controlled zones should be evaluated.

Industries relying on vented valves

You might be surprised at the range of industries. While commonly associated with oil and gas, vented ball valves are essential across many sectors. Any industry handling volatile or temperature-sensitive liquids relies on this technology to ensure safety and prevent equipment damage. The common thread is the need to manage pressure in closed-off sections of a pipeline.

- Cryogenics (LNG & Industrial Gases): To vent gasified liquid and prevent extreme pressure buildup.

- Chemical Processing: For handling volatile solvents and reactive chemicals that expand with heat.

- Water Treatment: In systems with significant temperature differentials, such as between outdoor and indoor piping.

- Shipbuilding: For fuel lines and hydraulic systems that are subject to changing environmental temperatures.

Vents in cryogenic & high-temp services

Cryogenic services, such as those for liquefied natural gas (LNG), are a prime example where vented valves are non-negotiable, as the trapped liquid will rapidly vaporize and expand. Conversely, in high-temperature services like steam or thermal oil, a cool-down phase can create a vacuum; a vented valve can help equalize this by allowing pressure back into the cavity. In both extreme hot and cold applications, managing pressure changes is paramount.

Key Takeaway: Vented ball valves are mandatory in cryogenic, thermal cycling, and volatile liquid applications to prevent catastrophic failure from pressure buildup.

| Application Type | Primary Risk Factor | Vented Valve’s Role |

|---|---|---|

| Cryogenic (e.g., LNG) | Rapid vaporization and expansion | Vents gas to prevent pressure >50x liquid state |

| Thermal Cycling | Liquid expansion due to heat changes | Relieves pressure during heat-up cycles |

| Volatile Liquids | Low boiling point, prone to flashing | Vents vapor to maintain pressure equilibrium |

This table clearly maps specific high-risk applications to the protective function of a vented ball valve, justifying its specification.

Specifying Your Ball Valve Vent

Once you determine a vented ball valve is necessary, correct specification is the next critical step to ensure system safety and reliability. Choosing the right valve involves more than just matching pipe size; it requires a detailed review of process conditions and material compatibility. An incorrectly specified valve can fail just as easily as a non-vented one.

Key selection criteria to consider

Let’s break it down. The primary factors to consider are the pressure and temperature ratings, which must exceed the maximum operating conditions of your system. You must also evaluate the process media to ensure all valve materials, including the body, ball, and seals, are chemically compatible. Finally, the valve’s end connections must match the existing pipeline for a secure, leak-free installation.

- Pressure & Temperature: Ensure the valve’s rating is sufficient for the application’s worst-case scenario.

- Media Compatibility: Select materials (body, ball, seats) resistant to corrosion from the process fluid.

- End Connections: Specify the correct type (e.g., flanged, threaded, welded) and standard (e.g., ASME, DIN).

What vent hole size do I need?

The vent hole size is typically standardized by the manufacturer based on the valve’s nominal size and pressure class. While a larger hole vents pressure more quickly, it can also create a potential erosion point or weaken the ball’s structural integrity if not engineered correctly. For most applications, the manufacturer’s standard size is sufficient, but custom sizing may be required for very high-viscosity fluids or rapid thermal cycling.

Material compatibility checks for media

Ensuring material compatibility is crucial for the long-term integrity of the valve and the safety of the system. For corrosive media like acids or seawater, you may need to specify corrosion-resistant alloys like stainless steel (SS316) or duplex instead of standard carbon steel. Similarly, the soft seals (seats and packing) must be selected based on their resistance to the process fluid and operating temperature range.

Key Takeaway: Specifying a vented ball valve requires a thorough analysis of pressure, temperature, media compatibility, and vent orientation to ensure safe and reliable operation.

| Specification Parameter | Considerations | Common Options |

|---|---|---|

| Body Material | Corrosion resistance, strength, temperature | Carbon Steel (A216 WCB), Stainless Steel (A351 CF8M) |

| Seat Material | Temperature range, chemical resistance, abrasion | PTFE, RPTFE, PEEK, Metal-seated |

| Pressure Class | System’s maximum allowable operating pressure | ASME 150, 300, 600; PN16, PN40 |

This selection guide provides a framework for making informed decisions during the procurement and engineering phases.

Ball Valve Vent Installation Rules

Proper installation is the final, critical step to ensure your vented ball valve performs its safety function correctly. Even a perfectly specified valve will fail to protect your system if it is installed incorrectly. Adhering to strict installation protocols, particularly regarding orientation, is non-negotiable for system integrity.

