Yes, butterfly valves can be used for throttling as long as you maintain the disc opening between 30 and 80 degrees. Many industrial operators struggle with flow control issues that lead to constant hardware replacements. Using the wrong equipment for modulation causes seat erosion and expensive system downtime that ruins your profit margins. A properly configured butterfly valve throttle provides a cost-effective solution for regulating liquids and gases in large-scale piping systems.

1. Can you use a butterfly valve throttle for flow?

You can use a butterfly valve throttle for flow regulation in systems that do not require high-precision micro-adjustments. These units perform exceptionally well in water treatment and HVAC applications where moderate flow modulation is necessary. The butterfly valve throttle must be paired with a high-quality actuator to hold the disc steady against fluid forces.

Is the disc travel range critical?

But here is the catch… you must avoid operating the disc at very low angles to prevent high-velocity “jetting” that destroys the valve seat. Staying within the optimal travel window ensures the hardware survives years of service without leaking.

- Maintain disc angles between 30 and 70 degrees for linear control.

- Avoid opening the valve less than 20 degrees during active throttling.

- Limit maximum opening to 80 degrees to maintain pressure drop control.

Key Takeaway: Successful throttling requires keeping the disc within a specific angular window to protect the internal sealing surfaces.

| Feature | Range | Benefit |

|---|---|---|

| Preferred Angle | 30° – 70° | Linear Flow Control |

| Minimum Angle | 20° | Prevents Seat Erosion |

| Maximum Angle | 80° | Maintains System Backpressure |

The following data analysis shows how disc positioning impacts the longevity of your industrial flow control assets.

2. How does a butterfly valve throttle liquid flow?

A butterfly valve throttle regulates liquid flow by rotating a circular disc to change the available cross-sectional area of the pipe. As you adjust the disc position, the resulting pressure drop dictates the volumetric flow rate passing through the body. This mechanical restriction allows you to manage system parameters effectively using standard rotary hardware.

Does pressure drop drive modulation?

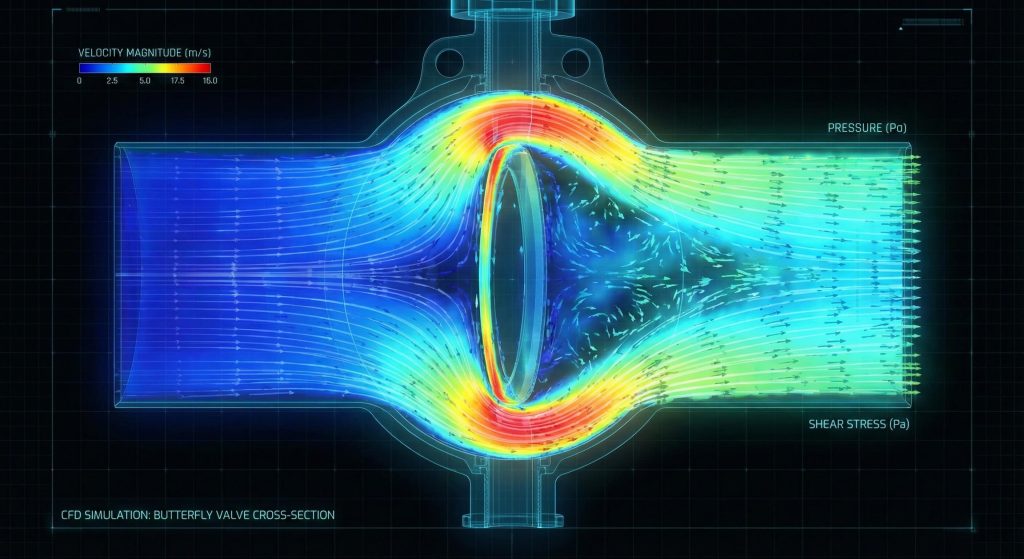

Wait, there’s more… the geometry of the disc creates two semi-circular flow paths that act like variable orifices within your pipeline. This dual-path flow characteristic helps stabilize the media as it passes through the valve body at high velocities.

- Flow velocity increases significantly at the edges of the disc.

- Pressure energy converts to kinetic energy during the throttling process.

- Standard discs provide an equal percentage flow characteristic for most fluids.

Key Takeaway: Fluid modulation occurs through calculated pressure drops generated by the disc’s angular resistance within the media stream.

| Variable | Influence | Outcome |

|---|---|---|

| Disc Angle | High | Flow Volume Control |

| Media Velocity | Medium | Erosion Risk Level |

| Pressure Drop | High | System Regulation Power |

This structural overview explains why specific mechanical designs are necessary for maintaining consistent volumetric output in your facility.

