Strategic Partnership Programs

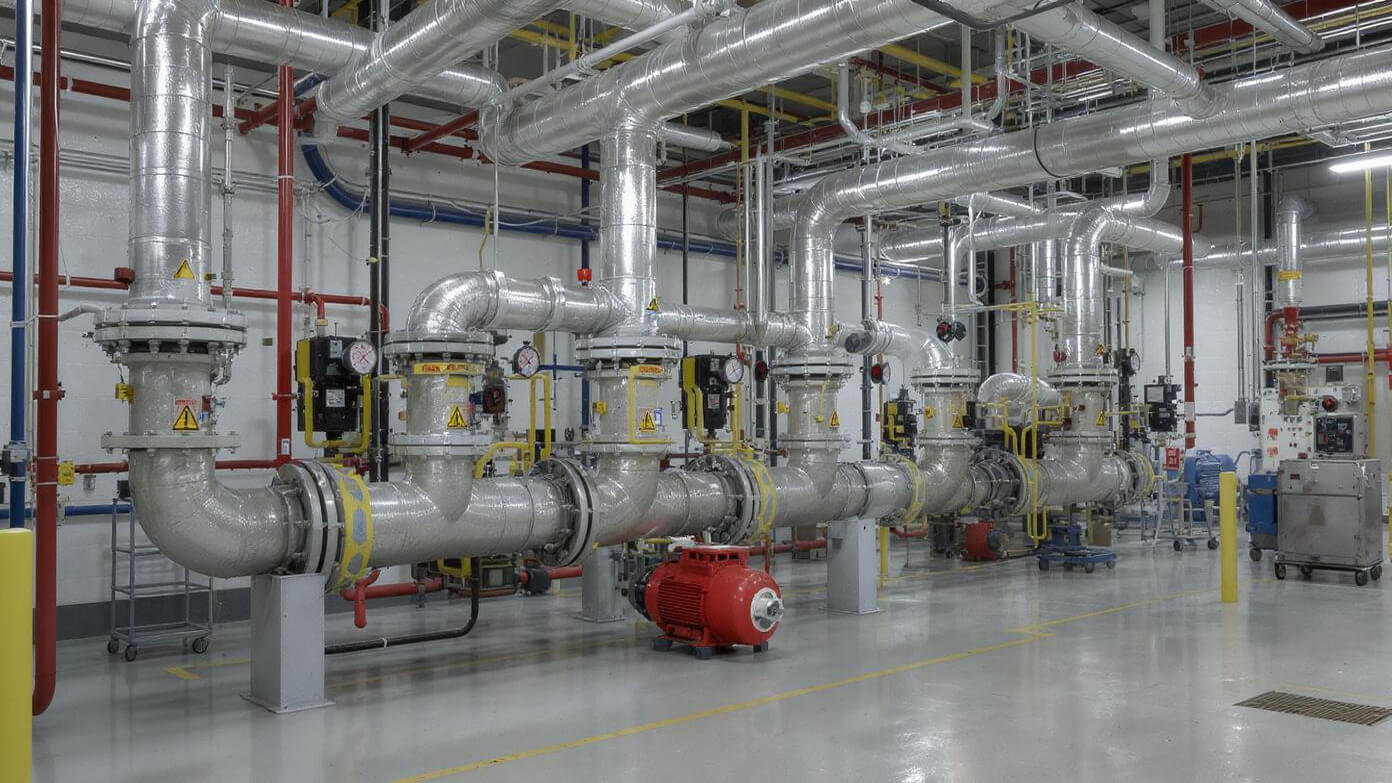

Structured manufacturing partnerships designed to optimize procurement efficiency and project execution through proven industrial expertise.