Correct orientation for proper function

The single most important rule is to install the valve so that the vent hole faces upstream when the valve is in the closed position. Most vented ball valves have a mark on the body or stem indicating the vent’s location, and the handle typically points toward this mark when closed. This ensures that any pressure buildup in the cavity is relieved back toward the pressure source, not into a potentially isolated downstream section.

Common installation mistakes to avoid

Here’s where things can go wrong. The most common and dangerous mistake is installing the valve backward, with the vent facing downstream. Another frequent error is failing to verify the vent’s orientation before pressurizing the system, as markings can sometimes be unclear or misaligned. Finally, using excessive pipe dope on threaded connections can clog the small vent hole, rendering it useless.

- Backward Installation: Installing the valve with the vent facing downstream.

- Ignoring Markings: Failing to identify and align the vent orientation mark correctly.

- Clogging the Vent: Using too much sealant that can block the pressure relief path.

- Incorrect Handle Alignment: Assuming the handle position without verifying the actual ball position.

Pre-commissioning and testing steps

Before putting the system into service, you must verify the installation. Close the valve and confirm that the handle position aligns with the manufacturer’s instructions for the vented (upstream) side. If possible, perform a low-pressure leak test to ensure the vent path is clear and that the valve seats and seals are performing as expected after installation.

Key Takeaway: The valve must be installed with the vent hole facing the upstream pressure source, and this orientation must be verified before commissioning to prevent catastrophic failure.

| Installation Step | Action Required | Rationale |

|---|---|---|

| 1. Orientation Check | Identify vent mark; align it to face upstream. | Ensures pressure relieves to the safe side. |

| 2. Secure Connections | Properly tighten flanges or threads without over-torquing. | Prevents mechanical stress and connection leaks. |

| 3. Pre-Commissioning Test | Conduct a low-pressure seat and vent path test. | Verifies correct installation and function before full operation. |

This procedural table underscores that a methodical, checklist-based approach to installation is essential for safety.

Conclusion: Secure Your System with Expertly Engineered Valves

Preventing system over-pressurization is not just about compliance; it’s about operational integrity and fundamental safety. The hidden danger of trapped pressure in a closed ball valve can be completely neutralized with the correct application of a vented ball valve. By ensuring that expanding fluids have a safe path to relieve pressure, you protect your equipment, your process, and your personnel from catastrophic failure.

At RUITO, we provide more than just valves; we deliver peace of mind with expertly engineered vented ball valves tailored to your exact specifications. With deep technical expertise, robust OEM/ODM customization capabilities, and a commitment to internationally recognized quality standards like ISO 9001 and CE, we ensure your systems are safe, reliable, and efficient. As your trusted high-end universal valve exporter, we are dedicated to helping you achieve unparalleled operational excellence.

Contact our technical team today to discuss your project’s specific needs and let us help you build a safer, more reliable system.

Frequently Asked Questions (FAQ)

- Can I use a standard, non-vented ball valve for cryogenic service?

No, you absolutely should not. Using a non-vented valve in cryogenic service is extremely dangerous, as the rapid vaporization of trapped liquid will cause a massive pressure spike that can lead to valve rupture. - How do I confirm if my existing valve is a vented model?

Generally, vented ball valves have an external marking, such as a small hole or stamp on the valve body, indicating the presence and location of the internal vent. If there are no markings, you may need to consult the manufacturer’s documentation or, if safe to do so, visually inspect the ball with the valve removed from the line. - Is a ball valve vent necessary for every single application?

No, it is not. Vented ball valves are only required in applications where a liquid can be trapped in the valve cavity and is subject to thermal expansion or vaporization, such as in cryogenic services, systems with significant temperature swings, or when handling volatile fluids. - Can I drill a vent hole into a non-vented ball valve myself?

Generally, no. Drilling a hole in an existing valve is strongly discouraged as it can compromise the ball’s structural integrity, violate the manufacturer’s warranty and pressure-retaining certification, and introduce metal shavings into the system. It is always safer and more reliable to purchase a valve that was designed and manufactured as a vented model. - Does the vent hole negatively affect the valve’s flow rate (Cv)?

No, it does not. The vent hole is located on the side of the ball and is out of the primary flow path when the valve is in the fully open position. Therefore, it has a negligible effect on the valve’s flow coefficient (Cv) and does not impede performance.