3. Why is butterfly valve throttle wear a concern?

Wear remains a primary concern because high-velocity media creates localized erosion and mechanical fatigue on the butterfly valve throttle components. When the disc sits partially open, it faces constant bombardment from abrasive particles or turbulent liquid streams. This continuous stress eventually compromises the bubble-tight shut-off capability required for system isolation.

Does high velocity cause seat erosion?

Here is the deal… the “jetting” effect occurs when fluid squeezes through a tiny gap between the disc and the resilient seat. This high-speed flow physically washes away elastomer materials like EPDM or NBR over time.

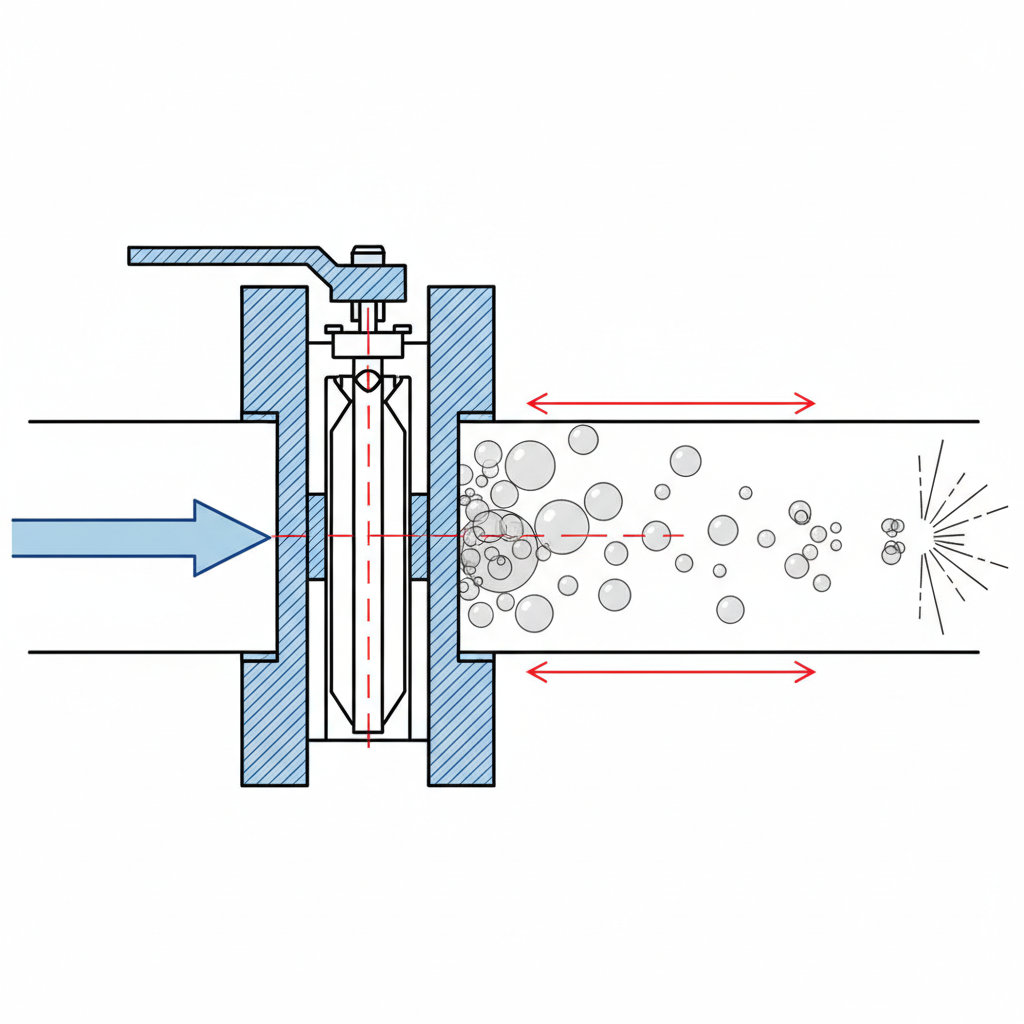

- Localized cavitation often occurs on the downstream side of the disc.

- Vibration from turbulence can lead to shaft bearing failure.

- Abrasive media accelerates metal loss on the disc edges.

