An API 609 butterfly valve is an industrial flow control device designed and manufactured according to the American Petroleum Institute’s rigorous standards for dimensions, pressure-temperature ratings, and testing protocols. Engineering teams often face catastrophic system failures when using uncertified valves in high-pressure oil or gas pipelines, leading to expensive downtime and safety hazards that threaten your entire operation. Integrating a certified api609 butterfly valve ensures structural integrity and standardized safety for your critical infrastructure.

What is an api609 butterfly valve in industrial systems?

An api609 butterfly valve serves as a standardized mechanical solution for isolating or regulating fluid movement within piping networks handling petroleum, chemicals, or water. This specific standard ensures that every valve produced meets the same geometric and performance benchmarks required for heavy-duty industrial use. Utilizing this api609 butterfly valve provides operators with the assurance that components are interchangeable across different global vendors.

Does this valve meet global safety standards?

Yes, this design is recognized worldwide for its ability to maintain tight seals in hazardous environments.

Think about it:

- Adheres to API 598 leakage testing.

- Follows ASME B16.34 pressure-temperature rules.

- Utilizes standardized face-to-face dimensions.

The best part?

It eliminates the risk of using non-compliant hardware in volatile systems.

Key Takeaway

The api609 butterfly valve is the definitive standard for ensuring that flow control components are safe, reliable, and physically compatible with existing global piping infrastructure.

| Standard Feature | Requirement | Benefit |

|---|---|---|

| Design Document | API 609 | Global Compliance |

| Dimensional Rule | Standardized FTF | Easy Replacement |

| Testing | API 598 | Zero Leakage |

This data confirms that choosing a standardized valve significantly reduces the complexity of long-term facility maintenance.

Why choose an api609 butterfly valve for your facility?

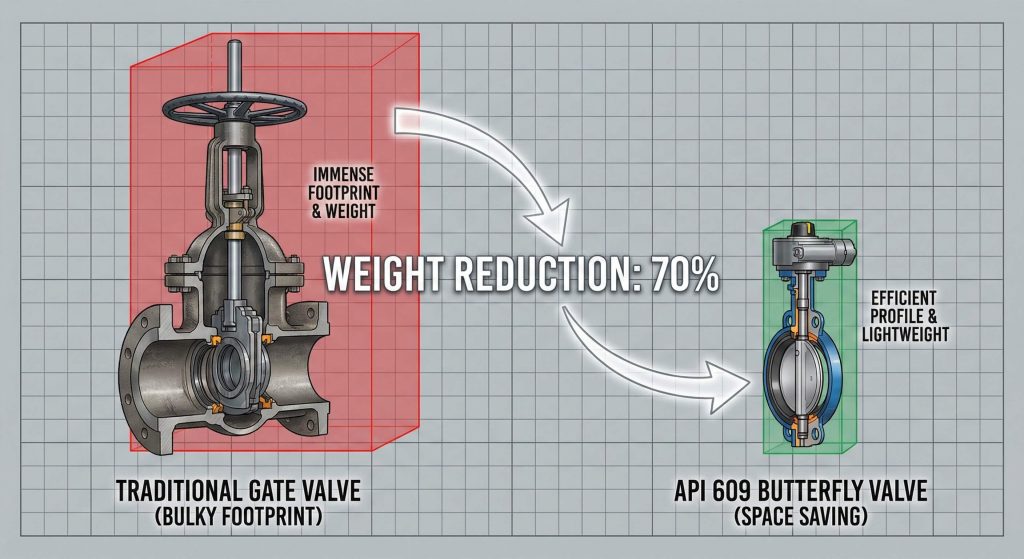

You should select an api609 butterfly valve because it offers a lightweight and space-efficient alternative to bulky gate or globe valves without sacrificing sealing performance. These valves provide a quarter-turn operation that allows for rapid shutoff during emergency scenarios. Implementing an api609 butterfly valve reduces the structural load on your piping hangers and foundations significantly.

Is it more efficient than traditional valves?

The streamlined disc design allows for high flow capacity and minimal pressure drop across the system.

Here is the deal:

- Weighs up to 70% less than gate valves.

- Compact footprint saves deck space.

- Lower torque requirements for actuation.

But here is the kicker:

You can automate these units with smaller, less expensive actuators to save on capital expenditure.

Key Takeaway

The api609 butterfly valve combines rapid operation with a lightweight profile, making it the most cost-effective solution for large-diameter piping systems.

| Comparison Metric | Butterfly Valve | Gate Valve |

|---|---|---|

| Installation Space | Minimal | Large |

| Weight | Low | Very High |

| Operation Speed | Fast (90°) | Slow (Multi-turn) |

The comparative data illustrates why modern refineries prefer butterfly designs for improving overall plant efficiency.