Volume Procurement Partner

Annual Framework Agreements

- Annual production capacity allocation up to 50,000 units with guaranteed delivery windows

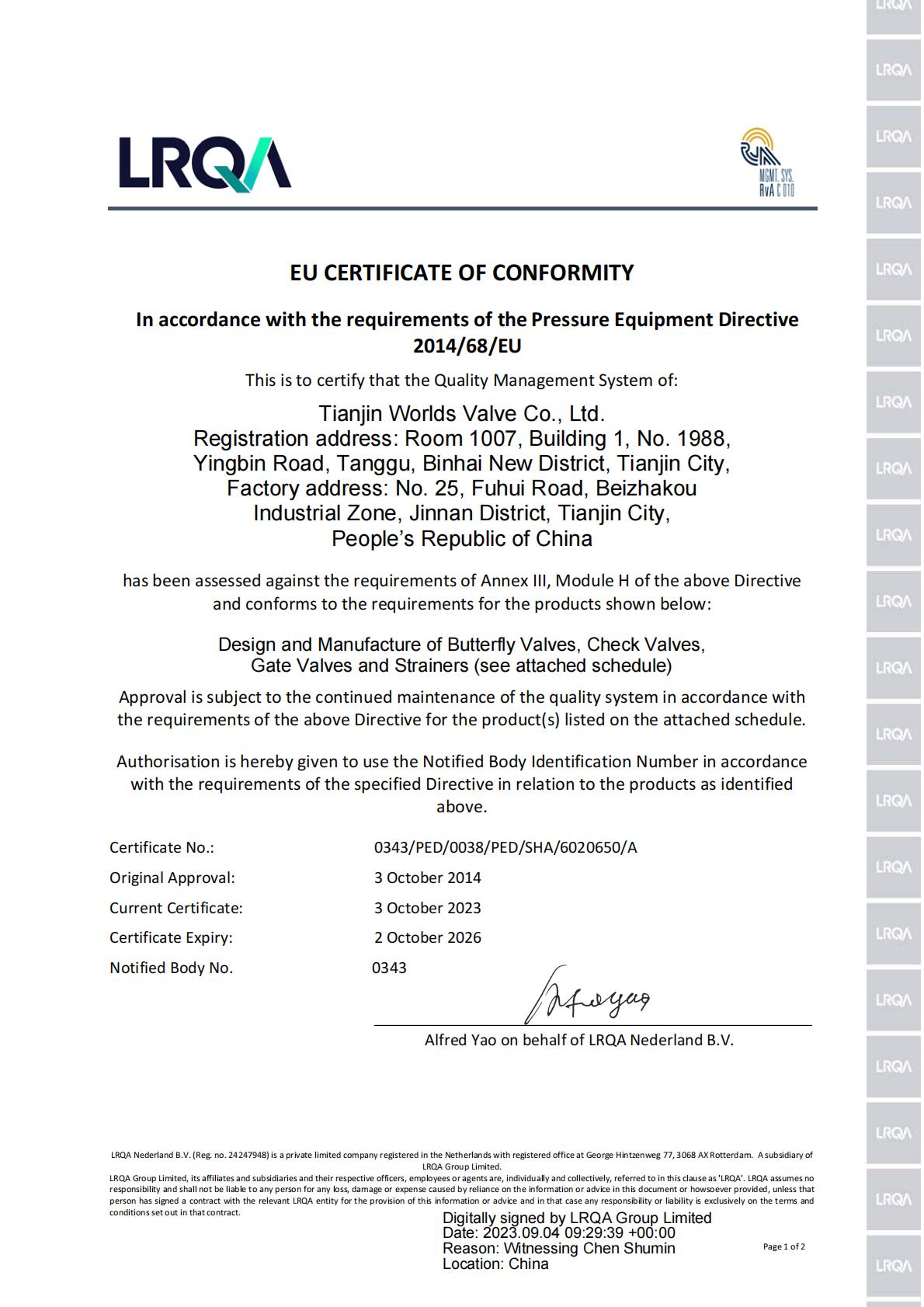

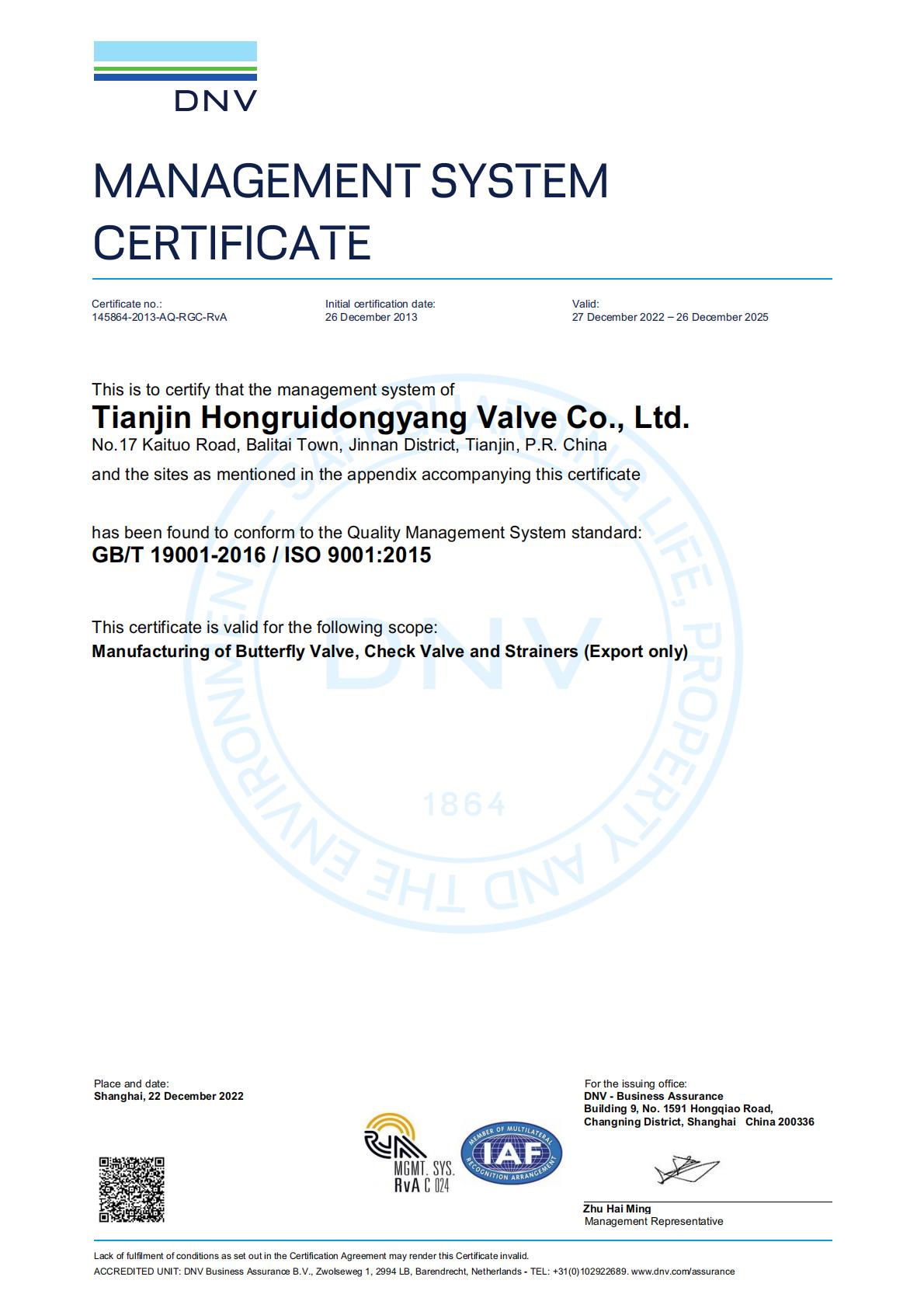

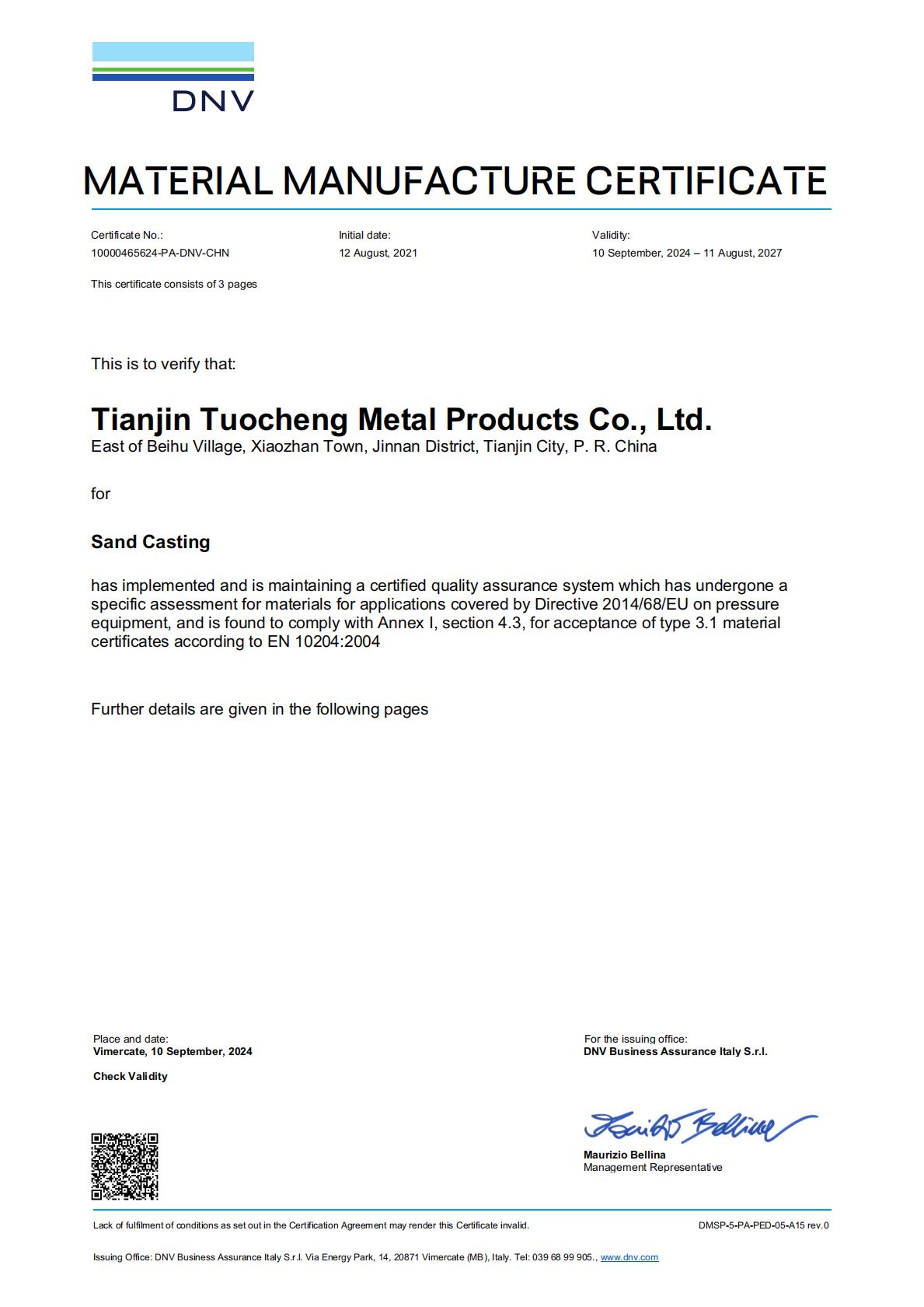

- Comprehensive technical documentation packages including CAD files and test certificates

- Dedicated quality control protocols with batch tracking and third-party verification support

- Flexible payment terms including 45-day credit facilities for established procurement cycles

- Volume-based pricing tiers with transparent cost structures and annual price protection

Establish predictable supply chains through dedicated manufacturing capacity and systematic quality assurance processes.

Engineering Collaboration

Custom Manufacturing Solutions

- Technical consultation services with 24-hour response commitment for specification analysis

- Custom tooling development and design optimization based on client specifications

- Prototype manufacturing with accelerated 10-day delivery for design validation

- Priority production scheduling for project-critical components with milestone tracking

- Compliance documentation support for ISO 9001, CE marking, and industry-specific certifications

Deploy specialized manufacturing expertise to solve complex engineering challenges through collaborative technical development.

OEM Manufacturing Alliance

Integrated Supply Chain Partnership

- Dedicated production lines with reserved capacity allocation for multi-year contracts

- White-label manufacturing capabilities including custom branding and packaging specifications

- Executive-level quality review protocols with quarterly performance assessments

- Supply chain transparency with real-time production tracking and inventory management

- Comprehensive technical support including remote troubleshooting and application guidance

Secure competitive advantages through integrated manufacturing partnerships that ensure consistent quality and reliable delivery performance.

Leverage 15 years of manufacturing expertise and proven delivery performance to strengthen your supply chain strategy.