Key Takeaway: Preventing premature wear requires selecting hardened materials or advanced offset designs for any modulating application.

| Wear Type | Cause | Impact |

|---|---|---|

| Cavitation | Pressure Fluctuations | Disc Pitting |

| Erosion | High Media Velocity | Seat Leakage |

| Fatigue | Turbulent Vibration | Shaft Failure |

Understanding these wear patterns allows your maintenance team to predict failure points before they halt your production line.

4. Does disc design affect butterfly valve throttle?

Disc geometry in your butterfly valve throttle determines the turbulence levels and control sensitivity across the entire travel range. Standard flat discs are cost-effective but often create excessive turbulence that destabilizes the flow at high pressures. Specialized contoured designs help smooth the fluid transition and reduce the drag forces acting on the actuator.

Is a contoured disc profile superior?

Think about this… a streamlined disc edge allows fluid to rejoin more smoothly behind the valve, which minimizes the wake area. This reduction in turbulence directly improves the accuracy of your flow loop and reduces mechanical noise.

- Streamlined edges reduce the torque required for disc movement.

- V-port disc inserts provide much higher rangeability for precision tasks.

- Thicker disc profiles offer better structural integrity under high-pressure drops.

Key Takeaway: Selecting the right disc profile balances the need for flow capacity with the requirement for stable modulation control.

| Profile Type | Flow Stability | Best Application |

|---|---|---|

| Flat Disc | Low | Low-Pressure Water |

| Contoured Edge | Medium | General Industrial |

| V-Notch | High | Precision Chemical |

The following technical comparison highlights how disc shapes influence the hydraulic efficiency of your piping network.

5. Can wafer types handle butterfly valve throttle?

Wafer-style butterfly valve throttle units are suitable for mid-line regulation where space is limited and budget constraints are tight. These valves are lightweight and easy to install between existing pipe flanges using long bolts that span the valve body. They provide a compact solution for flow control in systems with moderate pressure and temperature requirements.

Are installation alignments important?

The best part? Wafer valves use the pipe flanges for structural support, making them very efficient for weight-sensitive applications like shipboard systems. You must ensure the valve is perfectly centered to avoid uneven wear on the internal liner.

- Improper centering leads to disc interference with the pipe wall.

- Long bolts are susceptible to thermal expansion in high-heat systems.

- Wafer designs lack the dead-end service capability of lug-style valves.

Key Takeaway: Wafer valves offer a space-saving throttling option but require precise alignment to maintain their sealing integrity.

| Install Factor | Requirement | Risk of Failure |

|---|---|---|

| Centering | High Precision | Edge Scouring |

| Bolt Torque | Even Distribution | Body Distortion |

| Flange Seal | Gasket Alignment | External Leak |

Proper installation techniques ensure that your low-profile valves perform as reliably as heavier flanged alternatives.

6. Is offset design better for butterfly valve throttle?

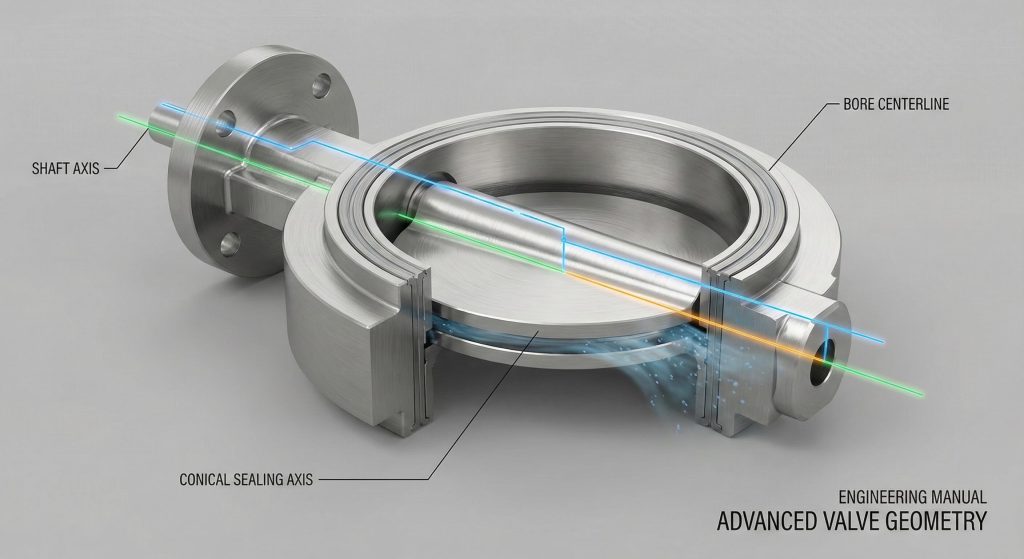

An offset butterfly valve throttle is significantly better for longevity because the cam-like action lifts the disc away from the seat immediately upon opening. This design eliminates the constant friction found in standard concentric valves where the disc always rubs against the elastomer. Using offset technology reduces the wear on your seals and extends the interval between maintenance cycles.