Which types of api609 butterfly valve designs exist?

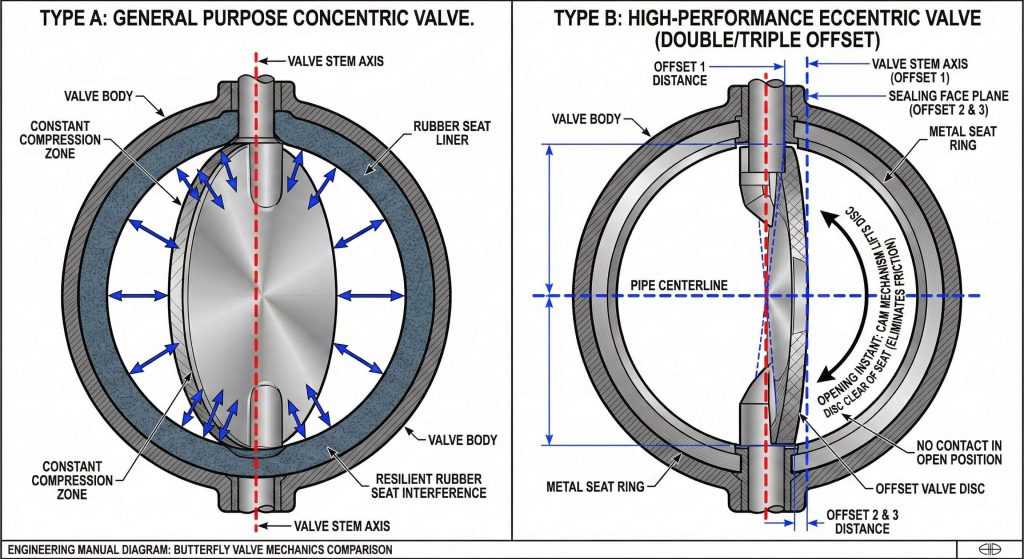

The industry classifies the api609 butterfly valve into Category A and Category B to address varying levels of mechanical stress and pressure. Category A involves concentric designs where the stem passes through the center of the disc, ideal for low-pressure utilities. Conversely, Category B includes high-performance offset designs used in more demanding process conditions.

What is a Category B design?

Category B valves utilize eccentric offsets to reduce friction between the seat and the disc during rotation.

Consider this:

- Double eccentric for high pressure.

- Triple eccentric for metal-to-metal sealing.

- Handles extreme thermal cycling.

Now for the good part:

These designs allow the valve to operate in steam or hydrocarbon services where resilient seats might fail.

Key Takeaway

Understanding the distinction between Category A and B is vital for matching the api609 butterfly valve to the specific pressure and temperature requirements of your application.

| Valve Category | Typical Seat | Primary Application |

|---|---|---|

| Category A | Resilient (EPDM/PTFE) | Water & HVAC |

| Category B | Metal or Reinforced | Oil, Gas, Steam |

This classification system allows engineers to optimize material costs while maintaining high safety margins for critical services.

Where to install an api609 butterfly valve for best results?

Optimal placement for an api609 butterfly valve includes refinery storage farms, chemical processing lines, and large-scale municipal water systems. Their ability to handle diverse media makes them a versatile choice for nearly any fluid transport infrastructure. You will find an api609 butterfly valve most effective where frequent isolation and flow regulation are required in tight quarters.

Is it suitable for offshore platforms?

Yes, the compact and corrosion-resistant nature of these valves makes them ideal for the limited space found on offshore rigs.

Look at the facts:

- Resists seawater corrosion with proper alloys.

- Fire-safe designs protect critical assets.

- Meets maritime safety certifications easily.

The real story?

They provide the durability needed for the world’s harshest environments without excessive weight.

Key Takeaway

The api609 butterfly valve is a multi-industry workhorse that excels in any environment requiring high-volume fluid control and dependable shutoff.

| Industry | Typical Fluid | Valve Requirement |

|---|---|---|

| Petrochemical | Crude & Refined Oil | Fire-safe / Metal Seat |

| Water Treatment | Wastewater & Brine | Corrosion Resistance |

| Power Gen | Cooling Water | High Flow / Low Drop |

Industry-specific applications prove that this valve standard is adaptable enough to secure diverse global supply chains.