Why do triple offsets reduce friction?

You might be wondering… how a metal-to-metal seal can achieve bubble-tight shut-off while still allowing for frequent modulation. Triple offset valves use a conical sealing geometry that ensures the disc only contacts the seat at the final point of closure.

- Double offset designs protect the seat during the middle travel range.

- Triple offset hardware handles high-pressure steam and gas modulation.

- Metal seats resist the abrasive effects of high-velocity media better than rubber.

Key Takeaway: High-performance offset valves are the gold standard for demanding throttling applications in the oil and gas industry.

| Design Type | Friction Level | Temperature Limit |

|---|---|---|

| Concentric | High | Lower (Soft Seat) |

| Double Offset | Low | Medium |

| Triple Offset | Zero | High (Metal Seat) |

This analysis confirms that investing in offset designs pays for itself through reduced spare parts consumption and increased uptime.

7. When should you avoid butterfly valve throttle?

You should avoid a butterfly valve throttle in applications requiring extreme precision at very low flow rates or when handling highly abrasive slurries. While these valves are versatile, they have physical limits regarding their rangeability and resistance to high-pressure cavitation. Using them in the wrong environment leads to catastrophic failure of the disc and seat within weeks.

Does cavitation happen at low angles?

Believe it or not… when a butterfly valve is nearly closed, the high pressure-drop creates vapor bubbles that collapse violently against the downstream pipe wall. This phenomenon, known as cavitation, can eat through solid stainless steel if left unmanaged.

- Standard butterfly valves typically have a 20:1 rangeability ratio.

- Precision dosing requires valves with higher resolution at the bottom end.

- Slurries with large particles will quickly erode the disc’s leading edge.

Key Takeaway: High-pressure drop applications and abrasive media often require specialized globe or pinch valves instead of butterfly designs.

| Hazard | System Effect | Recommended Valve |

|---|---|---|

| Cavitation | Pipe Pitting | Globe Valve |

| Slurry Wear | Disc Erosion | Pinch Valve |

| Low Flow | Poor Control | V-Port Ball |

Evaluating your media characteristics early in the design phase prevents costly engineering errors later in the project.

8. How to optimize a butterfly valve throttle setup?

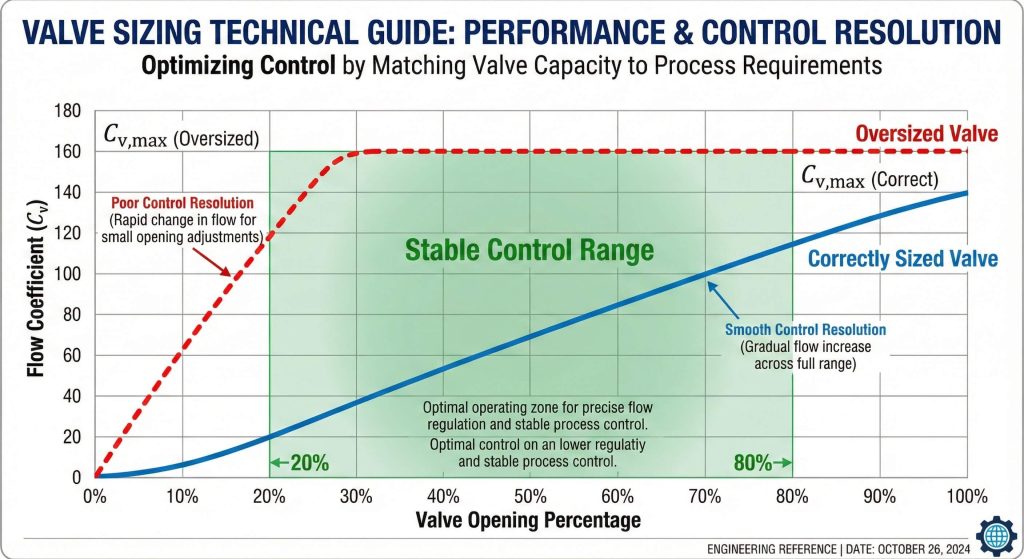

Optimization of your butterfly valve throttle starts with sizing the valve based on actual flow coefficients rather than the pipe diameter. Many systems suffer from “oversized” valves that must operate at tiny opening angles just to meet the process setpoint. Sizing the valve correctly ensures the disc stays in the stable control zone between 40 and 70 percent open.