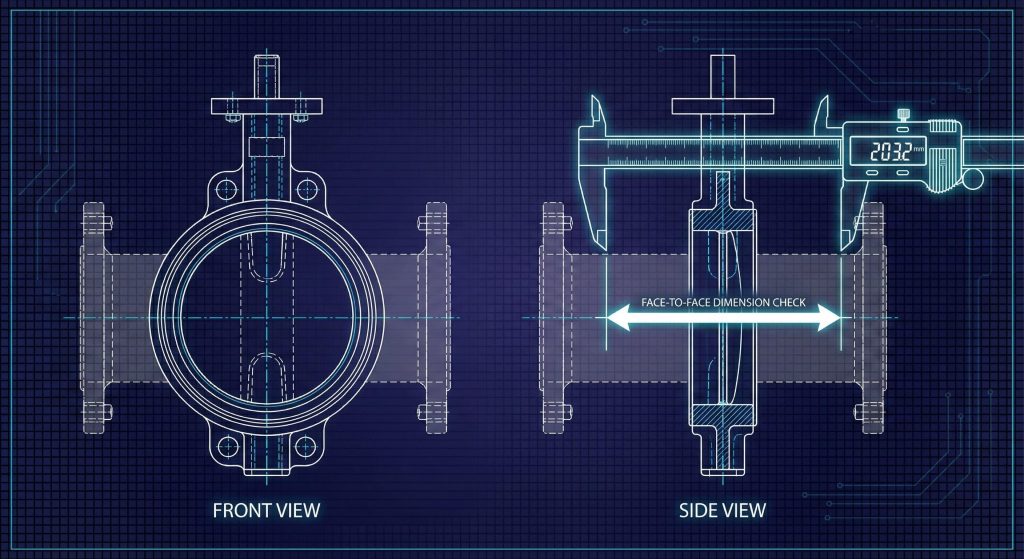

What specs define an api609 butterfly valve exactly?

The technical specifications of an api609 butterfly valve are defined by precise face-to-face dimensions and strict material compliance. These standards ensure that a valve from one manufacturer can replace a unit from another without modifying the pipeline. Every api609 butterfly valve must also adhere to specific pressure-temperature ratings based on its body material.

Does face-to-face length matter?

Absolutely, because standardized lengths ensure that your replacement parts will fit perfectly between existing pipe flanges.

Check these points:

- Eliminates custom pipe fitting costs.

- Simplifies inventory management for plants.

- Guarantees alignment with international standards.

Believe it or not:

A single millimeter of deviation can prevent a successful installation during a time-sensitive maintenance shutdown.

Key Takeaway

Strict adherence to API 609 technical specifications eliminates installation errors and ensures that your flow control system remains modular and easy to service.

| NPS (Size) | Category A FTF (mm) | Category B FTF (mm) |

|---|---|---|

| 4 Inch | 52 | 54 |

| 8 Inch | 60 | 64 |

| 12 Inch | 78 | 81 |

The data shows that Category B valves often require slightly more space due to their robust high-performance internal components.