Should you size by Cv instead of pipe?

What does this mean? If you use a valve that matches your 12-inch pipe but only need 30 percent of its capacity, you will experience “hunting” where the actuator never finds a steady position. A smaller valve with a higher velocity profile often provides much smoother control.

- Calculate the required Cv at minimum, normal, and maximum flow.

- Select a valve size where normal flow occurs at 60 percent opening.

- Use digital positioners to ensure repeatable disc placement.

Key Takeaway: Proper sizing is the most effective way to eliminate control instability and protect the valve from high-velocity damage.

| Sizing Step | Tool Used | Desired Result |

|---|---|---|

| Flow Calc | Cv Software | Correct Valve Size |

| Positioner | Digital Link | Precision Response |

| Dampening | Actuator Tune | No Control Hunting |

By following these sizing guidelines, you can transform a standard isolation valve into a high-performance modulation instrument.

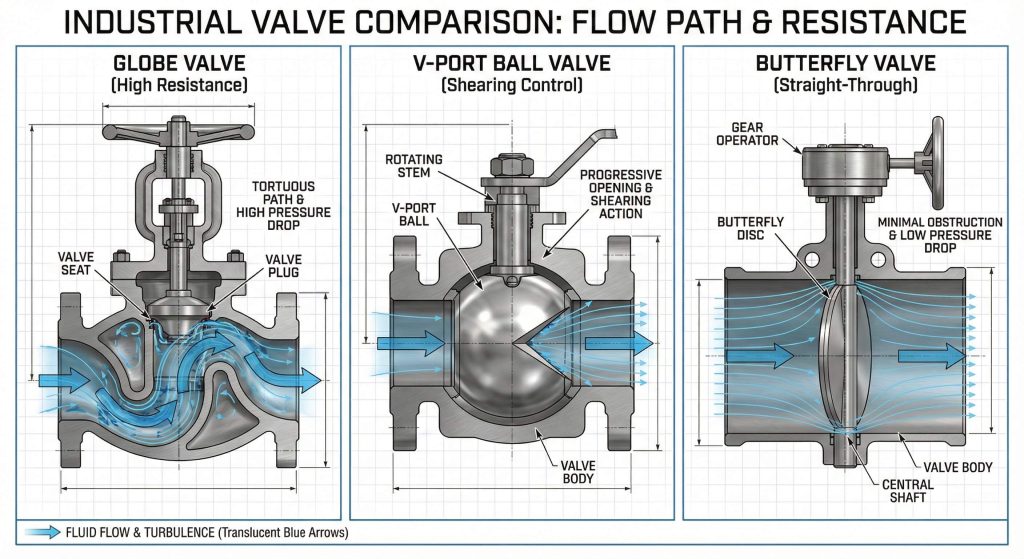

9. What are butterfly valve throttle alternatives?

Globe valves and V-port ball valves are the primary alternatives to a butterfly valve throttle when your process demands higher rangeability or precision. Globe valves provide a tortuous flow path that is ideal for managing high pressure drops without the risk of cavitation. V-port ball valves offer a “middle ground” with excellent rangeability and a more compact footprint than traditional globe designs.

Do globe valves offer higher precision?

The reality is… that globe valves allow for much finer increments of adjustment because the plug moves linearly away from the seat. This makes them the preferred choice for boiler feed water and high-pressure steam modulation.

- Globe valves handle much higher pressure drops than butterfly units.

- V-port ball valves resist clogging better in fibrous or pulpy media.

- Butterfly valves remain the most cost-effective option for large line sizes.

Key Takeaway: Choose alternatives when your application involves extreme pressures or requires control resolution beyond the 20:1 range.

| Valve Type | Precision | Cost (Large Size) |

|---|---|---|

| Butterfly | Moderate | Low |

| V-Port Ball | High | Medium |

| Globe | Very High | High |

Selecting the right valve type for each loop ensures that your entire facility operates at peak hydraulic efficiency.