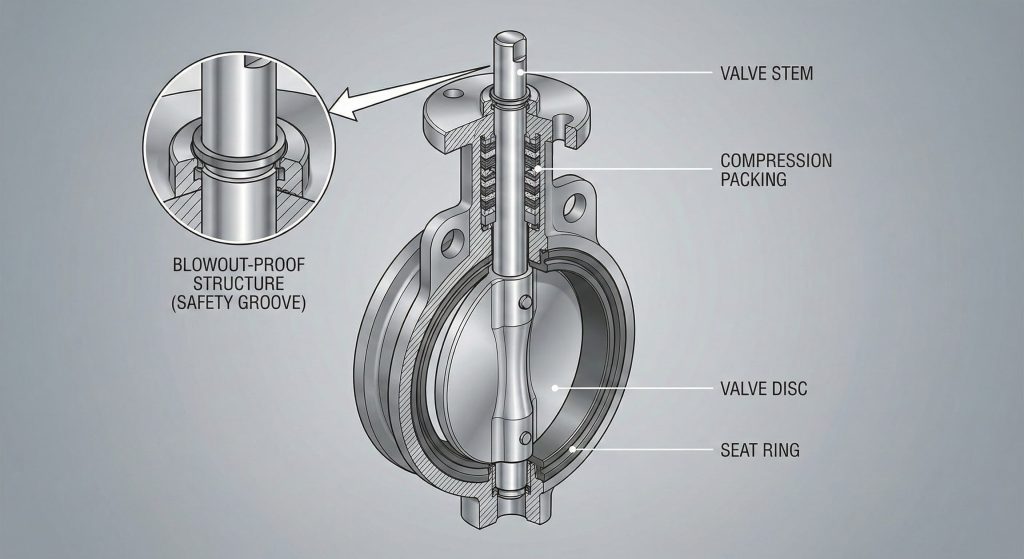

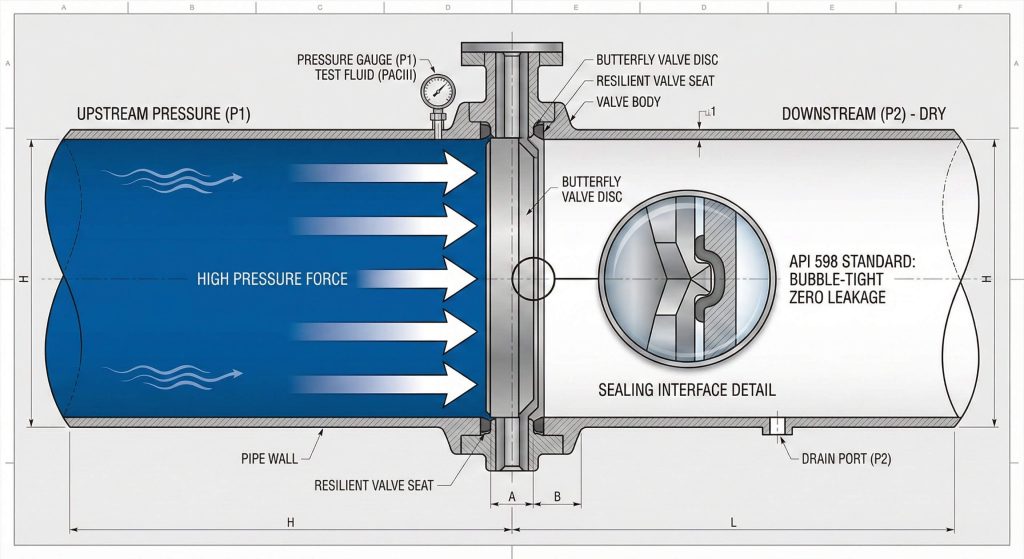

What parts form an api609 butterfly valve assembly?

The primary components of an api609 butterfly valve include the valve body, the rotating disc, the stem, and the sealing seat. The body acts as the pressure boundary, while the disc moves 90 degrees to block or allow flow. A high-quality api609 butterfly valve also features specialized bearings and packing glands to prevent external leakage.

Is the stem blowout-proof?

Yes, the API standard mandates a blowout-proof stem design to prevent the stem from ejecting under high internal pressure.

Here is why:

- Enhances safety for onsite technicians.

- Prevents environmental contamination.

- Maintains structural integrity during failure.

What is the bottom line?

Safety mechanisms are built into the very core of the assembly to protect your workforce.

Key Takeaway

Each component within the api609 butterfly valve is engineered for durability, ensuring the entire assembly functions as a high-security barrier against leaks.

| Component | Common Material | Function |

|---|---|---|

| Valve Body | WCB Carbon Steel | Pressure Containment |

| Disc | 316 Stainless Steel | Flow Obstruction |

| Stem | 17-4PH Stainless | Torque Transmission |

Selecting premium materials for these internal parts is the best way to extend the service life of your industrial assets.

How to select an api609 butterfly valve for acid service?

When choosing an api609 butterfly valve for corrosive environments, you must prioritize material compatibility with the specific chemical being transported. Selecting high-grade alloys or specialized coatings prevents premature erosion of the valve seat and disc. A properly specified api609 butterfly valve will remain operational for years even when exposed to aggressive sulfuric or nitric acids.

Can I use stainless steel?

Stainless steel is an excellent choice for many acidic applications due to its natural resistance to oxidation and chemical attack.

Keep this in mind:

- CF8M is the standard for chemical service.

- Hastelloy options exist for extreme cases.

- PTFE seats provide an inert barrier.

Ready for the best part?

Using the right materials reduces the frequency of expensive valve replacements and hazardous leaks.

Key Takeaway

Material selection is the most critical factor in ensuring that your api609 butterfly valve survives the harsh conditions of chemical processing.

| Acid Type | Recommended Material | Benefit |

|---|---|---|

| Dilute Acids | 316 Stainless Steel | General Resistance |

| Strong Acids | Alloy 20 or Hastelloy | Superior Durability |

| Caustics | Ductile Iron with PTFE | Cost Efficiency |

This guide helps procurement teams make data-driven decisions that prevent equipment failure in high-risk environments.

How to test an api609 butterfly valve for leak safety?

Testing an api609 butterfly valve involves rigorous shell and seat pressure trials to verify that no fluids can escape. These tests are usually performed using water or air at pressures exceeding the valve’s maximum rating. An api609 butterfly valve must achieve a “bubble-tight” seal during these procedures to pass the quality inspection.