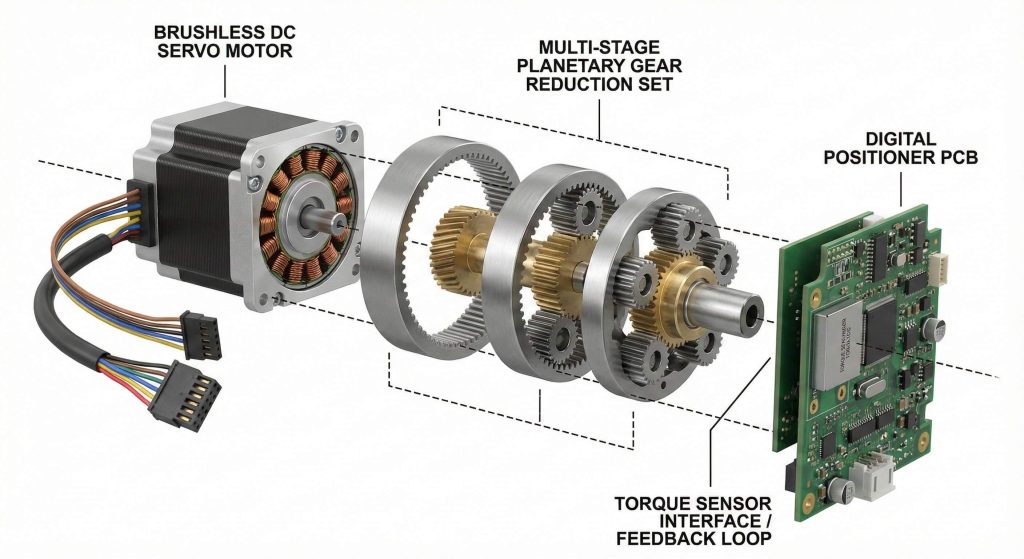

10. Does automation help butterfly valve throttle?

Automation provides the real-time feedback and high torque necessary to maintain a stable butterfly valve throttle position under varying line pressures. Manual handwheels are often insufficient for throttling because the fluid forces acting on the disc can cause it to “slam” shut or vibrate. Smart actuators integrated with your PLC ensure that every adjustment is precise and repeatable.

Can smart actuators prevent failure?

It gets even better… modern smart positioners can track the “health” of the valve by monitoring the torque required to move the disc. If the torque increases suddenly, the system can alert your team to a potential seat obstruction or bearing failure.

- PID loops allow for automatic adjustments based on downstream sensors.

- Electronic limits prevent the actuator from forcing the disc into the seat.

- Remote monitoring reduces the need for manual inspections in hazardous areas.

Key Takeaway: Automation turns a simple mechanical valve into a data-rich component that supports predictive maintenance strategies.

| Feature | Automation Benefit | System Impact |

|---|---|---|

| Feedback Loop | Constant Adjustment | Process Stability |

| Torque Sensing | Early Warning | Prevented Downtime |

| Digital Link | Remote Control | Operational Safety |

Implementing advanced control technology ensures your flow regulation hardware survives the rigors of modern industrial production.

Frequently Asked Questions

Can I use a standard butterfly valve for steam throttling?

No, you should avoid standard soft-seated butterfly valves for steam; instead, use triple offset metal-seated valves designed for high-temperature service.

How do I stop my butterfly valve from vibrating during throttling?

You should ensure the valve is properly sized for the flow and use a stiff, high-torque actuator with a digital positioner to hold the disc firmly.

Can I throttle abrasive fluids with a butterfly valve?

Yes, but only if you choose a valve with a ceramic or hardened alloy disc and a reinforced liner to withstand the constant wear.

How often should I inspect a butterfly valve used for throttling?

You should perform a visual inspection every six months, as the constant high-velocity flow wears down the seat much faster than in on-off service.

Can I achieve a 100:1 rangeability with a butterfly valve?

No, butterfly valves typically max out at a 20:1 or 30:1 rangeability; for higher precision, you should look at V-port ball or globe valves.

Conclusion

Mastering the use of butterfly valves for flow control requires a deep understanding of disc travel ranges and hydraulic forces. By selecting the correct offset designs and utilizing smart automation, you can achieve reliable modulation while minimizing your long-term maintenance costs. Our team provides the engineering expertise needed to optimize your critical fluid systems for maximum efficiency. To find the perfect hardware for your specific application, contact us today and let our specialists guide your next project to success.