Is API 598 testing required?

API 598 is the standard testing protocol referenced by API 609 to ensure uniform quality across all manufacturers.

Look at the process:

- High-pressure shell test.

- Low-pressure seat closure test.

- Visual inspection for weeping.

The real story?

This testing provides the empirical evidence needed to trust the valve in a high-pressure pipeline.

Key Takeaway

Mandatory pressure testing according to API 598 ensures that every api609 butterfly valve provides zero-leakage performance upon installation.

| Test Type | Pressure Level | Objective |

|---|---|---|

| Shell Test | 1.5x Rated Pressure | Structural Integrity |

| Seat Test | 1.1x Rated Pressure | Zero Leakage |

| Air Test | 80-100 PSI | Fine Leak Detection |

Verified test reports are the only way to guarantee that your facility meets modern environmental and safety regulations.

How to maintain an api609 butterfly valve properly?

Proper maintenance of an api609 butterfly valve requires regular cycling and inspection of the stem packing to prevent fugitive emissions. You should also lubricate the gearbox or actuator at scheduled intervals to ensure smooth operation during emergencies. A well-maintained api609 butterfly valve can serve your facility for over 20 years with minimal intervention.

Should I lubricate the stem?

Lubricating the stem and bearings reduces friction and prevents the valve from seizing during long periods of inactivity.

Observe these steps:

- Use compatible industrial grease.

- Inspect seals for debris buildup.

- Cycle the valve every 90 days.

But wait, there is more:

Predictive maintenance prevents the need for emergency shutdowns by catching wear early.

Key Takeaway

A proactive maintenance schedule for your api609 butterfly valve is the most effective way to protect your long-term operational investment.

| Maintenance Task | Frequency | Expected Outcome |

|---|---|---|

| Visual Inspection | Monthly | Early Leak Detection |

| Full Cycle Test | Quarterly | Prevents Seizing |

| Seat Replacement | 5-10 Years | Restores Sealing |

Consistent care ensures that critical safety valves function perfectly when they are needed most.

Who makes a reliable api609 butterfly valve for B2B?

Finding a reliable supplier for an api609 butterfly valve involves verifying their manufacturing certifications and past project performance. You should look for partners who offer comprehensive technical support and 24-hour engineering responses. A top-tier manufacturer will provide full material traceability for every api609 butterfly valve they deliver to your site.

Do they offer custom solutions?

Many high-end manufacturers can customize the valve materials and actuation systems to meet your specific project requirements.

Check for these services:

- OEM branding for global distributors.

- Custom alloy casting for special media.

- Video consultations for engineering teams.

The best part?

You get a flow control solution that is tailor-made for your unique industrial challenges.

Key Takeaway

Choosing a manufacturer with deep technical expertise and strong quality certifications is the final step in securing your facility’s infrastructure.

| Supplier Criteria | Importance | Why it Matters |

|---|---|---|

| ISO 9001:2015 | High | Quality Management |

| API 609 License | Mandatory | Safety Compliance |

| Engineering Support | Vital | Rapid Troubleshooting |

Partnering with an established expert ensures that your B2B procurement process is efficient, safe, and fully documented.

Conclusion

The api609 butterfly valve is the cornerstone of modern industrial flow control, offering a perfect blend of safety, standardization, and mechanical efficiency. By adhering to the American Petroleum Institute’s rigorous criteria, these valves solve the most common pain points of procurement and maintenance teams worldwide. Whether you are managing high-pressure steam, corrosive chemicals, or municipal water, these components provide the reliability needed to keep your operations running smoothly. For technical consultations or to request a quote for your next project, please contact us today and speak with our expert engineering team.

Frequently Asked Questions

Q1: Can I use an api609 butterfly valve for steam service?

Yes, Category B high-performance or triple-offset designs are specifically engineered to handle high-temperature and high-pressure steam safely.

Q2: What is the best seat material for water treatment?

EPDM is generally the best choice for water infrastructure due to its excellent resilience and cost-effectiveness in non-corrosive environments.

Q3: Can I replace a gate valve with a butterfly valve?

Yes, provided the flow characteristics and pressure ratings match, a butterfly valve offers a much lighter and more compact solution for the same line size.

Q4: What is the most common reason for valve failure?

Improper material selection for the process media and lack of regular cycling are the leading causes of premature valve degradation and seizing.

Q5: Can I automate an API 609 valve after installation?

Yes, these valves feature standardized mounting pads that allow you to install pneumatic or electric actuators at any time without custom modifications.